The porch is an integral part of any private house, cottage or cottage. Manufacturing ...

|

|

The roof provides a house protection from precipitation and bad weather. For the roof ... |

The roof of any type is subjected to the destructive effect of rain and snow. When erecting ... |

Installation of slopes from sandwich panels

The procedure for finishing slopes is a rather important process on which the quality of the window functioning directly depends. A sandwich panel becomes quite popular for the finish of the slopes. This is due, first of all, with their light weight, unpretentiousness of leaving and stability before household loads. We will consider how to independently install slopes from the sandwich panels further.

Table of contents:

- Sandwich Panel Description and Features of the Material

- Slopes from sandwich panels: advantages and properties

- Installation of slopes from sandwich panels: Features of the structure of the material

- Installation of slopes from sandwich panels: technology for conducting

Sandwich Panel Description and Features of the Material

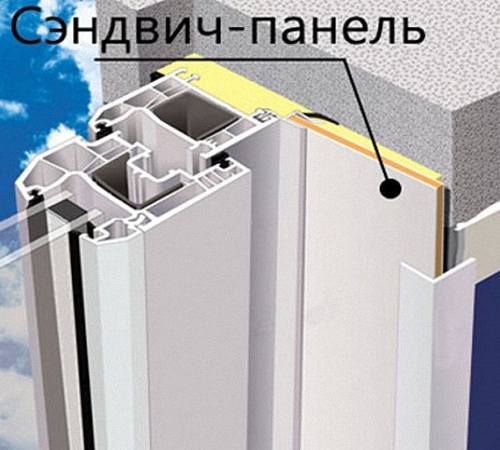

The sandwich panel is a finishing building material, which consists of three layers. The upper and lower layer of the sandwich panels have the appearance of a hard base, such as plastic, wood, metal, and the inner layer is a heater.

In order to tightly glue all the components of the sandwich panels, two methods are used - cold and hot pressing. There are two options for sandwich panels: wall and roofing.

The scope of use of sandwich panels is most often associated with the construction of rapidly far -minded buildings.

The sandwich panels differ among themselves in the main components and by the type of insulation, which is laid between the sheets.

Most often, mineral wool is used as insulation for the manufacture of sandwich panels. For its manufacture, molten basalt fibers and their combinations are used. Such panels are great for the construction of slopes, as they are distinguished by high indicators of heat and sound insulation. In addition, they are stable before mold, fungus, moisture, exposure to aggressive substances, temperature fluctuations, etc.

Polyurethane foam panels are also a fairly common option, since they have such positive characteristics:

- stability to insects, fungus and mold;

- inexplicability;

- Fire safety;

- Hydro-, heat and sound insulation.

Polistyal sandwich panels are practically not used to build slopes due to lower characteristics of sound and thermal insulation. In addition, this material is less stable before moisture than previous types of insulation.

The last option is a fiberglass panel sandwich. This type of insulation has unsurpassed properties of sound absorption. Among the shortcomings, we note instability before high temperatures and the weight of the weight of the overall structure.

In relation to the type of material that is located on the outside of the sandwich panel, they are:

1. From galvanized steel - the material is characterized by ease of operation and ease of installation, not suitable for the manufacture of slopes.

2. The sandwich panels from alucinka are also not recommended to be installed on the windows, primarily due to the fact that the slope will lose the presentability of the appearance.

3. The use of drywall for the manufacture of sandwich panels is definitely suitable for installing slopes. This material is easy to handle and lightly in the decoration. Such slopes will look very harmonious.

4. The coating from the plastisol is also quite durable, since its composition contains special additives that improve the strength characteristics of the material and its stability before exposure to adverse conditions. This material is highly resistant to mechanical influences, at the same time it does not have harmful additives, therefore it is recommended for use both inside and outside the room.

5. Plastic sheets of polyvinyl chloride or polypropylene are recommended for use for the arrangement of slopes.

There is a wide variety of sandwich panels in relation to their texture and color.

In addition, this material has the following advantages:

- simplicity of work;

- weight ease;

- high level of sound absorption;

- excellent thermal insulation;

- stability before moisture, and, accordingly, with a fungus and mold;

- lack of need for additional finishes;

- Fire safety;

- wide area of \u200b\u200buse;

- environmental Safety;

- A wide selection of the desired model, color, shape and configuration.

But, at the same time, the sandwich panels are distinguished by the following shortcomings:

- instability before huge loads;

- Unstability before scratches.

Slopes from sandwich panels: advantages and properties

The most important advantage of sandwich panels made of plastic is their one hundred percent stability before moisture, and accordingly the formation of mold and fungus on their surface is unacceptable. Since the slope section is characterized by the presence of an unstable temperature, due to cold air outside the window and warm indoor, the slopes are often present in the form of moisture. The use of plastic sandwich panels allows the slope to withstand condensate. However, the plastic sandwich panels do not have the insulation, since they are filled with ordinary air, so their properties of heat and sound insulation are significantly reduced.

If you compare the sandwich panel of plastic with drywall, then the last option of course loses both in moisture resistance and in weight. The sandwich panel is much easier to install as a slope than a drywall, in addition, after installing a sandwich panel, there is practically no garbage and dirt.

Using white sandwich, the window makes the window visually larger and more attractive, and the simplicity of caring for this material allows you to easily wipe the slopes with a slightly damp cloth.

In addition, in order to work with sandwich panels, a special tool is not required. All work is carried out quickly and easily. To remove household pollution, it is enough to wash the slope with soap water or any detergents.

The price of a sandwich panel for slopes is quite acceptable, given all its positive characteristics.

If we compare the classic plastic slopes with sandwich panels, then the first option is more resistant to moisture, and the second is the best thermal insulation characteristics. Thermal insulation is provided by extruded polystyrene, which fills the space between the plastic panels.

The use of a sandwich panel for arranging slopes of the metal -plastic window significantly increases its operational characteristics and positively affects the duration of the window.

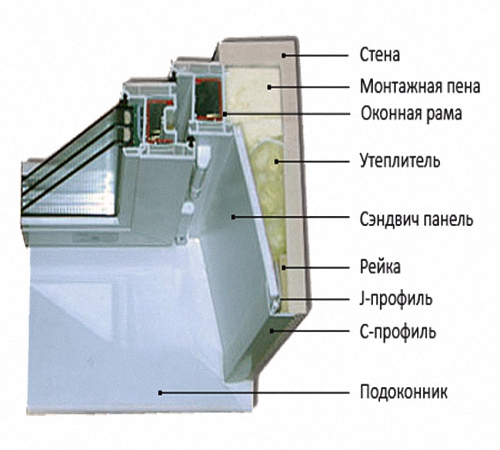

The structure of the panel implies the presence:

- J and C-shaped profiles;

- guide wooden rails;

- polystyrene in the form of insulation;

- upper decorative panels.

The main function of the C-shaped profile is to fix the panel on the inside of the slope. Thus, the angle in the room does not need additional repair or decoration after the installation of the sandwich panel.

The rail is connected to another profile on which the panel made of plastic is located. The main function of the insulation is to fill the voids in the cavity between the main part of the slope and the plastic panel. Thus, the stream of cold air enters the insulation, pushes into the barrier and does not penetrate the room.

Any means in which abrasive substances are not suitable for washing panels. In addition, the sandwich panels for slopes are stable before exposure to ultraviolet radiation, during operation they do not change color and are not able to secrete harmful substances during heating.

Installation of slopes from sandwich panels: Features of the structure of the material

If we consider the design features of the slope from the sandwich panel, then they have much in common with plastic slopes. The main components of those and other slopes are the following components:

1. The profile in the form of P is called the starting, all work on installing slopes begin with this type of profile. It is mounted horizontally and verticals of the window and connects the slope and its other sections.

2. Directly the panel itself is a composite material, inside which there is a heater in the form of polystyrene or polyurethane, and outside, it is covered with two plastic panels. The standard thickness of the panel most often used to arrange slopes is 2.4 cm. Although its size depends on such factors as the size of the window, the material from which the walls, load, etc. are made.

3. The profile in the form of the letter F is called the platband. It has the same form as the starting profile. However, it contains a wide protruding strip that blocks the mounting seams between the outer corners of the window and the panels.

There are other options for manufacturing and mounting sandwich panels. For example, to fix the front section of the panel, various kinds of fasteners are used in the form of brackets, in which plastic platbands are installed in the form of rails.

Installation of slopes from sandwich panels: technology for conducting

To carry out work on the decoration of the slopes of the sandwich panels, you will need:

- directly sandwich panel;

- starting P-shaped profile;

- roof profile;

- liquid plastic, if any;

- roulette;

- stationery knife;

- screws, size 0.25x0.7 cm;

- screwdrivers;

- electric drill.

Roulette will help measure the value of the width and height of the slope. It is according to these values \u200b\u200bthat three areas should be cut from the panel, which will correspond to the side parts and the windowsill.

If it is planned to carry out work on the decoration of only one slope, then you do not need to buy a whole sandwich panel, just remove the measurements, and order a slope of the desired size directly from the manufacturer.

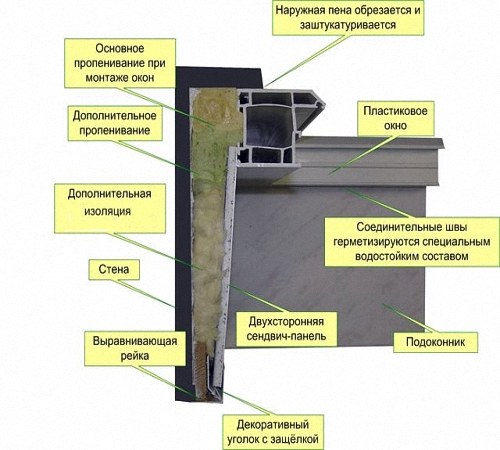

With the help of a sharp stationery knife, cut off foam, in the slopes, if any. Pay special attention to the sections located near the end groove, since the starting profile will be installed here.

The main factor affecting the quality of work is the correct execution of trimming. Since it is this process that contributes to the minimization of the slots between the slope and the surface of the window. First, cutting one section of the side strip and its installation in the groove is carried out. Next, the upper part of the profile is mounted, use exclusively the factory edges for the docking. After installing the upper profile, the installation of the last lateral start profile should be installed.

Then conduct additional sealing of the window blocks. It is she who will help to securely fix the starting strip on the slope section. This will require the presence of a sealant on a polyurethane basis. After drying it, proceed to the next stage of the construction from the sandwich sloping panel with your own hands.

Next, the sandwich panels themselves, previously cut to the specified dimensions, are installed. Keep in mind that the panel cut should be made strictly at right angles. In case of non -compliance with this rule, cracks form between the slopes, leading to the appearance of drafts and cold bridges.

Installation of the sandwich panel itself is quite simple, to make it enough to install the panel in a previously mounted profile. First, the side panels are installed, and then the upper. There are several ways to fix the panel in the opening. The first is mounting foam, a rather convenient option that easily and quickly fixes the panel. In this case, the foam needs to be selected in a low -decker. Thus, it is not able to create a pressure that deforms the slope. To carry out such fixation, special experience is required, since with a too large number of foam, the slope will occur.

The option of fixing the panel using self -tapping screws is possible. For these purposes, a screwdriver will be required. The second method is more reliable, but less aesthetic.

The next stage involves the installation of platbands. When fixing the panels with foam, first you need to wait until it hardens. The inside of the slope is subjected to a small incision, then the platband is covered with glue and installed on the wall. As glue, it is possible to use liquid nails.

The last stage in the installation of slopes is to close the butt areas between the slopes and the windowsill. For this, the use of silicone of such color as a slope and a windowsill is recommended.

If the panels were fixed using screws, then in order to provide additional sound and thermal insulation of the window, the following actions should be performed:

- temporary dismantling of the F-shaped profile;

- filling the cavity between the slope and the sandwich panel using mounting foam;

- polymerization of the material;

- Excess trimming;

- Installation of profile in place.

Slopes from sandwich panels video: