Automatic doors have recently gained more and more popularity. They are...

|

|

The security and inaccessibility of any home depends on many factors, and the presence ... |

If you are looking for inexpensive and practical material for finishing the ceiling in household ... |

How to install a windowsill for a plastic window

Installation of the windowsill is the final stage of installation of a metal -plastic window, which, most often, is carried out by the installers of the company where you ordered this window. However, the installation of the window sill itself is a simple procedure compared to the installation of a window block, and you will be able to do it yourself. Let us consider today what kind of window sills are, and how to install a window sill of a plastic window.

Content:

Varieties of the window sill

The windowsill is designed to play in the interior not only an aesthetic role, but also to perform a protective function. It is on the windowsill that the temperature changes are constantly affecting, it is he who suffers from constant falling of the rays of the sun and moisture on it. The window sill can also serve as a place for the location of the winter garden, the creation of a countertop or shelves for books. Therefore, the material from which the window sill is made should have good operational characteristics.

PVC window sills

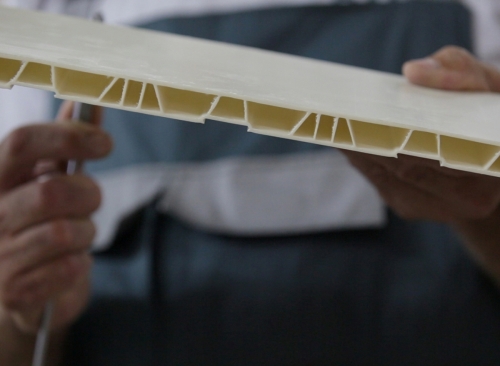

Polyvinyl chloride products consist of hard PVC, which is covered with a heat -coated film. High-class polymer plastics with different additives demonstrate similar properties as the window PVC profile.

A special design of PVC-patronesses provides high strength, resistance of the structure to temperature exposure and sunlight, as well as durability. Such products are not relaxed and do not rot. A distinctive property of plastic window sills is moisture and steam resistance, prolonging the service life of a window structure. DSP and wooden window sills are deformed as a result of moisture: the chipboard swells, the tree cracked, lamination or paint begins to exfoliate on such a window sill.

After installing plastic window sills on the windows, there is no need to carry out repeated painting, varnishing or applying a polishing composition. Care for PVC products is to use water and detergents. Plastic window sills have the lowest cost in comparison with other window sills, so traditional wooden structures are gradually replaced by PVC models.

At the same time, plastic prices differ. It all depends on the quality of the raw materials used and the composition of the material.

Polyvinyl chloride is difficult to process in its pure form, so it is mixed for the production of products with different plasticizers, the share of which can reach 30% depending on the necessary properties of the final product. The smaller the expensive plasticizer in the PVC, the more fragile the plastic. In addition, the type of plasticizer also determines the environmental safety of plastic products.

The internal ribs of the stiffness of the plastic window sill provide additional strength of structures. Resistance to damage and the appearance of the PVC of the window sill for plastic windows depend on the coating. For the lamination of PVC-patronesses today, three types of films are used: laminate based on melamine resins, laminate based on acrylic resins and PVC.

The highest quality representatives of this variety of window sills are widely used as an internal and outdoor element to protect windows, because functionally PVC window sills are quite durable. One of the simplified options is decorative pads on the window sill, which is a thin bar with a nose covering an unaesthetic old windowsill and serving a rather practical alternative to the entire element.

Composite window sills

The composite windowsill consists of two components of the base and coating material, which is applied to the finished board. These are window sills from MDF/chipboard, DPK and PVC. Their coating is different veneer, laminates, PVC film. The wood-and-steamboxes of chipboard are made of wood particles through their hot pressing using different binders, as a rule, formaldehyde resins. For the manufacture of chipboard as the starting raw materials, waste from processing - sawdust and chips of deciduous and conifers are used.

The combination of low cost and good technical characteristics makes chipboard a popular material for the manufacture of window sills to plastic windows. This material does not bell out in comparison with wood and almost does not swell, and also withstands the touch of hot objects. The most important minus of the products from the chipboard is the presence of formaldehyde resins in the composition of formaldehyde, which may become a threat to human health in case of improper processing of the material.

Wood fiber slabs of medium strength MDF are made of very small sawdust, subject to special processing - their own collapse. The material after that is dried and with the help of lignin and paraffin is glued into the plates. Therefore, the MDF is an environmentally friendly material. In the manufacture of window sills from MDF or chipboard, a veneer or laminate is applied to the base. In the line of laminated window sills, the buyer offers a wide list of colors and drawings imitation of various breeds of wood, granite and marble.

Such window sills are wear -resistant, racks to scratches and harmful microorganisms, and immune to the effects of light and ultraviolet radiation. They can be washed with soft and non -ambrase agents. However, when buying such a windowsill, remember that when moisture gets through the ends, it will swell and begin to crack. Therefore, it is necessary to treat the ends well with thermo -insulating materials. Damage to the coating of the window sill from chipboard and MDF leads to the loss of its moisture resistance and the inevitable replacement of the windowsill.

The wood-polymer composite is a new generation material, which contains a natural or chemical polymer and wood filler, which is modified by chemical additives. The DPC is characterized by the best properties of wood, while due to the plastic, it is much reduced by such disadvantages of natural wood as the exposure of mold and rotting, surface defects and grief.

The wood -polymer profile with a large amount of wood filler in appearance resembles MDF, and with its small content - plastic. DPK can be planned with a shirt, saw, drive nails into it. It can be stained in the mass or prostrate finish with ordinary enamels and paints, or faced with natural veneer and synthetic films.

Windows from wood-polymer composite have an attractive appearance, they are strong and durable. However, like natural wood, such products can change their color under the influence of the rays of the sun, as well as swell and deform in conditions of high humidity. In addition, for the domestic DPP market, it is a relatively new material, and therefore the price of window sills for plastic windows is a little overpriced.

Concrete window sills

Previously, concrete plates of standard shape, which were installed with the aim of decorating the lower section of the window opening were very popular. Today, traditional concrete slabs from the market are mixed with more decorative analogues made of decorative concrete. The color palette of such material is extremely diverse and extensive, moreover, concrete is resistant to ultraviolet light, which allows it to preserve his coloring in its original form.

It is also necessary to note the high strength of decorative concrete, which allows you to make window sills from this material that have a large surface area. A wide window sill will become an additional shelf on which even heavy items can be stored. In addition, thanks to modern technologies and the achievements of science in the manufacture of window sills, it became possible to create products without seams.

Woodwear from wood

Since time immemorial, wooden window sills have been considered a traditional option for decoration of space under the window. In a wooden log house, an ordinary cherry board played the role of the windowsill. Today it is an interesting material from a decorative point of view: you can see this by looking at the photo of window sills for plastic windows. For the highest quality window sills, an array of wood of valuable breeds of ash, beech, oak, cherry, chestnut, maple, red tree are used. Products are simpler made of Siberian larch and pine.

The choice of width, and the more exotic material for the manufacture of a window sill, the more expensive the final product will be more expensive. During the production process, wood is subjected to drying and polishing, then the surface is treated with mastic made of wax and vegetable oils, waterproof impregnations and protective varnish. The properties, time of service and the characteristics of the future wooden windowsill depend largely on the quality of drying and wood of wood.

Window windows from an array of wood are very expensive. Among these products are the most expensive window sills from ash, the price of which is 30% more oak, this wood retains the shape better, since it is less fragmented. The most economical raw material is loose and soft pine, but during operation on such window sills, dents from sharp and heavy objects can remain. Therefore, the window sills of oak, beech and pine are most often chosen.

Some manufacturers make window sills for the sake of reducing the cost of production with multi -layer, as well as in width glued from the strips. The layers are located for greater stiffness in such a way that the wood fibers are crossed cross. Bonding occurs when exposed to high temperature and pressure. After that, protective coatings (paints, mastics, varnishes, antiseptics) are applied to the workpiece to protect this material from UV radiation and moisture.

The advantages of wooden window sills are obvious: high thermal insulation properties, breathability, the ability to withstand large temperature changes, durability. However, such products are whimsical in care. They cannot be abundantly wetted with water, cleaned with solvents and abrasives, it is advisable to protect the surface from freezing. It is customary to wash the dust with a dry cloth. Once every 3 5 years, it is advisable to update a layer of varnish, wax or paint on the surface of the window sill.

Stone window sills

A fairly popular option under the window is a product made of natural or artificial stone. The most durable window sills are from granite. And if you planned to buy just such a product, then you should definitely check the certificate of products that indicates the radiation purity of the used raw materials (I class of safety), because this mineral has the ability to accumulate radiation.

Onyx and marble do not have such minuses, and this does not affect their decorativeness. Marble designs have a wide variety of shades and fit perfectly into almost any interior. Onyx products have the ability to skip light, you can install light bulbs under the windowsill to create an amazing effect of transliness.

Models of natural stone window sills are durable, but they are quite whimsical, they are afraid of the effects of chemicals and scratches, and light products also do not make contact with various coloring liquids: sparkling drinks of bright color, coffee and tea. Therefore, today, along with natural stone, its artificial counterpart is widely used to create window sills.

Artificial stone natural is not inferior in aesthetic and physical parameters, and it costs almost the same. Artificial stone consists of mineral filler (70 90%) and polymer binder - resin. By adding various dyes to a mass, you can make a window sill of any shade. One of the main advantages of artificial stone window sills is to connect without seams, which allows you to achieve absolute monolithic surface.

This material is resistant to all kinds of chemicals, thermal and durable, but is afraid of scratches. It is best treated with polishes and soap solutions. The window sills from decorative artificial stone are hygienic: for a long period they remain clean, since they do not settle bacteria with mold, and they also do not emit harmful substances.

Installing PVC window sill with your own hands

Installation of the window sill to plastic windows requires certain skills from workers, because the incorrect installation of the window sill threatens you with poor thermal insulation of the window structure and spoiled winter evenings. The installation of this product in most cases is carried out simultaneously with the replacement of the window frame. This is more economical in terms of the cost of materials and the expenditure of monetary resources, more convenient and faster.

Determination of the size of the window sill

The windows made of PVC are best suited to plastic windows. Work should be started by calculating the size of the window sill for a plastic window. To determine what the length of the window sill should be, it is necessary to measure the width of the opening with a roulette and add at least 60 millimeters to the value obtained, since the window sill on each side for slopes should be at least 30 millimeters. Otherwise, the plastic corner and f of the profile, which are used in Installation of slopes, they will play for the windowsill, and this is considered unacceptable.

The width of the plastic window sill is very simple. Remember that the permissible protrusion from the opening of the window sill is 50-70 millimeters, otherwise it will block the battery and will interfere with the passage of heat, which can provoke fogging and formation on ice windows. However, under the window design itself, the window sill is started approximately 20 millimeters. Accordingly, these figures should be added to the depth of the window opening, which is measured from wall to profile.

Production of the blank of the windowsill

Using the obtained values, cut the blank of the windowsill of the width and length you need. Make the process of cutting the grinder itself, because with its help you can achieve perfectly even edges. If this tool is not at hand, you can take an electrician, but they will have to saw it carefully. In the absence of a jigsaw, the blank can be sawn down even with a regular saw.

But if your blank of the windowsill is not included in the opening, then the parts should be cut out that interfere with it. Or you can make sure that the protruding parts of the window sill on the left and on the right are recessed into the wall. After installing the window sill on the plastic window in this way and putting up these recesses, you can achieve the effect of the monolithic of the wall and the windowsill.

To do this, you need to make small recesses in the wall with a perforator. By putting the windowsill to the opening, take marks for cuts, taking into account the above, and cut the rectangles interfering in the installation on the left and right. Now the harvesting of a plastic window sill is considered completely ready to install in place.

Surface preparation

Before installing a plastic window sill, the horizontal surface must be cleaned properly from dust and building debris. In this case, take into account that the windowsill, regardless of manufacturing, should always be installed towards the room under a small slope so that the water from watering plants or condensate is not going under the frame. Sufficiently inclined a couple of millimeters.

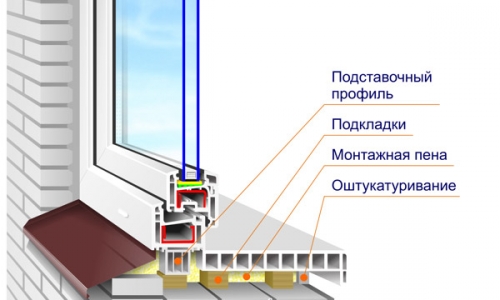

Before fastening the window sill to the plastic window, install special spacers or wedges that need to be sinking with a gypsum solution. They are necessary in order to set the window sill on the necessary level. Then prepare the lining under the windowsill. They should be selected so that the product is tightly adjacent to the frame, however, without excess. The lining should not perform so that they do not have to be cut later. Check how smoothly it will be to install the windowsill.

Fastening of a plastic window sill

There are several ways to attach a plastic window sill:

- on two -component polyurethane foam (the most common method);

- on glue with struts acting as a press;

- on special brackets, including the situation where the width of the windowsill is much exceeds the window opening;

- using special holding brackets.

After that, moisturize the surface slightly, apply the mounting foam along the frame, install the plastic windowsill, fixing it, and fill all the remaining voids with foam. Remember that the foam is able to expand very much in volume, so you need to be neat and careful. After the mounting foam is completely freezed, you can remove the spacers and check the quality of the window sill installation for a plastic window using a level. The scene of the window sill with slopes and the frame is sealed with acrylic.

+

+