Each of us several times during our lives passes through such an event ...

|

|

The conditions of comfortable residence in the rooms of the attic directly depend on correctly ... |

How nice to walk barefoot on a warm wooden floor! But what to do if the floor is already ... |

How to install a closer on the door

To ensure smooth closing of the door, a closer is used. In the ratio with the type of door on which they are installed, there are several varieties of these mechanisms. We will consider how to correctly install the door closer and about its features.

Table of contents:

- Features of the door closer and its device

- Installation work and door closer diagram

- How to install a closer on the door: Installation instructions

- Deuter for sliding doors and standard designs: Choice Rules

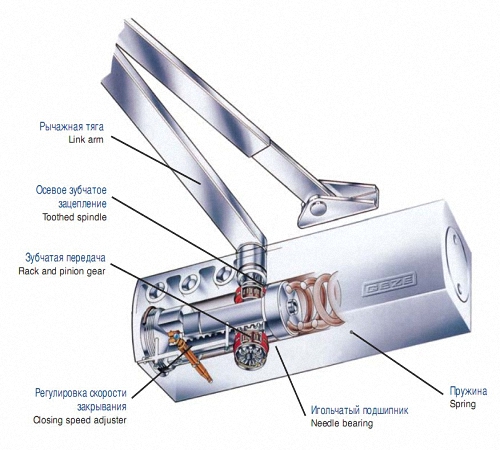

Features of the door closer and its device

As the main element of most modern closers, a spring is used. It is she who is able to smoothly control the procedure of closing and opening the door. Therefore, on one installation of the closer, the installation process does not end. It is also required to set up and adjust it, which allows the door to open in a certain mode.

If a closer is installed on the door, then it is less worn and its life is significantly increased. The closer helps to reduce the load on the surface of the door, its accessories and loops. In addition, closers are mounted not only on the doors located at the entrance to the building, but also on interior, bath or intermediate doors.

In relation to the installation technology of the door closer, they are divided into:

- a tab of the overhead type, which are installed on the door paving boxes, on the areas of door loops or on the rod;

- Floorous designs - their installation is carried out during the floor decoration, the design of such closers is carried out when drawing up drawings of the entire building or premises;

- Hidden type devices - are installed inside the box or canvas, to install them, it will require milling data of structural elements, so their installation is a very long and complex process, which is not within the power of everyone.

The directors of the first - overhead type differ in simplicity and ease of installation. Installation rules, most often indicates the manufacturer himself in the instructions or technical passport of the door.

In addition, some manufacturers equip the door with a special template, which depicts all the installation points of the closer.

It is preferable to choose precisely such products in which the instructor installation procedure is clearly and clearly described. Although even in this case, attention should be paid to certain nuances, which we will talk about later.

Internal mechanical closers are:

- With the presence of a toothing rail and gears - this type of device has a hydraulic circuit and mechanical re -instant transmission, precisely because of this, it is possible to create smooth door movements in the presence of an extensive range. The main difference between this type of device is the presence of a strong clamp when snaping the handle and connection of the seal; In order to achieve maximum efficiency in the argument, it is necessary to establish a lever gear.

- The internal mechanism with a cam structure - it is the cervical fist that belongs to the function of transmitting the effort of elastic elements to the spindle. These types of mechanisms are widespread in the closers of both floor and hinged or built -in type; To increase its performance, slider or channel traction should be installed.

DETERENTER of the door photo:

Tip: Before proceeding to the direct installation of the closer on the already used door, take care of its repair and adjusting the entire fittings.

Installation work and door closer diagram

Devices with levers or sliding types are mounted on any side of the interior and street door. If the door is input or external, then it is better to fix the closers inside, in order to avoid their damage under the influence of precipitation and temperature changes.

Since the principle of operation of the device consists in smooth flow of machine oil from one section of the closer to another, and when frosts occur, the density and viscosity of the oil increases, and this affects the work of the closer.

We offer to consider the most popular installation schemes of the door closer for the door:

- The standard installation work is based on fixing the closer on the surface of the canvas, a door frame is used to fix the lever;

- There is an option to fasten the closer according to the upper scheme: that is, it is installed on the surface of the upper part of the box from the beam, and the door leaf is used to screw the shoe itself;

- With a parallel location, the lever is fixed in a parallel rather than vertical position, using the mounting corner.

When choosing one or another version of the door installation scheme should be guided by how the door loops are located on the door.

During the opening of the door, the case of the closer part of the closer on the canvas should be installed, and the installation of the shoe should be carried out on the box.

If the door is opened from yourself, then it is best to fix the lever on the canvas, and the case on the box.

During the acquisition of the closer for the door, keep in mind such factors as the direct load from the door and its width, which affects the greatness of the opening. If the power of one closer is insufficient for its normal functioning, then two such devices should be installed.

In addition, non -standard situations may occur in which the door clearance has insufficient height. For this, in the process of performing the installation, the presence of plates or special corners will be required.

In this case, it is recommended to use the parallel diagram of the closer installation:

- The first option involves the parallel consolidation of the lever, while the installation of the shoe is carried out using the mounting corner, which is attached to the box;

- For fastening the box, a mounting plate is used, and the work is carried out on a boxed beam.

There are options for closer thrust. Among their advantages should be highlighted:

- optimized design;

- The presence of the ability to modernize the device using the use of an electromagnetic latch or a fireproof signaling device.

For the functioning of this type of closer, you will need to make certain efforts. In addition, there is no opportunity to control from work. Although the presence of a limiter in the form of an insert allows control over the work and angle of door opening. For installation of most modified closers, it is necessary to use the perpendicular installation circuit. And to fix universal models, installation work is possible from any of the convenient sides.

Tip: in the process of installing a channel or slider -type closer, on the side reverse to the location of the door hinge, you should mandatory the limiter, triggered when the door leaf is fully opened. Instead of a limiter, it is possible to install a specialized stopper.

How to install a closer on the door: Installation instructions

When the argument is determined and the installation scheme is selected to carry out its installation and setup. We offer to familiarize yourself with the recommendations by installing the door leader with your own hands:

1. If a special model in the form of a template is included in the package, then it is applied to the installation site and fixed on it using tape.

2. On the points indicated by the manufacturer, it is necessary to drill holes, under the fasteners. It is necessary to make two holes for fastening levers and four to fix the device itself.

3. It is preferable to prepare holes in advance, before the installation of the case. First, the lever is fixed, and then the body box.

4. When the device and lever are fixed, one more part should be installed on the argument surface, which is responsible for the thrust and make settings in the relationship with their length.

5. Keep in mind that the lever should be located vertically in relation to the surface of the door leaf in a closed position.

6. The surface of the screws for adjustment should be located in parallel to the side of the loop bar box.

Each manufacturer of closers equip his device with special fasteners that do not need to be replaced, since the device will not be able to function normally. The main thing in the process of installing the door closer is to comply with all the instructions indicated by the manufacturer, then the device will last a long and efficiently.

The next stage involves setting up the device. It begins after connecting the traction mechanism with the main working part. The design of the design is set by settings of screw mechanisms. It is the screws that set the speed of opening and closing the door with a ratio with two modes:

- The first screw allows you to set the speed with which the door will open from fifteen to one hundred eighty degrees;

- And the second screw programs the speed of opening the door from zero to fifteen degrees.

In order to set the required speed, it is necessary to turn the screws in the right direction. Keep in mind that excessively zealous adjustment of the screws will lead to their breakdown, loss and even leakage of oil in the closer.

There are additional parameters for adjusting the closer, namely:

- Sun - the resistance device is overly sharp when opening from 75 to 105 degrees;

- But - a latch that delays the canvas in the open position;

- A device that provides tightening a certain moment in the process of movement of the canvas.

When all work on setting and adjusting the closer is completed, close its axis using a decorative cap. If all the rules of operation of the doors are observed, then the device will last a long time.

Deuter for sliding doors and standard designs: Choice Rules

The closers are installed on both standard doors and on sliding structures in the form of barriers and even a gate.

Buying a closer is a complex process that requires certain knowledge that will help you choose a high -quality device that has a long service life.

Before buying a closer, you should focus on such indicators:

1. The size of the door leaf and the total weight of the structure.

The first and most important parameter of any device is power or pressing with which the door closing procedure is carried out. Therefore, with an increase in the size of the door leaf and its weight, the power of the device required to close it increases. Some designs require installation of two closers at once.

The closure of the closers is calculated taking into account European standard calculations, and the seeds are determined by classes. The closer, which belongs to the first category, is designed for installation on a small and not heavy door, and the leader of the seventh category is able to close massive structures. To install a standard type of standard type of third, fourth and fifth grades on an ordinary door.

2. Setting and adjusting the door opening power is the second parameter for which the closer is selected.

The main options for setting closers:

- closing power;

- Closing time.

In addition, there are additional functions for which the closer is set up:

- The presence of a wind brake allows you to protect the door from the blow to the surface of the wall during winds or opening;

- During the delay in closing, the door closes more slowly, it is very convenient when transporting large cargoes;

- It will not be superfluous to the presence of a hard fixing moment when using which, the door remains open for a certain time;

- In addition, there is an opportunity to smoothly adjust the spring mechanism.

3. The type of device in the ratio with traction characteristics.

In the ratio with this criterion, such types of closers are distinguished:

- standard devices;

- devices with sliding thrust;

- Coinders with devices fixing the canvas in one of the convenient positions.

4. An important factor in choosing a closer is the type and method of its fastening.

In relation to the type of installation, closers are:

- superficial;

- floor;

- hidden.

The most convenient option is the installation of a superficial closer. In addition, such closers have the optimal cost and are easily set.

5. Climate working conditions.

In the process of installing the door, this factor must be taken into account. Since some types of closers are able to function exclusively at a plus temperature, while others are resistant to temperature differences, therefore they are installed both on the street and indoors.

6. The duration of operation and the availability of special protection.

There are models with special protective mechanisms that protect them from extraneous invasion. These parameters determine the standards of the European model, they are affected by the maximum number of torn off and closing cycles. The average value of the argument is at least 450 thousand closing and opening cycles. In addition, high -quality materials that are stable before external influences, including corrosion, should be used for the manufacture of the closer body.

7. The appearance of the closer and its cost.

The designer’s design is significantly affected by his functional purpose. Deuters are both large and miniature sizes. In addition, these devices are distinguished by a wide color scheme, so it is not a problem to choose a closer to the color of the door. If the closer is made of steel, then the colors are slightly limited by white, gray and dark brown colors.

The cost of closers is determined by the number of functions that it is capable of performing the quality of materials used in the process of its manufacture. It is better to spend money on a more expensive model, which will serve on the door for several years than buying cheap closers, after half a year, requiring replacements.

How to install a closer on the door of the video: