Polistyle foam is quite interesting material. The method of receipt was ...

|

|

Particular importance has recently been attached to an increase in the functionality of buildings with ... |

The windowsill is the same practical and integral part of the window design of the window as ... |

Parquet board - which is better. Choosing a parquet board

At first glance, the topic affecting the foundations of the correct choice of the parquet board does not deserve much attention, but if you delve into the deep and purely practical essence of the problem, you can make sure that this topic is worthy of close attention and discussion. This is largely due to the external similarity of the parquet boards of competing manufacturers, which significantly complicates the choice of a simple layman who is not familiar with hidden nuances. Moreover, in order to draw the correct conclusion about the duration of the operational period of parquet, it is necessary to have deep theoretical knowledge in the field of wood, giving exhausting answers to many similar questions. In this article, we will introduce the reader to the main aspects of the correct choice of the parquet board, as well as consider the top of the most popular parking manufacturers.

Content

- Parquet board: traditional wood or exotic rocks?

- The thickness of the parquet board and the factors affect it

- What do you need to know about the dimensions of the parquet board?

- Glane selection: its effect on the quality of the facial layer

- Parquet board: Which company is better?

Parquet board: traditional wood or exotic rocks?

The parquet board, which won the struggle for leadership among durable flooring, is today presented in a wide assortment. For its production, natural wood is used, which determines a certain set of properties of the finished material. Thanks to the use of natural raw materials and spectacular styling, a parquet board, the photo of which is presented in the article, has become one of the most desirable materials selected for floor decoration.

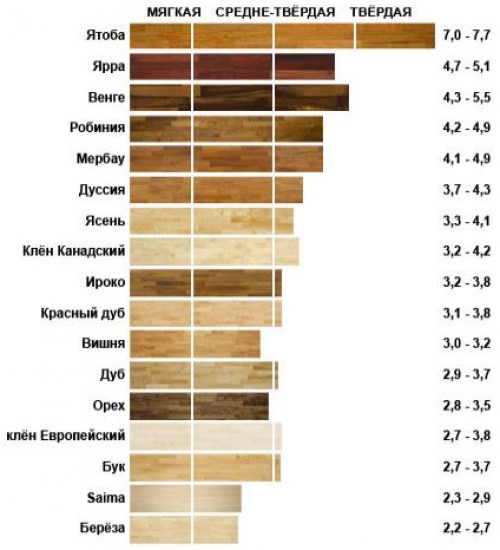

Considering the main aspects of choosing a parquet board and answering the question: which is better?, Pay attention to the wood species used for its production. Today, in the process of producing a parquet board, almost all known wood species are used, which have proven themselves in terms of wear resistance and durability.

The manufacturer is not disdained not only by traditional, but also for breeds of exotic origin, which contributes to a huge selection of finishing material in the construction market. But, despite this, oak, beech, maple, walnut, ash, cherry, mirbau and wenge are especially popular among manufacturers.

- Parquet of oak is considered a sales leader, due to the high strength, hardness and durability of the raw materials used. The parquet board, the oak for the production of which acted as the main raw material, is practically not subject to high humidity and the deformation associated with it, and also does not dry out after a long time and effectively demonstrates all the advantages of oak raw materials.

- Walnut parquet board, which has proven itself in terms of high strength, is unpretentious in care and is characterized by high operational properties. Due to the high solidness of the nut, which is much higher than the oak, allows the use of a walnut parquet in rooms with a potentially high mechanical load on the flooring, and the pronounced structure of the material allows the use of nuts for decoration of premises of various destinies.

- The parquet, for the production of which was used by Beech, in most cases acquire for children's rooms and bedrooms, due to its pleasant light cream and the ability to visually expand the space of the room. Book parquet is characterized not only by high strength, but also by resistance to increased humidity.

- A cherry parquet board and a potion board from ash are characterized by a rich variety of shades, among which the most original pink and dark coffee are recognized as the most original. The richest palette of shades and exquisite various drawings will make the parquet a harmonious addition of any room.

- A variety of Merbau wood, which is characterized by a rich brown shade, complemented by golden veins, is used to produce moisture resistant parquet, due to the large percentage of oils in the structure of wood. Wood processing, which is one of the production steps of the manufacture of parquet, resistant to moisture and damage to rodents, determines the high cost of finished finishing material.

- The wood of exotic African origin of the Wenge today is just starting to gain popularity among manufacturers of furniture and flooring, but has already managed to prove itself as a wear -resistant, not subject to increased mechanical influences, the material for the production of flooring, which is characterized by a practically black hue and an original shade with ethnic notes .

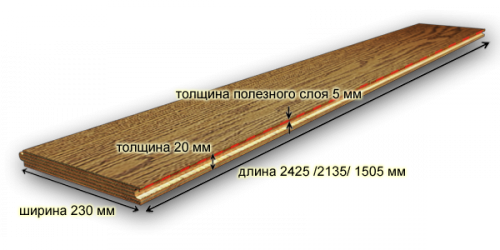

The thickness of the parquet board and the factors affect it

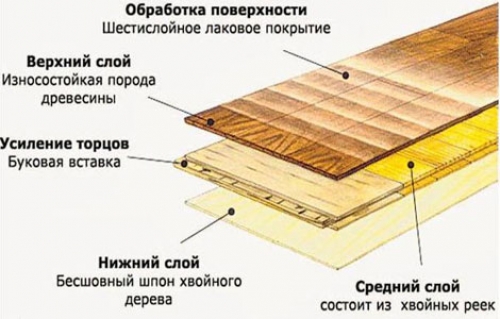

In most cases, the structure of the flooring is represented by three layers that determine the thickness of the parquet board:

- Upper one, for the manufacture of which the most valuable wood species are used, such as oak, cherry, beech or nut;

- Average, represented by the most powerful stove, for the manufacture of which the thin layers of conifers are used together;

- The lower layer represented by spruce rocks, the thickness of which does not exceed 2 mm.

A significant practical conclusion follows from this, according to which the quality of the parquet board mainly depends on the material used to produce the fundamental upper layer, as well as the thickness of the latter. We must not forget that the amount of grinding, which is capable of withstanding the parquet coating, is determined by the thickness and qualitative characteristics of the outer layer.

What do you need to know about the dimensions of the parquet board?

The quality of the parquet board and prices depend on its original dimensions, which should not exceed the maximum permissible indicators.

- Thickness no more than 20 cm;

- Length from 2 to 2.5 m;

- The thickness should also not go beyond a certain framework: 7-25 mm.

Practical conclusions

- For facing the board, the thickness of which is 7 mm, the veneer is used, in connection with which it does not lend itself to the cycle;

- Given that the board 10 mm thick is not much stronger than the previous one, it requires a very accurate relationship, since excessively sharp movements can cause scratches and scuffs;

- According to experts, the optimal thickness of the parquet board is approaching 13-15 mm, since in this case the thickness of the worker (upper) will be 4 mm;

- A massive parquet board, which is characterized by a thickness exceeding 25 mm, withstands significant loads, due to the fact that the emphasis is projected not only on the main upper, but also on the middle layer. The use of such a board is relevant not only in conditions of apartments with concrete floors, but also of old houses, where the installation of wooden floors on the lags is still practiced.

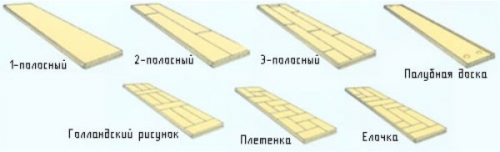

Glane selection: its effect on the quality of the facial layer

Among the parameters that most clearly affect the quality of the facial layer, the selection of planks is considered. In other words, the selection of planks is one of the ways to sort the parquet coating in accordance with the following indicators:

- Cut the wood layer;

- The presence of mechanical defects (knots, cracks);

- Color palette;

- Fiber orientation and wood pattern.

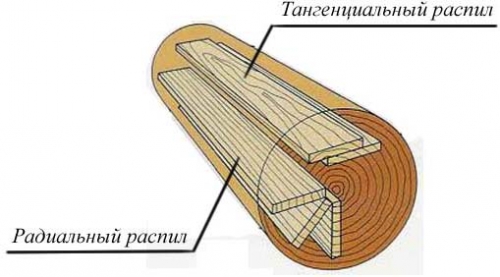

Manufacturers offer to distinguish between radial and tangential cut options:

- A radial cut method of the cut, which is parallel to the diameter of the barrel, while the wood fibers are oriented along the surface of the trash, that is, the cut line is made through the center of the barrel. In addition to excellent physical and chemical indicators, such a board is characterized by the highest level of stability, the most uniform color and the perfect pattern. The level of accelerated and swelling for a board with a radial cut is half as much as for a board with a tangential method of sawing.

- The tangential cut of the saw line passing along the tangent line relative to the tree trunk. Such a board is characterized by a pronounced, colorful pattern and a pattern of annual rings is clearly visible. In terms of technical parameters, the tangential cut is significantly inferior to radial, but in view of the low number of rejected material, the price of a board with a tangential sawing is characterized by a lower cost.

Taking into account the method of sawing, several types of selection are distinguished, the main ones are:

Natural

It implies the presence of planks, sawn both tangential and radially. Selection of the type of nature excludes the presence of large defects, except for microscopic knots. The board of this breeding type is characterized by original color transitions and a variety of drawings;

Select

The material of this breeding type is rightly called the leader in its market segment, which is due to the use of this selection uses only radially sawn strips, which are characterized by colorless color and even wood pattern, which will perfectly complement the interiors made in the classic style;

Rustik (country)

Which does not imply selection by the method of sawing, and includes boards not only of the radial, but also to the tangential method of sawing. Selection parameters for this type of selection are the color and quality of wood. Rustic selection is characterized by a lively, naturalistic pattern, as well as significant changes in shades, in connection with which it might seem to many overly colorful. A similar type of parquet allows the presence of an inclination of fibers, heart -shaped rays and larger mechanical defects.

Parquet board: Which company is better?

The main manufacturers and importers of the parquet board are the following companies:

Tarkett

The Serbian company Tarkett, according to numerous Internet users, heads the TOP-15 of the most popular flooring companies.

The Serbian manufacturer offers a rich range of colors, so he is able to please even the most demanding buyer. The Tarkett parquet board is distinguished by high technical characteristics, which contributes to its operation not only in the conditions of the apartment, but also of commercial institutions.

Kahrs

The KahRS parquet board is the main competitor of Tarkett and claims to be a well -deserved struggle in the competition of manufacturers. For a parquet board, a lot of positive reviews are characterized by a lot of serum, but products from individual collections, according to the consumer, are not stable under the influence of a slightly fluctuating humidity and moderate climatic changes. A significant drawback of the products of the Swedish manufacturer is recognized as an overstated cost.

Polarwood

Parquet Polarwood, which is the products of the popular Finnish manufacturer Karelia-Upofloor, deserves that the quality and technology of the production of the economy-segment Karelia is not different from the parquet occupying the premium segment of Karelia. A minor and only difference lies in the noticeable simplicity of colors and the presence of small mechanical defects that do not affect the quality of the flooring.

Barlinek

The Polish Parquet Board Barlinek, which has gained wide recognition among consumers, due to low prices, is suitable for lower social strata of the population that repair the economy class. Despite the democratic value, products produced taking into account European standards can safely fight for victory in the competition against such briffians of production as Tarkett and Upofloor. The only drawback of the company products from the Diana Forest collection, which is characterized by very weak locks prone to rapid breakdown.

Leroy Merlin

Leroya parquet board is made exclusively from materials of natural origin, which allows you to consider it environmentally friendly material. It is formed from three layers, which are connected under the influence of high pressure, which determines the high strength of the material. The spike-paz system used by the manufacturer promotes easy installation. The unpretentiousness of leaving and high durability, important advantages of the Leroy Merlin parquet board.

Yes, so that with parquet

Yes, so that there are no problems with the parquet, you must definitely take a parquet board, which is already covered with varnish or oil, as you like. I myself have a Barlinek company for several years, and I advise everyone who asks this company, there are no troubles with it at all, the main foundation for it is well aligned. To do this, it is best to put the plywood, and only then everything goes quickly