Often cottage villages and horticultural massifs do not have a centralized ...

|

|

Laminate is especially popular among flooring. This multi -layer ... |

The choice as a chimney for a stove is a brick device before ... |

The technology of laying the laminate on the concrete floor. Do -it -yourself laminate instructions

The laminate is a popular floor covering, which occupies a leading position on the use of material both in residential premises and in firms, offices. The material is widely used due to its practicality, resistance to wear, ease of mounting and care, external attractiveness. But in order for the coating to serve for a long time and does not lose its type, it is necessary to lay the construction product on a correctly prepared basis. Most often, laying occurs on a concrete floor.

Table of contents:

- Varieties of laminate

- Laminate laying recommendations

- Preparation of the base for laminate

- Laying laminate on a concrete floor

- Laminate substrate

- Laminate installation instructions

- Tips for the proper operation of the floor surface from the laminate

- DIY laminate installation

- Recommendations for choosing a laminate

Varieties of laminate

Laminate is a material that is widely used in office and residential premises. Outwardly, the material is similar to wood. Laminate is of different types, but despite the differences in the characteristics, the structure of the laminate is this:

- base;

- craft paper;

- decorative layer;

- polymer film coating.

It differs in different characteristics:

- by class;

- by moisture resistance;

- by decorative features;

- according to the method of mounting;

- according to the clutch systems between the sheets.

It depends on the class where you can install the product. The class is like this:

- 21, 22, 23 - the lowest level of resistance to wear, cannot be installed in public places, in moist rooms, it is considered a temporary coating;

- 31-33 grades for residential premises, where there is intensive movement: corridor, hill, hallway;

- The 34th grade is very durable and has protection from getting wet, withstands contact with water for up to three hours, recommended for public premises with a large movement of people;

- 42 and 43 class of Extra premium class is impossible to buy on free sale, it is made to order, supernature material for non -residential premises.

Such types of laminate are distinguished by moisture resistance:

- the moisture resistant is applicable in rooms with high humidity: bathroom, kitchen, laundry, processed with special protective material;

- the waterproof is able to contact water without violating integrity up to three hours, and the locks of the material are processed.

According to decorative qualities, such surfaces are distinguished:

- the glossy polished shiny surface of the laminate is quite attractive, the disadvantage is a slippery surface;

- for natural imitation of wood, silky surface;

- texture as close as possible to natural appearance;

- matte is used in children and halls, not slippery, does not require frequent polishing;

- country artificially aged material.

According to the installation method, they highlight:

- adhesive maximum fixation with glue, but the process takes a lot of time and cannot be disassembled or transferred;

- castle fixation with locks.

Laminate laying recommendations

Making a decision to lay a laminate on a concrete floor requires careful preparatory work. For high -quality styling, it is necessary to carefully prepare the concrete base, correctly calculate the quantity and purchase high -quality goods.

As for the concrete floor, practice shows that before laying the laminate, it is necessary to pay close attention of the surface. Most often, the base is far from perfect, and this can cause a poor -quality final result. The floor can be uneven, tuberous, with cracks and pits. In houses of any type, in old or new ones, concrete coating can require restoration.

Even minor irregularities can cause deflections of laminate sheets, breakdown of interlocal locks, and the formation of cracks between panels. Unevenness under the laminate can become a source of reproduction of pathogenic microorganisms, moisture accumulation, and a fungus.

So that the laminate does not behave loudly, it is necessary to fit the most dense fit of the material to the concrete surface. With the bevels of the floor, the substrate will be the first to deteriorate, which will cause rapid destruction and the most laminate sheet. The floor should be monolithic and horizontally even.

Preparation of the base for laminate

The start of work on laying the laminate is completely dependent on the state of the floor. If necessary, the concrete surface must be leveled.

Most often, such situations happen:

- In general, the floor area is a whole, relatively flat, minor damage and cracks in this case are partial repair work to eliminate minor defects. Cracks are putty, the tuberosity is cleaned, the cavities are aligned with the help of a solution. After the solution dries, the surface is cleaned and becomes ready to lay the laminate.

- Significant changes in heights are noted, in this case, restoration is impossible, a new coating is necessary by screed. This manipulation will lead to the leveling of the floor, but the height of the room will decrease significantly. Do not forget about the centimeters that the laminate and substrate will take. To get around this a little, you should not use a concrete solution, but a dry modified mixture. It will help not lose as many centimeters as when using concrete solution. The solution freezes in a short period of time, the disadvantage of such a tool is its high cost. This method is also called self -leveling floor.

You can check the readiness of the surface for styling after screed using a piece of large -sized polyethylene. Cover a fragment of the film at night, in the morning look at its surface while condensate falls, the floor is not dry enough and laminate laying early.

Sometimes masters recommend laying the OSB, FEP or Plywood panels under the laminate. How justified is this? As practice shows, the material will take a few centimeters of the height of the room, eventually begins to make extraneous sounds, and the wooden environment of the material can become a seedling for insects or rodents.

Laying laminate on a concrete floor

After the final readiness of the concrete surface, there is a queue of laying the laminate. Not everyone knows that a few days before laying the laminate, the material must be unpacked. This will allow panels to adapt to the surrounding temperature and humidity of the room.

Having made a laying of waterproofing, which can be an integral piece of polyethylene, they begin the main work of laying the laminate. Experienced builders are recommended to residents of the first floors in parallel with the laying of plates, insulate the floor. This can be done using thermal insulation material.

Laying the substrate can combine hydraulic and thermal insulation, since the material fulfills these functions in full. Also, the substrate does not allow the material to contact the concrete floor and this extends the life of the laminate.

The functions of the substrate can perform the following materials:

- a budgetary inexpensive option is considered foamed polyethylene, it is sold in the form of a sheet and in rolls;

- thin -layer extrusion polystyrene foam;

- from traffic jams and rubberized materials, the material is high -quality and hardy, but expensive;

- special multilayer substrates of various compositions are able to waterproof and maintain heat.

After laying, the substrates move to the finish stage of laying laminate plates.

Laminate substrate

Construction markets offer an abundance of materials for repair and construction. The laminate, as we already know, is in great demand, and concomitant goods, such as a substrate, are also offered in the assortment. This item differs in price, quality, material. The most popular are the following materials:

- cork substrate;

- isolon substrate;

- foamed polysterol;

- coniferous or tile substrate of wood.

The foamed polyethylene substrate is the most economically affordable. The material is easily laid and the parts are connected to each other with tape. There is such a substrate with an additional element of aluminum foil. This allows the material to maintain heat better. But this material also has disadvantages:

- the material is thin and it quickly subsides;

- with mechanical exposure, the material is easily torn.

Polystyrol is similar to the above. It is more durable, does not deform during loads, has reliable sound and thermal insulation abilities.

The new materials that have appeared relatively recently is a coniferous substrate. But during this time, both supporters and opponents of this type of material appeared:

- on the one hand, the material is environmentally friendly, without impurities, but how then to explain the presence of coniferous particles?

- the substrate eliminates the irregularities of the floor due to its softness, but the same quality can cause deformation of laminate sheets;

- the structure allows you to circulate the air, but coniferous material is attractive for microorganisms and fungus;

- it is guaranteed that the shrinkage of the material will not happen, but, on the other hand, this contradicts the top quality of the substrate.

A cork substrate is considered one of the highest quality materials. It is such a substrate that provides a long service life of the laminate, is not subject to shrinkage, and withstands high loads. Camping material is considered environmentally friendly, in addition, it is worth noting the following features:

- antistatic capabilities;

- noise insulation;

- ease in laying material;

- insignificant weight;

- there are no irregularities;

- fire resistance;

- accessibility of the material, a large assortment in construction stores;

- special impregnation prevents the spread of mold, fungus, does not attract rodents.

The cork substrate is sold in plates and in rolls, the thickness of the material does not exceed four millimeters.

The disadvantages of this material are the high cost and the need to use additional materials for vapor barrier.

Laminate installation instructions

When laying the laminate, you cannot avoid cutting the material. A hacksaw can help cut the panel, but it is preferable to use an electrician. A hacksaw can make a cut line uneven, with a damaged inner film.

There is a certain procedure for laying the laminate.

The very first substrate is laid, it performs several functions at the same time:

- shock absorber;

- noise insulator;

- vapor barrier.

Experts also recommend using a vapor barrier film. It can be an ordinary film, but always thick, at least two hundred millimicron. The film is spread over the entire area of \u200b\u200bthe room and connected by special tape. A substrate is laid on top of the film. It will protect the laminate from strokes on the concrete surface. This will avoid extraneous noise when moving and will not be damaged during operation, it will be able to maintain the form for a long period of time. The seams of the substrates are also sealed with adhesive tape.

After manipulations with the substrate, a clean, flat surface without global differences in height should be obtained.

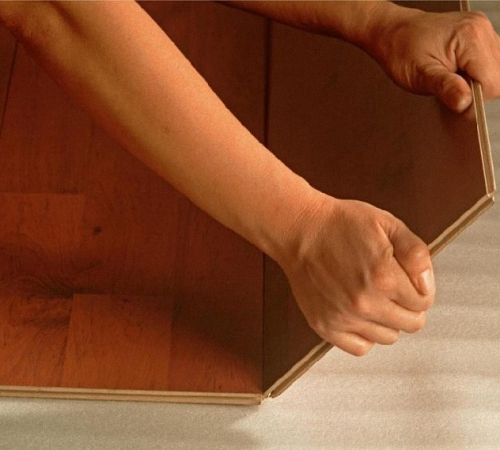

After that, you can proceed to laying sheets of laminate. There are special locks on the edges of the plate that grows between the edges of the material. The first sheet is laid from the wall, and wedges for a gap are installed between it and the material. If you do not provide such a space, after some time, the laminate plate can bend. The next plate is invested in the previous castle. This is done to the end of the row. The second also fits, only without the use of wedges. The wedges are inserted between the walls and panels around the perimeter of the entire room.

After laying the laminate sheets has ended, it is necessary to install the baseboard. To cope with this task, you should prepare tools:

- corner of the template;

- drill;

- baste drill.

In order for the flooring surface to serve for a long time, it is important to comply with the recommendations of specialists on the proper operation of the material.

Tips for the proper operation of the floor surface from the laminate

Laminate - reliable and practical material, is durable, but in order for the floor to be able to last a long time, it is necessary to rationally treat it and remember important moments:

- the laminate cannot be installed in rooms with high humidity, a kitchen, a bathroom in which the material will deteriorate very quickly, spilled water should immediately be collected from the surface of the material;

- if scratches or other defects appear, it is necessary to use a special solution, grout;

- when the cracks appear between the panels, the grout should be used, it will help prevent moisture from entering the sheets and their premature damage;

- when cleaning in rooms where the laminate lies, it is necessary to use special detergents to care for such material, a rag for the floor should not be wet, water is destructive for such a coating.

If you follow these tips, the life of the laminate will last significantly.

DIY laminate installation

Experts evaluate their work on laying the laminate. If you plan to lay the laminate yourself and save money, you need to study the theoretical side of the issue and have an idea of \u200b\u200bhow to properly lay the material.

The whole process can be divided into stages:

- polling surface preparation;

- laying of the substrate;

- laminate laying.

Each of the stages has its own characteristics, it is necessary to responsibly perform each of the stages. The result of the right choice in the purchase of material, substrate, will be a high result and surface, resistant to wear.

Recommendations for choosing a laminate

The laminate gradually displaces linoleum from apartments, which has become a non -modern, carpet, provoking the development of allergies, a parquet, the price of which is very high. The laminate is strong, beautiful and stylish material that can give the room a solid appearance. In order for the purchase of the material to bring the expected result, it is worth carefully studying the issue.

When choosing a laminate, you need to approach the choice of material very thoughtfully. The thickness of the product is a characteristic that determines both the choice of a substrate and the calculation of the rocks. If the laminate is laying with already installed doors, it must be remembered that the floor level will rise and this can become an obstacle to the functioning of the doors. It is necessary to take into account the thickness of the material in the neighboring rooms so as not to install the threshold in a room that is not always appropriate.

Publishing when choosing a material is from such factors:

- company name;

- producing country;

- price;

- wear resistance;

- moisture resistance;

- environmental Safety;

- compatibility with the style of the apartment;

- resistance to mechanical damage;

- resistance to scratches.

When buying a laminate, take into account for which rooms it is provided for whether any additional protection is needed for it.

Any master will be able to lay a laminate on a concrete floor in an apartment, not even very experienced, the main thing is to study the characteristics and features of the laminate. If you still have questions, which material to choose, how to lay it correctly, what should be taken into account in the laying process, watch the video. After viewing the plot, you will have no questions for how to do it correctly and rationally.

for such recommendations, idiots

according to such recommendations, idiots lay laminate and neighbors from below then suffer from noise. Where is your layer that extinguishes stress noise from the laminate?