The use of reinforcement in the process of knitting the foundation can significantly improve it ...

|

|

An excellent type of street flooring is a terrace board. She differs ... |

To ensure high -quality operation of the fireplace, you should correctly install a chimney in it ... |

Combining the joints of linoleum with your own hands. Instructions for the use of glue for linoleum

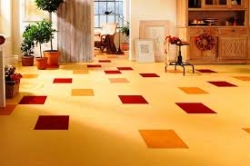

Linoleum is one of the most popular finishing materials. The scope of its application is not limited to residential premises, apartments, houses, cottages. Linoleum is distinguished by good performance, therefore, it is widely used for floor decoration in public institutions with high operational burden. There are several ways to hide joints between linoleum canvases. We will talk about how to create a beautiful, imperceptible hermetic seam with our own hands.

Table of contents:

- DIY linoleum accessories options

- DIY cold welding technology

- How to solder linoleum at home: hot welding technology of linoleum

- Connection of the joints of linoleum video

DIY linoleum accessories options

Several methods of connecting linoleum are distinguished. The choice of one or another is based on the individual characteristics of the room, the type of linoleum coating and the styling method.

We will get acquainted with the methods of connecting linoleum more:

1. Bilateral tape. Prepare the surface for work, clean from dirt and dust. If necessary, grind. Check the connection of the joints, it should be as accurate as possible. If necessary, adjust them with a clerical knife or scissors. Stick the tape to the floor, gradually remove the protective film and glue the linoleum. This method is quite light and low -cost, however, during operation, there is a likelihood of discrepancy between joints. In addition, this method is unreliable, when washing the floor with water and moisture getting between the joints, they diverge over time.

2. Thresholds. This method is relevant when moving from one room to another. It is based on the use of a special threshold, which hides the junction between the two sheets of linoleum. To fix the threshold, special screws or corks made of plastic are used. In this case, it is possible to obtain a reliable connection at an affordable cost. Among the shortcomings, we note:

- difficulties in selecting the color of the rock;

- The protrusions of the threshold above the floor.

When combining linoleum based on felt, only this method is used, since the thresholds securely fix the coating, unlike glue or tape. The use of glue is a more costly process, in addition, it often contains toxic substances that are released during operation. Thresholds, compared with the adhesive method, are safer and do not require periodic ventilation of the room when connecting the joints of linoleum.

3. The method of hot welding. This method is highly laborious, requires the use of special tools and skills in working with them. However, as a result, a holistic seamless coating is obtained, which manifests itself perfectly during operation.

In the process of connecting linoleum, the presence of hot welding will require:

- high -power hairdryer;

- special tourniquet on PVC base;

- knife and nozzles.

Linoleum is installed with a slight overlap, then a recess in the form of a groove is cut along the length of the joint. Using a building hairdryer, the surface is heated to a temperature of 450 degrees, and then a tourniquet is installed in the groove with a special nozzle and is heated until a perfectly even joint is obtained. After the seam has cooled, cut it with a knife.

As a result, it is possible to get a seam that is practically not different from the linoleum itself, the connection is sealed and reliable. Among the shortcomings, we note:

- cost of work;

- a long process and the need to ventilate the room;

- The use of this method to combine the domestic variant of linoleum is excluded, since under the influence of high temperature it melts.

4. Cold welding method. One of the simplest and most reliable options for combining linoleum joints. To execute, the presence of:

- painting tape;

- a knife with a measuring Linek;

- adhesive composition for welding.

Linoleum sheets are fitting until a perfectly flat seam is obtained. The edges are aligned and cut, if necessary. The edge of linoleum is glued with adhesive tape. The coating is cut and filled with a special composition in the form of cold welding. After the welding is completely dry, the painting tape is removed.

Keep in mind that the hit of cold welding on linoleum leads to its destruction and the appearance of traces, which cannot be removed. Therefore, when working with this material, it is necessary to show special accuracy. If cold welding all the same fell on linoleum, wait for complete drying, and then remove the knife from the surface.

Among the advantages of this method we note:

- ease of independent use;

- lack of necessity in the call of the home -made master;

- The possibility of repairing linoleum coatings.

If you want to get a reliable and sealed connection of linoleum joints, we recommend that you still dwell on the last two versions - cold or hot welding.

DIY cold welding technology

One of the most common methods of gluing linoleum is the cold welding method. It is based on the use of a special adhesive composition that forms a colorless coating that perfectly seals the connection. Among the advantages of using cold welding to connect the joints of linoleum with our own hands, we note:

- obtaining a monolithic, neat and reliable connection, which is outwardly invisible, is felt only with tactile contact;

- The availability of special equipment does not require, a sufficiently standard set of tools for work, so the costs of laying linoleum coating are reduced.

There are three options for adhesive composition for cold welding of linoleum:

- adhesive composition A type;

- adhesive composition from the species;

- The adhesive composition of the type.

We offer to familiarize yourself with each view separately. When choosing a particular glue, take into account the features of linoleum coating, the accuracy of the compounds.

The adhesive composition for cold welding of the type A is liquid in consistency, as it contains a large amount of substances based on the solvent. Thanks to this structure, the edges are effectively relaxed for connection. However, it will not be possible to combine joints with large compounds, since the adhesive composition has a too liquid consistency.

Therefore, the adhesive composition A is used to connect the joints with minimal discrepancies. The adhesive composition is an ideal solution for only acquired linoleum, which was cut in the factory.

The adhesive composition of the species C is characterized by the presence in the composition of a large amount of substances based on PVC. The adhesive composition is characterized by a dense and saturated consistency, so it easily fills the wide gaps between the sheets. An excellent solution for repairing linoleum coating, which was operated earlier. The adhesive composition does not require sheets ideal for fitting, easily fills large cracks. After drying, a neat, almost invisible connection is formed.

The adhesive composition of the type for linoleum is used very rarely and only by professionals, it allows you to combine sheets of multicomponent linoleum options.

Instructions for connecting the joints of linoleum with cold welding:

- High -quality welding of the joints of linoleum allows you to get the ideal seam in density, which is not subjected to mechanical influences, as well as moisture and chemicals for gap washing.

- In place, the joints of the two paintings are installed by a bilateral sticky tape, so cold welding does not fall into linoleum.

- The adhesive strip is allowed strictly along the seam, while trying not to hurt the coating itself.

- A special needle is put on the adhesive composition of a shaped nozzle, which makes the seam less noticeable.

- Install the needle into the section, fill the cracks with glue. When glue appears on adhesive tape, move on in the direction. Fill in this way the entire seam.

- The drying time of cold welding is indicated in the instructions from the manufacturer and is usually about fifteen minutes.

- After that, remove the sticky tape from linoleum and check the condition and smoothness of the connection.

For the fastest and maximum gluing, read the recommendations for linoleum soldering with cold welding:

- When buying linoleum, take into account the fact that it is necessary to connect sheets with an overlap of at least 5 cm, so it will be possible to achieve the maximum even as possible between the canvases;

- For work, use rubber gloves, cold welding with skin is undesirable;

- Be sure to use the needle nozzle for glue, with its help, the joints between the canvases will be filled as quickly and accurately as possible;

- Upon contact with glue with linoleum coating, wait for its complete drying, and then remove it with a clerical knife.

How to solder linoleum at home: hot welding technology of linoleum

To perform hot welding, the availability of equipment for welding linoleum is necessary. A special hairdryer with a nozzle, warms up the canvas to the required temperature. Previously, linoleum is glued to the base.

The hot welding method for natural linoleum is especially often used. Additionally, you need to purchase a tourniquet to connect the joints of linoleum. The joints between the canvases are sealed in the process of solidifying polymer substances, which are previously warmed up with a hairdryer.

The connection of linoleum at home by hot welding is quite difficult to produce, especially without experience with these equipment. Therefore, we recommend entering this process to specialists in order to avoid damage to the paintings.

If you still decide to do it yourself, follow the instructions below:

- Prepare all the tools necessary for work in the form:

- special knife;

- construction hairdryer;

- Burn.

Treat the end areas on linoleum with a knife. The result is a groove -like surface, which reaches the main part of linoleum.

- Remove garbage and dust from the floor on which the coating is located. Turn on the hair dryer, and warm the linoleum to 350-380 degrees. Install a special nozzle in which a tourniquet will be installed.

- After installing the tourniquet, heat the linoleum with a hairdryer, gradually reaching the joint line. The tourniquet must melt gradually and evenly.

- After the welding is completed, remove unnecessary sections of the tourniquet, use a sickle knife or special equipment for these purposes.

- Follow the accuracy of the received connections, the knife is set in parallel to the floor, in order to avoid damage.

- Welding welding with hot welding is divided into two stages. Work should start from the opposite sides, and completes the overflow of paintings at the site.

Do not forget, except for a hair drying hair dryer, prepare a special nozzle that improves the quality of the work performed and warms up only the necessary areas.

Choose a high-quality hairdryer, the maximum heating temperature of which is 500-600 degrees. To maintain a constant temperature on the device, there are special sensors. In addition, pay attention to the number of operating modes.

If the volume of work is large, then the welding will be long, the hair dryer, in this case, must have sufficient power to perform this process, in order to avoid its overheating.

Before starting work, the chamfer is removed from the coating strips, thus, a wedge -shaped deepening is obtained. It is in it that the tourniquet will be in the future, which, when heated, will turn into a polymer liquid substance. A special nozzle for a hairdryer warms up this particular site. The groove on the snot should tightly press against the seam, for the maximum uniform heating. Keep in mind that the polymer substance should evenly fill out the ditch without playing the surface of the floor. Only in this case, it is possible to achieve aesthetically attractive docking. When we hide the joints of linoleum with a hot method, you should be especially careful when working with a hairdryer. Since excessive heating of the polymer substance leads to the appearance of sloppy butt joints.

full brake

full brake