The installation of the door frame is accompanied by the installation of the door on the loops. The...

|

|

Parquet is the most expensive and noble flooring. But even the most ... |

Liquid nails are a type of construction glue intended for connecting ... |

Gender of the second floor: instructions for arrangement

In the process of building a multi -storey building, one of the main questions is the type of floor arrangement on the second floor. How to calculate the correct load and how to make the floors of the second floor such that they have high operational characteristics below.

Table of contents:

- Wooden floor of the second floor - recommendations for arrangement

- Warm floor on the second floor: installation features

- The floor of the second floor - concrete flooring

- Floor floor overlap: additional recommendations

Wooden floor of the second floor - recommendations for arrangement

The installation of a wooden floor on the second floor is appropriate as in a wooden one, and in a brick building. Wooden floors make the room cozy, they are harmless to health and radiate beautiful light.

The technical parameters of the construction of a wooden floor on the second floor are distinguished by the following requirements for the floor:

- It must have maximum rigidity, and at the same time have a minimum deflection value;

- When installing a wooden floor, all technological requirements should be observed and at the same time the design should be simplified;

- The functional side involves the stability of the floor before the influence of moisture, abrasion, duration and reliability of operation;

- The wooden floor should be hygienic, fireproof;

- must provide heat and sound insulation;

- The mandatory criterion is the presence of hydro- and vapor barrier;

- Full correspondence of the bearing capacity of the operational load on the building.

The aesthetic aspect of the construction of a wooden floor involves the attractiveness of the appearance and compatibility with the overall style of the premises.

A certain type of load, furniture, people living in rooms, heating devices, etc. are assigned to the floor of the second floor.

We offer to familiarize yourself with the instructions for the construction of the floor on the second floor on wooden beams.

Among the varieties of wooden floors, only two of their options are distinguished:

- lag,

- Board.

The floor built on the basis of beams involves a low expense of funds, since these materials are less expensive than lags. In addition, the beams provide a high level of resistance before loading, which means that the floor will last a very long time.

The only drawback in the construction of the floor on beams is its low level of sound insulation. The beams are installed in the frame part of the building, and therefore the noise level increases several times.

Before starting work on the arrangement of the floor on the beams, the number of beams that will be required in the process of performing work should accurately determine. In addition, you should correctly calculate the interval between the stacked beams.

There are two methods that will help to do this:

- a computer program in which it is necessary to specify the floor area and some parameters of the room;

- The standard section size, which is 15x15 or 20x20 cm.

The best version of the tree that is suitable for flooring on the second floor is pine. Materials made on its basis differ in lightness and simultaneous strength.

To install a bar in a building made of brick and wood is produced in different ways.

When arranging a brick building, special recesses in which the beam will be installed are in advance. After installing the beam, you should tightly close the joints between it and the wall.

In addition, certain rules should be fulfilled that are required when working with wooden beams:

- Before installing, the beam is treated with fireproof and antiseptic agents;

- Do not use the resin to cover the entire area of \u200b\u200bthe beams, since the tree will not be able to pass the air on its own, which means that condensate will accumulate on the floor;

- The distance between the bearing wall and the beam is a maximum of five centimeters.

To install the beams in a wooden house, you just need to cut down special cells in which the beam will be located. All previous requirements regarding wood processing are also applied.

Instructions for the construction of wooden floors on the beams of the second floor:

1. The first stage of operation includes the installation of a draft floor from ordinary boards or bars. They should be adjusted regarding the size of the room or the entire floor. Follow the flatness of the floor and the quality of laying boards.

2. The next stage involves the waterproofing of the flooring, for this modern roller materials are used. A simpler way to waterproofing, which does not require special investments, is the processing of the draft floor using a clay-sand solution. The option of laying roofing material is possible, the sheets of which should fit tightly to each other.

3. Next, it is necessary to carry out a number of works related to the insulation of the floor. There are mass options for insulation of a wooden floor, among them it should be highlighted:

- the use of simple slag, filled up in interbrus sections;

- mineral wool;

- sawdust;

- Styrofoam;

- Keramzit.

The most effective and common type of insulation is mineral wool, which is laid in such a way as to ensure its tight fit to the boards. This type of styling will help prevent the formation of cold bridges and increase the energy efficiency of not only gender, but the entire building as a whole.

4. After installing the insulation, proceed to the next stage - the installation of vapor barrier. This option is not always installed when installing a wooden floor. Although it is better to take care of the presence of additional vapor barrier, which, firstly, will become an additional layer separating the floor and mineral wool, and in case of flooding or a small amount of water, prevent its contact with the insulation, and secondly, it will become an additional protective layer of wooden Paul.

5. The installation of the main sex acts as the final stage. There are two options for conducting this process:

- flooring

- Installation of label floor.

To improve the quality, mounted floor, special boards are mounted before installing the flooring, in the form of lag. With their help, additional ventilation underground space is equipped, and the level of noise in the room is significantly reduced.

The option of building a floating floor is possible, which is freely fixed in the walls and creates the effect of swimming in space. Physically, this aspect is practically not noticeable, but it helps to significantly improve the soundproofing characteristics of the building.

As a finish coating, it is recommended to use strict floorboards or chipboard, and then carry out finishing work in accordance with the design of the room.

Warm floor on the second floor: installation features

Before learning about the technology for installing a water floor on the second floor, we offer to familiarize yourself with its advantages and disadvantages.

The advantages of the installation of a water warm floor include:

- uniformity in the heating of the floor throughout its area;

- the invisibility of all heating components used in the process of warm floor;

- the ability in heating of a large area, with a minimum expenditure of cash;

- Attractive appearance.

The main disadvantages in the installation of a water warm floor are:

- complexity of constructive nature in the process of installation of the structure;

- the presence of a water pump;

- the occurrence of difficulties in regulating floor temperature;

- water pressure surges in the system;

- The possibility of leaks and the difficulty in finding it.

It is not recommended to be used when arranging a warm water floor of a metal pipe, as they are subject to corrosion and have a short life. It is better to resort to an alternative option in the form of polyethylene, polybulane or metal -plastic pipes. The duration of the operation of pipes of this species reaches forty -five years or more.

There are two types of system for the arrangement of water floors:

1. Concrete technology - consists in the location of the pipes on the floor, which is covered with a layer of concrete on top. When using this method, more material, labor and temporary investments will be required. Since the preparation of the solution will require the presence of cement and sand, and to dry the screed will take at least three weeks.

2. The flooring type of water flooring involves its installation using ready -made components that do not require time to dry. Although this method is more costly than the previous one. This method is divided into three subspecies: polystyrene system, module installation, rack installation.

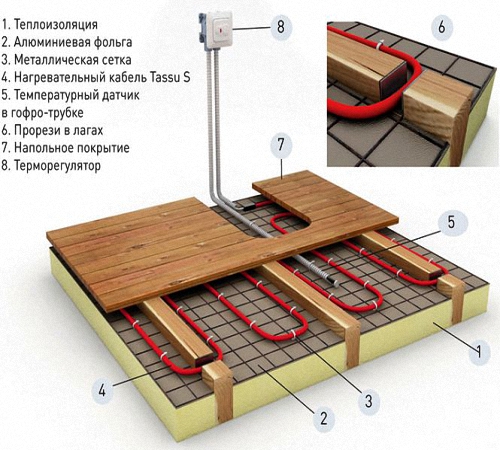

It is the last option that is used in the process of arranging a warm floor on the second floor.

It implies the installation of thermal insulation material in the interrogation. At the same time, mineral wool or polystyrene is used as a heat insulator. In the process of laying boards, at least 2.8 cm thick. A groove space is left, up to two centimeters wide. In this space, the components of the warm floor in the form of aluminum plates and pipes will be placed. The final stage includes the installation of the rough coating and the finish flooring.

Another important stage in the process of installing a warm floor is the installation of a collector group, which is sold in any of the construction markets. After installing the collector cabinet, the supply and return pipes is installed. The main function of the first of the pipes is to provide the system with hot water, as it is connected to a boiler or source of hot water. The second pipe is responsible for transporting cooled water to the place of heating. To ensure the circulation of this process, noston is used.

Tip: When choosing the place of installation of a collector box, you should adhere to the center of the room and install it in the lower part of the wall. This procedure will ensure uniformity in the heating of the warm floor.

Do not forget about the installation of special valves for each of the pipes. They will help, if necessary, to stop the operation of the system in order to carry out repair work in it or save money on floor heating.

The connection of a plastic pipe with a locking valve occurs using compression fittings. Then, the collector is connected to the valve, a drain valve is installed from one end, and from the second - an air bend. Installing a simple plug is less functional. When a collective cabinet is assembled, work is carried out on the installation of the warm floors described above.

The floor of the second floor - concrete flooring

The most durable option for the construction of the floor on the second floor is the device of a monolithic floor.

As the main stages of this process, is:

- Installation of formwork;

- reinforcement;

- the process of pouring with a concrete mixture;

- Paul drying;

- finish.

The formwork installation procedure is quite complicated, as it requires special attention and preliminary calculation. It is necessary to calculate the distance between the supports and the thickness of the layer itself. This value directly depends on the area of \u200b\u200bthe floor and the power of the building itself.

We give an approximate calculation of these indicators. With the thickness of the concrete layer of fifteen centimeters, the distance between the backups will be about 150 cm.

After completing the installation of the formwork, proceed to the next process called reinforcement. To do this, you need a certain amount of metal rods, the cross -section of which is 12 cm. Of them, it is necessary to build a grid, the value of each cell of which will be about twenty centimeters.

The preparation of the concrete screed should be treated with special caution, since the operational characteristics of the floor will depend on its quality. The advantage of equipment is precisely the screed is the ability to carry out almost any finishing work, such as the installation of ceramic tiles, parquet, laminate, linoleum, polymer floor, etc.

Due to the fact that the screed is evenly laid on the inter -story coating, it contributes to the uniform distribution of the load and an increase in the strength of the house.

Recommended concrete brand for the preparation of concrete solution - M400. The filler is sand or crushed stone of a small fraction. At the same time, the ratio of concrete with sand is one to three. Fill the screed occurs at once, it is forbidden to fill the screed in different days in one room, since it will lose strength.

Recommended time for using the solution of a maximum of two hours. At the same time, do not forget to use a concrete vibrator that will help get rid of excess air and provide strong adhesion of concrete and reinforcement.

Floor floor overlap: additional recommendations

When building the floor of the ceiling of the second floor, it is recommended to use the beams that are installed on the floor location. Then, they are solved with an electric shirt, on the side that will be the ceiling of the first floor. This process will make a wooden ceiling more attractive. Next, it is necessary to install bars that will form a black coating as a floor and a ceiling. For finishing the ceiling, a wooden lining is best suited, which will create harmony with beams. And, for the equipment of the floor, it is necessary to first lay a layer of waterproofing, thermal insulation, vapor barrier, and then proceed to the installation of the floor covering and finish.

Consider the option of finishing the floor of the second floor, the availability of work will be required:

- laminate,

- drywall,

- insulation.

The laminate coating is laid on the finished surface of a wooden or concrete floor. And drywall is attached to the ceiling area.

Before installing the laminate, it is recommended to carry out a number of preparatory work on the insulation of hydro- and sound insulation of the floor.

Tips for flooring on the second floor:

- When installing a warm water floor on the second floor, it is necessary to lay out a rolled -type insulation before installing the pipes, and fill the inter -tube areas with a thick drywall, which will increase the rigidity of the structure, then another layer of insulation is installed and laminate is mounted;

- When installing a real environmentally friendly wooden floor, you need to carefully select materials, as a black floor, purchase ordinary boards that have low humidity, for the main floor it is necessary that there are no knots, dark spots are absent, and they should be completely dry;

- When building a panel house, use the panel type that will be finished with a laminate as a floor, and you need to install a lining based on foamed polyethylene, which will create a damping effect;

- Adjustable floors will help to increase sound insulation and provide a ventilated space under the floor, as a result of this there is no appearance of condensate, fungi or mold.

twit

twit

Article misleading

The article is misleading everyone who reads it!

You can never close the floorboard of the second etegel with an additional layer of vapor barrier! And even more so waterproofing! Note the key are the prefixes "Isolation !!!"

Steam will be loved in some collisions through the first layer! And the second layer this moisture is the ban .... and it flooded with a rottenance !!!

Brave smell ... mold .... decay of the lag !!!

The floor will decay in the end!

The vapor barrier should only be on the ceiling of the first floor!

The boards of the second should be as open as possible so that moisture is blown up to the attic and from there to the street!