Yacht varnish has long been successfully used to process wooden surfaces ...

|

|

The use of liquid foam as a heater is distinguished by a mass of advantages ... |

The first task that arises from the owner after buying a site for construction ... |

How to determine the floor level

One of the most important stages in the repair is the work to equalize the floor. To do this, you should determine the floor level, the presence of irregularities on its surface and select a method to eliminate these defects. We will talk about the features of determining the floor level further.

Table of contents:

- How to check the floor level: tools and materials

- How to measure the floor level using a rack bubble level

- How to determine the floor level using a hydraulicarian and laser tools

- How to set the floor level by the rotational level

- How to measure the floor level using optical equipment

- Instructions on how to repulse the floor level of the rack bubble level

- How to raise the floor level using laser equipment

- How to set the floor level and level the floor, if there are differences on it

How to check the floor level: tools and materials

There are various tools with which the floor level in the room is determined. Among them, various laces, plumb line, various levels and their substitutes are distinguished. But it is best to use specialized equipment that has high accuracy in calculations.

Quite common devices are the mechanisms of companies such as Bosh, Skil and others. If you decide to buy such a device, then you should familiarize yourself with certain characteristics that will help its further operation:

1. The device should have a simple design. This facilitates its preliminary configuration and adjustment, in addition, simpler devices are easier to fix, in case of their breakdown. The best option is a laser line -like level.

2. The cost of the device is directly determined by the degree of its use and functional purpose. If you need an instrument only to carry out repairs in the house, then it is better to give preference to inexpensive models. Otherwise, it is better to choose better equipment options that will last you for a long time.

3. The presence of a functioning function allows you to independently configure and regulate the necessary positions in both vertical and horizontal position.

4. The possibility of installation on the wall is necessary if the measurement is carried out not only on the floor, but also on the walls or on the ceiling.

5. The type of energy content is also quite important and is reflected in the total cost of the device. There are levels that work on batteries or directly from electricity. The second option is less convenient, since while working on the street or in a house without electricity, you will need to use an additional battery.

With a small area of \u200b\u200bthe room, you can do without purchased tools and use improvised means. The presence of small errors on the floor is allowed if carpet or linoleum coating is installed on the floor. If the finish coating is presented in the form of parquet or tiles, but the base should be perfectly even. In this case, it is better to use modern levels of laser type than improvised threads.

How to measure the floor level using a rack bubble level

To determine the irregularities on the floor, you can use the usual level, which quite often allows you to check various sections of the building for evenness. The cost of this device is quite affordable, this explains its high popularity. The standard bubble -level length is one meter, but there are devices and more than two or three meters. Some tools are also characterized by the presence of a digital display, the accuracy of which is much higher than that of simpler models.

To measure the flatness of the floor, the line with a level is applied to it close around the entire perimeter of the room. It is possible to beat off the height of the floor under the screed. In this case, the level should be applied to the wall and with the help of a pencil you need to draw the height of the future floor around the perimeter.

In order to determine the evenness of the floor, while applying the level, you should look at the bubble, it must be located strictly in the center. Among the advantages of using this tool in the work, we note:

- affordable cost of the tool;

- simplicity of its use;

- convenience in work;

- Autonomy and independence from power supply.

However, this tool has the following shortcomings:

- With its help, you cannot measure large areas of the room;

- indicators differ in the average level of accuracy;

- It will take quite a lot of time to perform work.

If there is a slope on the floor, it is recommended to set the level on the bars and determine its location.

How to determine the floor level using a hydraulicarian and laser tools

The bubble level is able to determine the floor level only in a small room, for larger rooms, the presence of a hydraulicarian will be required. This mechanism consists of collecting vessels, tubular shape. Inside the level is the water of a tinted color. It is with its help that the floor level is determined.

After setting the level on the floor, the liquid on one and the other should be located symmetrically. Otherwise, there are irregularities on the floor.

If you do not have a water level, then making it yourself will not be difficult. The glass flask has certain marks, which determine the deviation from the norm.

The use of the laser level is distinguished by a high level of accuracy. Using this tool, it is possible to measure the distance between the floor and the necessary landmark. Upon receipt of the same data, the floor is distinguished by absolute evenness. Among the advantages of using laser equipment, we note:

- compact dimensions;

- ease of use;

- High level of accuracy in the readings.

However, laser mechanisms are characterized by a low working range. However, modern devices provide high performance of this equipment. It is enough to simply install the mechanism in the right position, according to the instructions from the manufacturer. The device will perform further actions independently.

The principle of operation of this tool is based on diodes, with the help of which a powerful light flow is formed. It is in the ratio with its display on the walls that high -precision measurements appear. Some laser mechanisms are distinguished by the presence of built -in dampers, in this case, in the process of random troaking the device, it is self -leveling and continues to work.

Any laser level is able to rotate around its axis, without stopping the tripod. On measuring devices of this level there are special rubber linings that protect them from dirt and dust.

To beat off the floor line, it is enough to note a new floor level using points, and then connect them to each other. The work is quite fast and simple.

How to set the floor level by the rotational level

Using the rotation device, it is possible not only to measure the curvature of the floor, but also to exhibit and design the results. This equipment is most often used by professionals, due to its high cost. In the process of rotation, it is transformed into a line, a horizontal or vertical nature. Further work is carried out using a rail.

Rotation levels have a rather complex mechanism of work in which there are LED bulbs. In this case, it is possible to simultaneously carry out several projections in one plane. There are several varieties of rotational instruments for measuring the floor level:

- hand tool;

- pendulum parts;

- electronic equipment.

Using the last option, it is possible to simultaneously measure more than five planes. Electronic mechanisms are very sensitive even to the smallest errors, since they have several sensors. In addition, some devices are combined, for example, a pendulum and electronic mechanism.

The rotational leveling level has a small range of actions, but it has the highest accuracy, of all the above devices.

How to measure the floor level using optical equipment

Optical leveling devices are more common for measuring territorial sections outside the room. However, their use in the process of determining the curvature of the floor is quite real.

The principle of operation of this equipment is quite similar to the rotation device. However, using it in a room with a large area, the accuracy of the results will be higher than that of the rotational.

The disadvantage of using this device is the fact that at least two people will require its operation. The cost of this equipment is also very high, cheaper models will cost at least two hundred dollars, and professional installations will cost more than a thousand dollars.

Instructions on how to repulse the floor level of the rack bubble level

1. Prepare the room for work. For this, all furniture and items located on the floor should be taken out of it. It is preferable if the floor is absolutely empty. Only in this case, it will be possible to get high -precision results.

2. A basic line should be carried out along the entire perimeter of the room, on which the floor screed will be located. This line should be identical and parallel to the floor.

3. In order to draw such a line, use a laser level, if any.

4. Next, on each of the wall sections, the distance from the floor to the line should be measured. It should be the same everywhere. If the distance is different, then you should determine the highest point between the floor and the line.

5. From this site, a line is held, one meter above it. The value of the screed should be taken from this point and draw a new line. Thus, with the help of a bubble level, the floor level is beaten off.

In the presence of another device, with its help, the curvature of the floor is also measured and the highest point is determined. Based on it, work is already carried out on the calculation and determination of the height of the screed.

How to raise the floor level using laser equipment

To ensure accuracy in measurement from the floor and from the walls, all unnecessary objects are removed. The room should be absolutely empty. Set the laser level on the floor. Give preference the highest point if you find it.

Direct the beam to the wall. After installing the laser level, mark the floor of raising the floor with a pencil. Next, draw a line.

After detecting the highest section on the floor, a small part of the painting cord should be pulled on it. The second part of the cord is pulled on the opposite wall. In the absence of tubercles in the process of pulling the cord, this point is removed. Otherwise, in order to remove irregularities, use a hammer or some kind of tool that will help to make it a racing.

After determining the highest section on the floor, you should rise from this point by another 5 cm and draw a line around the perimeter of the entire room. This marking will serve as a place for the construction of the screed and alignment of the floor.

Tip: Keep in mind that while working with laser equipment, you should use points, since otherwise, there is a risk of detrimental harm from lasers for vision.

How to set the floor level and level the floor, if there are differences on it

There are many ways to align the floor, among which we note:

- Self -enveloping mixtures that can fill in the boards in height of two or three millimeters;

- the use of screed, which is relevant in the presence of large changes;

- adjustable floor on the lags, in this case, the installation of each of the lag is carried out in relation to the difference on the floor;

- Dry team screed, which is also capable of aligning the floor level;

- Plywood plywood on the floor.

The choice of one or another option depends on the individual characteristics of the premises, the material condition of its owners, the further decoration of the floor and the degree of its curvature.

In the presence of an almost even surface on the floor, extruded polystyrene foam or dry screed should be used for additional leveling. The work is carried out quite quickly, during their execution in the room there is no dirt, dust and moisture.

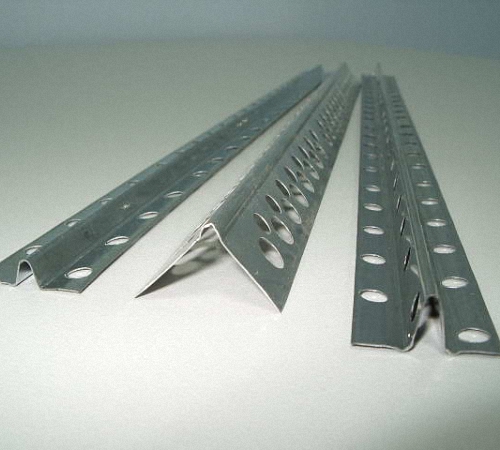

However, leveling should be carried out with particular care. For these purposes, it is advisable to use special P-shaped elements. Next follows the process of backfilling with a dry mixture. Alignment is carried out in relation to previously installed beacons. In this case, the floor is located at the same level and is evened.

If there are small changes in height on the floor, then to align it, it is enough to make a screed of 0.5 cm. A concrete solution or special self -leveling mixtures is based on the screed. They help equip a perfectly even coating for laying tiles or laminate.

A cement-sand screed helps to get rid of very large differences in the height of the floor. The process of laying it is quite long and painstaking. In addition, it will take an additional time to dry out the screed and give it strength.

The use of lag will help get rid of large solutions to buy and prepare a concrete solution for screed. With their help, it is possible to level the base much faster.