The wooden house is fashionable, beautiful, environmentally friendly, safe. That's why...

|

|

Among the wide variety of foundations, its monolithic options differ in a special ... |

To date, there are a large number of finishing materials for the ceiling ... |

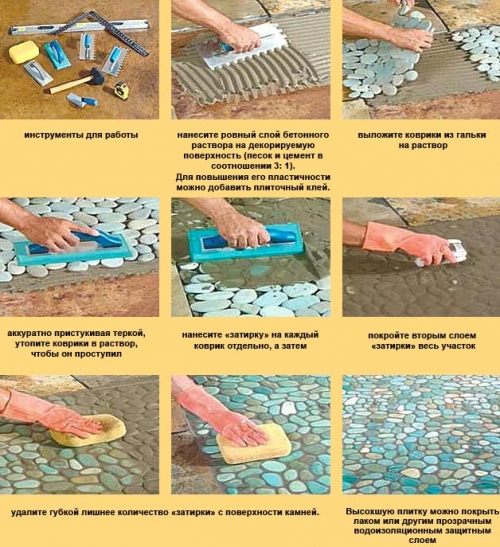

Mosaic floors: styling and process

Mosaic floors, for the manufacture of which marble baby are used, are characterized by growing popularity, and today they can be found in premium apartments, elite trade and office centers, as well as medical and educational institutions. Being a product of crushing marble, marble crumbs, is a wide range of use, however, on an industrial scale, it found its application in the manufacture of bulk concrete-brain floors that differ in high decorative and operational characteristics, which will be discussed later. Marble mosaic floors practically do not equip in residential premises, but they remain out of competition when arranging flooring in public places, on terraces and open public sites. The arrangement of any floor covering implies the need to comply with a certain, technologically significant sequence of actions, which will obtain flooring with proper operational characteristics. Due to this, work on the arrangement of mosaic concrete floor is associated with certain difficulties, the installation process deserves a more detailed consideration.

Content

- Use of marble crumbs in the manufacture of flooring

- Advantages and disadvantages of mosaic flooring

- Materials and tools for pouring the mosaic flooring

- Mosaic floors: arrangement technology

- Preparation of the base is the key to effective installation of a mosaic floor

- Separation installation: recommendations of specialists

- Preparation of a mosaic-concrete mixture: Procedure for action

- Mosaic floor filling technology: step -by -step guide

- The final stage of surface grinding

- Squirrel arrangement additional decorative effect

- How to repair mosaic floors?

Use of marble crumbs in the manufacture of flooring

Marble is a natural rock, characterized by a high density and a unique granular-critical structure. The characteristic high operational characteristics, as well as low water absorption and resistance to aggressive influence of external factors, made marble one of the most popular materials on construction sites, the popularity of which increases day by day. The aesthetic characteristics of marble, supplemented by its ability to deeply convey the unique texture of natural stone, determine its widespread use as a decorative finishing material.

The rapid development of innovative technologies and the emergence of new high -tech equipment contributed to the appearance of analog material of marble crumbs, the production of which is based on the use of for most of the non -laws of marble production, their further crushing and packaging in the faction. Due to the fact that marble baby is formed in the process of production of marble products, this methodology for the manufacture of marble material was developed for the purpose of its economical consumption. To date, marble crumbs used to install mosaic floors are one of the most common practical options for the use of marble. Thanks to the decorative characteristics of marble material, the floors, which include the specified rock, can be used for decorative design of various interior solutions.

This type of flooring consists of several layers:

- The lower or underlying layer represented by a concrete screed, which is made of cement-sand mortar and laid directly on the base of the floor (for example, a concrete base made on a compacted soil, a reinforced concrete screed, filled on a layer of insulation or reinforced concrete slabs of the ceiling). The thickness of the lower layer of mosaic floors is a variable parameter and depends on the design features of the flooring. On average, its thickness is 20-35 mm, and in the case of arranging the heat circuit of heating 40 mm or more;

- The upper or facial layer represented by a concrete-brain mixture, which consists of a cement solution with the addition of marble crumbs. Being also a variable parameter, the thickness of the mosaic-concrete mixture layer can reach from 15 to 25 mm and depends on the size of the fraction of decorative mosaic inclusions.

Important!Despite the fact that in the process of production of a mosaic floor of marble crumbs it is not used more solid blocks of marble material, this type of flooring is characterized by properties inherent in a whole rock. In this regard, having preferred mosaic tiles to the floor, you will receive a reliable flooring, the operation of which will be carried out for a long time without the need for current cosmetic repairs.

Advantages and disadvantages of mosaic flooring

Like any other material, mosaic floors made of marble crumbs are characterized by a certain set of advantages and disadvantages.

Advantages of mosaic floors of marble crumbs:

- Thanks to the exceptional strength of the floors of marble crumbs, they are equipped mainly in places characterized by a large accumulation of people and high cross -country coverage, for example, metro, shopping centers and other public institutions;

- Increased moisture resistance of mosaic concrete coating with interspersed of marble crumbs;

- The marble baby is endowed with all the characteristics of marble of the starting raw materials from which it is made, in connection with which, we can draw conclusions that it is characterized by increased wear resistance. And given the natural variety of shades of marble and their resistance to ultraviolet radiation using marble baby, you can embody your most daring design fantasies, arranging a floor covering with exquisite drawings;

- The environmental friendliness of marble and its unpretentiousness in care. It is easily cleaned using conventional detergents and, if necessary, is subject to disinfection, in connection with which, laying this flooring is welcome in children's and medical institutions;

- Mechanical friction and the fall of objects on the floor of marble crumbs is not accompanied by the appearance of a spark and cracks, which indicates the fire safety of the coating and the possibility of its arrangement in the workshops and enterprises where strict requirements for the fire safety of the flooring are imposed;

- Resistance to aggressive effects of chemicals implies the absolute indifference of the coating to organic solvents, alkaline solutions, emulsions and mineral oils;

- In the process of making mosaic floors of marble crumbs, you are practically not limited by anything and get the opportunity to create the most amazing drawings and patterns, which allows you to turn floors from marble crumbs into a real work of art.

However, the floors of marble crumbs are also characterized by certain disadvantages, which will be discussed later.

Disadvantages of mosaic floors made of marble crumbs:

- Like any other stone coating, a concrete-brain floor of marble crumbs is quite cold, and therefore, it is necessary to think over the option of its insulation in advance;

- Despite the variety of color palette and resistance to ultraviolet radiation, sooner or later yellowness may appear on the surface of the flooring of marble crumbs;

- Due to the fact that the mosaic floor of marble crumbs is characterized by a long operational period, it is necessary to carefully treat the selection during its installation, giving preference to neutral or classic drawings. This is due to the fact that over a long time of the flooring service, the drawings with which it is decorated go out of fashion, morally obsolete and becoming not relevant. And taking into account the fact that the dismantling of the old coating is a fairly laborious process, it is necessary to approach the issue of selecting a picture even more carefully;

- Installation of mosaic flooring is quite expensive, due to the higher cost of marble crumbs, slightly exceeding the price of more traditional materials. However, the cost of the mosaic floor also depends on the quantity and complexity of decorative elements.

Important! Marble baby is used not only as the main component in the process of pouring the mosaic-concrete floor, but also for the manufacture of decorative mosaic tiles on the floor, the production of which is carried out on the basis of mosaic crumbs of three classes. The color scheme of the used mosaic crumbs can be either natural and obtained by artificial processing.

Materials and tools for pouring the mosaic flooring

In the process of forming mosaic floors, marble is used not only large and medium, but also a small fraction, crushed stone, marble screening and marble flour, as well as ground marble. To give the material the necessary shade, aggregates and decorative pigments will be required. In the process, it is necessary to prepare equipment and a certain set of tools:

- Sander;

- Concrete mixer, which can be replaced by an electric drill equipped with a mixer nozzle;

- Construction vacuum cleaner;

- Electric shield;

- Level and rule;

- Polishing powder;

- Abrasive stones characterized by granularity 60-80 and 230-325;

- Container for kneading the solution;

- Rubber scrapers and soviet shovels;

- Bulgarian;

- The end diamond circle.

Mosaic floors: arrangement technology

The procedure for arranging mosaic floors using marble crumbs includes several consistent stages:

- Preparation of the base, including alignment of the rough floor with the help of a cement screed;

- Installation installation of special divisors;

- Preparation of concrete-mram mixture;

- Pour the prepared composition followed by grinding the surface.

In order to make mosaic floors as efficiently as possible, we proceed to a more detailed examination of each of the stages above.

Preparation of the base is the key to effective installation of a mosaic floor

High-quality laying of mosaic concrete coating is impossible without a thorough preparation of the base on which it will be equipped. In order for the preparation to be as effective as possible, it is necessary to first remove the old flooring, and then prepare the so -called draft floor. According to experts, the most suitable basis for mosaic flooring is a monolithic reinforced concrete slab covered with cement screed.

In stages, we will consider the process of preparing a draft base, which includes a number of consistent mandatory operations.

- First of all, preparatory measures begin by removing the old flooring, which can be represented by linoleum, laminate, parquet, as well as boards or plywood;

- If in the process of preparing the base, you found cracks, irregularities or excavations, make them aligned with putty and pour the self -leveling mixture, paying special attention to the areas where the riser pipes pass;

- Next, using a hard metal brush, clean the surface of the base, which will increase the adhesive characteristics of the coating;

- Having cleaned the surface, make it diluted, taking care of the removal of all microparticles formed in the process of cleaning the base. For these purposes, you will need a construction vacuum cleaner;

Separation installation: recommendations of specialists

- After you have completed the preparatory measures, proceed to the installation of dividing veins, the presence of which will provide high strength of the flooring. If you form a plain flooring, the installation of separators is carried out similarly to the one that is carried out during the installation of the cement screed, that is, with a step equal to 1.5 m. Provided that the floor level will not exceed 25 mm, it is recommended that the most suitable dividers are recommended Use square pipes with a diameter of 25x25 mm dimensions.

- If you plan to equip a floor covering with an ornament, it is important to know that installing dividing veins in this case will have its own characteristics. First of all, in accordance with the planned ornament and additional color inserts, mark on the basis of, after which, install your separator for each part. Separation veins, in this case, are thin plates of brass or aluminum, each of which is characterized by a certain form. In rare cases, for repeated drawings of a rectangular shape, glass partitions can be used as separators.

Preparation of a mosaic-concrete mixture: Procedure for action

Important!In the process of arranging mosaic floors of marble, it is recommended to use marble crumbs of various sizes, which will revive and detail the prepared pattern, making it more natural. To achieve the required level of detail, they use marble crumbs, the dimensions of the fraction of which reach from 5 to 10-15 mm, selecting it, in accordance with the required proportions.

Consider the procedure for preparing a working mosaic-concrete mixture.

- To lay mosaic floors, it is necessary to prepare a working mixture consisting of cement, marble crumbs, stone flour and water. To achieve the optimal consistency of the solution, before adding marble chips it is washed with running water, which will increase the degree of adhesion to other components of the solution.

- Washing marble crumbs of various fractions, it is mixed in equal proportions and added to it the cement of the M400 brand at the rate of 1 part of the cement for 2 parts of a mixture of marble crumbs of various fractions;

- If you plan to make a colored flooring, adding a dye to the mosaic mixture, the type of which depends on the original color of the marble crumb and the required saturation of the prepared pattern. In order to gain uniform saturation during the manufacture of the mosaic floor, it is necessary to pre -prepare a dry mixture of the dyes of each shade in a sufficient volume. Most often, natural pigments are used as dyes (marble flour, ocher, iron sword and ultramarin). In total, the number of dyes used should not exceed 30 % of the original from the original amount of cement.

Important!All components of the mixture are mixed in a dry form, after which the water is added in such an amount that the solution acquires uniform cashitsa consistency.

Important! Adding water must be carried out portions so as not to make a mistake with the consistency. For a more accurate calculation of the required proportion, you can use a measuring capacity. However, to facilitate the task, it is recommended to focus on the proportion of 1: 3: 0.5, where three parts of a mixture of marble crumbs of various fractions and half -part of the water account for one part of dyes and cement.

Mosaic floor filling technology: step -by -step guide

The device of floors made of marble crumbs includes the following stages:

- First of all, a solution of cement and sand is prepared, taking them in ordinary proportions. By consistency, the ideal solution should resemble a putty. The prepared solution is poured with a thin layer and aligned. Thus the lower lining is prepared;

- After a slight, primary compaction of the solution, the entire mounted area is filled with a mosaic solution, which is compacted using special ironing or vibrors. If at the end of the pouring of a mosaic solution you find excess fluid, they must be removed with a rubber spatula, and then finally leve the solution;

- After solidifying the solution, which occurs within a week, the beacons are removed. To achieve a qualitative result, for the period of flooring, it is important to maintain its constant humidity.

The final stage of surface grinding

- In order for the surface to acquire an elegant and attractive appearance, after its final drying, it is necessary to grind it. To grind the surface, use special grinding machines equipped with a movable disk on which abrasive nozzles are fixed.

Important! To facilitate and speed up the grinding procedure, moisten the surface processed with water and at the same time apply small quartz sand to it. If at this stage you find any defects, they must be filled with a solution prepared in advance, after which the final grout is made using a marble bar.

- If you make a mosaic floor with a complex pattern, it is important to make not only its grinding, but also polishing the surface, for which you can also use a grinding machine equipped with felt nozzle. For the final processing of the mosaic floor, use wiping paste, the use of which will increase the efficiency of work.

Squirrel arrangement additional decorative effect

To give the final stroke to the floor covering, designers recommend betting on the installation of skirting boards. Their manufacture can be carried out both at the stage of laying the surface, and at the end of its arrangement. As a material for the manufacture of skirting boards is a mosaic mixture similar to the one used to fill the coating. The manufacture of skirting boards is carried out using special templates that will give them the desired shape. The template can be made of wood or metal. In rare cases, a cement-sand mortar is used to install skirting boards, on which the plates-stoves made of the main flooring material are fixed.

How to repair mosaic floors?

Despite the fact that the mosaic floors are quite unpretentious in care, they can eventually lose their original attractiveness, which determines the need to repair flooring. To return the surfaces, pristine shine, it is necessary to polish it. To extend the life of the concrete surface, it is recommended to use strengthening impregnations and sealants, the application of which is carried out in accordance with the instructions. To give the flooring of greater decorativeness, it is covered with special varnish.

The technology for manufacturing a mosaic floor of marble crumbs is quite old, as a result of which they can be seen in ancient Greek temples, and in medieval castles, and in modern architectural objects. They still do not lose their relevance, remaining valuable cultural and architectural heritage.