Would you like your house to look like a medieval castle or a palace? Design ...

|

|

There is a common problem in regions with snow winters ... |

Among the variety of door locks, which is represented in the construction market, ... |

Do -it -yourself cork floor in the kitchen

The cork covering of the floor is long known for a long time, but, at the same time, newfangled, the most environmentally friendly, safe, functional and beautiful type of flooring. You can lay cork floors in absolutely any room: children's, living room, bathroom. And the cork floor in the kitchen is the best combination of quality, safety, originality at a reasonable price for a fairly long period.

Content:

- Camping floor: properties and types

- Cork floor in the kitchen: how to choose the right

- Do -it -yourself cork floor in the kitchen video video

- Camping floor in the kitchen photo

Camping floor: properties and types

Cork floors This is a lot of positive properties enclosed in the structure of the cork tree: the cork consists of many cells filled with air bubbles.

And that is why the cork flooring has unique properties:

- cork ecological natural type of flooringAfter all, they make it from a cork tree bark, and although other materials and substances (varnish and glue) are sometimes used in the production of a cork covering of the floor, the cork still retains its natural primacy and safety.

- plug moisture -resistant material, Which, with the right approach to the choice of a specific flooring from the cork, can be safely laid in the bathroom or kitchen.

- traffic jam is one of the best noise insulators, therefore, if the apartment has children and animals, the traffic jam on the floor is the best solution to avoid complaints from the neighbors.

- cork natural insulationTherefore, by laying the cork coating on the floor about warm electric floors, it is no longer advisable to think, the floors will be warm. Which, in turn, is saving on electricity, as well as the purchase and organizations of the electric warm floors themselves.

- cork heat -resistant and non -combustible material: it does not burn, but only carved when exposed to open flames on it, while, unlike plastic, it does not distinguish any harmful substances when charred.

- the cork has a fairly textured surface, do not slipt, even in a wet state, and is antistatic:dust does not stick to the floor and clothes.

- traffic jam is one of the few modern natural materials with antibacterial, anti -infic and insecticidal properties, those. Bacteria, mold, fungus and insects with a cork are completely not terrible.

- traffic jam with volumetric memory: When deformation from a blow or prolonged exposure, for example, the legs of a chair, a table or a cabinet, the cork coating in this place changes the shape, is raised, and after the termination of the influence, it acquires the original appearance even and holistic.

- traffic jam is a lot of original color, from completely natural, to unthinkable, and textured solutions: marble, baby, wood,

photo printing

for any interior.

Another positive quality of cork floors is the ability to choose the necessary type of cork coating on the floor.

In value and quality, the following types of cork coating on the floor can be distinguished:

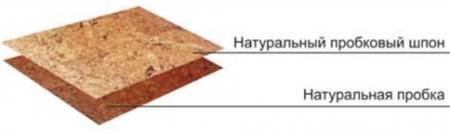

- The most expensive and high -quality option: a whole cork The whole veneer of the cork tree bark.

- The most affordable option, with the least quality, to a greater extent, this applies to the appearance of the cork aglagirat (cork baby) - pressed waste production waste. It is more often used in the form of a technical traffic jam.

- The optimal combination of price and quality: a cork coating produced from combinations of both a whole veneer of cork tree and cork crumb.

By laying, there are the following types of cork coating on the floor:

- Technical traffic jam This is a variant of the cork covering of the floor used, more often, as a black layer of the substrate, with the aim of insulation and sound insulation of the floor, under another flooring: laminate, cork laminate, plank floor.

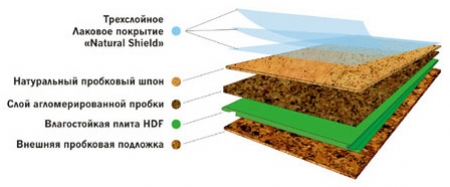

- cork laminate/cork parquet/cork floating floors This is a variant of the castle connection when laying cork floors. The lamella of the cork laminate has the type and dimensions of the standard laminate lamel, but the next structure: the base of wood-fiber plate, on which a technical cork is glued, on both sides (from the upper and lower side of the plate), and on the upper, facial, additionally, additionally, side On the technical cork the veneer of the cork tree bark, a layer of several millimeters covered with special protective varnish.

The lamellas are connected with a typical lock-paz lock.

- Gloring cork coating on the floor:Such a coating of several layers of cork consists: the lower layer is a pressed cork, the upper whole veneer. The total thickness of the panels is 4mm, 6 mm.

and standard dimensions: 30cm by 30 cm, 45 cm. 45 cm, 30 cm by 60cm. The cork is glued to a specially prepared, even, flooring on a special glue. After laying the glue plug on the floor, the surface of the floor is covered with a layer of varnish. It is such a cork floor that can be performed in the form of absolutely any pattern or drawing.

Cork floor in the kitchen: how to choose the right

The kitchen is complex: temperature and humidity changes, and sometimes water on the floor, which is why special requirements are made to all the materials used in the kitchen.

A cork coating for the floor of the kitchen is

- Moisture -resistant floor: No spilled liquids and increased humidity are terrible for the cork,

- heat -resistant and not a combustible floor:what, in the conditions of the kitchen and cooking there is a big plus,

- safe floor option: Even if there is water on the floor, the floor surface does not slip, and the dishes when falling will not stun the neighbors and, most likely, will not break.

But, all this is possible only when using glued cork coating on the floor in the kitchen.

Thanks to the glue and the prepared base of the floor, it is possible to achieve a tight fit of the panels of the cork coating to the floor, complete sealing of joints-sections, due to the same laying on glue and finish processing of the entire cork floor with varnish.

Cross floors in the kitchen are reviews of which are not very flattering, most likely, they were floating cork floors more simple in laying and not demanding on the black floor surface. But it is precisely this type of cork floor, a cork laminate floating cork floors, due to its locking connection that is not moisture-resistant, and are not suitable for places with high humidity, i.e., for bathrooms and kitchen.

Do -it -yourself cork floor in the kitchen

So how to make a cork floor in the kitchen so as not to regret the choice made?

First, stock up on both money and time: The base of the floor is a cork coating for glue should be perfectly even. For this, an organization is necessary not only screed, which in itself for a long time, the screed dries for 28 days. But also the alignment of the floor with the help of self -burning mixtures, which will make the floor even smooth. For a cork coating for glue, a thickness of 6 mm, this is quite important. And this means that the cork floor in the kitchen is the price of which is already quite decent, even when performing all types of work on organizing the screed, it will increase.

Secondly, a tool is needed, Although not particularly expensive and not specific: a roller, a spatula, a kiyanka, a knife, a square, a roulette and a laser level. And also, glue, varnish and cork coating on the floor. The amount of cork coating for a particular room is calculated by the formula:

The area of \u200b\u200bthe room + 5% of the total area of \u200b\u200bthe room.

Thirdly, it is important to give the cork coating for 2 days to adapt to the microclimate of the room, In which they will be laid so that the seams do not rise or part, and the floor surface remains even, smooth, beautiful and functional - protected from moisture and dirt. To do this, it just needs to be kept indoors.

And only then on the prepared surface of the floor, with markings, the adhesive cork coating of the floor is laid.

How to lay an adhesive cork floor in the kitchen will demonstrate in more detail and clearly:

Camping floor in the kitchen photo

The result of the work will be a beautiful, even, practical and environmentally friendly cork floor in the kitchen: