Speaking about skirting boards, we mean most often those that are intended for ...

|

|

Vetonit (Vetonit) is a trademark that produces powder building ... |

The popularity of such finishing material as liquid wallpaper in the interior ... |

Polymerip paving slabs Features of installation

Polymer -old tiles are a new building material, which is offered on the domestic market recently. Such a product has many advantages, which is proven by Western experts. In this article, we will consider the characteristics, features of the choice and installation of polymer -sand tiles.

Table of contents:

- Product characteristics

- Polymeriper tile production technology

- Advantages of polymer -sand tiles

- Application of tiles

- Recommendations of specialists in choosing paving slabs

- Polymeriperic paving slabs laying technology

- How to lay a polymer-sand tile on a cement-sand mixture

- Recommendations of styling experts

Product characteristics

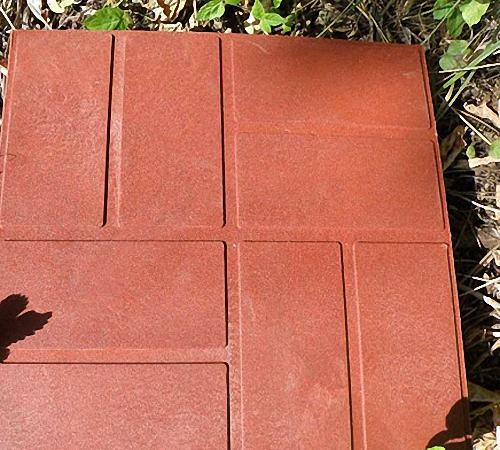

Modern technologies for the production of tiles based on polymers allow you to create a durable and reliable material used in construction. Polymer -old paving slabs have many advantages over other types of products, for example, concrete or pressed. Most buyers choose this material, the price and quality of which corresponds to the price of products.

In the manufacture of polymer -sand tiles, specialists adhere to certain technical parameters that would create high -strength and stable properties of the product to temperature changes. This material has a long service life, which determines the advantage of building material over other types of products, in particular, the tile made of cement.

The main characteristic of the tiles is highlighted that when laying polymer -sand tiles, cement dust does not appear. Also, the product has the properties of plasticity, which avoids cracking and damage to the building material during styling work. It is easy to care for the product, because it is easily washed and does not absorb water, which increases the shelf life of the material. The water resistance of the tile allows you to transfer sharp temperature changes, especially in the winter.

In its shape, the tile has different drawings and shades. Despite the significant size of polymer -sand tiles, the product has a low weight, and is also great for laying on a concrete base or for an operated roof. In this case, the product is laid on special supporting parts. If the material is used for laying the roof, it is recommended to put the tile on the waterproofing layer on top of the stands or crushed stone. Such tiles can be used as a cladding of the basement of the house or used to lay curbs.

Polymeriper tile production technology

The process of manufacturing the product has a certain technology, when performing which you need to adhere to the correct ratio of components. The composition of the tile is determined by the following materials:

- sand, the dimensions of the fractions of which should be no more than 3 mm;

- dyes that determine the shade of the product;

- polymers, as a rule, are used primary crushed, but secondary ones can be applied as savings;

The most important and main component is sand, the component part of which is 75 percent of the entire mass of the solution. Before use, it is advised to rinse and sift. Further, the sand is poured into certain furnaces in which it is heated at high temperatures.

The price of polymer -sand paving is determined by production technologies, which have a certain sequence:

1. First of all, it is necessary to chop or agglominate the raw materials used. If polymer crumbs are used, then this process is passed.

2. Further, it is important to mix sand, baby, as well as dyes and additives.

3. The prepared mixture must be melted into raw materials at a temperature of 250 degrees.

4. After that, the solution must be given the press and form finished slabs.

5. Lastly, the products are packaged and sent to construction stores.

In the production process, special equipment is used, which provides an automated tile production system. This allows you to create a strong and reliable product, which has a long service life.

Advantages of polymer -sand tiles

Polymer -sand tiles can be used in different types of improvement of a summer cottage or urban territory. In many cases, the product is used to lay pedestrian zones, different sites, cafes, retail pavilions and other rooms. Polymer -old tiles have greater wear resistance, unlike asphalt or concrete coating. In general, the product has many advantages that are determined by the following parameters:

1. The long expiration date of the product. As a rule, the average service life of tiles can be at least 30 years.

2. The product has the properties of water absorption and frost resistance. If the building material absorbs water, then as a result of temperature differences, small cracks are formed, which will contribute to the deformation of the tile. Features of the polymer -sand product allow you to avoid such destruction, since the percentage of water absorption is about 0.03.

3. The strength and plasticity of the polymer -sand tiles, the photo of which is presented on this site. Such building material does not crack and does not prick, which reduces the amount of waste when laying the product, its transportation and operation. Such a product is difficult to divide into several parts, which has high resistance to wear.

4. The tile has a low weight, which allows it to be easily and practical to transport and mount it. It can be used for laying on the roof or in the inter -story floor.

5. It has low thermal conductivity, which does not hold snow and ice on the surface of the product.

6. This tile is made of materials that do not create a sliding area.

7. Polymer -sand tiles have acidic and oil resistance. As already known, the popular material is a polymer, which has stable properties to the influence of the external environment, as well as to chemical and other substances. In this product there is a minimum risk of fungus, mold or alkali.

8. The parameter of technological work. Polymer -sand tiles can be done by different options. When performing work with your own hands, the installation technology is done manually, and the specialists have a special tile machine. The presence of other devices in the work allows you to quickly process tile elements, namely cut, drill or mill the product and the like.

9. Polymer -sand tiles are environmentally friendly material. For example, asphalt coating with high heating begins to secrete carcinogenic substances that harm the external environment. This tile can only form cement dust. The product at high temperature does not overheat and does not soften, which allows you to maintain the initial properties of the product. Thus, the tile does not harm different plants, seedlings, as well as people's health.

10. Tiles have high wear resistance. During styling work, dust does not appear, which determines the long expiration date of the product.

11. Such a product is easy to repair. Polymeripesic tiles can be temporarily dismantled for laying different communications.

12. The product has a beautiful and aesthetic appearance, which is determined by the wide color scheme of the material. Over time, the shade of the tile is not lost, and the product itself has different shapes and geometry, which allows you to create different variations of paths, decoration of sites, and so on.

Application of tiles

As a rule, the product is widely popular among builders, owners of country houses, owners of summer cottages and so on. The field of use and application of the material is determined by the established categories:

1. Laying polymer -sand paving slabs, the video of which can be viewed at the end of the article is carried out in the local area. As objects of design, sites near arbors or pools, as well as garden paths and the like, can be used.

2. The tile will perfectly complement the landscape design, as well as different floral and plant compositions on the site near the house.

3. The plate is often laid on a service station, car wash and gas stations.

4. The product is used to carry out the ground covering of shopping centers, parks, playgrounds and so on.

Recommendations of specialists in choosing paving slabs

In construction stores, a wide selection of polymer -sand tiles is offered, the choice of which corresponds to certain parameters:

1. Addresses of dyes. The shade and number of added dyes determine the characteristics and properties of the product. For example, the use of German dyes will ensure the long expiration date of the product, and Chinese paints will eventually lose its color under the influence of ultraviolet rays.

2. Uniform coloring of the tiles. Heterogeneous staining of the surface of the product denotes the factor that in the process of work, poor -quality substances were used. This may apply to the characteristics of production technologies and staining tiles.

3. Other intersperses on the surface of the tiles may indicate the use of poor -quality components in the production process. For example, white stains may indicate a non -compliance with a certain temperature of the manufacturing of the material. Such a product may not have high -strength properties.

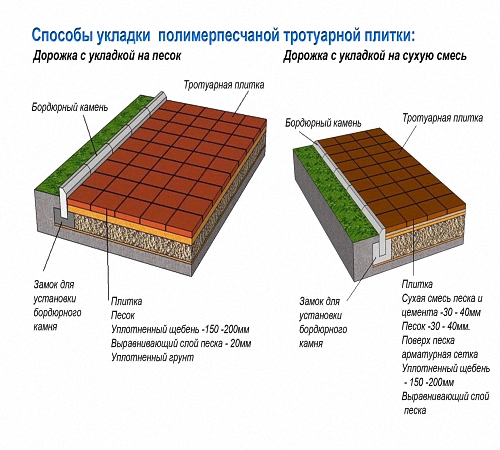

Polymeriperic paving slabs laying technology

As a rule, the tile installation process must be started with the creation of a sand cushion with gravel or styling on a concrete base. The choice of styling method should be determined by the type of soil and the purpose of the future area. For example, the installation of tiles on a sand base is perfect for garden and pedestrian paths and the like. If the site has unstable soil, it is necessary to use the technology of laying on crushed stone, which is recommended to be used for automobile parking. The installation process for concrete is done for heavy cars.

For styling, you will need to prepare certain materials:

1. A mixture of sand and cement, the ratio of which should be 1: 4.

2. To lay the tiles on the concrete base, it is necessary to prepare a special glue or a solution of concrete.

3. For unstable soil, it is advised to use a layer of crushed stone.

The styling technology has the following sequence:

- The work site must be prepared by previously leaving the surface and sealing the soil.

- Next, lay a layer of crushed stone, the thickness of which should be 15-20 cm.

- After that, the sand is poured with a thickness of 2 cm, which will allow you to leve the previous layer.

- Next, the main amount of sand is poured, the thickness of the layer of which should be about 6 cm.

- Using a special hammer, you can start laying tiles. The gaps between the elements should be about 4 mm.

- The gaps present must be filled with sand.

How to lay a polymer-sand tile on a cement-sand mixture

1. At first, a platform is prepared, which is advised to align it, and then seal the soil.

2. After that, a dense layer of crushed stone is laid 15-20 cm.

3. Next, pour sand to align the surface of 2 cm, after which a thorough layer of 3-4 cm is filled up.

4. A reinforcing mesh is placed on top of the sand.

5. Next, a layer of dry mix of sand and cement is filled up.

6. Using a rubber hammer, masonry tiles should be made.

7. All gaps between the tiles should be poured with a mixture of sand and concrete.

The method of laying tiles on a concrete base has this sequence of work:

- It is necessary to create a layer of crushed stone with a thickness of 15-20 mm.

- After that, a concrete screed is carried out 5 or 10 cm.

- The tile should be laid on a layer of concrete solution, the mixing of the components of which should be 1: 3. An alternative may be tiled glue styling.

- All seams are important to fix the cement-sand mixture.

Recommendations of styling experts

Features of laying tiles are in the usual installation technology of traditional paving stones and other types of products. As a rule, the choice of installation should be determined by the type of soil and certain conditions of operation of the material. Experts advise to adhere to such requirements when laying polymer -sand paving slabs, which you can buy at any construction store:

- Installation of tiles must be carried out in dry weather.

- It is not recommended to sprinkle products with sawdust.

- The approximate gaps between the tiles should be about 5-7 mm.

- It is necessary to calculate the drain of water residues from the surface of the tile.

To lay tiles, it is necessary to prepare a flat surface, the basis of which should be a pillow of sand and crushed stone or cement. With increased load on the tile, the base should be carefully strengthened, as well as equipped with a water drain system. The technology of work is not complicated, but requires certain attentiveness.

Hello, on the site

Hello, on the site of the manufacturer of the Tetto polymer-sand tiles, there is exhaustive information, about the features of this material, comparative characteristics, as well as a test site with tiles, photographs where styling was carried out in various ways and on various glues http://tetto.ru/polimerpeschanaya-plitka

As well as use options, for example, the floor in the gazebo, laying tiles on lags, using special stands.