Ready -made greenhouses from ideal aluminum profiles and cellular polycarbonate, undoubtedly ...

|

|

Repair of a removable formwork is an important process that must be carried out regularly ... |

To make a docking of two linoleum paintings invisible and durable is used ... |

DIY wooden platbands

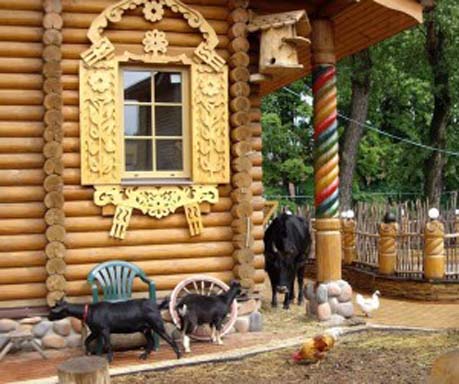

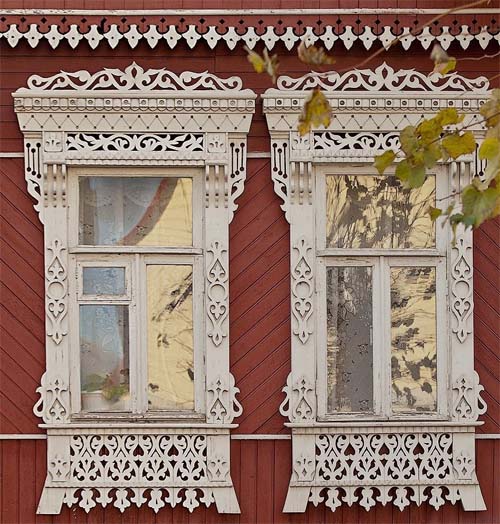

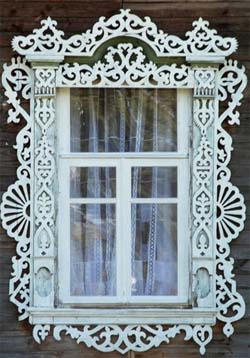

After installing windows in a wooden house, there is always a gap between the wall and the window frame. The easiest way to eliminate it is to install platbands. In addition to functionality, they play the role of a decorative element that decorates the facade of the house and makes its appearance unique and completed. One of the most beautiful are carved wood plates.

Content:

- Types of wood platforms

- Wood for the manufacture of platbands

- Tools necessary for the manufacture of carved platbands

- Basic rules for the manufacture of the platband

- Preparation for work

- Installation of platbands on the windows

Types of wood platforms

To date, platbands exist not only wooden, but also wood-fibrous, plastic and even ceramic. But the most popular material for their manufacture is still wood. This is due to its environmental friendliness, affordable price and high aesthetic qualities. In addition, wood can be restored, thereby extending the service life.

Smooth or profiled from whole bars. If in the future the platbands are painted, then coniferous rocks are used, most often pine. In the manufacture of valuable wood, they are covered with varnish. As fasteners are nails, screws or liquid nails.

With curly carvings of whole bars.Mostly made of valuable wood of wood and covered with varnish. They can be attached to both screws and simple and liquid nails.

Smooth or profiled from glued bars. They can already be made with a finish made of laminating film or veneer of expensive wood, which allows to exclude the need for additional finish processing. But, also without decoration, designed for painting.

Stylized for a certain style.The most expensive type of platbands that are made exclusively on order.

In addition, they are divided in appearance into flat, shaped and curly platbands.

Flat.The cheapest and simplest type of platbands. But it has a low aesthetic value.

Shaped. Most often they have a convex surface, which has cuts, protrusions or grooves. They are more expensive than simple flat ones. This is due to the production technology for which it is necessary to use special equipment.

The platbands are wooden figured. They are elements of decor and give the house individuality. They are produced on special machines equipped with vertical mills. In this case, the desired drawing is programmed, and the machine automatically produces surface milling. But, despite the latest technologies, the capabilities of such equipment are limited.

And only the master can make an openwork relief. The price of handmade wooden platband will depend on the complexity of the ornament and wood of wood.

But the main difference between manual milling and machine is that the machine does not make an through thread, but only applies a pattern to a certain depth of wood.

Wood for the manufacture of platbands

If it is necessary to make a flat or shaped platband, then a simple pine is used. For the manufacture of carved, soft wood, such as linden is required. It can easily be processed even with manual tools and is easily polished. But because of its high hygroscopicity, it needs a high-quality finish coating. This implies the application of several layers of paintwork.

In regions where significant temperatures are possible, as well as high humidity or vice versa, a dry climate, wooden platbands from dense and solid wood are made. These include birch and oak, which are extremely difficult to process, but they will last more than one decade. Therefore, platbands from wood of wood are most often made on milling machines.

The only disadvantage of all types of wooden platbands is high hygroscopicity, which over time leads to their cracking and drying. This can be avoided periodically by updating the protective paintwork.

Tools necessary for the manufacture of carved platbands

The through thread is the most affordable way of decorating platbands for non -professionals. It will not require special skills, one must only have patience, zeal and a sense of beautiful.

A large number of firms are offered, various platbands manufactured by industrialized. But it is much more pleasant to make him himself. Manual milling machines, ordinary or electric jigsaws, various types of drills, chisels and hacksaws can be used as a tool.

Basic rules for the manufacture of the platband

When making wooden platbands with their own hands, it is important to consider that after installation they should not interfere with the normal opening of the windows. Therefore, the internal sizes of the platband are made larger than the window frame by 2-3 cm.

The upper part of the platband is called a kokoshnik, if necessary, it can be increased by fastening the parts with spikes. The lower part is called the towels and is attached from the wall of the wall for water flow. It also has a thread that matches the style of a kokoshnik thread, but the bar for it should be 1 cm of the thickness of the upper bar.

Before installing the platband, it is necessary to nail the rails around the perimeter of the entire window - this will completely close all the irregularities of the wall. The joints, at the same time, should be carefully fitted.

All platbands are performed in a single style.

Preparation for work

For the manufacture of a carved platform made of wood, you should stop your choice on a board 3-4 cm thick. It is optimal for free opening of the window sashes. The width should be sufficient to cover the edges of the walls and protect them from moisture. Alder, linden, aspen or coniferous rocks can be used as wood.

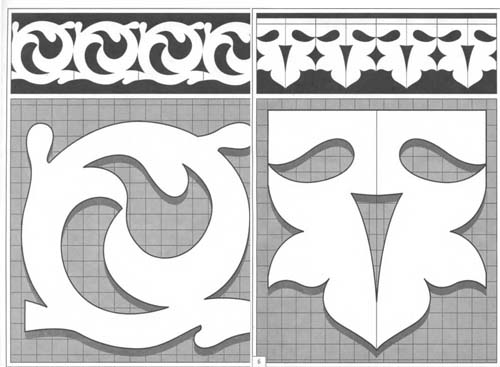

The choice of small ornament is not the most successful solution. It will be poorly distinguished at a distance, and for manufacturing it will require more time and a special thin tool. Therefore, the ornament should have large elements that are clearly visible from afar.

The location of carved elements along the wood fibers will protect the platband from cracking. This is especially true for coniferous wood.

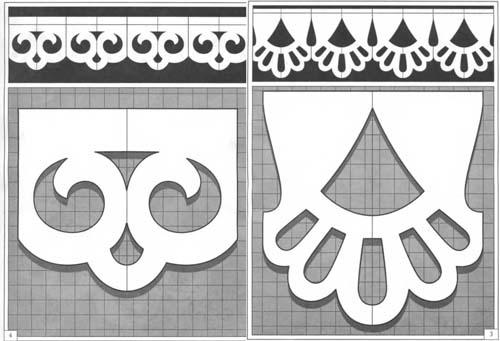

First use simple patterns. The simplest for beginners in the thread are round elements of the pattern, which are simply drilled with a drill. Below are sketches of samples of wooden platbands.

In more detail about their manufacture, you can get a haste on the video.

Installation of platbands on the windows

Stencils can be made independently or transferred a drawing from ready -made sketches. First, a pattern is applied to the workpiece, then a hole is drilled using a drill and the necessary ornament is already cut from it with a jigsaw. Next, the carved platbands must be well sanded with sandpaper.

After carved blanks are made, they should be correctly connected. In total, there are two methods of connecting: on the spikes or connection of a non -berelment. The first method is much simpler and more popular, the second is extremely rare.

A special glue is used for fastening the platband. It is important that it is synthetic, since a fungus may appear in an organic compound, and moisture also collects. All this is very harmful to wooden platbands.

If the elements are attached to nails, it is advisable to first lubricate all the joints with glue, and only then fix with nails. We should not forget about the processing of all joints and especially spikes with glue.

It is easiest to install platbands on the windows with wood screws. You can decorate their hats with the help of sawdust mixed with glue, which will be painted in the future. But even without this work, self -tapping screws will be almost invisible against the general background.

Ready -made platbands must be covered with a protective composition, which will extend their service life for many years. To do this, it is better to use special impregnations, which are quite periodically updated. The paint, no matter how high -quality it is, will begin to crack and peel off over time, and it will be much more difficult to fix it.

When choosing a pattern of the future platband, it is very important to take into account the style of the whole house, because they should harmoniously complement it. Here are a few examples of photos of wooden carved platbands.