The selection of a heating system for a private house is a rather complicated and responsible process ...

|

|

Brick classic of private housing construction. He has established himself as durable ... |

Among the variety of materials for insulation of the home, choose the right option can be ... |

How to make an even floor

Smooth floors in the house are not just an indicator of a beautiful and high -quality repair. A perfectly flat floor is 100% functional use of both furniture, doors, and flooring themselves. Indeed, in the presence of even, in one level throughout the apartment, sexes, you can not think about how to join all kinds of flooring to one level, without steps and changes. With properly organized even floors, you can easily and easily open and close the interior doors, do not correct and not to repair the dumbfounds due to incorrect slopes and irregularities of the floor surface, constantly opening cabinet doors and drawers.

Content:

- What is an even floor for

- How to make an even floor: Types of screed

- How to make an even floor: the views of the flooring

- A smooth floor with your own hands video video video video

What is an even floor for

Paul repair is the first and one of the most important stages of any repair.

Flat floor, subsequently this is:

quickly, qualitatively and beautifully laid and properly functioning flooring:

- if the floor is uneven, then the laminate diverges at the seams and rises the house and completely loses its aesthetic appearance;

- linoleum lies in waves and only emphasizes the irregularities of the floor, and subsequently, bubbles and quickly wipes and breaks;

- boards of a wooden floor creak, bend;

- laying ceramic tiles on the floor occurs faster and, although not with less financial costs, because It requires a screed device, tile costs, although it will be required several times less than when laying on layers, but quality will increase significantly. Ceramic tiles laid on an even floor will not float, as when laying on layers, with uneven black flooring, during subsequent operation, will not be removable due to the presence of voids and reduction of adhesion, due to a more viscous tile glue.

- no steps and differences when connecting various kinds of flooring in the framework of one apartment: everything lies with one beautiful, functional and safe carpet, which is much easier to clean and not be afraid to stumble, forgetting about the presence of an inappropriate and unplanned step.

Beautiful, quickly and correctly installed and functioning interior doors:

- in the case of uneven floors, the interior doors set in terms of the level, visually, do not seem, because The gaps between the door and the floor can be of different levels or even waves;

- the interior doors installed by the non -competent and experienced master, in an apartment with uneven floors, may not be closed or, conversely, they will not be fully filled with, violating the integrity and beauty of the entire door.

Furniture on even floors not only costs better, but also lasts longer:

- they are installed on the uneven floors of the cabinet, chests of drawers, kitchens and other furniture, even despite the presence of adjustable legs, are uneven, and sometimes even very dangerous due to the shakiness of the entire structure;

- doors, drawers (closers), if the furniture is on an uneven surface, can spontaneously open. And this, again, is the possibility of injuries, a violation of the general aesthetic type of furniture, as well as the rapid wear of the closers.

Therefore, people who made in their apartment or house a flat floor reviews about its operation, as well as the quality of the entire repair, leave only positive

How to make an even floor: Types of screed

An even floor price for which is a significant percentage of their estimates of the entire repair of the premises a prerequisite for any quality repair.

You can align the floor in the following ways and types of screed:

- Dry screed: The type of screed on the beacons, as the main material of which are dry bulk materials of expanded clay, expanded clay, slag. On top of the screed material, a black base of gypsum-fibrous plates, plywood, which do not screed, is laid, i.e. The floor remains even.

Pros of dry screed: It is performed quickly, with sufficiently minimal financial costs, does not weight the floor design, so it can reach the thickness of the layer up to 20 cm. In addition, the dry screed is a good insulation and insulator of the floor.

- Half -smoked screed: The type of screed on the beacons, the main material of the screed itself is a cement-sand mixture with a minimum addition of water. Such a screed is made by a ramblem that requires skill, patience and time costs and, preferably, a special tool. The layer of the screed itself should be at least 5 cm or more. That is why, it is more often used on an industrial scale in the organization of the draft floor.

Pros of half -dry screed: Due to the small amount of liquid in the mixture, to flood the neighbors from below, if you align with its help in the apartment, it is practically impossible.

- The cement screed of the floor: The type of screed on beacons, the main material of which is ready-made cement mixtures or homemade cement-sand mixtures. The minimum layer of the cement screed from 1.5 cm. Although, with such a thickness of the screed for aligning the floor, self-powerful mixtures are often used, and it is advisable to use the cement screed with a thickness of the required layer of 3-10 cm. The cement screed is a monolith that is quite a suffering of the floor structure, therefore Applying it on loggias, balconies, in houses with wooden ceilings is extremely not desirable. The cement screed dries, reaching the full readiness of 28 days, which is long enough, because All this time, you can not start laying the finished flooring of the floor.

The pluses of cement screed: Envals the irregularities from the floor with significant changes in height, durable, suitable for organizing underfloor heating.

- Self -burning floor screed: The type of floor screed according to lighthouses, as material, purchased self -combined mixtures are used on a gypsum basis. It levels irregularities from a few millimeters to 5 cm. But, due to decent value, it is used for alignment, minimal changes in heights that remained after aligning the floor with a half-dry or cement screed, making the floor rather not even, but smooth. When pouring the floor, it dries quickly enough, so it requires skills and experience. Due to its fragility, walking on the finished flooring is not desirable due to its possible painting, requires a quick organization of the final sex. For this reason, a self -burning screed is organized immediately before laying the final floor.

The pluses of a self -burning screed: It dries quickly, makes the floors not only perfectly even, but also perfectly smooth.

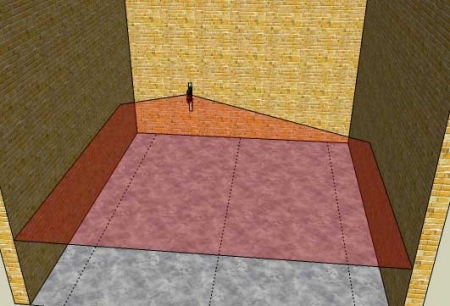

- Paul on adjustable lags:a special type of floor used to organize an even wooden floor. Lags are set in level, to some extent, they themselves are lighthouses and the carrying floor design, at the same time.

The pluses of the floor on adjustable lags: Ideal for aligning wooden floors, it is performed quickly and clean enough, does not weight the floor structure, allowing you to align the differences and raise the floor level by 5 25 cm.

In the process of organizing any kind of screed or a method of leveling the floor, you need to know how to check the flat floor. To do this, it is best to use a high -quality laser level, because Bubble levels require constant calibration, because The error of such levels, in the process of active operation, increases.

How to make an even floor: the views of the flooring

According to the results of the repair, we see only a finishing, finish flooring. And it, as well as the black screed, should be even. To do this, take into account the following:

- Laminate It is best to put on a solid even base: dry, cement, self -combusive screed.

- for laying ceramic tiles You also need a strong base, therefore, a cement screed is best for its laying. You can also lay tiles on a dry screed, but only with the help of special tile adhesives

- Linoleum It will be even, long and qualitatively lying on a flat floor, made using a cement screed and additionally aligned and smoothed with self -combat mixtures. But its laying on the floors on adjustable lags, as well as on a dry screed, is not desirable: the floor on a wooden or gypsum-fibrous basis under linoleum begins to condenses, and then mold and rot.

- boardwalk (wooden) floor It is impossible to lay smoothly and correctly without organizing adjustable lags, with the help of which wooden floors become even, ventilated, which means they will last a long time. In the case of laying the floor boards on a cement, albeit even, screed, the boards will be almost impossible to fix, with a 99% guarantee, it will lead them from moisture from the screed itself, the absence of a ventilation clearance between the screed and the wooden flooring of the floor.

A smooth floor with your own hands

There are general principles of screeding to align the floor:

- Clean the surface of the floor, primer it.

- organize waterproofing with special liquid mastics or film (in the case of a dry screed).

- We set and install the beacons.

- Pour the mixture of the screed, tighten it with the rule according to the beacons (cement screed, half -dry and dry screed), defend the mixture with a special spatula and roller (a self -burning screed).

- We are waiting for drying.

Before laying the final floor, we clean the screed and again primer it. After the soil dries, the screed and the black flat floor are ready.

About how to make a smooth floor of the video will tell more clearly:

So the floor is aligned with the help of self -enforcing mixtures:

Groove the floor with a dry screed

And filling the cement screed looks like this

You can see how to make a wooden floor even here: