Enough part in the process of flooring, such a material as chipboard is used. Among...

|

|

Today, the construction of wooden houses, and especially houses from the galled ... |

The garage is the coveted word for any motorist. I want ... |

How to knit reinforcement for the foundation

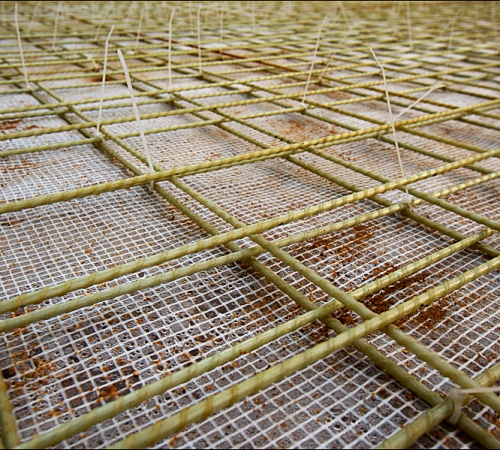

The use of reinforcement in the process of knitting the foundation can significantly improve its power and strength characteristics. There are several ways to knit reinforcement, about how to knit reinforcement for the foundation, we will consider further about their features.

Table of contents:

- Reinforcement for the foundation at home: Features of choice and calculation

- Reinforcement for the foundation: the main species and their features

- Foundation reinforcement scheme: strengthening the strip foundation

- How to knit reinforcement on the foundation manually

- How to knit reinforcement on the foundation: Methods and technology

Reinforcement for the foundation at home: Features of choice and calculation

Before proceeding with the direct knitting of the reinforcement for the foundation, you should first select the materials to perform this process. It is on the diameter of the reinforcement for the foundation that its strength and the rigidity of the frame directly depends.

Before buying reinforcement, it should be determined by its relative strength. The ratio between the area of \u200b\u200bthe frame and the foundation of 100% by 0.1%, that is, the reinforcement is 0.001 part of the foundation.

Reinforcement for the foundation calculation:

1. For example, it is planned to reinforce the foundation, the width of which is 25 cm, and a height of 80 cm. In order to calculate the area of \u200b\u200bthe reinforced area, 25 cm x 80 cm \u003d 2000 centimeters of square.

2. The resulting number should be multiplied by 0.001 and the minimum diameter of the cross section of the reinforcement in the foundation is 2000 x 0.001 \u003d 2 cm.

3. For one bunch, 30 cm of reinforcement must be used. Each connection consists of four ligaments. Therefore, to determine the number of reinforcement, you should calculate the number of ligaments and multiply this value by 30 cm.

The use of knitting in the process of manufacturing a reinforced frame for the foundation is explained primarily by the fact that such a connection is more reliable than welding. The seams that are formed during the welding of the reinforcement are inclined to gradually collapse, which means such a foundation is unreliable, and after several decades will become unusable.

The technological process of performing reinforcement knitting is based on the connection of the valves of the reinforcement in such a way that they are crossing each other, tighten and twisted using pliers.

The option of using a special pistol is possible, which greatly simplifies the process of mating. Choosing the diameter of reinforcing bars should proceed from these parameters:

- the number of floors in the building;

- massiveness of the structure;

- The type of foundation: finely or deeply buried;

- The quality of concrete, etc.

For the manufacture of reinforcement at the factory, special equipment is used, thanks to which the final product is characterized by high quality and a long service life.

In the ratio with structural features, the surface of the reinforcement can be of two types:

- corrugated;

- smooth.

For the manufacture of perforated reinforcing bars, a special form is used, due to which a corrugated cross section is formed on their surface in the form of two ribs, these rods are distinguished by the presence of a round section. Such reinforcement is more durable and stable before mechanical damage. In addition, the reinforcement with a corrugated surface is characterized by higher adhesion to concrete, in the process of reinforcing the foundation. For the manufacture of such rods, various kinds of steel are used, the most popular options of which are 35 GS and 25 GS. In the ratio with the class of the reinforcement, the strength characteristics of the material change.

In the ratio with the thickness of the reinforcement, it is also divided into classes, but the diameter of this material is on average from 8-25 mm. The maximum length of one rod is 120 cm.

In the process of choosing reinforcement for the construction of the foundation, you should give preference to materials that differ:

- the presence of resistance before corrosion;

- excellent adhesion characteristics;

- the presence of plasticity;

- high level of strength fatigue.

The reinforcement for the strip foundation is selected from class A 2. There are several options for marking this reinforcement:

- A 300;

- A 400;

- A 800;

- And 1000.

The surface of these rods has the form of a braid, corrugated. These features can improve its adhesion with concrete. In order to ensure vertical holding of reinforcement, it is recommended to use hot -kettle fittings. It differs in the presence of a smooth surface.

The optimal diameter of reinforcing bars for standard single and two-story buildings is about 1-1.5 cm. Auxiliary reinforcement should be a minimum of 0.5-1 cm.

Please note that as the main part of the frame, exclusively corrugated reinforcement is used, and the auxiliary should be made of smooth reinforcement.

Reinforcement for the foundation: the main species and their features

Composite reinforcement for the foundation is a non -metallic material used in the process of reinforcing the foundation. Among the shortcomings of this material are noted:

- The reduced qualities of elasticity, compared with steel, are four times, so this reinforcement is more resistant to bending, which means that it has a lesser possibility of gap;

- The temperature range of use is not more than 500 degrees, if the heating temperature is higher, then the reinforcement loses technical characteristics;

- It cannot be welded, although some manufacturers at the ends of the reinforcement are mounted by steel tips that allow it to be welded to each other.

Despite this, composite reinforcement has a large number of advantages, among which it should be highlighted:

- high strength to break;

- lightness than steel by 8 times;

- The cheapness of the material is another advantage, since the cost of composite reinforcement is much lower than metal;

- The convenience and ease of transportation, this reinforcement is quite easy, so there are no problems in the issue of its delivery to the construction object;

- Since metal is not used in the process of manufacturing composite reinforcement, it differs in resistance before corrosion;

- In addition, the fittings based on composites are not capable of conducting electricity, and is characterized by low thermal conductivity;

- differs in a long service life;

- Light on installation.

Plastic reinforcement for the foundation is a good option for arranging the foundation, for a small building. In addition, the use of this type of reinforcement will significantly save both monetary and temporary resources.

Composite reinforcement, in turn, is divided into two categories:

- fiberglass reinforcement for the foundation;

- Reinforcement based on basaltoplasty.

Foundation reinforcement scheme: strengthening the strip foundation

Before starting work, you should decide on the type of reinforcement used to knit the frame. In addition, under the strip foundation there should be already dug and prepared pit. The formwork is also mounted before the start of knitting.

After preparatory work, the process of installing vertical rods, which differ in a smooth surface, follows. The diameter of such rods is about one centimeter. The interval between them is 50-80 cm. Two belts located horizontally are knitted on these rods. They create the main part of the frame and are the main reinforcing element.

The main purpose of this design is to retain the overall load from the building, the prevention of cracking or deformation of concrete. During the installation of the strip foundation, it is necessary to equip exactly two horizontal belts, however, depending on the load from the building, their size and thickness of each are individually selected. If the maximum width of the foundation is 40 cm, then it is better to perform double reinforcement, that is, to use two rods in the lower part to form a belt and two in the upper.

With a larger width of the foundation, it is necessary to use three rods, one of which is located between the other two. The use of four rods is a fairly unexplored option, since it is enough to choose a reinforcement with a large diameter to form a more rigid and stronger frame than increase the number of rods.

The determination of the height of vertical rods should be carried out based on the direct height of the foundation itself. The connection of vertical rods with horizontal is made in such a way that vertical rods do not protrude more than 10 cm. Pay special attention to the corner areas. Since they are most susceptible to stress and compression. If the corner areas are incorrectly reinforced, then the system will lose strength.

Therefore, rods, they never lay to each other at an angle of 90 degrees. They bend and combine into cross tapes. Each of the rods is overlapped 25 cm. Thus, the frame will have high strength and will not bend under the weight of concrete.

For additional strengthening of corners, a reinforcing mesh is used, the cross -section of the cells of which is 200x200 mm. Their installation is carried out from above and at the bottom of the foundation, and the connection with vertical sections is performed every 50 cm.

Installation of a reinforcing frame should be carried out on a previously prepared concrete pillow, that is, the bottom of the pit is poured with concrete by 6-8 cm. The pillow helps to prevent the contact of the reinforcement with the ground, which means that the metal will not be corroded.

How to knit reinforcement on the foundation manually

In the process of knitting reinforcement, a special tool is often used, however, in its absence, this process can be carried out manually. To perform independent knitting reinforcement, the presence of a wire, in a diameter of about one millimeter, pliers or a special hook, will be required. It is the last device that will help to tighten the wire around the reinforcement itself.

It is possible to replace the wire with plastic clamps, however, in this case, it is forbidden to walk on the surface of the reinforced frame, when pouring it.

Instructions for knitting reinforcement using a metal wire:

1. Cut the wire, 30 cm in size. Fold it half.

2. Wrap the rod with wire with diagonally, put it on the hook.

3. Set the free end of the wire in the hook.

4. First, turn it clockwise until the connection is securely fixed. No need to squeeze the wire so that it does not break by accident.

If it is planned to assemble a frame of reinforcement for a columnar type of foundation, then the option of using an exceptionally smooth type of reinforcement is possible. Keep in mind that knitting such reinforcement is much more difficult, since the wire constantly slides. For these purposes, special equipment is used - a knitting gun.

For the knitting of the reinforcement in the slab foundation, the presence of a strength frame is required. For these purposes, it is necessary to use steel reinforcement, the diameter of which is 1.6 cm. It is it that will allow tiles to reinforce both in the upper and lower parts.

On the bottom of the plate, it is also recommended to use plastic compensators, it will help to evenly distribute the entire load. Keep in mind that rods should protrude from the frame in the form of allowances that connect the wall and plate among themselves.

How to knit reinforcement on the foundation: Methods and technology

To make a hook with which the reinforcement is knitted, it is enough to use the usual unnecessary electrode from welding or a nail. Any of these materials must be bent in a hook -shaped shape. More reliable - a nail, it will need to use a screwdriver for its bending.

For knitting the reinforcement, you need to place the wire in two rows in the perpendicular position. Close it with a special device and start crochet or knitting mechanism in the form of a pistol.

There are two options for knitting pistol:

- electric;

- Battery.

The principle of their work is to uniform wiring around the reinforcement. However, the cost of this gun is too large, so they are not used for one -time use.

The use of knitting, and not welding of the reinforcement is primarily associated with the fact that when cooking, the quality of steel occurs and it becomes more fragile. The strength characteristics of the structure worsen. To fulfill the knitting of the reinforcement, the availability of:

- wires - this element is the most important in this process, since the connection strength directly depends on the quality of the wire, it is recommended to use a burned wire with a round section and a diameter of about 1 mm for knitting;

- In addition, it will require the presence of a hook and plastic latches, keep in mind that if plastic clamps are used, then such a foundation is not allowed to leave for the winter, since plastic, under the influence of frost, is cracked;

- Plastic beavers must be laid between the surface of the formwork and reinforcement, the main function of this element is to create a protective layer that will not allow the metal to contact the soil.

If it is planned to knit reinforcement on a horizontal surface, on which inaccessible places are practically absent, then it is best to use a gun. Its main advantage is the speed of work. In addition, the option of using a store hook is possible, however, it is inclined to rust or break over time.

A very important factor that determines the quality of knitting reinforcement is the same screed on each of the areas of the frame. Thus, the design will be more stable and is not deformed under the influence of concrete, and then the load from the building.

Reinforcement for the foundation video:

For reinforcing the foundation

To reinforce the foundation during the construction of a country house, the builders advised buying reinforcement at Steel-Pro http://www.steel-pro.ru/armatura/ they have sales at the best price, with delivery. The order is placed quickly, the managers shows that competent .. I recommend