One of the most important stages in the repair is the work to equalize the floor ...

|

|

If, recently, wet spots began to appear on the ceiling, which after a while ... |

You need to choose the color of a stretch ceiling at the finish stage of the design of the design of the room .... |

Marmoleum. Characterization and installation of the material

Rolled floor materials are one of those materials that are initially presented by high requirements, which are most responsible for linoleum and laminate. The unconditional convenience of use, a long service life and the richest assortment of models determine that the buyer prefers to vote with a ruble for his favorites. However, here the buyer is waiting for difficulties. Laminated MDF panels (laminate) or linoleum? The lack of significant differences in price only complicates the choice. But no one canceled free competition, the struggle for the buyer, relevant among the manufacturers, had a tendency to grow and reached their climax when manufacturers refused to invent the bicycle and took up the development, at first glance, new, but, as it turned out, well -forgotten old material, representing a symbiosis of linoleum and laminate. So Marmoleum appeared material from the new line of the manufacturer of Forbo, the name of which later became a household name.

Content

- Marmoleum new material from environmentally friendly raw materials

- Advantages of marmoleum, which need to pay attention to

- Disadvantages of the coating of marmoleum

- Output forms, classes and individual characteristics of marmoleum

- Marmoleum Forbo. Historical facts

- Technological features of laying marmoleum of various forms of release

- Floor care of marmoleum

Marmoleum new material from environmentally friendly raw materials

Marmoleum, can rightfully be considered a new step in interior design, but a similar statement, the essence of which is that this is Marmoleum, is a product of innovative technologies that take place in the arena of the modern market is only half the truth. Despite the fact that Marmoleum, which you can buy in any construction store, is considered new material, this statement is not justified. In fact, this is a material produced using old technologies, in the manufacturing process of which ultramodern equipment was used. As a result of the modification of the proven manufacturing and using only natural components, consumers got the opportunity to no doubt to acquire high -quality flooring, combining the advantages of linoleum and laminate.

Linoleum from natural raw materials Marmoleum attracts consumers' attention with its unique composition, in which there are no artificially synthesized components. The raw material base for the manufacture of marmoleum includes a cork tree bark, linseed oil, wood flour, chalk and resin of coniferous trees. The decorative properties of Marmoleum are not inferior to the technological unique way of staining and applying the picture not only allows the material to maintain its decorative characteristics for a long time, but also allows us to significantly diversify the color range of the material. The growing popularity of Marmoleum is also facilitated by other advantages of the material that will be considered in the article.

Advantages of marmoleum, which need to pay attention to

- Absolute environmental safety of marmoleum, due to the use of only natural components in the manufacture of only natural components;

- Non -toxic and, moreover, hypoallergenic marmoleum has bactericidal properties;

- The affordable price of Marmoleum also contributes to its popularization among a variety of segments of the population: the flooring with Marmoleum will cost 20-30% cheaper than its finish with laminate;

- The presence of insulating characteristics of marmoleum determines the absence of the need for additional heat and sound insulation;

- Resistance to external damaging factors and the hygiene of natural linoleum is another advantage of the material. According to the results of research, it turned out to be indifferent to the effects of solar radiation, moisture and mechanical deformations. The paint spilled on a coating from Marmoleum does not stick to it, and therefore, its cleaning does not require the use of specialized cleaners, it is enough to wipe the floor with a rag;

- The lack of a tendency to accumulate static electricity and absolute non -combustibility.

- Marmoleum is characterized by a variety of shades and textures, which currently includes more than 100 primary colors and a tint palette, which includes more than 2000 options;

Thus, Marmoleum, the characteristics of which are presented above, receives Honored Championship among finishing flooring. Due to its resistance to temperature and humidity changes, the effects of chemical reagents, mechanical loads, as well as the lack of need for specialized cleaning, Marmoleum in the kitchen is the optimal solution for those who are a connoisseur of premium -class finishing materials.

Disadvantages of the coating of marmoleum

Despite the abundance of advantages inherent in Marmoleum, this material is not devoid of shortcomings, which also need to be said a few words.

- The fragility, especially expressed at the edges, necessitates extremely careful handling of the material in the process of laying it, as well as compliance with certain rules, for example, twisting marmoleum into a roll can only be carried out once, and the basis of the material should be outward;

- The tendency to harden, which, on the one hand, is favorable for the floor, and on the other, can cause crack formation. In addition, since time the material is somewhat blurred over time, which is also only a relative drawback, which has its positive aspects and makes it possible not to close up the seams between the tiles that will smoothly converge over time.

- The severity of the marmoleum, associated with residual plasticity and favorable subject to flooring, eliminates the use of the material for wall decoration, which will cause a possible violation of the integrity of the material under the influence of gravity;

- And, finally, the lack of the possibility of obtaining an even cut during the cutting of the material is determined by the fact that Marmoleum is cut only along the walls, where an uneven cut can be covered with a baseboard. This somewhat limits the decorative capabilities of the material to lay out a pattern of standard tiles.

Output forms, classes and individual characteristics of marmoleum

Forms of the release of marmoleum

- The rolled marmoleum, which is characterized by standard indicators of width of 2 meters, and variable width indicators that change depending on the class of the material.

- Marmoleum tiles of standard dimensions 50x50cm and 30x30 cm;

- Standard panels 90x30cm, equipped with an improved castle system, which provides for the installation of the lock with glue;

The rolled marmoleum is a modified variety of PVC linoleum, which is based on cork crumb, which increases the heat and sound insulation properties of the material, as well as ensuring its additional flexibility. A flexible and elastic base, which ensures the suppleness of the material during the installation process, and as a result, facilitating this event, is the cause of the significant drawbacks of marmoleum detected during operation.

Here are the main ones:

- A tendency to increase the linear size of the material during operation, to prevent which the master advises linoleum to lay down and only then press with a skirting board;

- The legendary wear resistance of the marmoleum, due to its increased rigidity, can result in another disadvantage of the material with an unstable structure, which is the cause of pits from furniture. High rigidity affects the quality of the elasticity of the material, which causes a violation of its original structure;

- The cork crumb, which allows the use of the toxic substances of the laminate, also adversely affects its elasticity and slightly reduces thermal conductivity.

Despite all the existing myths about the fragility of the rolled marmoleum, we will try to dispel your fears: with careful handling of the material, in the absence of its excesses and compliance with the instructions, rolling, pruning and laying the material will not cause you unnecessary troubles.

Marmoleum photo

Classes of Marmoleum

Speaking about the classes of Marmoleum, we highlight the three main ones:

- 41-43 grade of marmoleum is characterized by the presence of the upper decorative layer exceeding 3 mm. It has the greatest resistance to mechanical influences and is mainly used to finish public premises with a continuous flow of visitors;

- 31-33 grade. Marmoleum designed for decoration of industrial premises. The thickness of the upper decorative layer is not more than 2.5 mm. It is characterized by less resistance to alternating loads than such for the previous class marmoleum, however, static loads of the prerogative of the described class;

- 21-23 grade marmoleum of general purpose. It differs from previous classes less than the thickness of the upper layer (less than 2 mm), however, for the decoration of residential premises, it is considered the most preferred option, not only in terms of lower cost, but also more wear resistance. It is important to note that this variety of marmoleum, the price of which depends on class affiliation, is most preferable for decoration of residential premises.

Thus, a logical conclusion suggests itself, the essence of which is that you should not choose the most expensive material in the pursuit of its greater wear resistance. The first class of Marmoleum, despite the large thickness of the upper layer and the highest cost, is not resistant to static loads, and therefore, under the influence of long -standing furniture on linoleum, mechanical deformations can form. This can be avoided by choosing a cheaper material designed for decoration of residential premises and has more resistance to static loads.

Marmoleum Forbo. Historical facts

As already mentioned, the American company Forbo has become a pioneer in the production of a qualitatively new variety of linoleum, called Marmoleum.

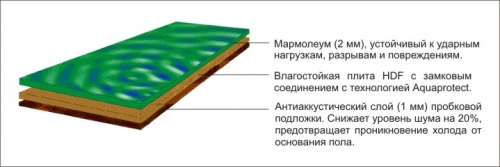

Subsequently, the word Marmoleum became household and began to be used to name similar products of other manufacturers. In accordance with the results of numerous tests, the Forbo Marmoleum is a flooring that meets international quality standards and meet the requirements for environmental safety. The most popular among consumers is the Forbo Marmoleum, characterized by the presence of a castle mechanism that is produced using Aquaprotect technology. The coating is carried out in the form of a panel or tile, the basis of which is a cork and moisture resistant NDF, covered with a protective layer.

The Forbo Marmoleum is resistant to mechanical factors, as a result of which it is not terrible for him to damage animal claws, thin female hairpins and other influences that would become fatal for other flooring. No wonder Paul Marmoleum Forbo is called the indestructible.

Technological features of laying marmoleum of various forms of release

If in the process of laying the marmoleum you decide to use the tools for the laminate, then you need to use them with great caution, since the edges of the material are characterized by fragility. Ideally, it is better to give preference to a rubber or wooden hammer and a clamp, with a clock of at least 150 mm, but in general, the set of tools remains standard.

Preparation of the basis

In most cases, there is no need to prepare the basis before laying the marmoleum, since it can be laid on the previous coating using any mounting glue, however, if the previous coating has been severely wear, it is better to lay the marmoleum directly on the concrete base, without caring about the need for additional thermal insulation, Since Marmoleum is a high -quality heat insulator. In the case of the installation of Marmoleum on the previous coating, the tile laids the tank using glue, while the panel, in view of their fragility, it is better to mount on the concrete base.

The concrete base and cement-sand screed are necessary in additional alignment. It is necessary to get rid of acute protrusions that can reach 1.5-2 mm and are removed using a drill or grinder. Having aligned, dust is swept off the floor, the remains are collected by a vacuum cleaner, and the floor is sprayed with water.

Cutting the material

The cutting of the material must be started by determining the number of whole tiles or panels, after which the number of rows that will lie along the length of the room is determined. In the process of measurements, it is necessary to take into account the clearance of at least 15-30 mm around the perimeter, which is closed using skirting boards. It must be taken into account so that in the process of deformation the coating does not rise after time.

Laying tile marmoleum

The tile marmoleum, equipped with a castle system, is often laid on a plastic base, which is overlapping. It is used to prevent condensate formation. In the process of Marmoleum, a click does not require the use of glue, as a result of which laying is carried out by a floating way. In the process of installation measures, the tiles are connected according to the groove-glue system. The first tile must be laid by retreating 1 cm from the wall, while the groove is directed towards the opposite the wall, and the crest to the wall. Each subsequent tile of the first row is inserted into the groove of the previous tile under a small inclination.

The laying of the second row is also carried out under an inclination with the mandatory formation of a compensation seam, for which it is necessary to put the bar under the tile. Having installed the remaining tiles, the bar is removed, and the locks are clung. Having completed work on the last row, you must make sure the rows are parallelized and check the distance from the wall to the tiles. Monting the final row, part of the groove is removed, a small amount of glue is applied to the tile and beaten with a beam. The gap formed between the wall and the tile is closed with the help of a baseboard.

Rolonnaya marmoleum. Features of the flooring

The flooring of the roller marmoleum is carried out mainly in large, commercial premises. The technological features of the flooring in this case do not differ at all the flooring of commercial and semi -commercial varieties of linoleum. However, there are some nuances that must be observed:

- the base should be absolutely clean, without traces of paint or oil substances;

- mandatory use of specialized glue.

Laying panel marmoleum

The panel marmoleum gained the recognition of consumers due to the simplicity of installation measures. Installation of the fast floor, as consumers called it, is carried out several times faster than the installation of a traditional tile floor.

In the process of installing panel marmoleum, it is important to observe safety rules and handle the panels carefully, since the material is prone to the formation of cracks and deformations. In order to correctly carry out the installation of panels, it is necessary to closely study the structure of the material, since the spikes located on the sides of the panels can be easily damaged with inexperienced circulation.

Floor care of marmoleum

During the care of the coating, it is not recommended to carry out machine cleaning, and in the process of manually use abrasive sponges. From the point of view of the greatest efficiency, dry cleaning has established itself, and in the case of difficult to displayed spots, wet cleaning using neutral cleaning agents. Currently, specialized cleaning agents are invented to maintain a presentable type of solid sex.