The greenhouse is called the best option for growing vegetable and fruit crops in ...

|

|

Polymer -old tiles are a new building material, which is offered on ... |

To ensure smooth closing of the door, a closer is used. In relation to the type ... |

Select a substrate for a parquet board

Before discussing how to choose a substrate under the parquet floor, it is worthwhile to understand what purpose the substrate performs and what functions it carries. The flooring substrate, as an integral element used in laying floating floors, which includes and the parquet floor is able to ensure comfortable operation, as well as extend the service life of the parquet board.

The substrate performs the following important functions:

- This material helps to smooth out small defects of the base of the floor;

- Provides excellent sound insulation from shock noise arising from vibrations created by the work of household appliances, as well as when walking;

- It helps to increase the thermal insulation of the floor, due to the low coefficient of its thermal conductivity, which undoubtedly contributes to the creation of the perfect microclimate between the draft floors and the parquet board;

- Ensures the redistribution of mechanical loads on the parquet board;

- The flooring substrate has high waterproofing abilities, protecting the parquet board from the destructive effects of moisture, which extends the life of the parquet board.

It is these requirements that are put forward to the modern substrate under the parquet board. In addition, the substrate, depending on the material of manufacture, has a number of positive characteristics, including durability, environmental purity, strength.

Today, among the products presented in the modern building materials market, there are several main types of substrate, widely used in laying parquet floors. The foil and cork substrate, the substrate for the parquet floors of Tuplex and the parkolase, as well as the substrate of foamed propylene, each of them, has its own distinctive features, technical and operational characteristics.

Tuplex parquet- three -layer polymer material in combination with polystyrene foam used as a middle layer. This material, thanks to its manufacturing technologies, is one of the best insulating materials. This material is good for using it at low floors temperatures in country houses and cottages. It perfectly protects against moisture and condensate due to its vapor -permeable lower layer, which absorbs moist vapors in the inter -layer space of their polystyrene foam, which are subsequently excreted through the open edges of the substrate material. Therefore, when using blunts, special ventilated skirting boards are additionally used as a substrate for parquet floors, which do not delay moist evaporation and, moreover, hold the parquet board perfectly.

Parkolag substrate, with its complex structure, which is based on a bitumen layer with cork granules evenly placed in it also has excellent characteristics. This type of material is also called a bitumen-pro-bonding. The unique structure of this substrate provides excellent microventration of the material. Parkolag has high soundproofing and thermal insulation properties. Its only minus when using it in hot climatic conditions, or in the immediate vicinity of thermal pipelines, the bitumen mastic in this material can distinguish formaldehyde in large quantities, which undoubtedly harms health.

Foamed The most budget type of material used as a substrate for a parquet board. Its peculiarity is its structure, which is porous, and each of the por of this material is filled with air, which provides excellent thermal insulation and soundproofing abilities of this material. In addition, it perfectly protects against moisture emanating from the base of the floor. A small disadvantage is the fragility of this material, the shelf life of which is from 7 to 10 years, after which it is subjected to the decomposition process and turns into powder.

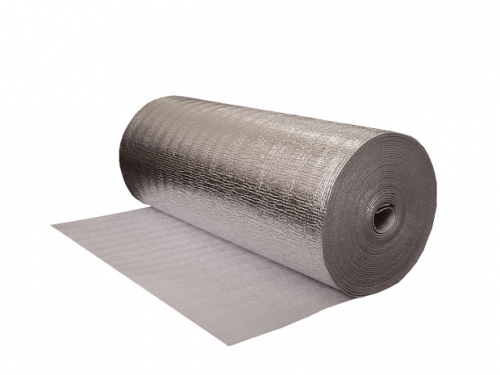

Foil substrate This is more advanced material from foamed propylene, since it is it that is the main material for foil. The foil layer gives the material the best thermal insulation and waterproofing properties, and also perfectly absorbs noise. The foilized substrate is often used when laying boards with hard fixation, and inexpensive flooring, with a short service life, which is, for example, a laminate.

Camping substrateThe material traditionally used in laying a parquet board. Exceptional this material is made by its natural natural properties excellent sound insulation and thermal insulation, environmental purity and mechanical strength of this material, which is not pressed over over time. This material is not susceptible to decay processes, perfectly smooths out the irregularities of the base of the floor, and has special wear resistance. The only disadvantage is its ability to moisture release. Therefore, it is more often used when laying a parquet board in residential premises with low air humidity. A cork coating in rolls with a thickness of 2 to 8 mm is produced. The thickness of the substrate for the parquet board made of cork material should not exceed 2 mm.

Before you opt for a certain form of a substrate for a parquet board, the following factors should be taken into account:

- Operating conditions, and here the humidity of the room will become an important factor;

- Selecting the flooring material for the floor. In the event that the material is an inexpensive laminated parquet, with a limited service life, the use of a cork coating as a high cost, does not justify itself as a substrate;

- Environmental safety of the substrate for a parquet board;

- Quality characteristics of each individual type of substrate.