We all live in difficult times, and sometimes the only safe place is our ...

|

|

In order to protect your plot or house from extraneous invasion, it is protected ... |

Crossing special designs that share floors. They can... |

Put the bulk floor KNAUF with our own hands - instruction

In most cases, the floor structure is a screed. The wet method based on cement-sand mortar is most familiar and popular. But dry (team) technology, although it is used much less often, is a much more economically attractive way. The bulk floor can be used both in construction and repair work in residential and non -residential premises. The leading position in the market of dry bulk floors is rightfully occupied by the German company KNAUF.

Content:

- Characteristics of the bulk floor KNAUF

- In what cases is the installation of the bulk floor KNAUF is recommended

- Follow Paul Knauf with your own hands

- Technology of bulk floors KNAUF. How to avoid errors during installation

- Price for bulk floors Knauf

Characteristics of the bulk floor KNAUF

KNAUF company is widely known in the construction market and has been maintaining the high quality of its materials for many years. It produces gypsum plasterboard sheets, grooves, hypos -fingering sheets and many liquid building mixtures, including primers, putty, adhesives, etc. But their business card in our country is the KNAUF bulk floors, which will be discussed in this article.

KNAUF Superist

This is an environmentally friendly material of high quality. Great for premises, which are presented with increased fire safety requirements. It has good sound and heat-insulating properties. It is used as a compensating layer if the backfill thickness does not exceed 15 cm. The size of the sheet is 250x120x1 cm and 250x120x1.25 cm.

Peculiarities:

- high fire resistance;

- high styling speed;

- there is no need for wet stages of work;

- creates a good microclimate in the room;

- meets high world standards.

Moisture-resistant KNAUF SUVERS

It retains all the advantages of ordinary KNAUF-lists, but at the same time is characterized by high moisture resistance. The dimensions of the sheet are 250x120x1 cm and 250x120x1.25 cm.

Elements of the floor of Knauf Superpol

They are produced at a factory of moisture-resistant gypsum-fiber KNAUF-SUPERS. During their manufacture, two sheets are glued with dimensions of 150x50x1 cm, resulting from a total thickness of 2 cm. All over their perimeter there are folds of 5 cm wide.

The bulk floor KNAUF consists of a layer of PVC film, expanded clay for leveling and the floor elements themselves. As the main advantages, short periods of work, lack of dirty work, creating a perfectly flat flooring and a convenient location of all communications are distinguished. This floor is suitable for laying not only on a flat surface, but also for an uneven base with cracks, recesses or tubercles.

Advantages:

- a completely even and strong base of the floor is created, capable of withstanding a load of 500 kg/m2;

- hypoallergenic material;

- throughout the operational period, faults do not appear and there are no creaks;

- after installation, the floor is immediately ready for operation;

- on the embankment floor of the KNAUF, you can install any plasterboard partitions;

- excellent sound insulation (especially important for residents of multi -storey buildings), which can not be said about the cement screed or bulk floors;

- there is no risk of pouring neighbors from below, because when working, water is not used;

- paul Knauf is much warmer than a concrete screed;

- all work is performed quickly and without loss in quality. To make the floor in the room 18 meters, with all materials and tools, professionals will need no more than 3 hours. And this is especially important for those who make repairs in the apartment in which they live;

- you can fill the floor in the rooms alternately without losing level.

Any flooring is mounted on the resulting even surface of the bulk floor: parquet, laminate, tile or porcelain tile.

The only thing that is prohibited is the installation of a warm water floor, they are replaced by electric warm floors. Thanks to the layer of expense clay, the floor has excellent thermal insulation.

In what cases is the installation of the bulk floor KNAUF is recommended

- If the repair or reconstruction of the floor is carried out in old buildings or in houses with wooden ceilings. Since it can significantly reduce the load on the supporting structures of the house.

- In the case when preparing the base of the floor is required as soon as possible.

- In the cold season, when there is no way to make a cement-sand screed.

- If it is necessary to arrange an electric warm floor in wooden inter -story floors.

Follow Paul Knauf with your own hands

There is nothing complicated in doing it with your own hands. The main thing is to purchase materials, prepare tools and follow step -by -step instructions.

Preparation of the surface of the base

If repair work is carried out, then the old floor covering is removed first. In perfect leveling of the surface, there is no need, but all construction garbage, including from the cracks, should be carefully removed.

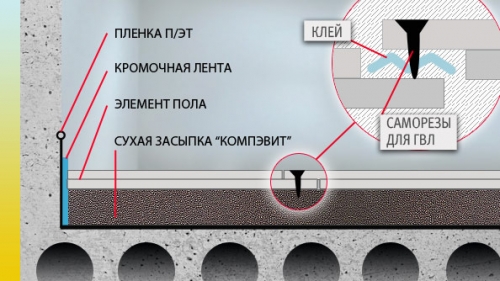

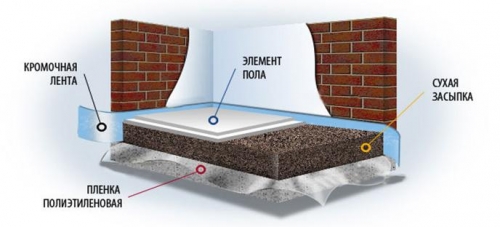

The device of steam and moisture insulation layer

This is an important stage of work on which the duration of the flooring depends. The fact is that moisture for bulk floors is destructive, slabs swell under its influence and the facial coating spoils. A layer of PVC or vapor barrier film laid under the backfill, protect it from moisture exposure, which will inevitably form on an inter -story floor.

Using the level (best laser or water), marks of the upper level of the backfill are applied to the walls.

Its height depends on the uneven base of the floor, and varies from two to six centimeters. Another 2 cm of the thickness of the prefabricated base will be added to the resulting height and as a result the floor level will rise. Then, a film with an overlap on each other is laid on the floor by at least 20-25 cm and glued with construction tape. She must go to the walls to the marks put earlier and be fixed with tape. You can use modern vapor barrier materials as a film, a plastic film with a thickness of 200 microns is also suitable for concrete flooring, and for wooden bituminized paper or permamine.

Tip: Before laying a moisture -resistant film, you should close all the holes and cracks in the surface of the base using a rapidly hardening alabaster. In the presence of wires, they are placed in advance in the corrugation and pressed to the floor. It must be taken into account that the minimum layer of expanded clay above the corrugated pipe is 2 cm.

Sound insulation arrangement

This stage allows you to completely exclude sound bridges and protect the floor from deformation during thermal expansion. To do this, along the perimeter of the entire room, a gap along the walls is an equal 10 cm, in which thermal insulation material is placed.

You can limit yourself to foam rubber tape, which has a thickness of 1 cm, and a width of 10 cm. On sale they have self -adhesive and simple, which are attached to ordinary adhesive tape.

Filling expanded clay

The loose material, in the role of which expanded clay, is necessary to create a flat surface, as well as for heat and sound insulation. Expanded clay is poured onto the film and leveled according to the marked marking by the rule. Siliconer or quartz sand, swollen perlite sand, fine -grained slag or wrecking production of expanded clay can be used as filling material. All these materials have low hygroscopicity, practically do not settle, have high porosity and good feud.

The thickness of the backfill layer directly depends on the degree of irregularity of the floor slab and on the need to install engineering communications in it.

On average, there is enough layer thickness of 3-5 cm, but if it exceeds 6 cm, then you will need to increase the screed with an additional layer of plates.

How to fill a dry screed correctly

- The first profile is installed near the wall, and all subsequent at a distance of 1.5 m from each other (the length of the rule). They should be parallel to each other;

- then the height of the profile points is determined and the thread is pulled. To change the height of the profiles, the remains of plates or planks are placed under them;

- after all the work is completed, the guide profile should be checked once again. To avoid its deflection, supports under it are located at least after 70 cm;

- according to the prepared guides, expanded clay is poured and leveled by the rule or a wide spatula. These works are carried out in the respirator due to a large volume of dust;

- when the layer is aligned, the profile gets along with the supports, and the formed holes are filled with expanded clay and divided. Then everything is compacted;

- if in the future you will have to lay a prefabricated floor from the opposite input of the door, then you should take care of the islets. They are made from squares of chipboard, GVL or plywood and are laid on a layer of expanded clay;

With a perfectly flat surface of the base, the need for dry backfill is absent, it is replaced by sheets of extruded polystyrene foam. Also, thermal insulation materials (EPS, mineral wool, glass wool, etc.) are also used along with dry backfill, when it is necessary to strengthen the thermal insulation of the floor. The heater slabs should fit tightly to each other, excluding even small gaps. Along the walls is a brown tape.

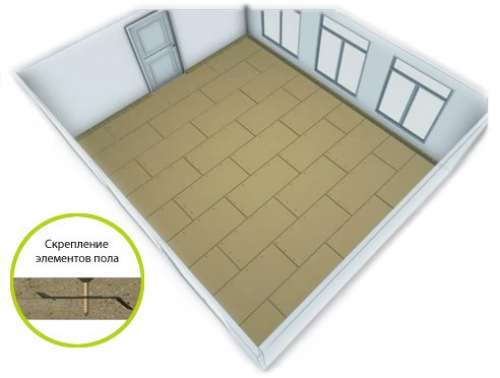

Laying gypsum fiber sheets

The laying of sheets on a dry screed starts from the door so that there is no need to walk on it during work. For dry screed, sheets of chipboard, moisture -resistant plywood, OSP, moisture -resistant drywall or asbestos sheets can be used. But the most durable and durable material is the prefabricated elements of the floor of the KNAUF company. It can simply be gypsum fiber sheets glued in two layers or with an additional polystyrene foam.

The assembly of the first row is very important, as it is decisive for the further course of work.

It is better to do this work together. Since the weight of one sheet is 17 kg, and it is very difficult to hold it on outstretched hands. On the first sheets, the folds are immediately cut off, this is done so that the sheet is laid exactly on the surface and does not deepen when it is advanced on it into expedding.

Sheets are laid on the principle of brickwork, that is, with a displacement of joints.

Thanks to this location, a place is formed to fix the neighboring sheets. Self -tapping screws should be twisted through the folds around the perimeter of each sheet at a distance of 15 cm from each other. For additional strength, all seams are glued with PVA glue.

Castle Paul Knauf Video

Technology of bulk floors KNAUF. How to avoid errors during installation

Despite the fact that KNAUF Superopol is a high -quality technology for installing a bulk floor for years, it also has disadvantages.

The first drawback concerns not so much technology as the lack of a professional tool for its device in Russia. Official representatives provide training videos of all stages of work, but there are simply no equipment for working in their catalogs.

Falz is forever cut off from the extreme sheets to the wall, which is a large mistake, which will necessarily lead to the sketching of the floor in this place.

The beacons left in the backfill lead to deformation of the prefabricated flooring. Ceramzit will still shrink over time, and the lighthouses will remain in place, which will cause problems in the future.

Particular attention must be paid to the moisture content of expanded clay. If it is not suffered enough, the floor deformation cannot be avoided.

With proper installation of the bulk floor, Knauf has only positive reviews. It is durable, durable and safe for human health. Great for operation in residential premises, and in places, with high cross -country ability.

Price for bulk floors Knauf

The formation of the cost of the bulk floor KNAUF depends on several components. With a floor thickness of 5-8 cm with installation work, a square meter of floor will cost 1300-1500 rubles.

To hide engineering communications will require a total floor thickness of 7-8 cm. The price will be about 1,500 rubles, of which 900-1000r materials, and everything else for work. It is much cheaper to do all the work with your own hands, but without sufficient experience it will take much more time. So, for professionals, it will take only 1-2 days to install a floor by 50 square meters, and if you do it yourself, then at least twice as long.

Approximate prices for materials for the bulk floor KNAUF:

- moisture -resistant sheets 320p/m2;

- expanded clay 1500r/m3;

- moisture -resistant film 20r/linear meter;

- carbon tape 180r/skeleton;

- self -tapping screws from 200r/packaging.

Good afternoon. First

Good afternoon.

The first remark: it is better to turn the profiles with “horns up” and fill them with expanded clay, so that expanded clay at cyclic loads (from steps, etc.) does not squeeze out lower icages in the cavity of profiles. As a result of which expanded expansion loses its stability and geometric accuracy

Profiles must be removed

Profiles must be removed

But what about the pipes

And what to do with heating pipes that go to the floor, the pipes of thermal walking, you need to come up with some kind of sleeve, in the case of replacing the pipes.