That linoleum laying on a wooden floor It is enough ...

|

|

Modern production technologies provide the opportunity to make ... |

The construction of the house on the floats is a complex process. Switching is the connection of the soil with ... |

Laying a massive board: methods and technology

Massive board is one of the most strong materials for flooring. Outwardly, it resembles a parquet board, but differs from it in structure, because Completely consists of a wood array. Such a coating is much more practical and durable: it is more resistant to environmental influences and withstands more loads and grinders.

Installation of the parquet board is carried out at the finish stage of finishing work. In order for everything to go smoothly, it is necessary to familiarize yourself with some features of the material, as well as choose a way of laying depending on the temperature and humidity of the room.

Content:

- Characterization of the material

- How to choose a massive board?

- Preparation of a wood array for styling

- Massive board laying technology

- Methods of laying a massive board

- Laying a massive board on a concrete or cement-sand screed

- Laying a massive parquet board on plywood

- Installation of a massive board on an existing wooden coating

- Laying a massive board by a swimming method

- Laying boards on brackets

- Laying boards on the lags

- Installation on an adhesive substrate

Characterization of the material

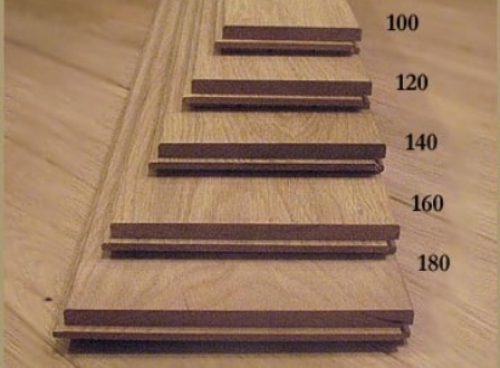

A massive board is made with small ridges and grooves at the edges, which allows you to tightly and quickly shake the floorboards. The width of the boards from the array is 12-20cm, and the length varies from 50 cm to 3 m. The array has a chamfer from the outside. Therefore, after the installation between the joints, a tiny gap remains. In the event of various kinds of deformations, the distance between the board is filled without curving the flooring. The back side has longitudinal cuts and small transverse notches, which reduces the load on the board and reduces the voltage of the fibers, thereby preventing their destruction.

The installation of the array involves the presence of hard, durable and even, and most importantly completely dry foundation. So, the humidity of the screed should not be more than 6%, and concrete ceilings are 4%.

In order to avoid random damage, even before the start of laying, all installation and construction work should be performed: installation of ventilation and heating system, wall cladding, and installation of window blocks.

How to choose a massive board?

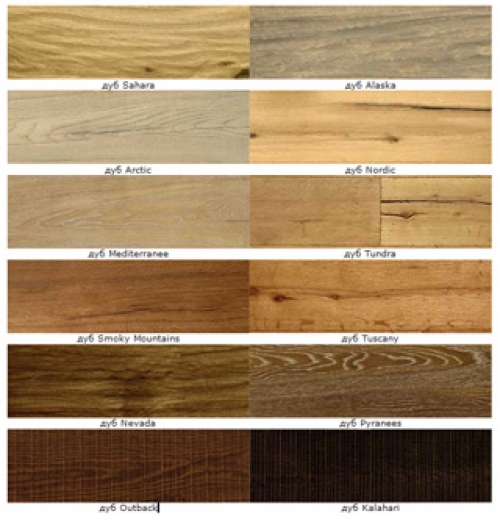

For the manufacture of boards from an array, wood is often used both exotic, foreign, and domestic species. Both of them are equally suitable for laying wooden floors. Therefore, when choosing wood, it is more likely played by its color and place of operation than the environment of wood. Of the European breeds, the lights include: alder, ash, walnut, larch, grab and beech. From exotic - Giveya, Mersawa, Merant, Siam, Karagach, Sukupir. Among the pink breeds are Suri, cherries, cherries, as well as a pear. Their wood is considered the most capricious. It requires constant control of moisture: a board from most light woods is not recommended to dry heating, but it is also impossible to install in a room with a high percentage of humidity.

If it is necessary to install the flooring in the room with strong temperature and humidity changes, then it is worth stopping the choice on rocks, the wood of which contains a large number of oils. For example, oak, Lapacho, Merbau, Kumaru, etc. Representatives of red-brown tones: Iroko, Kamshe, Dussia, Afromosia, Guarea, Merbau, Yarra, Kemas, Belian, Tentopling, as well as Keranzhi. Palander, Ventte, moraine oak are traditionally used for the manufacture of a dark massive board.

The stability of wood should be taken into account, its reaction to the effects of atmospheric differences. So, the oak resistance to deformations is greater than that of the beech. The choice of the breed depends on which of the rooms the coating will be located.

For the corridor, hall and hallway, in which the loads on the fibers of the array increase, it is advisable to install solid domestic breeds (oak, tick, ash, etc.) and exotive wood. For guest rooms and bedrooms, you can use a wooden array of any breed.

Preparation of a wood array for styling

5-7 days before installation, the array is unpacked for acclimatization in the room where it is planned to be laid. In order to ensure air circulation, you need to lay the product on the stand. The humidity of the dies should not exceed 5-12%. Then the wood will not change the shape after the styling.

Massive board laying technology

Laying a wood massive resembles the installation of a laminate. The array with self -tapping screws is fixed on any of the bases from the spike side.

The floorboards must be thoroughly incorporated with wedges. A gap of 7-10 mm is usually left between the wall and the array.

Laying the first row of coating is carried out with a groove to the wall. The fasteners are carried out by self -tapping screws on the front part and covered with skirting boards.

The installation of a wide board is performed on the front side, and the place of recess of the screw is masked in the tone of the wood pattern. The massive board is laid in the direction of sunlight perpendicular to the window opening.

Methods of laying a massive board

Preparing the base is also the key to successful styling. There are several types of foundation for the wood massif. Installation is carried out on reinforced concrete ceilings (on a screed and fraud of plywood, screed and lag), on wooden floors (chipboard, plywood and lags), floating way (on screws, brackets) or on an adhesive substrate.

Laying a massive board on a concrete or cement-sand screed

The installation of a wood array is performed according to a final screed using special glue, resistant to temperature differences, which makes its use safe enough for fixing on a heating floor.

Before laying, the screed must be checked for strength and verify the absence of damage. To determine the degree of moisture in the base in its different shares, a perforator create several holes. Humidity up to 6% is considered within the norm. If the percentage of humidity is slightly higher, take care of the waterproofing of concrete with a film.

Laying a massive parquet board On the plywood

In the conditions of our climate, an array is often laid on a plywood base with the arrangement of additional waterproofing.

First, the plywood is cut into rectangles of 5070 or squares 5050 cm. Next, the sheets are laid on mastic or glue, and then fastened with dowels. At the same time, 5-6 dowels go to each section. The humidity of the plywood base should not exceed 10%.

After laying, plywood begin to install an array. To fix the dies, it is better to use two -component glue. Every 25-30 cm, side fasteners are carried out with airshores. The finished flooring is cleaned and slightly polished. A massive floor board, the laying of which is done correctly, does not require thorough grinding.

If the installation is performed in violation of the technology, the screed is polluted or the base has not been properly dried, the plywood sheets are shifted, then subsequently this can lead not only to the deformation of the floor, but also to a change in the color of the fibers.

Installation of a massive board on an existing wooden coating

Before starting work, it is necessary to make sure that the strength of the old base and only then conduct its preparation. The surface of the already existing base from wood for maximum alignment and removal of excess paint or varnish, is polished with a ribbon grinder equipped with an abrasive ribbon. After that, the wooden coating is thoroughly cleaned.

The wooden array is mounted in the same direction as the old base. The already existing flooring is lined with sheets of plywood, and then proceed to grinding a plywood black layer.

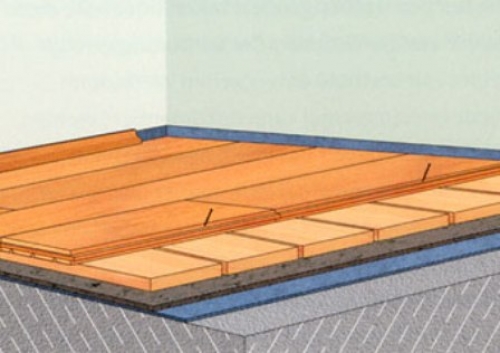

Laying a massive board by a swimming method

The installation of the floating coating is carried out so that the array is attached separately, i.e. Without connecting with the base. The compound is performed between the expanses of the array itself. Such a coating can withstand large mechanical loads and moisture differences precisely due to what is not connected with the draft floor. This method is suitable for heating floor arrangement.

Climatic conditions fluctuations can lead to certain changes in the size of the boards. To minimize deformation, self -tapping screws with a protective anti -corrosion layer are used as a mount.

Laying boards on brackets

The method of installation on brackets belongs to the so -called floating. About 50% cheaper is the laying of a massive board. The price of services is formed taking into account the costs of materials and time for execution, which can be significantly saved.

This type of styling has a number of other advantages:

- simplicity of installation;

- environmental friendliness (impregnation, primer and glue are not used in the laying process);

- laying speed;

- with the use of brackets, the stability of the array to the effects increases;

- the possibility of local or large -scale repair without a complete replacement of the coating;

- reducing the risk of deformation due to the fact that the array is laid separately, without fixing to the main flooring.

Professional laying of a massive board with fasteners on aluminum brackets with silicone compensators guarantees a strong connection of the dies to the ends. This design can be mounted yourself on any even coating.

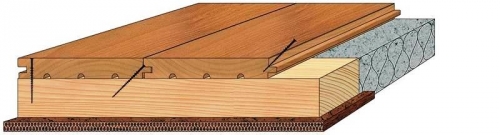

Laying boards on the lags

Traditionally, the installation on the lags is carried out during the reconstruction of the premises, as well as, if necessary, align the floor covering in the shortest possible time without the use of cement mixtures. To compensate for the height of the floor, when creating small catwalks in living rooms-studios or commercial premises, logs from the beam are also used as the basis.

Before mounting the structure from the lag, they will certainly waterproof the floor with foam or polyethylene.

Lags are laid out parallel to each other in opposite walls and pull the threads with an interval of 1.5 m. Lags are installed along each thread. It is advisable to fill the space between the lags with insulation. Next, sheets of fiberboard are mounted on the base from the lags, then the wood massif is laid.

Installation on an adhesive substrate

This installation method has become even more accessible with the appearance of an elastinol of a unilateral adhesive substrate with thermal and soundproofing properties. The joints of the array is practically not noticeable, because Glue provides excellent clutch. Laying using the substrate significantly reduces the possibility of swelling of the material. The process takes place without the use of glue and brackets. Labor -intensive construction of an additional basis is also not required. On the concrete base, the substrate is laid with the sticky side to the bowls, after which the wood array is carried out.

Among the advantages of a massive board is its durability, low thermal conductivity, environmental friendliness of the material (does not contain chemicals) and soundproofing properties. The life of this material depends on the care and is 100-120 years. At the same time, coniferous rocks can last much less. The reason lies in the properties of wood. Pine, for example, is less resistant to climatic and mechanical influences than other types of wood. Do not allow excessive humidity in the room and the floor covering of the array will last you for a very long time.