Preparation of the surface, one of the main stages before laying the coating. ...

|

|

Any private plot of land needs to be surrounded by a fence. Sometimes he performs ... |

Today photo printing on suspended ceilings More and more is gaining ... |

Laying a square laminate

Despite the fact that the laminated coating is popular, proven for a single decade, a square laminate is a relatively new flooring. The need for the production of a square laminate is understandable and dictated by the fact that the standard laminate represented by longitudinal plates does not always harmonize with the holistic interior concept of the room. If in the process of installing the flooring you feel the need to make some kind of original decision and, at the same time, you want to choose a reliable material that solves a lot of functional tasks, a square laminate will be the most preferred option for you. Thanks to the unique form of this material, you can successfully simulate a parquet decorated with a complex artistic pattern, ceramic tiles or a coating made of natural stone. However, the popularity of the laminate is determined not only by its aesthetic characteristics. In addition to external attractiveness, the laminate is practical and not requiring complicated care, the price of which is significantly lower than that for natural parquet. And the technology of laying a square laminate is not associated with some difficulties. Like traditional lamellas, the new version of the laminate is a prefabricated design consisting of several layers, the knowledge of which will most effectively work with the flooring. Despite the fact that in order to facilitate the assembly of the flooring, the manufacturer provides instructions for laying it, in this article we will consider me not only the guide to laying a square laminate, but also the nuances that must be observed during the installation of the material.

Content

- Laminate structure: characteristic of the layers of material

- Classification of square laminate: main classes

- Advantages and disadvantages of a square laminate

- Distinctive features and subtleties of a square laminate installation

- The most popular square laminate manufacturers

- Laying a square laminate: step -by -step guide

- Laminate care: fundamental directions

Laminate structure: characteristic of the layers of material

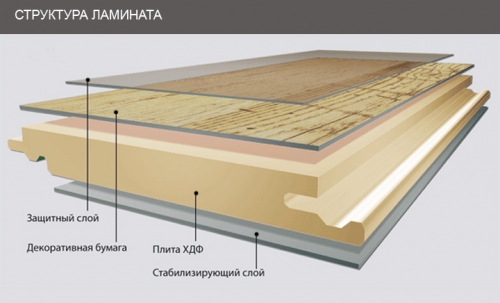

The construction market calls for customers to pay attention to two variations of the laminate traditional lamellas of rectangular shape and square panels with dimensions of 60 x 60 cm. Using the latter allows you to create exclusive interiors with the most noble appearance, which explains the popularity of the material. Using a square laminate 60 x 60 cm, imitating marble, wood, a fabric canvas or tiles, you can realize original interiors, amazing even eminent designers with a modern approach. The structure of the laminate includes at least four layers. The name of each of them is predetermined by its functional purpose. Consider the layer of the laminate structure:

1. The melamine protective layer is the first that a person’s leg is in contact with the walking on the surface of the laminate. It is completely transparent. The protective layer responsible for the integrity and wear resistance of the pattern of the panel protects the material from chemical and mechanical exposure, ultraviolet radiation and high humidity, as well as other aggressive environmental factors;

2. The decorative layer represented by decorative paper is responsible for the appearance of the material and can be supplemented by an inlay, which can be not only a plain pattern, but also a complex decorative pattern;

3. The main layer, represented by the segment of the wood-braid plate, determines the structure, shape and operational characteristics of the material. The highest strength is the products of the HDF class, on the ends of which there are locks of Lock and Click type laminate;

4. The stabilizing layer is intended for uniform distribution of the load on the flooring and preventing its deformations. It is represented by waterproof paper saturated with resins, which protects the chipboard from excessive exposure to excess moisture.

Square laminate photo

Classification of square laminate: main classes

Depending on the strength characteristics, the square laminate is divided into several classes. Before buying a square laminate, it is necessary to analyze all the features of the material in the aggregate, otherwise even clear observance of all points of step -by -step instructions for laying the laminate does not guarantee the proper result, in this case, will soon lose its operational and aesthetic characteristics. In addition, the laminate class determines the belonging of the material to a particular price category, but, despite this, the concept of classes is relative. This was proved by specialists in the production of floor materials who, having conducted a number of studies, were confidently able to argue that the wear resistance of low -class lamellas, produced by a well -known brand, is significantly higher than the wear resistance of a high -class laminate produced by an unknown company. In addition, North American masters in the process of their work use another classification.

Consider the characteristics of the laminate in accordance with its class belonging:

- Class 31 laminate belonging to this class is suitable for home use and fully demonstrates its advantages only in case of laying in the bedroom or home room;

- Class 32 laminate of this class is characterized by higher wear resistance and can be used in rooms with greater cross -country ability than a square laminate belonging to grades 31. Such rooms are kitchens and offices with a small area;

- Class 33 This laminate class is characterized by high strength and is designed to install flooring in rooms with high cross -country ability, such as shops, offices, etc.

- Class 34 laminate with the highest strength characteristics, and therefore, it is used in rooms subject to the highest loads, for example, in production enterprises and public places with high cross -country ability.

Advantages and disadvantages of a square laminate

- A square laminate belongs to a group of materials protected from abrasion and mechanical damage;

- The square laminate is resistant to ultraviolet radiation. Thanks to this advantage, it can be under the influence of direct sunlight for a long time and at the same time not change its shade;

- Affordable pricing policy. The ratio of a square laminate to a low price category cannot but affect its popularity. At the moment, a square laminate is one of the most affordable types of flooring;

- High strength characteristics due to the entry into the structure of the laminate of the high-class wood-and-based laminate, which stabilizes the shape of the material;

- Rich color scheme and an extensive choice of artistic imitations. Using a square laminate, you can simulate the skin, metal, stone and many other materials;

Important! Patterns applied to a square laminate amaze with their diversity this can be stylization for natural materials, for example, stone or wood, or imitation of metal and tiles. Modern designer technologies made it available, respectively, in demand, a decor that demonstrates an aged surface, the most striking example of which is wiped parquet. No less popular is an imitation of a large tile. Its demand is explained by the fact that, despite the high aesthetic characteristics of a real tile, it, being too slippery and cold, is not convenient in operation.

- The square laminate is absolutely fireproof, which is due to the lack of combustible materials in its composition;

- Resistance to high humidity and temperature changes;

- The presence of castle systems significantly facilitates the laying of a square laminate, so the installation of this material is one of the most affordable for an inexperienced master;

- The flooring, for the installation of which a square laminate was used, is not demanding in care and does not need specialized maintenance;

- The surface of the square laminate is characterized by antistatic properties.

Disadvantages of a square laminate:

- The use of synthetic components in the production of the laminate;

- Despite the fact that the features of the upper layer of the square laminate allow it to be considered moisture -proof material, in fact, everything is not so smooth, and the joints between the plates are a vulnerable flooring. However, experts assure that nothing will happen to such flooring if you do not become an acting person such an emergency as flooding. Wet cleaning will not affect the performance of the coating.

Distinctive features and subtleties of a square laminate installation

Speaking about the layout of a square laminate, two main options should be noted:

- Traditional styling It is the most economical and simple way to lay laminate and involves placing flooring elements parallel to the directions of the room. In the process of installing the flooring, the indicated method may occur problems associated with laying the laminate in the places of bulging of the door frame and in the places of exit of the risers;

- Diagonal styling A method that is most suitable for spacious rooms, since in rooms with a small area you will most likely face the difficulties associated with the preparation of the material. This technology involves laying the laminate at an angle of 45 degrees towards the wall.

Consider the basic principle of laying the laminate. If during the installation of the coating from rectangular lamellas, the basic principle of laying is to ensure that there are no compounds in which four strips converge, then in the case of a square laminate the situation is folded opposite. Installation of a square laminate must be carried out similarly to the installation of ceramic tiles so that the seams between the panels form crosses.

In the process of installing flooring from a square laminate, you can save on the laying of the substrate, which is due to the unjustified application. If before laying the floor covering you carried out the installation of a concrete or cement screed, this will be quite enough, since it will act as a reliable draft base for the flooring.

Distinctive features of the installation of a square laminate:

- During the installation of a square laminate, it is important to monitor the symmetry of the picture and the presence of gaps, which should be 2 mm for each square meter. Ideally, the picture applied to each square can be completed and repeated repeatedly;

- Installation of a square laminate is always directed at itself;

- Between the coating and the wall it is necessary to maintain a gap of at least 1 cm, which will prevent deformation changes in the laminate in the case of its temperature expansion.

Important! Cross -shaped joints are quite vulnerable, in connection with which, experts recommend carefully approaching the choice of flooring, evaluating the quality of the castle joints.

The most popular square laminate manufacturers

The most popular brands, under the name of which a square laminate is produced, are the following:

- Chinese brand Floor Step, ART collection. This company is engaged in the production of non -standard laminate for parquet. Due to its unique ability to shadow old people, even interiors made in a modern style, the collection is in high demand even among eminent designers;

- Quick Step brand. The ARTE collection of the popular Belgian manufacturer is considered the most popular due to high quality and acceptable price of lamella. The Arte collection fully meets the requirements for the laminate: plates are characterized by a wide format, a 9-mm thick and thin beam. And the ratio with the underfloor system makes this option ideal;

- German manufacturer of a square laminate Unik Step presents a collection on the market Imreal;

- Chinese manufacturer Zigartcalls to pay attention to a collection of own production called Palace.

Laying a square laminate: step -by -step guide

Preparatory stage: main events

- An important parameter, which is recommended to determine the specialists before laying the laminate, the cost of a square meter. It consists of the cost of the material and the cost of the work of a specialist, however, if you do your own styling, the importance of this parameter for you is somewhat losing its relevance.

- One of the first measures taken at the preparatory stage is to measure the floor area in the room and the calculation of the required number of whole lamellas. To avoid re -visiting a construction store, purchase material with a margin. After acquiring the laminate, experts recommend taking its acclimatization, that is, leave for several days in the room in which the installation of the flooring will be installed.

Important! Ideal microclimatic parameters for laminate acclimatization:

- Environmental temperature +22 degrees;

- Humidity is not more than 55 %;

After 2-3 days, you can safely start installing the flooring.

- An equally important event at this stage is the preparation of the surface. It is important to remember that the floor should be as smooth as possible, and surface drops should not exceed 2-3 mm. Even if at first glance, it seems that the surface of the floor is perfectly flat, experts still do not recommend neglecting the measuring tape. Otherwise, all your work will be in vain, and the laminate will soon lose not only aesthetic, but also operational characteristics. To avoid this, professionals recommend using the following instructions:

- First of all, evaluate the evenness of the base. Ideally, a segment of two meters long should be characterized by the absence of heights of more than 2-3 mm, which, if any, can lead to weakening and subsequent separation of locking joints;

If you find such irregularities, take the following events:

- If you plan to lay a laminate on a concrete base and found irregularities on it, pour a concrete screed.

Important!In order to align the concrete surface, experts recommend using bulk mixtures that most efficiently cope with the task and practically do not increase the floor level.

- If the laying of a square laminate is carried out on a wooden base, it is aligned with an electric shirt. If, in addition to irregularities, you find the bending floorboards, replace them or repair them;

- In case of working with a cement base, you must be aware that it needs additional protection against moisture. To provide it, it is necessary to lay a plastic film with a thickness of 3 mm by carrying out overlaps on the walls of up to 20 cm. All available places of the docks are glued with mounting tape.

- Another no less important stage in the preparation of the laying of materials that form the amortization pillow and provide additional sound insulation. A layer of foam or hemaphone used for these purposes will not only reduce the noise effect, but also reduce the thermal conductivity. The material must be laid with an overlap on each other at least 10 cm. As in the case of the film, the joints are glued with mounting adhesive tape.

Important!When purchasing a square laminate, pay attention to the presence of a thermal insulation layer located under a water -repellent substrate. In case of its presence, the use of foamed polyethylene is prohibited.

Laying a square laminate: installation features

- The installation of a square laminate begins with the opposite left corner of the room, moving away from left to right;

- The first panel must be fenced off from the wall using special wedges 1 cm thick;

Important! The installation of spacer wedges around the entire perimeter of the room will prevent the expansion of the material under the influence of temperature and humidity and subsequent deformation changes.

The principle of installation of the laminate varies somewhat depending on the type of locking joints:

- If there is a click lock type, it is necessary to bring the parse to the previously laid panel at an angle of 30 degrees, insert and lower it to the click and adoption of the right position with the panel;

- In the presence of a locking type Lock, the panel is brought strictly horizontally, and after substituting a wooden bar that protects the panel from damage, carefully drives it with a hammer.

Important! A wooden block can be replaced by a rubber hammer, which is much more convenient to work with.

- The assembly of the second row is carried out separately from the first, after which they are connected;

- By laying the laminate, you will encounter such areas where a whole panel will not fit (for example, the end of the row or the presence of heating pipes). In this case, you will have to resort to cutting the panel using a grinder or an electric jigsaw.

- Similarly, fill out the entire area of \u200b\u200bthe floor.

Laminate care: fundamental directions

- Laminated floors are easy to care for, and following our advice, you can do it yourself.

- Laminate care can be carried out both a dry and moist way. In the first case, the main instruments of care are the vacuum cleaner and a dry rag, in the second, a soft rag moistened in water, and a cleaning agent. In the absence of a special cleaning agent, you can use the usual soap solution. The use of polishing agents and wax is prohibited, as they can leave ugly stains on the surface of the laminate.

Important! Complex pollution (felt -tip pen, pencils and lipsticks) can be removed using methyl alcohol. In the case of pollution of the laminate with wax or chewing gum, it is necessary to wait for their hardening and remove them by treating the surface with paste for the laminate.

- To preserve the pristine type of laminate, the following measures must be taken:

- Prevent the drop to the surface of the laminate of sharp objects;

- Do not use abrasive cleaning agents;

- Removal of all available contaminants to be carried out using a means with a neutral level of PH;

- Exclude the use of a steam cleaner;

- Carry up the upholstery of furniture with soft fabric and special protectors.