An excellent type of street flooring is a terrace board. She differs ...

|

|

To make a docking of two linoleum paintings invisible and durable is used ... |

At least once in a life, every person came across a buzzing at night annoying ... |

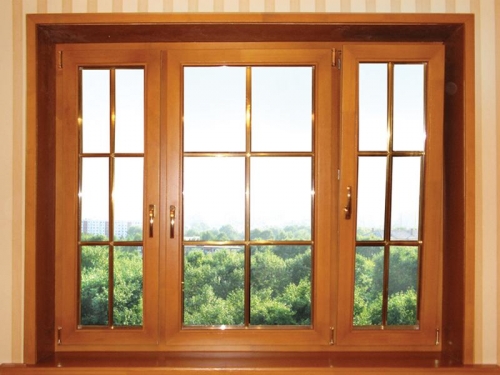

Installing wooden windows with your own hands

Some time ago, the appearance of plastic windows in the construction market made a real splash. Still, because they overshadowed wooden in almost all indicators. People no longer had to paint window frames every year to bring them in proper form, and insulate them with the onset of the winter season. Double and triple double -glazed windows became a reliable barrier to street noise and drafts, and the care of plastic frames was not difficult.

Content

- Wooden windows return their positions

- Should I independently install wooden windows?

- Where is it better to start

- How to get rid of the distortions of the window opening?

- Put the window in place correctly

- There should not be in a good window of cracks

- Window sill and tolls can also be installed on your own

- Basic installation rules

Wooden windows return their positions

But still not so cloudless. Some manufacturers use poor -quality plastic to reduce their own costs and the cost of their products, which allocates a small amount of poisonous substances, but still having a negative effect on people, animals and even plants.

That is why the installation of wooden windows gradually returns the lost popularity. People, surrounded by many artificially created things that are not always safe for health, give more and more preference to natural materials. Modern technologies allow you to make wooden windows that practically do not differ in other characteristics from plastic ones. In wooden frames, double -glazed windows are now installed that reliably protect the room from cold and noise, modern compounds perfectly protect the tree from decay or wetting, leading to swelling and deformation of the frame, and painting materials are distinguished by durability and resistance to climatic changes.

Should I independently install wooden windows?

Do not forget that in many respects the excellent quality of the window (moreover, this applies not only to wooden, but also any others) depends on how accurately the technology for installing wooden windows is observed. Even a small indentation from the rules can cause a quick failure or negate the expected effectiveness.

In principle, the installation of wooden windows with your own hands does not differ in any complexity, therefore, if you need to put ready-made frames in the opening, then if you have minimal building skills with this work, you can cope yourself. But it should be borne in mind that in this case no one except yourself guarantees good quality of work, and if something suddenly goes wrong, then there will be only any work to correct the shortcomings at your own expense.

Where is it better to start

Of course, it is necessary to start installing wooden windows from the manufacturer with the preparation of the window opening. It should be an even rectangle, without distortions, large potholes, cracks and other defects. If the room is still installed in the room, dismantle it and carefully clean all the surfaces of the opening from construction waste, dirt and dust.

How to get rid of the distortions of the window opening?

The next stage should be taken with all seriousness, because these are measurements of the window opening. All measurements are made both inside and outside, and in three places: along the edges and in the middle of opposite sides. If the opening is significantly skewed, and it is not possible to straighten it, then it is necessary to increase the size of the window so that they exceed the value of the maximum level of the external opening by at least 10-20 mm in height and by 25-40 mm in width. This can be done by installing additional profiles on the window. Such a measure will avoid the appearance of cracks between the frame and the opening in places of strong distortion. There is another way to get rid of this frequent defect is an increase in the dimensions of the window box, but it is better to entrust it to professionals who can do it right and accurately.

Ideally, the dimensions of the new window should be less than the internal size of the window opening for 25-30 mm. Such a margin is necessary for the placement of insulating materials. In addition, the presence of a window sill should also be taken into account, so in the lower part of the opening it is better to leave 50-60 mm.

Put the window in place correctly

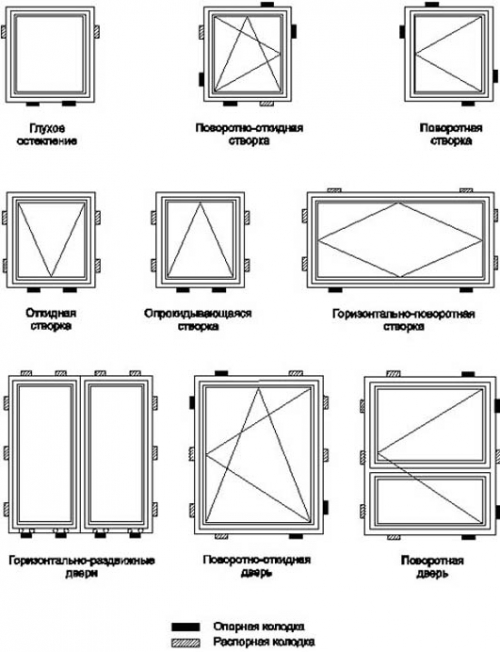

You can insert the finished design into the opening in three ways, and the cost of installing wooden windows in any case will be approximately the same:

- Using mounting pads.

- On mounting plates.

- In a through way.

The frame should be installed on bars, the height of which is equal to the height of the window sill.

Wooden windows are best installed closer to the outside. This will save most of the opening of warm.

We fasten the window in a perfectly even opening

The first method is not suitable for every window. The fact is that for fastening with blocks an absolutely even opening is needed, and this is not always possible to achieve this. If the opening meets the requirements, then first it is covered with a waterproofing layer, and mounting pads parallel to the window frame are already attached to this layer. After inserting the box, the vertical and horizontal are leveled to the level using wedges.

Fix the window with mounting plates

In the second case, special mounting plates are attached from the sides and on top of the frame, while they should be located at a distance of 250 mm from the edge. First, the plate is installed so that it looks into the room, and then, bending it off, attached to the inside of the window opening with the help of self -tapping screws, but without tightening them.

If the dimensions of the windows exceed one and a half meters, then you will need to install one or two additional plate.

After installation in this way, the window in the same way, as in the previous case, is adjusted by wedges, is aligned and finally fixed with self -tapping screws.

The most reliable way to fasten the window frame

In this case, you will have to face the need to remove glasses or double -glazed windows. This is done very simply: first, graduates are carefully separated, and then glasses are removed. On the lateral and upper inner surfaces of the frame, holes are planned and drilled. Now the frame can be installed in place, but the holes in the walls can be drilled only after it is completely aligned in level.

We screw the screws, but so that they can be easily moved, since first you need to adjust the position of the frame both horizontally and vertically. This is done in the same way as in the two previous cases, that is, with the help of wedges.

There should not be in a good window of cracks

In order to prevent the penetration of cold air and moisture into the room, it is necessary to eliminate all the cracks between the window box and the opening. The most common way to get rid of the cracks is damping with mounting foam. With a lack of experience, this is almost impossible to do this qualitatively. Too many foam can deform the frame and cause a skew of the entire window. Of course, you can use wooden spacers that prevent deformation, but it is better not to risk and purchase any other insulating material.

Window sill and tolls can also be installed on your own

When installing the windowsill, it must be slightly brought under the frame, but at the same time it should protrude 45-50 mm relative to the wall. After that, it needs to be leveled by level and adjusted as tightly as possible to the frame. Now we take off the windowsill, and the whole space under the frame is disconnected with mounting foam. After installing the window sill in place, the space under it is filled with foam.

In order not to move the windowsill from the place when damping, it is recommended to put a small load on it, for example, several containers of water.

The ebbs are installed even easier. First, they are cut off in size with a margin of 60 mm (30 mm each for each direction). Then the tide is first screwed with self -tapping screws to the lower part of the frame, and then pointedly fixed from the inside with mounting foam.

Basic installation rules

So, we repeat the basic rules for installing wooden windows, the observance of which will allow you to independently and reliably install a wooden window:

- High -quality surface preparation.

- The corners should be 90, and the difference in the length of the diagonals should not exceed 10 mm.

- The gaps are required: from below 50-60 mm, on the sides of 15-20 mm.

- It is better to install a frame in the second quarter of the window, counting on the outside.

And in conclusion, so that the whole process is clear, we bring to your attention a small video installation of wooden windows, in which all the main stages are correctly examined.