The house is the business card of its owners. From how ...

|

|

More and more city residents dreams of leaving their apartment and leaving away from ... |

A good roof in country households is an important component of a comfortable ... |

DIY parquet grinding

High -quality wooden parquet is a very durable coating. But even, despite the sparing operating conditions and leaving care, sooner or later its surface is growing. The varnish becomes dark or dull, scratches and cracks appear, the parquet darkens and that is the most offensive uneven, i.e. spots. And about the state of parquet after prolonged operation in extreme conditions, such as walking in street shoes, furniture on wheels, heavy cabinets and bedside tables without stands, frequent flooding and much more, and there is no need to speak. As a result, deep potholes and furrows from wheels, in some places exfolved or cut varnish, large cracks between the strips. What to do? Change the flooring? Not worth it. With the most part, grinding the parquet will cope with the problems, its update by removing the upper layer and grinding and varnishing of the surface. This type of work is quite complicated, very laborious and responsible, but it can be mastered independently if you are patient. A great help is the variety of special equipment that greatly simplifies the task.

- Tools and materials for grinding parquet without dust

- Parquet grinding: work cost and equipment rental

- Grinding the parquet with your own hands

- Grinding Parquet: Video - Instruction

Before you finally decide that you need exactly the grinding of the parquet and all the work that it includes will be enough, you need to check the condition of your flooring. There are times when the cosmetic repair of a wooden floor is useless.

It makes no sense to polish the parquet if:

- The parquet has rushed so much that the cracks between the strips are 5 mm. The entire coating is a grin of dry planks.

- Parquet swelled due to getting wet. This problem cannot be solved.

- The most passable place was too filament. For example, in the area of \u200b\u200bthe threshold of the room in the person’s passage area there is always a difference in heights between the Parquet strips. So, if less than 5 mm remains from the top of the Istered planks to the connecting sponge, the grinding is meaningless.

- There are visible deep bumps or potholes.

- The wooden floor constantly gets wet from the fumes from below. In this case, it is necessary to completely remove the coating, waterproofing the base and only then lay the new one.

- Part of the wood is source to be a bug to a sharpener.

- The room appeared mold or rot.

The problems listed above are associated with various factors: initially incorrect styling, under -in -law wood, non -compliance with the technology of laying a wooden floor and too difficult operating conditions. In all other cases, it will be quite high quality to remove the upper varnished layer of the parquet, and the updated parquet shines with fresh wood.

Tools and materials for grinding parquet without dust

Parquet grinding work can be performed both manually and machine. The latter, although more expensive, is less laborious and faster.

If there is not enough finance even to just rent equipment, then you can phenie the parquet manual cycle. This tool is a metal plate, one edge of which is bent and sharpened so that it is convenient to remove the lacquer layer, and the rest of the plate is enclosed in a wooden handle. It is very difficult and hard to work with a manual cycle, the hand gets tired quickly, and the work in the pose on the karachi leads to back pain. Nevertheless, with the help of it you can process the entire surface, even in particularly hard -to -reach places. When grinding, the parquet with the help of cycles removes a rather large layer of wood, but there is no much dust, as small as in machine work.

In addition to manual cycles, sandpaper can be used. It is fixed to the soles of the shoes and then the parquet with the legs is wiped. This method is also difficult to call easy.

That is why grinding machines for the mechanized performance of such work are increasingly popular.

Equipment and tools

The grinding of the old parquet consists of several stages, and each of them uses its own type of equipment.

Parquet -grinding machine of drum type Used for deep cycling of any wooden floors. These machines are in demand in the territory of the Russian Federation, they are reliable, durable and relatively cheap. The most common grinder of this type is the CO-206 unit, which is produced at the Odessa factory in Ukraine. It is equipped with a comfortable drum with a width of 200 mm and a pump that collects dust forming during grinding in a special vacuum bag. The weak point of the S-206 parquer-grinding machine is rubber glued to the drum. It can be damaged if the abrasive (sandpaper) is poorly clamped or the car ran into a nail or self -tapping screw sticking out of the floor. The full cost of such a grinder is about 1300 1700 cu

Planning grinding machines are single -disc and three -disc. They are used for thin grinding of parquet floors and floors from a massive board, for grinding before tinting or tinting, for interlayer grinding when coating the surface of varnish, as well as during tinting or for applying oil. The cost of such a machine is simply fantastic, so they purchase it not for personal use, but for high quality professional work. Planning grinding machines are in demand not only due to reliability, but also in the convenience of use, multifunctionality and the ability to carry out almost jewelry work with parquet. The most common is the German grinder Lagler Trio, the cost of which is 8500 10000 cu

Bootit is used to grind hard -to -reach places under heating radiators, in the corners and near the edges. All machines of this type are unified, abrasive circles on Velcro with a diameter of 150 mm are used, they are also equipped with a vacuum. The most common models are CO-401 (Odessa, Ukraine), Lagler Flip and Lagler Elan (Germany).

Grinding machines are expensive, they are acquired only by companies engaged in parquet work or renting equipment. It is the last service that must be used by those who want to do work on their own. If you order the grinding service in this company specializing in this company, you should know that prices in different organizations depend on the grinding of the parquet on the equipment used. The more expensive and better, the more expensive the work.

Industrial vacuum cleaner It is necessary to remove all the dust from the surface and cracks of the parquet floor. If this is not done, the opening of the varnish will be poor -quality.

In addition to all of the above, you need scissors to cut sandpaper, tools and keys To fix the abrasive on the drum.

Expendable materials

In the process of grinding the parquet, you will need materials, the number of which depends on the area of \u200b\u200bthe room and the complexity of the work.

- Sandpaper. At different stages of grinding, paper of various granularity No. 40, 60, 80, 100 and 120 is used. A minimum of one sample is spent on the floor with an area of \u200b\u200b20 m2, which is enough to refuel into the car. For example, for a drum -type parquet -grinding machine, you need No. 40 paper 2000 mm long and 200 mm wide.

- Putty for sealing cracks (approximately 5 kg). It is selected in the tone of wood or prepared independently from the liquid component and wood dust, which remains after grinding.

- Varnish Or oil. Parquet varnish consumption is about 5 kg per 10 m2. The most common Forbo, Resident, Loba, Flow and others.

- Valiki and brushes for applying varnish.

- Rubber spatulasfor putting putty.

Consumable materials are best purchased with a margin, since the exact consumption cannot be calculated.

Parquet grinding: work cost and equipment rental

For comparison, consider two options: if you order a grinding service and if you do everything yourself.

If you ask the question of how much grinding the parquet costs, then you must immediately pay attention to the list of work provided. Repair organizations always indicate what is included in one or another cost. Let us give an example.

Parquet grinding services:

- Complex of work 1: Drum -type cycles, putty and varnishing in 3 layers will cost 10 11 cu for m2.

- Complex of works 2: Cycles with a drum machine, grinding with a flat grinding machine, putty gap and opening with varnish in 3 layers 12 13 cu for m2.

- Separately, grinding a drum type 2.5 3.5 cu. for m2.

- Separately, the grinding of the plane -grinding machine Trio is 2.5 3.5 cu M2.

- Separately putty of slots 1.25 1.5 cu for m2.

- Separately matting 1.25 1.5 cu M2.

- Application of an additional layer of varnish 1.25 1.5 cu For the layer.

- Paul coating with gel 1.25 1.5 cu For the layer.

Let's calculate how much such a list of works for 20 m2 will cost: cyclisting with a drum machine, flat -grinding, putting the cracks, matting, an additional 2 layers of gel and 4 layers of varnish. We will count at the minimum rate.

2.5x20 + 2.5x20 + 1.25x20 + 1.25x20 + 1.25x2x20 + 1.25x4x20 \u003d 150 + 50+ 100 \u003d 300 cu

Total, grinding services Parquet will cost us in 300 cu for 20 m2.

Now let's calculate how much it will cost us dIY parquet grinding:

- Renting a parquer -grinding machine 18 20 cu per day.

- Renting a flat -grinding machine 37.5 40 cu per day.

- Rent a boot - 10 12 cu per day.

- Elevator paper No. 24, 30, 36, 40 3.25 3.5 cu For m. linear.

- Elevator paper No. 60, 80, 100 2.875 cu For M. Pog.

- Elevator paper No. 120, 150 2.75 cu For M. Pog.

- Parquet putty 60 cu for 5 liters.

- Parquet varnish 150 300 cu for 10 l. Consumption 80 100 g per m2.

- Toning composition for parquet 50 cu for 1 liter. Consumption 1 liter up to 40 m2.

- Consumables (rollers, brushes, etc.) 60 80 cu

We count: 18+38+10+3.25x2+2.87x2+2.75x2+60+150+50+60 \u003d 403 cu.

As you can see, even if you cope with work in one day, i.e. You don’t have to overpay for rent, all the same, taking into account the materials, you will spend more than when ordering the grinding services for professionals.

Grinding the parquet with your own hands

Performing work on grinding the old parquet The task is responsible and time -consuming, it is better to entrust it to professionals. But if you want to do everything yourself without resorting to the help of specialists, then you will need an exact instruction, what to do. In addition, even if you decide to order a grinding at the repair organization, knowing the sequence of work and nuances, you can control the quality of execution.

Preparatory work before grinding

The very first task that needs to be completed is to check the quality of the parquet for the subject, but whether it makes sense to grind it. What criteria was described at the beginning of the article.

Before starting work, all the furniture is carried out from the room, the plinth is removed, and the floor is checked, whether there are rolled dies or not. Quite often, wooden skirting boards in old houses are pinned to the floor tightly. In order not to damage the coating, they can be left. The torn parquet planks are glued back. If it is necessary to repair the parquet to eliminate creaks, failures, etc. We carry out repair work.

We inspect the entire surface of the parquet floor for protruding nails or screws. They must be drowned in wood at least 2 3 mm so that they do not damage the abrasive. The last touch is and vacuum the floor.

Only after all preparatory work can you purchase materials and rent equipment. It is most convenient to draw up rent early in the morning. Keep in mind that the weight of grinding machines is very large (about 70 kg), for work you will need at least two such heavy machines. Do not forget to stock up on a costume like Musk Khalat, Berushas or headphones and a respirator. Despite the presence of a bag of a sprayer, it will not work out without dust. It will be less than without it, but it will be small and very dangerous, as it can easily fall into the respiratory tract.

Deep cycle parquet

Before starting work, open all the windows and close the doors. On the drum parquet grinding machine CO-206 We season the rough sandpaper.

No. 16 is used to remove the old olifa or varnish from the floor.

No. 24 40 is used to remove paint and the upper layer of wood.

No. 60 Universal paper for rough grinding.

Most often, for starters, they take paper No. 40. First, we make a passage by a machine diagonal of the room, from one corner to another. Then we move the machine to the wall and begin the passages along the wall and parallel to it. The width of the drum is 200 mm, so each subsequent pass should be shifted by 100 mm.

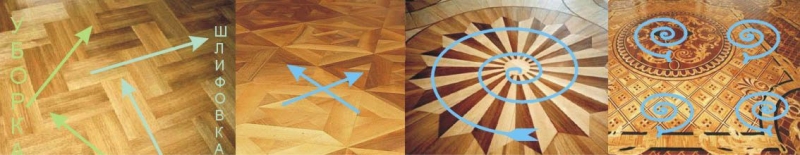

Important! The movements of the parquer -grinding machine should be along wood fibers. Only at the turns, short -term movement across is allowed. For an artistic parquet, movement should be circular in a twisting spiral.

At this stage, corners and inaccessible places do not touch. It is better to start from the far wall and move towards the most passable site. Dust from a vacuum cleaner can be poured into a plastic or plastic bag.

Important! It is necessary to raise and lower the parquer -grinding machine in motion so that the hollow does not form on the floor.

Be sure to monitor how much the drum presses on the surface of the floor. This can be adjusted with a special screw. If the machine removes too small a layer of wood, and the engine speed is normal, it is necessary to increase the drum pressure on the floor. If, on the contrary, it takes off too much.

As necessary, the abrasive should be changed.

Grinding of hard -to -reach places under radiators, corners and edges

After a rough cycle, spots of varnish in the recesses, in hard -to -reach places, near the pipes and edges, should remain. We grind the unprocessed surface angle grinding machine (boom). We refuel the skin No. 40 or No. 60.

In the middle of the room, the spots of the varnish are removed in circular motions, moving from the edges of the spot to the center.

In the corners and near the edges we remove the upper layer of wood, moving the machine from the edge of the treated surface to the wall and vice versa, pendulum movements.

Primary cyclation works are carried out until the entire surface of the floor and its shade are leveled.

Thin grinding parquet

Now enters into work planning grinding machine, a good option machine with three Trio discs. With the help of it, it is necessary to remove all the irregularities, burrs, scratches and potholes that remained after a deep cycle.

Economic paper is put on the discs in the following sequence: first No. 40, then No. 60, 80 and the final 100. We pass on the floor surface with a plane -grinding machine only 3 4 times (each time in different skins).

Each time we make two passes in one direction and in the opposite. The discs of one granularity change as it is wear.

After processing a flat surface, we proceed to grinding inaccessible places of the same angling machine. Only one disk can be filled into it. First, granularity No. 40, then 60 and 100. We grind until the surface becomes smooth.

Putting the slots parquet

Before the gaps in the parquet, it is necessary to thoroughly vacuum it. Despite the vacuum cleaner, there will still be wood dust. It must be removed.

For putty, the parquet can be used finished putty in the color of wood, or you can knead the liquid component with wood dust, which remained after the cyclist and grinding, and cook putty on your own. The main thing is to carefully read the instructions on the packaging.

Absolutely the entire surface of the floor sleepsthe resulting composition. To do this, use a rubber putty spatula. The solution should be distributed evenly, filling all the cracks, both between the strips and on their surface.

When the putty dries a little, i.e. will not take up hands, but it will be still soft, you need to quickly perform imitation of joints. It is performed by an awl under the metal ruler. The curved joints can be made by the line of the ruler, slightly pressing on it. The deadline for gelatinization of putty depends on its composition. For example, in alkyd and urequiric materials, solidification begins literally a minute after application, so you have to hurry.

Glee of grinding parquet

To remove excess putty from the floor surface, it once again grinds with a flat -grinding machine with sandpaper No. 100. This work can only be performed after the putty composition is completely dried. With finish grinding, the drum pressure is reduced, the machine is moved only in the direction of wood fibers. Valilee grinding is made until the surface becomes perfectly smooth, you can check this by running a hand on the floor surface.

Opening parquet varnish or oil

Before applying varnish to the parquet, it must be thoroughly vacuumed, otherwise the varnish will lie unevenly. And under a layer of varnish, clusters of dust or dirt will be noticeable.

Parquet covering the most responsible task in grinding works. If you make it poorly, you will have to cycle and grind it again.

Varnish is applied to 3 4 layers, each of them dries for about 4 hours, but if you wait longer, it’s not scary. Under parquet varnish you can apply a primer or tinting composition. The varnish is applied by a roller immediately on the entire surface of the floor and is quickly distributed along it, as it dries very quickly. If it froze unevenly, you will have to redo everything.

After applying the first layer of varnish and its complete drying, it is necessary to polish the surface again, removing the rise of the wood pile. We do this with a flat -grinding machine or angle grinding with sandpaper No. 100 or No. 120. Once again, we vacuum the floor, the walls and ceiling suddenly greeted fine dust and stuck to them.

Now apply the remaining layers of varnish. When the last layer dries, we vacuum the floor surface again.

In conclusion, I would like to note that the grinding machines are very noisy, you can work only during the day, with the permission of neighbors, when children do not sleep and always in headphones. In addition, the power and starting current of such machines are very large. Quite often, there are situations when the old wiring is not able to ensure full operation of the grinding machine and you have to use a generator or a powerful stabilizer. The severity and large vibrations of such machines do not allow them to use fragile women. The limited lease term of equipment may make you hurry and make mistakes. Consider all this, it may be better to contact specialists.

i remember the shot

i remember the shot, he made the floor, he was satisfied

In what sense

In what sense

Shot

Shot