When building one -story houses, a roof with two ... is very popular ...

|

|

Few in our country have not tried at least once wallpapering. Of course... |

Liquid wallpaper can be called a rather original solution for wall decoration in the apartment ... |

How to eliminate the screech of parquet

In large cities, a huge number of construction stores are operating, which are full of a variety of flooring. However, consumers prefer most often the good old parquet, according to which our grandparents also went. But still, the parquet floors have their drawbacks. Such a coating sometimes reminds of itself with a slight creaking, quiet, but terribly unpleasant and delivering incredible discomfort to all residents.

Content:

- The reason for the creak of parquet

- Dismantling of the parquet

- Elimination of cracks and potholes

- Repair of the base of the parquet

- Klinyev's driving

- Filling with adhesive composition

- Using a cement solution

- Sprinting to the parquet floor

- Filling mounting foam

- The use of metal anchors

- Bringing with self -tapping screws

- Tingle -ups of the parquet floor

Causes of creak of parquet

The parquet is attributed to the elite class of flooring, unfortunately, there are certain inconveniences that reduce the quality of operation of the floor. The most common problem is the creak of the parquet that appears over the years of its use. Many are interested in how to eliminate the script of parquet. But, first of all, it is worth finding out the reason for the appearance of this sound. You should immediately make a reservation that this is manifested with an old parquet.

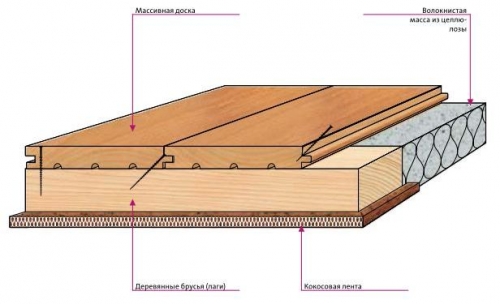

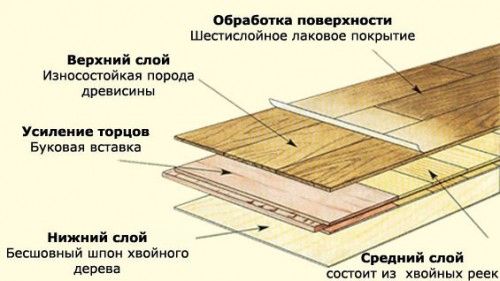

Since the parquet is made of natural wood, the creak can be considered a fee for the ecology. After all, the wood in itself does not contain any chemical additives that prevent the shrinkage of the material. The parquet creak appears when the parquet planks are disconnected from the base (bitumen mastic, concrete screed, screed with plywood sheets), while still friction appears among themselves. For the occurrence of sound, which is called the scree of the parquet, the minimum movements of the parquet bar are sufficient.

In some places, due to the fact that moisture evaporates unevenly from the array of the parquet board, the cavities can accumulate between the base and the parquet itself. It is in such places that the parquet begins to play. Over time, small garbage and dust accumulate there that exacerbate the situation. What other reasons for the creaking of the creak are known except to disconnect parquet boards from the base and accumulation of moisture?

Among the reasons for its occurrence, the following are distinguished: the drying of the parquet, the split of the parquet planks, the breakdown of the groove or crest, the dumping of the screws and nails, the exit of the screws and nails from their nests, the movement of ends and the lag of the boards in relation to each other and the absence of a gap near the walls. Thus, the source of the creak happens: the friction of the bar on the nail, with which it was nailed, the friction of parquet boards between themselves and the flooring under the parquet coating.

In order to avoid the creaking of the parquet of any varieties, there are many different ways. However, for starters, you still have to find the place in which the parquet creaks. To do this, walk around the parquet, while remembering the creak. Designate the points in the center of each creaking area so that you can subsequently pump glue there.

Typically, it is customary to combine the procedure for eliminating the creaking of the parquet with other restoration work, for example, wax or varnish. This will allow the parquet floor to last a long time, even given that the coating could have already been used for ten years.

Dismantling of the parquet

You can radically remove the screens of the parquet floor by completely replacing such a coating. In this case, we have to carry out the full dismantling of parquet strips with the preparation of the base and the next laying of the dismantled parquet, and then carry out a cyclist, polishing and varnish.

Such a solution is possible when all the dies or a large number of them moved away from the base. But this procedure, of course, is associated with a large cost of financial and temporary. But with a local creaking, it is worth using other narrowly focused methods.

Elimination of cracks and potholes

If the parquet does not just creak the parquet, but a loud crack is heard, this indicates a low level of humidity in the room, or the high temperature simply during laying the wood was somewhat damp, and now it has dry. Cracks are recommended to put a thoroughly in the color of the parquet, and cover the potholes with a large piece of putty on wood and apply imitation of wood on top.

You can also use casein adhesive with wood sawdust. After such simple actions, the parquet coating should be well sanded and covered with wooden varnish.

Wider cracks are useless to putty still crack. Therefore, you need to replace the parquet bar. To do this, select the planks that are suitable in color and size from similar wood as the whole parquet.

The restoration of the coating in this case will be as follows. Cross the dry plank with a chisel or a chisel for several pieces. Next, you need to remove them, starting from the middle, and remove the adhesive base. The hollow that remained after removing the Parnis must be carefully cleaned, gently leaving the base.

Prepare a new plank, cut off a comb from it, polish the cut place with caution with a shirt. If necessary, it is necessary to cut off the crests and grooves from neighboring parquets. If several planks are replaced, which are located nearby, then they should be pre -stained with each other to form a single riveting. Previously, you should make sure that a new plank is ideal in place of old planks.

After that, you need to pour a bitumen mastic to 150-170 degrees, or a suitable adhesive composition on the base that is freed from the parquet. Upstairs place the rivet, remove the flowing excess mastic or glue. After that, it is necessary to put some kind of load on a new plank. After the mastic or adhesive base dries, the restored area of \u200b\u200bthe parquet must be fucked, dust is removed and varnished from it.

Repair of the base of the parquet

If the flat floor creaks, then you need to lay plywood sheets on top of the base, which has a thickness of 12 millimeters. It is recommended to lay these sheets to the direction of the main laying of the strips at an angle. It is impossible to say that an unpleasant creak with this option for repairing floors will never resume, but it will allow you to get rid of the creak for a long time.

I would like to offer another option on how to get rid of the creak of parquet. However, in this case, it is necessary to consider what was the base under the parquet. If you put the parquet floor on the bitumen mastic, then in order to eliminate the creak you can do as follows. Take a construction hairdryer and with its help, protopy all the plates of the parquet so that bitumen melts under the parquet. Of course, having chosen this method, the main thing is not to overdo it, and at the end of the melting procedure, the mastic must be tightly pressed.

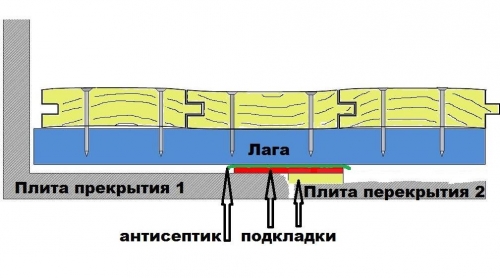

Klinyev's driving

The main reason for the formation of an unpleasant creak of poorly fixed planks to beams or lags. When a person walks on the floor, an unpleasant sound will appear as a result of friction of the planks against each other. To prevent this friction, it is customary to score a wedge between the board and the beam. If you do not have access to the lower part of the floor, the boards need to be fixed to the lags from above.

If the cause of the parquet creak is in the friction of the boards, you can drive into the cracks of the wedge, withstanding a step of 15-20 centimeters. It is important to make sure that the wedge data does not appear at the floor level. For this procedure, you will need: wooden wedges (of course), a hammer and a piece of a metal rod or a dopiliary. There is another technique to eliminate the creak of wooden floors to fall asleep into the cracks between the boards of talc or graphite powder.

Filling with adhesive composition

In order to independently eliminate the creak, you will need such tools and materials: an electric drill, a drill, which has a diameter of 2 millimeters, a medical syringe, a painting tape, a rag, wax crayons, dowels and polyurethane glue.

Fastening with glue looks as follows. Mark the point in the center of the defective places of the parquet that will be removed from each other by 15 centimeters, and stick the masking tape on them. Make the through holes of the planks with a diameter of 2 millimeters in the marked places and pour glue between the parquet and the base of the floor with a syringe through the obtained holes.

Then you need to let the glue dry for an hour, after which you can remove the tape. If suddenly traces of glue fall on the parquet, you can use the solvent designed for mounting foam. Press the parquet coating to the base of the floor with the help of heavy cargo and try not to walk in the repair areas.

In advance, it is worth picking up wax crayons to the color of your parquet and fill the holes a day after the repair work. Complete the work by polishing the parquet floor with the help of a rag.

Using a cement solution

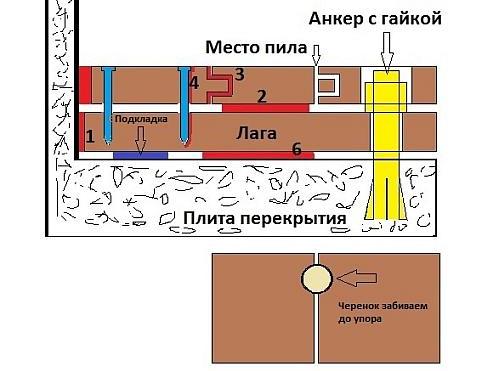

Drill a hole with a diameter of 1.6-2 centimeters in the floor with a perforator, and then pour a cement solution or heated bitumen in the middle in the middle that the creaking bar rests on the solution. In this very hole, it is necessary to score the cork and paint over it so that there are no traces.

The same way as removing the screening of the parquet is effective if the hole is drilled against the lag: in this case, a solution of cement milk from a ratio of 1: 1 (cement - water) is poured into a hole), and a wooden pin is glued into the hole in a day so that it is its end to its end He took out the floor slab. You can remove the rest of the pin by equalizing it with a parquet coating, clean, put a putty and paint over.

You can also drill holes of slightly smaller size than for the first time, and instead of used dowels with a screw, use liquid nails. This allows you to glue the strips to the base in such a way that they stop creaking, but in this case, drilled holes should also be thrown using a tree putty.

Sprinting to the parquet floor

Another method for eliminating the creaking of the parquet floor is the use of a lubricant made on the basis of wax with the addition of a certain amount of special solvent. Such a technique involves the introduction of a substance under the parquet using micro -conformity through douching. In addition, there is another method that is associated with the use of water lubricant, which will also be supplied under the pressure under the parquet.

Filling mounting foam

As a rule, the underground space has a height of approximately 9 centimeters, so you can use the installation foam after expanding an unpleasant creaking of the boards after expanding it to the floor covering. However, foam can be remembered during operation, and then collapse, which will provoke the renewal of the creak. Thus, this is a fairly costly way to remove the creak of parquet, and not too effective.

The use of metal anchors

If a concrete plate is based on the parquet floor, you can use metal anchors, which are exclusively fastened manually. First, it is customary to drill a small hole, install the metal shell and screw the spiral of an anchor. This method, of course, is effective for eliminating the creak of the parquet floor, however, costly, because for repair it may take up to 200 anchors at a price of 10-15 rubles per each.

Bringing with self -tapping screws

A fairly effective method of combating the screening of the parquet, which occurs directly in the places of contact of the sex board and lag, is the broach of self -tapping screws. The most problematic in this technique is the finding of Laga.

You must determine whether any communications undergo a defective floorboard. The whole procedure is a twisting 2-3 screws into the board. Using a drill, the hole on one side is drilled into the beam or lag through the board. It is necessary to drive a nail into it or, which is much better, screw the screws of the corresponding size. At the same time, pay attention to the hat or a screw need to be drowned in the board.

Tingle -ups of the parquet floor

If you have not yet decided what to do when the parquet creaks, try to pay attention to the next procedure. Terling, although it is a rather time -consuming process of eliminating the defect, but it acts at the same time cheap. This method implies the rechecking of the method of redemption of the state of the lag and the entire floorboard. If defects in the board are detected, you need to correct or replace.

The effectiveness of the method lies in the replacement of all nails with self -tapping screws, this procedure is called tightening. Self -tapping screws are deprived of the main drawback that is inherent in the nails, the creak in the areas of their connection with the tree.

A nail in wood will be held by its split layers, tightly covering the metal. But over time, the metal due to the weakening of the grip begins to rust and decrease in diameter. As a result, backlash is formed and as a result a sound appears. That's why the parquet creaks. Thus, the replacement of nails with self -tapping screws successfully solves all the problems of the School of the parquet floor.

After completing the data of the parking manipulations, you need to sandy plots and cover them with wax or varnish, which are suitable for the color of the rest of the parquet coating.

All of the listed methods to eliminate the creaking of the parquet floor are quite simple, but if all your attempts are unsuccessful, and the parquet coating will continue to creak, then you will only have two options: to call a special company that can help get rid of the creaking of the parquet, but this is you It will cost a lot, or choose the second option to dismantle the old parquet floor and lay the bar again.