Abundant rains, as well as the stormy streams of water that fall from the roofs, forced people ...

|

|

If you want to quickly and with the least costs solve the housing issue, ... |

Installation of plastic windows is an excellent solution to ensure comfort at home and ... |

How to install an aluminum window

Installation of aluminum windows is not very different from the installation of windows from other materials. However, there are some features in the assembly of the frame and adjust the finished design that must be taken into account when working with aluminum profiles.

Compliance with installation technology will provide reliable, durable and uninterrupted operation of aluminum windows. Consider how to correctly establish the main types of aluminum structures: rotary-oxide and sliding windows.

Content

- The design of aluminum windows

- Do -it -yourself aluminum windows installation technology

- Features of the assembly and installation of sliding aluminum structures

- Practical tips for the installation and operation of aluminum windows

The design of aluminum windows

Recently, the demand for aluminum windows has increased significantly. This is due to a significant expansion of their production and the advantages that are inherent in this type of glazing.

Aluminum structures are durable (service life of more than 50 years), light, reliable and have an unlimited sphere of application. Such high operational indicators are largely due to the design of the windows.

In the production of aluminum window frames, a set of window profiles is used, which includes:

- frame profile;

- skag;

- profile for the wings;

- shed profile;

- import Profile.

Such a set allows you to make windows of various configurations and any opening method.

- The folding windows of the window of the window leans back, opening the upper part of the window. Suitable for creating a window opening on stairwells, in pantries and places where the window is not required.

- The turning windows of the window sash open in a single plane, often inside the room.

- The rotary-oxide windows are the most common and convenient option. Most often used in glazing residential buildings and apartments.

- Deaf windows without the possibility of opening a window. They only perform the function of lighting the room. Popular when arranging facades of retail and office premises, as well as in glazing windows.

- Multicked windows are suitable for glazing loggias. There is the possibility of combination of shots of different types of opening.

- Sliding systems are conveniently used for limited space, for example, for glazing a balcony. Window wings are moved along the profiles.

All aluminum window profiles are available in two types.

- A warm profile with a thermo -insulating insert. It is used in the manufacture of doors and windows for heated non -residential and residential premises.

- Cold profile without insulation insert. Windows and doors from such a profile can be installed in non -heated buildings, or to arrange partitions inside heated rooms.

Do -it -yourself aluminum windows installation technology

Preparatory stage

Before starting directly to the installation of a new aluminum window, it is necessary to carefully dismantle the old structure and prepare the window opening.

For work, you will need such tools and materials:

- When removing the old frame, you can use:

- When installing aluminum windows, you will need:

- saw or electrician;

- chisel;

- fomka with nails;

- a hammer;

- construction mounting foam;

- screwdriver;

- punch;

- drill;

- metal drill;

- building level;

- construction knife;

- dowel-gvo;

- wooden blades.

You can dismantle the old wooden frame as follows:

- It will be easier to remove a box of structures from a window opening in several places with a saw or an electrician or an electrician with an electrician.

- In the place I drank (it is better to start on the underside of the window) to put Fomka’s frame and carefully remove it.

- After extracting the old window, you need to remove the windowsill. For this work, it is better to use a chisel and a hammer.

After completely dismantling the old design, you need to prepare the window opening:

- Remove concrete fragments and fasteners remaining after the old frame.

- If the window opening is substantially damaged or has distortions, then it must be leveled with cement-concrete solution. In this case, the installation of an aluminum window must be transferred for 1-2 days until the solution is completely solidified.

- Before installing a new window, it is advisable to spray the opening with water and primed.

In order not to damage the window opening during the dismantling, the efforts must be made in the window plane, and not in the perpendicular direction. With this effect, fasteners (nails) will easily be removed from concrete

Installation of an aluminum frame

The window structure made of aluminum enters in a partially disassembled state of the frame with fittings and a double -glazed window separately.

Consider how to install an aluminum window. Let's start with the installation of a window frame:

- If the window is received in the collected form, it is necessary to free the frame from the double -glazed window and the wings.

- The window frame is set in the opening and aligned with the help of wedges.

- Check the horizontal and vertical position of the window frame in terms of level.

- On the perimeter of the entire frame and walls, drill holes for fasteners.

- Anchor plates will be fixed using a dowel-grooves. With one self -tapping screw through the hole in the plate, mounting to the wall, the second self -tapping screw, through the second hole, to the frame.

- The mounting seam is formed in two stages:

The optimal distance from the side walls of the opening to the window frame is 5 mm. With an increase in this distance, additional plates must be used to align the frame

Installation of toll and window sill

The sequence of work on the installation of tide and window sill:

- On the outer perimeters of the frame (along the mounting seam), attach a vapor permeable tape, it passes the air, but delays moisture.

- To the lower part of the aluminum frame (outside), using self -tapping screws, attach an ebb.

- The gaps between the frame and the tide are treated with mounting foam.

- Cut the excess foam, and cover the joint of the joint with a layer of sealant.

- The windowsill must be brought under the frame, inserting it into a special groove.

- Level the location of the window sill in level.

- Plant the windowsill on the mounting foam.

- The junction of the frame and the windowsill is covered with a strip of sealant.

The windowsill can be installed with a small slope, this will additionally protect the window block from moisture penetration

Installation of a double -glazed window and adjusting accessories

The final stage of installation of the aluminum window is installed of the double -glazed window, hanging the wings and adjusting the window fittings.

When installing a double -glazed window, it is better to enlist the support of at least one person. Different liners can be used depending on the company's manufacturer. Their shape and quantity depend on the type of window profile (warm or cold), as well as on the type of opening of the wings.

Tipakte installation algorithm:

- According to the instructions, place inserts around the perimeter of the window frame.

- Install a double -glazed window.

- Fix the double -glazed window with stacks. They must be scored with a rubber hammer.

The technology for installing the double -glazed window is a time -consuming and subtle process that it is better to entrust professionals

Before hanging the sash on the window frame, you need to check the presence of the entire fittings and put the handle on the sash horizontally (open position of the window).

- Put on the sash on the lower loop.

- Take a loop-angle loop into the upper loop of the frame.

- Fix them with a pin and push them up until the latch is triggered.

In order for the pin to easily enter the loop and do not jam, the window sash should be pressed to the frame

After hanging the sash, it is necessary to finally adjust the fittings to tighten or settle the fasteners.

Features of the assembly and installation of sliding aluminum structures

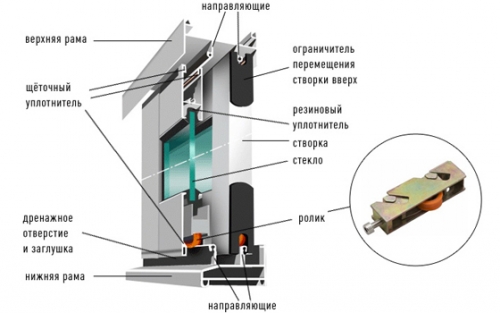

The design of sliding aluminum windows includes: guide rails, rollers and double -glazed windows.

Let us consider in stages how to install aluminum sliding windows:

- Installing a frame (installation technology is similar to the installation of a regular profile frame).

- Installation of guides:

- rulette measure the length of the horizontal sides of the window frame;

- apply markings on the guides and cut into parts of the desired length;

- the side sides of the cut are applied with a file;

- on the lower and upper part of the frame, drill holes every 30 cm;

- attach guides with screws to the frame.

- Insert the double -glazed window into the sash.

- At the bottom of the sash, attach a couple of rollers on both sides. The distance from the rollers to the edge of the sash is about 5 cm.

- On the horizontal and vertical sides of the sash, fix the brush seal of the Schlegel.

- The sash is installed first in the upper guide, and then to the lower.

- The movement of the wings must be adjusted using the adjusting screw (usually it is located in the lower part of the sash).

How to install aluminum windows: video

The distance from the guide to the outer edge of the window frame should be no more than 5 cm, otherwise, in winter the wall will freeze

Practical tips for the installation and operation of aluminum windows

In order for the window to serve for a long time, it remains strong and reliable, when it is installed, some basic technological rules must be adhered to:

- Before installing, the window must be checked for the presence of defects (curvatures, cracks, scratches).

- Metal plates cannot be used to adjust aluminum windows. You can level the location of the window with plastic or wooden wedges.

- It is necessary to seal the window opening with mounting foam strictly in the direction from top to bottom.

- It is strictly prohibited to bend the aluminum profile.

- It is better to treat slopes on aluminum windows with plaster or drywall.

Caring for aluminum windows is quite simple and consists in periodic wiping from dirt and dust. In addition, to maintain windows in an aesthetically attractive appearance, you can use silicone -based correctors and aluminum tar. These means effectively mask the censor and other shortcomings that appeared on the aluminum profile.

It is advisable to lubricate window fittings once a year. To do this, use oils that do not contain resin and acid.

The technology for installing aluminum windows is not complicated, and is not much different from the installation of wooden or plastic windows. However, some points, for example, installing a double -glazed window in the sash and final adjustment of accessories, are best entrusted to experienced specialists who can guarantee the strength of the finished design.

hello, the situation is this

hello, the situation was installed by the aluminum frame installed the SPD double -glazed window, and Patu Chali pour the floor with concrete, almost flickering with the lower part of the frame, the double -glazed window stole the oxidation from the lower part of the double -glazed window and it is clear that the liquid penetrated there under the light of concrete. The double -glazed window was sealed during acceptance. Can a concrete solution disrupt the tightness of the package glass?