Today, in the construction of country houses, someone uses modern materials and ...

|

|

The basement in a private house is a multifunctional room and important ... |

In the process of finishing measures, the need for decoration often arises ... |

Thermal insulation materials: types and properties

Among the variety of materials for insulation of the home, choosing the right option is completely difficult. Each of them is often shared by several species with the unique characteristics inherent in it. A comparative analysis can take a long time, so the idea of \u200b\u200bthe general properties of a particular insulation will help if you do not finally decide on the choice, then at least tell you which direction you should move in. The article will talk about building thermal insulation materials.

Content:

Thermal insulation materials types and properties

Styrofoam

One of the most popular thermal insulation materials for walls is polystyrene. It belongs to the category of inexpensive insulation and firmly occupies a leading position in it. I must say that this is fully justified. Its effectiveness is confirmed by a sufficient number of buildings of both residential and industrial purposes.

So, among its positive characteristics, it stands out especially:

- price. Production costs are minimal. Material consumption (compared to popular mineral wool) is one and a half times less;

- simplicity of installation. Foam will not require the structure of cores and guides. It is mounted on the wall by gluing;

- universality. The correctly selected type of insulation will create a reliable heat -shielding barrier of the floor, facade, walls, ceilings between floors, roof, ceiling.

He effectively copes with the protection of residents of frame houses from the cold, is laid inside the hollow brick walls.

The indicators, depending on the classification, are most conveniently considered in the table. Separation is based on an indicator such as density.

| Characteristics | Foam brands | Notes | |||

| PSB with 50 | PSB with 35 | PSB from 25 | PSB with 15 | ||

| Density (kg/m) | 35 | 25 | 15 | 8 | The types of PS 4, PS 1 have increased density |

| Personality on a break (MPa) | 0,30 | 0,25 | 0,018 | 0,06 | |

| Compression resistance (MPa) | 0,16 | 0,16 | 0,08 | 0,04 | |

| Ability to absorb moisture (%) | 1 | 2 | 3 | 4 | With a complete immersion for a period of 24 hours |

| Thermal conductivity (W/MK) | 0,041 | 0,037 | 0,039 | 0,043 | |

| Time of self -extinguishing (sec.) / Class of combustibility |

3

G 3 |

1

G 3 |

1

G 3 |

4

G 3 |

Provided that there is no direct contact with the open flame Normally combustible |

| Vapor permeability coefficient (mg) | 0,05 | 0,05 | 0,05 | 0,05 | |

All described species are permissible at a temperature of 60 to + 80C.

PS class material is made using pressing, which gives it an increased density (from 100 to 600 kg/m). It is successfully used as a heater of cement floors and where significant loads are assumed on the base. The remaining technical characteristics as a whole coincide with the above data for other types of foam.

Of course, for some numbers and coefficients, foam has discrepancies, for example, with more modern foamed polystyrene or foam, but the difference is so insignificant that it will be absolutely not noticeable to the residents of the house.

Therefore, the strengths of the foam are rightfully considered:

- a small coefficient of thermal conductivity, which allows you to maintain heat in buildings from any type of material from brick to gas silicate blocks;

- the structure of the cells in the foam is closed, so it extremely poorly absorbs the liquid. For insulation, this is an extremely important indicator, because when a water is gained, it loses its heat -saving properties. Basements, basement floors with direct contact (or threat of one) with groundwater are successfully insulated with foam;

- noise insulation goes as a pleasant addition to the function of reducing heat loss. The air, hidden in sealed cells of the material, successfully extinguishes even the most intense sound waves transmitted in space. In order to create a barrier for shock noise, one polystyrene can’t do;

- resistance to the effects of alcohols, alkaline and saline solutions, water -based colors in this material is developed at a high level. In addition, it is not chosen as a decent habitat of fungi and mold. It is worth noting that rodents on the contrary, they love foam very much and often prefer to settle in it. The fight against them by any available means will not allow uninvited neighbors to spoil the insulation;

- environmental Safety. The foam does not distinguish any harmful substances. The modern standard of this insulation is full compliance with sanitary standards;

- as additional protection against combustion, at the stage of production, antipypees are added to the main ingredients, designed to increase fireproof foam. And if there is no direct contact with fire, then it himself fades in a short period of time. But, in fairness, it is worth noting that it is nevertheless considered a combustible material;

- losses of the above properties will not happen, even if there will be short -term contact with the heat source to 110, but the prolonged exposure to more than 80 C will entail deformation and loss of characteristics.

The described temperature regimes belong to the category of anomalies, and are not found with a regular frequency, so it is impractical to make them the main motive for refusing the use of foam.

Penoplex plates

Foamed polystyrene, polystyrene polystyrene, extrusion polystyrene all this name of the same material sold in construction stores as a foam insulation. He is a relative of the usual foam for all, while considering the material standing on the step above.

The main difference begins at the stage of production, where extrusion installations are used. As a result, the shallow -mesh structure of the material has greater strength than its fellow foam. It is also distinguished by excellent hydrophobic indicators. In the scarlet cells, air is securely sealed that does not allow warm air to leave the room, but to cold, on the contrary, to penetrate inside.

The main properties of thermal insulation material:

- strength. It is achieved due to a unique homogeneous structure. At large loads, the plate does not deform, distributing high -quality weight, but at the same time it is easily cut by a construction knife into pieces of the desired size;

- environmental friendliness The material is proven by multiple research, it is racks to the formation of fungus and mold, rodents do not like it. Some types of organic solvents are able to soften the foam and disrupt the shape and structure of the plate. Therefore, when working with this insulation, it is recommended to avoid contact with such liquids;

- low vapor permeability implies a clear observance of installation technology and recommendations for use, so as not to create a greenhouse effect in the room;

- lifetime In polystomplex plates, it is at least 50 years. This is a guaranteed period of time during which the material will have its original characteristics;

- coefficient of thermal conductivity The main indicator for which foamed polystyrene is considered a good insulation. The low values \u200b\u200bof this indicator indicate that the house will be reliably protected from heat loss.

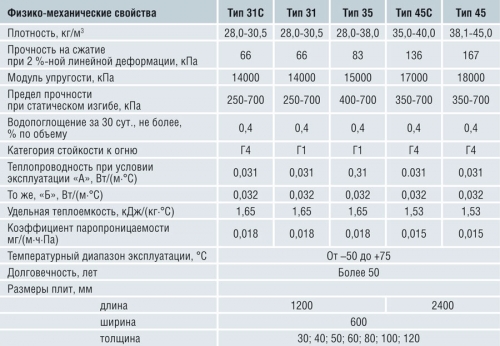

- Types of thermal insulation material of the foam and areas of their use are quite diverse (in brackets, the modern names of the material used earlier are given).

- The insulation of the facades (Penoplex 31 or wall). It is made with the addition of antipyrene. It is well applicable for basements, internal and external walls, partitions, facades. Its density is 25-32 kg/m, compression strength of 0.20 MPa.

- Foundation ( Foamine 35 Without additives for fire resistance or foundation). In addition to the name that follows from the name, this type is widely used in the arrangement of basements, a blind area and basements. The density is expressed in indicators of 29-33 kg/m, and the strength for compression is 0.27 MPa.

- Roofs. ( Penoplex 35 or roof). The pitched or flat roof of any type can be insulated using this type of polystyrene. It is quite dense (28 33 kg/m) to create an operated roof.

- Country cottages, saunas, houses. ( Penoplex 31 C or comfort). Universal insulation. Houses, roofs, walls and basements in small private buildings are the scope of its application. Density indicators of 25-35 kg/m, strength of 0.20 MPa.

Foamed polystyrene occupies decent positions in popularity thanks to good operational indicators.

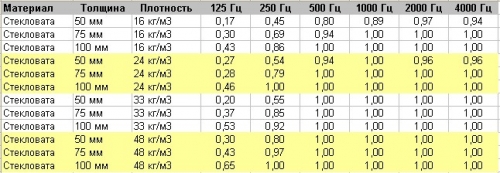

Thermal insulation material of the glass wool

The insulation known to more than one generation of builders today has undergone some modifications. But, in fact, he remained the same material from molten glass mass. Sand and recyclables of glass origin at a temperature of more than 1,400 C are stretched into thin fibers, which are formed in small bundles (with the participation of binding components), and then heated and pressed into a product resembling felt. The glass wool consumers gets in mats or rolls and is intended for insulation of both horizontal and vertical surfaces.

It belongs to the category of mineral materials and is still produced in large volumes, and this indicates the demand and the presence of a significant number of positive characteristics that should be acquainted a little closer.

- Fragility is more likely to significant drawbacks. So that the glass wool does not fly to the components during operation, the mats and the canvases are stitched. But from small particles flying in all directions, no reinforcement will save. Therefore, the equipment for a person who works with a glassy person should be serious: clothes that are well-closing the body, a dispenser mask, glasses and gloves.

- The thermal conductivity of the material is low, but compared with other materials of a similar purpose, it is considered high.

- The cost of glass wool leaves it competitive. Due to accessibility, it is in demand, especially since it really reduces heat loss.

- Convenience of transportation and application. Rolls and mats weigh with the material are weigh and packaging are compact enough to bring the entire volume for insulation of the house at once. It is not difficult to lay her too. The only nuance in the insulation of vertical bases, it can fall out of the frame, because it is flexible quite flexible and poorly. The problem is solved by the construction of the guides with a lower distance than the width of the mat. Cutting the material is easy.

- Safety. Certain inconvenience and harm to the health of glass wool can cause only at the installation stage. But with the correct organization of labor, troubles will not happen. And after the material is laid in the base and closed with drywall, chipboard or other finishing materials, he will not do any harm to a person.

- Lack of rodents. Due to the specifics of the material of the mouse and rats, this insulation does not choose this insulation to create cozy Ninge in it.

- Glaud is referred to as non -combustible materials.

- Sound insulation when using it is also provided.

Thus, using glass wool is most convenient for flooring and floors. You can show dexterity when decorating walls. The main disadvantage remains harmful dust, inevitable when cutting and rolling, but for some consumers a small cost more than blocks this minus.

Slag

Continuing a conversation about mineral insulation, it is worth mentioning the slag. It is made from domain slag. Since this is a kind of production of production (when smelting cast iron in domain furnaces remains a vitreous mass), the cost of its manufacture is small, and therefore the price of the finished insulation is quite affordable.

The slag is capable of blocking heat well in the premises, but it has enough disadvantages and restrictions on use to negate a low cost and good thermal insulation.

- So, the slag is afraid of moisture. Apply it in bathrooms or facades unjustifiably. At the same time, it is able to oxidize various metal details and structures with which it enters into direct and prolonged contact.

- To top it all of this, it pricks and requires the use of special protection during operation. Against its background, glass wool looks much more attractive, so slag in modern construction is extremely rare.

Mineral thermal insulation material

Basalt, stone, mineral wool, Rockwool under these names most often hides the same material.

- Its fibers are not inferior in size to slag, but they do not cause discomfort during installation. Safety in use is one of the first distinctive properties of this insulation from the category of minerals.

- The thermal conductivity of this material is calculated from 0.077 to 0.12 W/meter-Kelvin. The basalt cotton wool is called the best in all respects. It does not contain additional impurities harmful to the health, can withstand a long -term exposure to extremely high and low temperatures, convenient in use.

- And ordinary stone and basalt cotton wool are not amenable to combustion. The fibers will only melt, compose, but they will not allow the further spread of fire.

- Any buildings can be insulated with stone wool, both when building from scratch and for quite a long time in operation. The basalt insulation does not violate the microcirculation of air, which means that it can be used in those buildings where the supply ventilation does not function properly.

- Certain inconveniences for some builders may arise with the need to build a false wall. Without it, it will not work to lay the insulation. But in fact, the construction technology is very simple, there is not so much space is eaten by space.

- The material is environmentally friendly, well suited for insulation of wooden houses. It is strictly forbidden to get wet, so the waterproofing layer should be fulfilled according to all the requirements.

- The recommended thickness of the heat-insulating material for the middle strip is 15-20 cm, in the southern regions there are enough 10 cm of the layer.

- Stone cotton wool absorbs sound well. This is achieved due to the fact that its fibers are randomly located, and air accumulates between them in large quantities. Such a structure perfectly extinguishes sounds.

- The described insulation is chemically passive. Even if it is tightly in contact with the metal surface, then traces of corrosion will not appear on it. Rotting and infection with fungi or mold of stone cotton wool is also not characteristic. The material does not attract rodents and other pests.

- The only really negative point of its application is a fairly large cost.

Characteristics of thermal insulation materials

Ecowata

Ecowata is a heater produced from waste paper and various residues from the manufacture of paper and cardboard. In addition to these components, antiseptics are added to the composition of antiseptics. It is extremely necessary, because judging by the fact that 80% of the material is flammable cellulose, the level of combustibility of such a heat -insulating product is quite high.

Ecowata is not without flaws.

- One of them is her natural decrease in volume. It is able to settle, losing up to 20% of the initial laying level. To prevent this, Ecowatus is used with excess. The creation of the reserve will make up for the volume that decreases during operation.

- The insulation is quite well absorbed to moisture. This directly affects the ability to maintain heat. The material needs the opportunity to give moisture to the external environment, so the thermal insulation layer should be ventilated.

- In order to carry out installation, special equipment will be required.It is a device that with uniform density pumps the insulation, excluding its further shrinkage. In this regard, the help of hired specialists with experience with this type of insulation will be required. The wet method of application, which involves such difficulties, also opens the prospect of a break in construction work, while Ecowata will dry (from two to three days).

Of course, there is a method of dry insulation, but a better result is still in the above installation option. If horizontal surfaces can be insulated without using special equipment, then creating a layer of thermal insulation on the walls, it will be difficult to do without it. There is a risk of uneven shrinkage of the material and the creation of unsold cavities.

- Features of the material itself do not imply its independent (frameless) useWhen insulation is carried out using a screed. Unlike polystyrene foam plates, Ecowata does not have sufficient strength for this.

- It will be necessary to observe significant precautions when installing it:

- carry out work away from open fire;

- to exclude the contact of the material with any heat source that can lead to fluid. That is, when the surface is warming next to the fireplace or chimney, they will need to be separated from the insulation with basalt mats with foil coating or asbestos cement fences.

It would seem that against the background of such difficulties, one can immediately abandon the use of ecowan, but its positive aspects for someone can become a powerful incentive for its use.

- The material (even when accounting for a shrinkage) is quite economical.

- Such insulation is environmentally friendly and safe for health. An exception can be a material where boric acid or ammonium sulfates were used as antipyrene. In this case, Ecowatus will distinguish a sharp and unpleasant odor.

- It is a seamless insulation that does not have a cold bridge. And this means that heat loss in the winter will be reduced to a minimum.

- The material is inexpensive, allowing you to get good thermal insulation.

As a soundproofing material, Ecowata can compete with many materials described above.

Polyurethane foam (PPU)

Polyester with the addition of water, emulsifiers and active reagents, when exposed to the catalyst, form a substance with all the signs and indicators of good heat -insulating material.

Polyuertan foam has the following characteristics:

- low thermal conductivity: 0.019 0.028 W/meter-Kelvin;

- it is applied by spraying, creating a continuous coating without cold bridges;

- the light weight of frozen foam does not provide pressure on the structure;

- the simplicity of use without any fasteners makes it possible to insulate the surface with any configuration;

- a long service life, which includes resistance to frost and heat, any atmospheric precipitation, rotting;

- safety for humans and the environment;

- it does not destroy the metal elements of the structure, but on the contrary, creates anti -corrosion protection for them.

Walls, floor and ceiling its use is available everywhere. PPU will stay on glass, wood, concrete, brick, metal and even on the painted surface. The only thing that is worth protecting polyurethane foam is from exposure to direct rays of light.

Types of thermal insulation materials

Reflex heat -insulating materials

There is a group of heat -saving materials working on the principle of reflectors. They function quite simply: first they absorb, and then give back the received heat.

- The surface of such heaters is able to reflect more than 97% of the heat that has reached their surface. This is available for even one or pairs of layers of polished aluminum.

- It does not contain impurities, but is applied to a layer of foamed polyethylene for the convenience of use.

- A thin -looking material is able to surprise with its capabilities. One or two -centimeter layer of the reflective insulation creates an effect comparable using a fiber heat of heat from 10 to 27 cm thick. Among the most popular materials in this category can be called Ecofol, Penophol, Poriplex, Armofol.

- In addition to heat and sound insulation, such insulation create vapor barrier protection (and are often used in this capacity).

The conclusion is quite simple: the ideal insulation does not exist. Depending on the means, pursued goals and personal preferences (including convenience in work), everyone will be able to choose the best material for creating a warm and truly cozy house. But it must be remembered that when using each of the above insulation on the roof, mandatory waterproofing of thermal insulation material is required.

Here is polyurethane foam now

Here foam polyurethane is now very popular http: //uzti.su/stati/penopoliuretan-sovremennyj-teploisolyacionnyj-war ... because In terms of its properties, he crossed the glass wool and ecovata far. Thanks to the extremely low thermal conductivity of PPUs, it is very actively used where the task is to maintain heat.