Arched doors a decorative element that has long been used in the design ...

|

|

When you want to make repairs in the bathroom in the shortest possible time, spending at ... |

In snow winters, no construction can do without such protective structures as ... |

We build the foundation on the swimming units. DIY difficulties in installing a foundation with your own hands

The construction of the house on the floats is a complex process. Swearing is a connection of soil with water, localized at a certain depth. If it is necessary to build the foundation, a number of questions arise about how not to violate this education. Check out the options for the foundation on the float and the technology of their structure.

Table of contents:

- DIY house on swimming ups: Features and types of swimming

- Building the foundation on the swimming units with your own hands: how to deal with the swimming units

- Foundation options for swimming ups: fine -sized tape foundation with your own hands

- What is the foundation to do on the swimming unit: the technology of erecting a slab foundation

- Difficulties in erecting the foundation on the swimming units: DIY pile foundation on swimming upers

DIY house on swimming ups: Features and types of swimming

Thermal swimming is a type of soil, the basis of which contains sand of fine -grained type and a large amount of water. Since this mass is quite floating, it does not withstand a large load, and this negatively affects the construction process.

An incorrectly built house can simply tighten underground, and with the walls. Therefore, the construction of the building on the floats should be treated with great responsibility.

In the ratio with the type of soil, several types of floats are distinguished, each of which has individual characteristics and features. There are floats:

- true origin - in the form of clay sand, loam or sandy loam;

- false origin - in the form of engraving sand.

The first option is characterized by high hydrophobic characteristics. Such soil absorbs water well, has molecular interaction between particles. The flowerpot forms a special film with a minimum cleaning coefficient. The true composition is determined by external features. The bottom of the well is flooded with cement milk, when the soil is taken from the bottom of the swim, it instantly blurred. To determine the floats on the site, the soil is handed over to the laboratory.

If you dig a hole on the site, then it will instantly be filled with water in a red shade. After drying, the mass is quite dense in consistency. The floating layer gives difficulties during installation work, the soil, during construction fills out any recesses. It is quite difficult to create a closed circuit.

False swimming -ups are less dangerous, their composition does not have how strong molecular connections. The water at the bottom of the float is light, and easily evaporates from the soil. After drying, a mass is formed with a slightly loose structure. Before the construction of the house on the swim, decide on the content of the soil and the type of floating land in the laboratory.

Building the foundation on the swimming units with your own hands: how to deal with the swimming units

Take the fight against the swimming units with special responsibility, start this process after determining the type of swimming up. There are three options for eliminating the negative consequences of switches:

- artificial drainage;

- creation of a fence using a shopent walls;

- Fixation of swimming up on the basis.

The first option implies an open pumping of water from the swim. If it is necessary to drain the earth up to 600 cm deep, we recommend using the needleofilters. With a greater depth of irrigation, experts use special electrical drainage devices.

Spunt walls cut a layer of float. Thus, a certain pressure and the ability to withstand the load is created. A wooden dodgy board is clogged to a depth of 10 m, and metal options are suitable for a depth of up to 35 meters. This method does not work in the presence of dense soils between the swimmer.

Fixation of the swim on the site is performed in three ways:

- freezing;

- cementation;

- Silicatization.

The first option is quite unreliable. For its implementation, special freezers are used, however, at high temperatures, swimming still thaws.

Silication is highly effective and involves rolling liquid glass into the soil. Suitable for false switches. Prevents soil movements and improves the strength of the base.

With a true swim, only such methods of struggle are relevant:

- electrochemical;

- freezing;

- The protective method.

When digging a pit or trenches on the site, they are mandatory to strengthen their walls.

In addition, in the process of combating the swimming units, a drainage system is equipped, which is located below the level of soil. Swear contains small dusty particles connected to water, using high -quality drainage, it is drained, the structure becomes strong and the soil withstands the load. However, during the operation of the building, the periodic revision of the drainage system is a mandatory process.

When the sail is located below the freezing of the soil, a variant of the monolithic strip foundation of small laying with the mandatory presence of gravel backfill is possible.

If the depth of the tile is more than 50 cm, while the thickness is small, and under them there is solid soil, then we recommend that you stop on the pile version of the foundation.

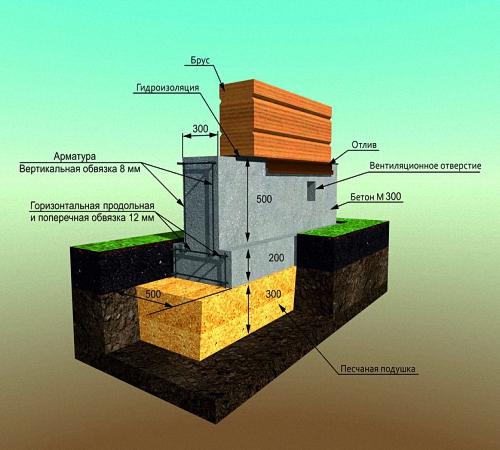

Foundation options for swimming ups: fine -sized tape foundation with your own hands

When putting a swim up up to 150 cm on weak -button soil, we recommend stopping on a fine -pounded tape foundation. If the basement is built in the house, then the base rises above the soil, but in no case is buried in the inside of the ground.

Instructions for the construction of a shallow foundation:

1. Carry the soil study to determine the type of swimming up on the site. Create the drawings of the foundation, they indicate its size, thickness, method of filling.

2. Prepare the site for work. Remove vegetation and garbage, align the surface, make a pit, according to the size of the foundation.

3. Equip horizontal drainage to avoid the capillary lift of moisture from the lower layers of soil. The depth of the pit for the foundation should not exceed 70 cm. At the bottom of the pit, set the pillow of crushed stone, then pour the sand of the coarse -grained fraction. Carefully compact the base with a special tool, gradually moisturizing it.

4. At the height of the basement of the structure, build the formwork. For its manufacture, use a laminated board, metal or plastic. We recommend that you dwell on the collapsible version. Check the evenness of the formwork installation. Put the waterproofing film or roofing material in the inside of the formwork - these materials provide additional waterproofing of the foundation on the floats and prevent concrete milk leakage when filling.

5. Further, in the ratio with previously carried out calculations and drawings, reinforcement is performed. To do this, use special welded and anti -corrosion reinforcement. The number of elements is determined individually and depends on the total size and weight of the house.

6. The next stage is the filling of a fine -trimmed foundation. For work, a concrete solution of high quality is a minimum of the 300 brand. To remove air bubbles from concrete and to improve its adhesion to the surface, special equipment is used in the form of a concrete vibrator.

7. Next, it is necessary to align the surface with a regular board or special devices. The ripening time of the concrete composition is at least 26 days. During this time, the foundation is covered with a film, in order to avoid precipitation on its surface and is protected from solar radiation.

8. After the concrete composition dries, the process of waterproofing and insulation of the foundation follows. Next, the backfill of the foundation pit is followed with sandy soil.

What is the foundation to do on the swimming unit: the technology of erecting a slab foundation

The slab foundation is used if the swim lies deeply on the heaving and moist soil. The cost of erecting a slab foundation is several times higher than a strip. However, this option is more resistant and good performance.

The slab foundation is also called floating, it withstands large buildings in the load, and when tuning soil or frosts, shifts directly with the entire house, without damaging it.

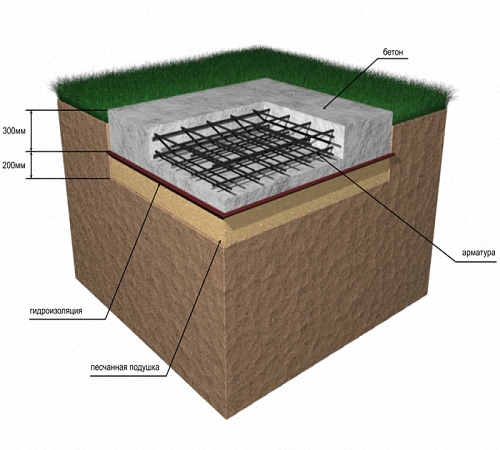

Instructions for the construction of a slab foundation on the swim:

1. In the ratio with the soil type, create the drawings of the foundation on the floats. They determine the size and thickness of the plate, the place of its location, the method of filling and other individual structural features.

2. Leve the site, remove garbage and vegetation. Pour it with gravel by at least 50 cm, compare and pour water tightly. Mark the territory using pegs and cord.

3. Put underground communications in the form of a water supply and sewage system. Waterproofing and thermal insulation of the foundation are performed before it is filled. To do this, adding from insulation and polystyrene foam is laid on the surface, then a waterproofing layer in the form of a roofing material or other roll material follows.

4. For the manufacture of formwork of the slab foundation, use boards or panel shield, about 50 cm high. Follow the strength of the formwork, since the concrete is quite heavy in weight and has a large load on the base.

5. The prepared surface, without fail it is covered with plastic film, glue the joints between the materials using ordinary tape. The film will prevent flowing of a concrete solution and make the plate movable, when tuning the soil.

6. For reinforcing the slab foundation, a corrugated bar is used with a diameter of 1.2-1.6 cm. The laying of the material is carried out in the form of a grid, with an interval of 15 cm. At the places of crossing the rods, the wire is used for the ligament. Laying the reinforcement is performed on top of plastic guides, the material should completely drown in concrete solution.

7. Prepare a concrete solution. For these purposes, specialized special equipment or ready -made factory concrete is used. Since the volume of work is very extensive, the usual concrete mixer is not suitable.

8. In the previously prepared formwork, pour a concrete solution, align it and treat it with a special vibrator. Use the rule for smoothing. Concrete drying time is about 3-4 weeks in dry and warm weather and 5-6 weeks in cold. It is recommended to cover the foundation with plastic film in order to avoid it getting wet.

Difficulties in erecting the foundation on the swimming units: DIY pile foundation on swimming upers

With a close location of the swim to the surface, we recommend that you stop on the pile foundation. This option is relevant if a powerful, stable soil is located under the floats.

This situation is characteristic of humid dusty soup, where the swim is not possible to drain and the only option remains the installation of piles. Among the advantages of a metal pile foundation, we note:

- Suitable for any type of soil;

- differs in a minimum amount of earthwork;

- It is built at any time of the year;

- The cost of construction is almost half less than that of the strip foundation;

- It is distinguished by high supporting abilities.

Instructions for the construction of a pile foundation on the swimming units with your own hands:

1. Clean the site from the upper soil layer by 10-12 cm. Mark in the ratio with previously compiled drawings. The number of piles is determined individually depending on the total weight of the building, its size and type of swimming up in the soil.

2. The option of using concrete or metal piles is possible. We recommend stopping on the second option. This method is less time -consuming, affordable in value and is not inferior in terms of efficiency of concrete piles. For installation of steel piles, special equipment is not required, and the work is performed in 1-2 days.

3. Rifle piles are ideal. These devices do not require preliminary drilling. They are installed and screwed into the soil. Therefore, there is no risk of flooding of the well and pumping of water.

4. Places installation of piles are determined in the drawing, the corner areas, the intersection of walls, as well as with an interval of 200 cm between the walls of the supporting purpose are mandatory.

5. To screw metal piles, at least two people will be required. A special design is characterized by a lever that must be rotated with screwing. Be sure to check the evenness of the design. It is not allowed to remove pile from the soil and screw it again in the same place.

6. For the installation of concrete piles, specialized equipment will be required. Previously, wells are built under them.

7. After reaching hard soil, the pile deepens into it by at least 100 cm. If necessary, a metal pile is executed. To remove the excess foundation, use a grinder, and then equip the strapping with metal structures.

When performing any earthwork, it is necessary to adhere to safety precautions. In case of damage to the integrity of the swim, the pit is flooded for several seconds. In addition, getting out of this mass is quite difficult. Therefore, during work, be sure to strengthen the walls of the pit with wooden boards, at a large depth of the pit, install the stairs, for a quick rise to the top. All work spend at least one, and better with two, three people.

The foundation on the swimmers of the video: