Due to the return of the popularity of wooden houses in suburban construction ...

|

|

The ceiling is filled with siding is an inexpensive and practical option for its repair. Besides,... |

Each cottage begins with buildings. Everyone does not want to carry garden equipment with me ... |

How to align a wooden floor with plywood

The wooden floor in any room over time inevitably begins to bend, crack and lose its original appearance. The main defects of the wooden flooring include twisted boards, irregularities and creaks, which are caused by wear and drying of the boards. Homeowners to hide these defects use various flooring. But before laying any flooring, it is recommended to align the draft base without fail. Today you will learn how to align the wooden floor with plywood.

Content:

The need to align the floor

Modern flooring for the most part is demanding on the basic base of the floor, so the procedure for aligning the wooden floor is considered an integral part of the repair work. The parquet board and laminate are very sensitive to the irregularities of the draft floor, which is explained by the presence of a lock connection. If the base does not satisfy the requirements for the installation of these coatings, then the lock will quickly lose strength, and a crack forms in this place, where moisture and dirt will fall, provoking further destruction of the flooring.

If the draft floor is slightly uneven (when dropping levels of height of about 2 millimeters per square meter), then you can fix it with ease, having a minimum of materials and tools. It is quite enough to treat the surface with acrylic sealant or cover with homemade putty from PVA glue and moistened sawdust. In addition, you can carry out the surface treatment of already aged boards, removing these boards, pulling them around and laying them again. The floor boards can be fixed with screws or nails.

But if the flooring has significant damage and large irregularities, it is recommended to lay leaf material on a wooden floor, which allows you to align and strengthen the base. For this purpose, you can use GVL, chipboard and plywood. The last material is most popular.

The use of plywood is rightfully considered a simple and quick way to align the floor in wooden buildings. Plywood is indispensable for leveling the wooden floor, as it has such key characteristics as relatively small weight, sufficient hardness of the material, great flexibility of plywood, high -quality grinding, resistance to loads, lack of unpleasant odor.

Plywood sheets due to the perpendicular placement of neighboring layers have high strength in all directions. For an accelerated device of a wooden floor from plywood on significant areas, you can choose large sheets of plywood. In addition, a dry screed using sheet material does not require large financial investments.

Aligning the wooden floor with your own hands

1. Choose a plywood

The choice of plywood for aligning the wooden floor will depend on the type of flooring, which you will lay later. For a soft coating - linoleum or carpet, thin sheets can be used, but you will not achieve complete leveling the floor in this case. For laminate or parquet, you need to buy a plywood thicker than 10 millimeters. Remember that the thickness of the plywood for a parquet board and laminate should be no less than the flooring.

The brand of plywood is customary to determine in accordance with the moisture resistance of the material. For industrial construction, plywood of brands FB and FOF are used. For individual work, Plywood FC and FSF is intended. We will consider in more detail the brands of the material that are intended for individual construction.

In the manufacture of FC plywood, gluing composition without the use of phenols is used, so this material is completely harmless and can be laid in the bedroom or children's room. Such plywood is resistant to mechanical influences and is of medium -resistance.

Plywood of the FSF brand is characterized by increased wear resistance, water resistance and mechanical strength. The material does not change these properties even with the differences in relative humidity and temperature. This is achieved through the use of phenol -formaldehyde adhesive resins. However, they are quite toxic, and such a plywood is better not to use in residential premises.

In accordance with GOST, four varieties of this material are presented on sale:

- First grade. Such plywood is the best in quality, since it is almost completely absent of visible external defects, however, the presence of a crumpled veneer or cracks of not more than 20 centimeters is allowed.

- Second variety. A plywood of this variety can have a slight sealing of glue (not more than 2% of the area of \u200b\u200bthe material) and wood inserts on its surface. In addition, there may be dents and scratches on the sheets, which reach up to 5% of the total surface.

- Third variety. A similar material may contain fallen and fused knots, as well as traces of wormholes.

- Fourth variety. This variety is recognized as the lowest quality, since the faner has many defects that have formed at the production stage. And although the disadvantages of this material are significant, the quality of gluing veneer is quite high.

Of course, when buying plywood for aligning a wooden floor, it is necessary to focus on your own capabilities. However, you need to take into account the following. The first option is ideal when leveling the floor, but in terms of price-quality ratio, the most suitable is the decision to buy a second-grade plywood. The fourth variety is not recommended to use a wooden floor with plywood.

Plywood is sold both in grinded and unnecessary. The designation Sh1 indicates that it is polished on the one hand, the Ш2 that it is polished on both sides, NS is an unnecessary plywood.

Without fail, a marking is made on a polished faner indicating the class of emissions of free formaldehyde. Marking E1 means that the presence of formaldehyde in the calculation per 100 grams of dry plywood mass will be less than 10 milligrams. The designation E2 indicates the presence per 100 grams of dry mass of 10 30 milligrams of formaldehyde.

From the foregoing, it follows that the best option for aligning the wooden floor is the second-grade plywood sheets with FC, Sh1, E1 and 10-12 millimeters thickness, which allows the floor to make the floor perfectly even.

2. Choosing the methodology of leveling the floor

The choice of the technology of aligning the wooden floor with a plywood should be carried out, having previously determined the state of the floor and assessing the degree of deviation of the top -relief relief from the norm. As a measuring tool for studying the floor surface, it is customary to use a two -meter level. Mark the points in the corners of the room, find and designate the centers of the lines of the conjugation of walls and floor, as well as the center of the room.

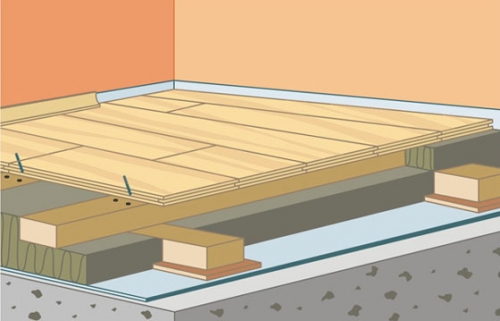

By dividing the space into peculiar segments, examine each site. With uniform deformation of the floorboards with a difference of 5 millimeters in the levels of height, you can align the floor with plywood by attaching the sheets to the planned floor itself. In case of height drops, more than 1 centimeter, but not higher than 8 centimeters, it is recommended to create point or strip supports. The whole procedure, in essence, is to arrange a crate from a beam or thick plywood.

3. Prepare the surface

For laying plywood on a wooden floor, you will need: an electrician, a screwdriver, roulette, level and screws with dowels. Before aligning the wooden floor, check the condition of the pipes and other communications that pass under the floor, since there will be no free access to this space after the completion of all work. Inspect the basis for suitability for use, repair the creaking sites and the replacement of old rotten boards.

Plywood sheets for several days in the room in which you will perform work. This will achieve the same humidity in the room and the material used, which will avoid the process of deformation of plywood sheets after styling. If the room is regularly heated, then you need to put the plywood sheets on the rib, as shown in the photo alignment of the wooden floor with plywood, and withstand at least two days. When conducting work in the room, which is heated periodically, the sides of the material should be slightly moistened with water at room temperature.

4. Try on the plywood

First of all, the cutting of plywood should be carried out, respectively, the size of the room. As part of this process, take into account the size of the damper joints: one centimeter at the walls and 3-4 millimeters between the blanks. Otherwise, moisture and temperature drops will provoke a swelling of the base. After completing the cutting, check the ends of the blanks for defects and relaxation. Runned plywood sheets is better not to use and replace.

After that, it is necessary to lay the plywood on the base in the order in which you will attach them. The joint of four corners is not recommended. Lay the plywood sheets with a shift, as shown in the video about the alignment of the wooden floor with plywood. Then number all the sheets. Focusing on the joints between plywood sheets, mark the location of the lag, and you can remove the blanks. The joints of the sheets should fall into the middle of the lag.

5. Install the lags

Lags for aligning the wooden floor are made of plywood, which has a width of 3-4 centimeters. They must be laid according to the marks made. Lags are attached to the floor with self -tapping screws or special glue designed for wooden products. In the process of laying, gaps between the lags and the floor may occur, in them it is necessary to lay pieces of plywood suitable in thickness. Before laying them, lubricate both sides with glue.

Similarly, you need to do if the base has changes in height.

Horizontal placement of lag is determined using the level. The evenness of the future flooring depends on the thoroughness of this process. After laying the lag, make the crate, its size should correspond to the size of the plywood. The space between the lags must be filled with the seal.

6. We fasten the plywood to the floor

After the lags have been installed, you can start aligning the wooden floor with your own hands. Fasten plywood to the wooden floor in accordance with the scheme. The blanks must be treated with an antiseptic before this. Fastening is carried out using self -tapping screws with plastic dowels. In order for the plywood to be not damaged from the beats of the hammer, drill a hole in the places of screwing the screw, which is equal to the diameter of the dowel. And then nickname the hole of a larger diameter. A self -tapping hat will hide in it.

The final processing of plywood will depend on the selected flooring. The surface under the carpet is covered with several layers of varnish. For the laminated floor, plywood base is polished, and then covered with protective varnishes. Under the parquet or laminate on the base, a special noise -absorbing substrate should be laid.

Thus, using this technology for aligning the floor and flooring, you can align almost any base. With careful work, as a result, you will receive a strong and even surface. The coating laid down on such a base can last more than one year. In addition, the plywood layer will be additional thermal insulation.

In recent years, on

In recent years, a serious struggle for the minds and hearts of consumers has unfolded in the Russian construction market. We are talking about those who started large -scale repair or “cosmetic” finishing work in their housing, and for this purpose acquires wooden flooring (parquet, parquet board, laminate, etc.)

Everyone knows that these finishing coatings require laying on a hard, even base, with a difference not exceeding 2 mm per 2 linear meters, and their flooring on a base with high humidity is unacceptable.

In the case of manufacturing the base of the floor of wet materials (“concrete screed”, which appeared on the market recently “half-dry screed”, etc.) The result requires thorough drying-at least 30-40 days, depending on the thickness of the base. Failure to comply with the requirements for the permissible moisture of the base of the floor leads to the appearance of mold on a wooden flooring and its rapid failure. Failure to comply with building standards associated with the stiffness or evenness of the base leads to the appearance of creaks, cracks and the subsequent indifference of such a flooring.

The foregoing tasks earlier, from the mid-90s of the last century to recently, decided three sex systems competing among themselves.

Depending on the purpose of the room,:

Concrete multilayer alignment

Adjustable structures

Or a dry screed "KNAUFF".

An attempt to reduce these three technologies led to deviations from existing building codes and rules. As a result, the mass distribution of low -quality products in the Russian construction market that do not meet the requirements of modern flooring materials to prepare the base.

Sellers of this, frankly, consumer goods are disordered by the fact of reducing the service of the finishing coating, in the case of an incorrectly prepared base. Consequently, we increase the amount of investments in the arrangement of the floor, and the result “laid and forgot” can really be forgotten - the costs of such “repair” will grow exponentially.

How to spoil with your "improvement" high -quality concrete multilayer floor

Experienced builders know:

In concrete multilayer alignment is used:

technology of rough alignment of concrete screed;

technology of more accurate alignment - leveling screed;

Group leveling of the flooring of a plywood sheet 12 mm thick.

The struggle of the floors. Divorce in Russian.

Each of these layers (with a floor thickness of not more than 3-5 cm) together with work and materials will cost the consumer from 600 rubles per 1m2. For parquet coatings, the use of all three layers is required (the parquet is glued to the base); For a parquet board or laminate (covered with a floating way, with fixation around the perimeter and without fastening to the base), two layers are enough, however, to the detriment of the comfort of the floor (loss of sound and heat-insulation, the lack of protection of the finishing coating from the moisture difference).

Thus, the cost of a multi-layer concrete base depending on the quality is 1200-1800 rubles per m2. And this is not the limit!

When lifting a given floor level per size of more than 5-7 cm, this method becomes even less profitable, since its price increases significantly.

Also, keep in mind that the use of such a weighted structure is not always possible due to the growth of additional loads on the floor slab; And the screed, using wet processes, requires drying from 30 days, which is not always informed to the consumer. Nevertheless, despite the difficulty of making the foundation in this way, with mandatory observance of all of the above requirements, a parquet or laminate coating on such a floor will last for many years.

The struggle of the floors. Divorce in Russian.

The so-called “know-how” “screed in a day” proposed in the last few years in the market is a simple client’s inflation, who wants “faster and cheaper”. Such a screed is made of a small fraction of sand and cement with polymer additives, which gives the concrete mass the appearance of a dense cottage cheese until it dries. The “cottage cheese” is distributed using a special pump, and then smoothed manually. The cost is 650 rubles per m2, cheap and angrily, everyone is happy. At first sight. Misleads the consumer and the name of this method - the method of semi -dry screed. But manufacturers are silent about the need to further level this innovation in order to achieve the required difference required by the standards (a maximum of 2 mm per 2 linear meters), and the mandatory removal of moisture.

The result is no 1200 rubles per m2. Cheaper? And the same 30-40 days of stretching moisture from the screed, in front of the flooring of the finishing coating.

How to spoil with your "improvement" high -quality adjustable gender

The struggle of the floors. Divorce in Russian.

A modern alternative to concrete multilayer leveling is the floor using adjustable structures.

Two types of DNT adjustable floor - floor along adjustable lags and floor on adjustable slabs - are designed to align the floor with different initial quality.

Options are distinguished by the thickness of the adjustable screed-3-5 cm (adjustable plates), 5-12 cm or 10-17 cm or more (adjustable lags). Both of these designs with a floor lifting height (the thickness of the adjustable screed) 5-12 mm cost an average of 1200 rubles per m2, which corresponds to the cost of the base made by the method of multi-layer concrete screed in the economy version (2 layers, without plywood). With an increase in this parameter, the price, unlike the previous method, changes slightly. At the same time, plastic tilt bolts and bushings (from a polymer of special strength) interacting directly with wood (plywood or lag) are used as fixing adjusting elements. A mandatory element of the adjustable floor is plywood or DNT plate, on which the finishing coating is laid.

Attempts to “improve” the technology of adjustable floors of DNT used in the Russian market for more than 20 years have led to a change in the type of fasteners and materials from which they are made. On the Russian market there are 2 main options for "pseudo-rationalization." In one case, furniture metal hairpins are injected directly into the thread of wooden lag, and in the second they are inserted into its holes and are tightened on two sides with nuts with washers.

Advertising themselves in the regulated sex market, manufacturers of the indicated “improved” structures at a comparable price with adjustable DNT floors (1200 rubles per m2), say supposedly increased reliability of the floor design, precisely due to the use of metal studs instead of a polymer.

Fundamentals of materials science in relation to adjustable floors

These statements are not substantiated and contradict the laws of materials science. Let's look at the loads for materials more carefully.

The struggle of the floors. Divorce in Russian.

In the first version of the “know-how”, the thread in the soft tree under the dynamic load is quickly cut off with hard metal, which leads to the appearance of the backlash and the rapid loosening of the structure. In the traditional case of patented DNT technology, the plastic bolt has approximately the same characteristics in stiffness with wood and interacts with it, without violating the integrity of the connection for at least 50 years (official tests of the Mosstroy and Academy of Subtle Chemical Technologies).

The struggle of the floors. Divorce in Russian.

In the second version of the “pseudo technology”, the wood from which the lag is made, drys out of the temperature and humidity drops, which requires constant dismantling of the floor and twisting the nuts on the stiletto. If this is neglected, then a gap appears between the nuts and the tree, and the backlash of the structure arises as a whole. Now imagine how easy it is to constantly dismantle and again lay the parquet, which is attached directly to the base?!

I also want to note the adjustment of the lag using corners attached to the floor. The lag aligned along the horizon is fastened from the sides with a corner of self -tapping screws. The unreliability of this design is obvious - with constant dynamic loads on the lag, part of the load is redistributed to mounts in the form of self -tapping screws screwed into the sidewalls of the lag, at an angle of 90 degrees, which leads to their bend and loss of strength of the entire floor structure.

Dry screed Knauuff

Another type of alignment of the base of the floor, also comparable in price with floors made of multi -layer concrete screed (economy version) and an adjustable floor, is a dry CNAUF screed (1250 rubles per m2).

The small faction of expanded clay is poured in the room on the base, and is aligned by smoothing it on the surface and mandatory tamping, followed by the flooring of GVP sheets with their attachment by the junction of the junction.

The struggle of the floors. Divorce in Russian.

With a faction thickness of not more than 3-5 cm, a well-compacted fraction does not sit from constant dynamic loads. But in order to achieve the required density of the screed when tamping it, it is necessary to repeatedly water this fraction with water and use special tamping machines. Of course, in this case, the indicated screed cannot be called dry, since the moisture accumulated during tamping requires its removal, before the flooring of the finishing layer of the floor. That is, we are dealing with a wet screed again, although “dry” is written on the package.

It is important to know that with a floor height of more than 5 cm, the use of this method of alignment for wooden flooring is not at all acceptable! In places of constant loads on the bulk mixture of such a thickness, it begins to sag, which makes a parquet or laminate into the worthlessness, covered on top.

conclusions

If you do not remain in the illusions of the sweet stories “Sharash Montazh” about the builders about remarkable leveling and preparing the base of one square meter of floor for 650 rubles for parquet, parquet board or laminate, then, whatever one may say, to make a durable and reliable floor according to all the rules and standards In construction is cheaper than for 1200 rubles per m2, it will not turn out to be any of the above methods. You can use the online calculator and first estimate the cost of preparing the base for the floor.

The struggle of the floors. Divorce in Russian.

At the same time, the same competitive advantages between concrete multilayer alignment, aligning the adjustable floor DNT or dry screed “KNAUFF” are the same with a thickness thickness of up to 5 cm. The difference is very significant, that during installation of the adjustable floor, wet processes are not used. This significantly saves time. In addition, the design based on the adjustable sex has increased heat and sound-insulation properties, unlike its competitors.

But if it is necessary to raise the floor to a height of more than 5 cm, adjustable DNT floors have a serious competitive advantage in terms of price-quality ratio in comparison with other methods of high-quality leveling of the floor for wooden flooring. In this case, the use of adjustable lag technology is most appropriate.

And, of course, none of the previously used technologies will give such an ease of installation of communications and various heating systems “warm floor”, like adjustable floors - after all, they have an air gap under the coating. Hofro channels of communications and pipes of water warm floor are conveniently placed in it, and additional heat-insulating mineral slabs can also be laid to achieve maximum insulation of the room from noise and cold.

So we advise, planning to repair and replace the floor, not to succumb to the sweet speeches of sellers, but carefully study the proposals, compare and make the right choice!