The growing popularity of wooden houses associated with their highest environmental friendliness, ...

|

|

Any house built, garage, cottage or bath need insulation ... |

It would seem, what a trifle these door handles! But, nevertheless, without them in no way ... |

Types of waterproofing. Classification, purpose, useful tips

It is necessary to protect from water all surfaces and structures that can somehow contact with water. In a country house, this is a foundation, a basement, a roof. Inside the house or apartment, this is a bathroom and a bathroom where leaks and flooding are possible. Inside the structures of the house, it can be a heater that must be protected from condensate or precipitation. Please note that it is necessary to protect against water not only where it is possible to penetrate, but also where washing or condensate waters can negatively affect the material of the structure. For this, there are various types of waterproofing, which differ in purpose, place of application, as well as materials. Over the past decades, the market for waterproofing has expanded significantly, absolutely innovative solutions have appeared, but the old methods of protection against water, such as laying roofing material, are also not forgotten. Among all the variety, it is not difficult to get lost. To facilitate the understanding of what kind of waterproofing is suitable for you, we will try to classify all types, as well as designate their purpose, pros and cons of the technology and installation features.

- Types of waterproofing

- Crystal waterproofing

- Bloody waterproofing

- Coloring waterproofing

- Sprayed liquid waterproofing

- Penetrating waterproofing

- Injection waterproofing

- Superdiffusion and diffusion membranes for waterproofing

- Bentonite mats

Types of waterproofing

Before moving directly to the listing of waterproofing types, I would like to clarify a very important point. Why is it necessary to protect against water? Is she really so terrible this H2O? Of course, if you have a knee of water in your basement, then everything is quite clear here to protect the basement from the penetration of water, plug the leak. Approximately the same principle is used when waterproofing the roof, the main task is to prevent leakage. But this is not the only trouble that water can cause. For example, you can cover the basement from the inside with mastic, and the basement will become dry. But is that enough? Water brings much more harm, seeping into the structure of the material. Salts dissolved in water gradually destroy the material, reducing its strength and durability. Therefore, it is necessary to protect the basement from the outside, not allowing water to penetrate the concrete.

And this is the basic rule, which must be remembered better to protect both the material of the structure and the room than only the room.

There are several classifications of waterproofing technologies: according to the method of arrangement, for the main purpose, for the name of the materials used, as well as at the place and time of application.

At the place of application exists internaland external waterproofing. Obviously, internal waterproofing is a complex of measures to protect against water, which is carried out indoors, for example, waterproofing walls and floor in the bathroom. External waterproofing is performed outside the structure, for example, the protection of the foundation from groundwater or protection of the roof.

By the time of usedistinguish Primary and secondary waterproofing. Primary waterproofing of structures is carried out immediately at the stage of construction of the facility. Secondary is repair measures. For example, if the primary waterproofing is damaged from old age or for another reason and does not cope with its task, then a set of measures for secondary waterproofing is performed. In this case, the old coating is removed, the surface is thoroughly cleaned and a new waterproofing layer is applied. It is also possible to apply a new layer over the old one, but this is not recommended to do this.

By purpose and features There are such types of waterproofing:

- Anti -nap. It works on the clamp.

- Underwear. Works for separation.

- Anticapillary.

- Sealing seams and conjugation.

- Superficial and complex purposes.

Anti -japorn waterproofing serves to protect against positive water pressure. For example, if the groundwater level around the basement is very high, then the anti -napal waterproofing of materials from materials that can easily withstand positive water pressure is equipped outside the basement wall. Sometimes such a technology is also called the pressure. This means that water presses waterproofing material against the walls with its weight. It does not make sense to use the same materials on the internal walls of the foundation, since there is another water pressure.

Removal waterproofing serves to protect against negative water pressure. For example, if, due to heavy rainfall or spring floods, water has accumulated around the foundation, then you can protect against it from the inside of the basement. Its pressure is small and acts on the separation of the material from the surface.

Anticapillary waterproofing Protects the material of the structure from the raising of moisture in it along the capillaries. After all, many building materials suck in water, which then rises along the capillaries. Such materials include both concrete and brick.

By the method of arrangement There are such types of waterproofing:

- Coloring.

- Crystaline.

- Plaster.

- Ever.

- Cast or sprayed.

- Premissive.

- Injection.

- Folding.

- Mounted protective sheets.

- Structural additives in concrete at the construction stage.

- Various film materials for protecting insulation and roofs.

Further, we will analyze in more detail the waterproofing technologies for the method of arrangement, since it is easiest to determine the purpose and features of installation on them.

Crystal waterproofing

Crystal waterproofing is a surface coating with various mastics, one -component or two -component elastic compounds with a thickness of 2 mm to 5 6 cm.

Appointment. It is used for external waterproofing of the building to process the foundation for protection against groundwater, processing a flat roof to protect against precipitation. It is also used for internal waterproofing processing of the basement walls, flooring and walls of the bathroom. With the help of coating waterproofing, cracks on the walls are closed. It is enough to recall how the waterproofing of panel houses occurs. From the side, they look like boxes, differently on rectangles.

As coating waterproofing, bitumen and all bitumen -containing materials are used.

Advantages. Cheap material.

Flaws:

- Bitumen becomes fragile at temperatures below 0 C and loses elasticity. Any deformation during the period of negative temperatures will inevitably lead to cracks and ruptures, and over time, the material will exfoliate from the surface. The service life of waterproofing from bitumen is 5 6 years. Sometimes even 3 4 winter cycles are enough for the material to fail.

- Working with hot bitumen is dangerous. Possible injuries in production.

- Careful surface preparation is required. It is necessary to clean the surface of the base of dust, garbage and influx of construction mortar, fill all the cracks, potholes and shells.

- Work can only be carried out in dry weather, concrete should be dry.

- High -quality primer processing is required.

- It is necessary to protect the waterproofed surface from possible mechanical effects of punctures and damage.

- The restoration of coating waterproofing due to damage can cost 3 4 times more than the initial application.

Conclusion: You can use coating waterproofing only when the probability of leaks is already small. For example, if the groundwater level is low, then you can coat the walls of the foundation with bitumen, make drainage around the structure and take rain water. The use of coating waterproofing on the roof is no longer relevant, since bitumen cracks in frosts, and the ice makes ruptures in it with its sharp edges. As a result, by spring the surface is not sealed.

Please note that polymer resins appeared on the market, bitumen-polymer and bitumen-resin mastics that can be applied in cold form. This method of application is simpler and faster than hot. But the disadvantage of polymer mastics is all the same instability to deformations. Any vibrations and mechanical influences will lead to the appearance of cracks and ruptures.

Bloody waterproofing

Enough waterproofing is rolled materials glued to the base. Most often, materials are laid in several layers from 2 to 5.

Appointment. It is used only for external anti -napal waterproofing. Rolled materials can be glued both to the vertical surfaces of the walls of the foundation, and to the horizontal surface of the flat roof.

The most common materials for glow waterproofing roofing material, permamine, only, polymerized bitumen materials based on fiberglass and polyester, rubber -bitumen. For example, Technonikol, Bicrost, Ruflex Grand, Hydroisol, Plastfoil, Tiploizole, Bireplast Norm and others.

Modern materials with polymer additives are more durable, not susceptible to rot and formation of mold in contrast to roofing material, the cardboard base of which quickly fails.

Advantages. Environmental materials can be laid on concrete, metal, wood, old roller coating, flat slate, asphalt concrete. Materials are resistant to aggressive environments, moisture permeable and economical.

Flaws:

- Careful surface preparation is required. Uneven are not allowed more than 2 mm.

- Sticking and fueling materials should be carried out with special care.

- The temperature during work should be not lower than + 10 s (there are exceptions to elastomeric and thermoplastic materials).

- The coating can break under the influence of mechanical loads or sharp objects, so it is desirable to protect it. In the case of waterproofing of the foundation, the clamping wall should be performed.

- The surface of concrete when gluing should be absolutely dry. With wet concrete there is no adhesion.

- It is necessary to control the quality of all welds and overflows of the material.

- Glue the material in several layers. It is difficult to get around the corners and complex reliefs of the base.

Despite the shortcomings, modern roll materials based on polymerized bitumen are successfully used to waterproof the foundations and roofs. It is better if the 1st waterproofing is used in combination with other measures.

Coloring waterproofing

Coloring waterproofing involves applying mastic in a liquid form with a layer of 3 6 mm. The resulting film has no seams and is quite elastic.

Appointment. It is used for external and internal waterproofing. With the help of painting materials, you can fight cracks in the walls, their crushing and erosion. Also, the waterproofing of the room from the inside can easily be provided with similar mastics. For example, the color of the floor and walls of the bathroom will protect from the flooding of neighbors and the destruction of wall material.

Materials: bitumen mastics with various additives of talc, asbestos, as well as mastic based on synthetic resins.

Advantages. Simply, cheap, fast, special skills in working with the material are not required. The coating is abrasion -resistant and vapor permeable.

Flaws. The fragmentation is about 5 6 years old.

Sprayed liquid waterproofing

The spraying of a polymer-bitumen emulsion on a aquatic basis is also called liquid rubber. One -component and two -component compounds are applied using special equipment with a mechanized way of spraying.

Appointment. Waterproofing roofs. Sometimes liquid rubber is used for waterproofing basements from the inside, but this is wrong. Pay attention to liquid rubber is not able to withstand the negative pressure of the water, it simply breaks away from the base. Therefore, its spraying in the basement is simply in empty money spent. If the water pressure is positive, such as on the roof, then this material can be safely used.

Materials. Synthetic rubber. Technoprok, Rapidflex, elastopase, elastomix, master Ruf, N2o Inopaz and others.

Advantages. During spraying, liquid rubber fills even the slightest pores, creating a tight coating. The surface is processed quickly due to the mechanization of work.

Flaws:

- A temperature is required at least +5 C.

- The coating is afraid of punctures.

- Before applying, the surface of the base should be dry and not frozen.

- A strong wind makes spray difficult. Work must be done in calm weather.

- High price.

- A complex relief requires a greater consumption of material, which leads to a total rise in price.

- Only specialists can perform work.

- Special expensive equipment is required.

- If the storage conditions of liquid rubber were not observed, for example, it was frozen in the warehouse, then sintering of the molecules will not occur, a porous pancake will turn out on the surface of the base, which simply will not perform its functions.

- You can use it only outside, it works on the clamp.

Please note that waterproofing with liquid rubber is advertised from each iron, they offer it to isolate flooded basements. As you have already guessed, the coating will last not longer than one season, and the money will be spent in vain. Use liquid rubber only on the outer surfaces.

Penetrating waterproofing

Penetrating waterproofing prevents the capillary lift of water in the pores of concrete. The composition for applying concrete is a mixture of Portland cement, thin milk quartz sand and active chemical additives. Penetrating waterproofing is applied to the wet surface, the composition is reaction with water, as a result of which crystals are formed, which fill all pores, cracks and capillaries and become part of the concrete itself, preventing water penetration. The depth of penetration of the composition into the thickness of the concrete can reach 15 25 cm. Some manufacturers of penetrating materials assure that their composition can penetrate 90 cm deep into the thickness of concrete.

Appointment. With penetrating waterproofing, concrete surfaces in the basements are processed. If the foundation is not possible to dig up, then it can also be processed from the inside with a penetrating composition. Various concrete containers, for example, silage pits, are also waterproofed by penetrating materials.

Materials. Penetron, Penoplag, Pumpeter, Maxplag, Hydrochite and other analogues.

Advantages of penetrating waterproofing:

- All work can be done inside the basement, there is no need to dig out the foundation.

- You do not need to dry concrete. The more deeply the concrete is moisturized, the better the crystallization reaction will occur and the composition will penetrate deeper.

- High -quality materials (penetron) are able to penetrate to a depth of 60 90 cm into the thickness of concrete with a total layer.

- Protection of the material from the inside is ensured, and not just from the outside. The penetration of water inside concrete is completely excluded.

- The composition has a functioning function. If a crack appears in concrete, then it is immediately filled with crystals.

- A long service life equal to the service life of the concrete itself.

- Concrete remains vapor permeable.

- The frost resistance and strength of the concrete increase.

- Additional expensive equipment is not required.

- Processed concrete is not terrible mechanical influences. For example, if you have a need to cleanse the silo pit with a metal scraper, you should not worry that you will break the waterproofing. Concrete can be drilled, dowel is twisted into it and other work injuring concrete.

- Environmental friendliness of the material. Can be used for surfaces in contact with drinking water.

- Some penetrating compounds can be used to seal fountain leaks.

Disadvantages of penetrating waterproofing:

- With penetrating compounds, only concrete, construction solutions, plaster and screed based on cement brand are not lower than M150 can be processed. Brick and stone are not amenable to the effects of penetrating waterproofing.

- Work can only be done at a temperature of at least +5 C.

- Before the start of work, it is advisable to remove the entire finish and the insufficiently holding plaster to the concrete itself. It is also necessary to open all cracks and degrease the surface of concrete if waterproofing of old structures is performed.

- Concrete should be carefully moistened.

Penetrating (impregnation) waterproofing is more suitable for processing fresh concrete. Old concrete must be thoroughly cleaned and degreased, since during operation all pores were clogged. For this, a sandblasting tool is used. Please note that penetrating waterproofing does not work on brick and stone.

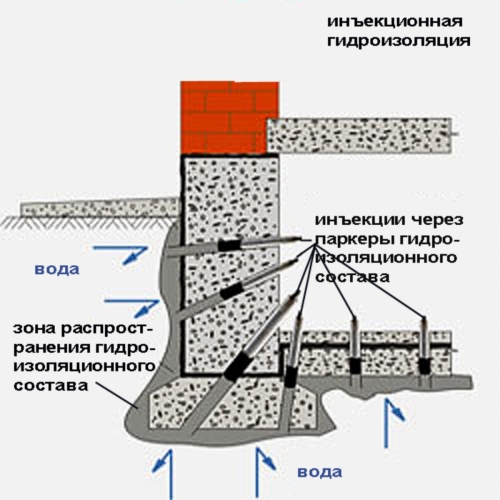

Injection waterproofing

Injection waterproofing consists in heating the repair liquid waterproofing composition into cracks, pores, joints of adjoining and the thickness of the old crushed material. It works not only on concrete, but also on brick, bute and masonry.

Appointment. The device for waterproofing seams and joints in the places of adjacent to the walls and soil, elimination of leaks in the walls, an increase in the bearing capacity and strengthening of dilapidated foundations of brick and Buta, cutting off the capillary leakage of water from the soil.

Materials. Acrylate gels, foam, resins, polymer compositions, rubber, cement -containing injection materials and other materials. Viperpur, stained-ups gel, Penepur foam, McCuscal Ingeskshn, Maxgraut inkshn, Manopur, Penesplitsil, Manopox-S, Manopox-15.

Advantages:

- It is not required to dig out the foundation.

- It works not only on concrete, but also on brick and stone.

- Effectively works when restoring waterproofing of various deformation joints.

- Eliminates the capillary suction in brickwork.

- The possibility of eliminating pressure and funding leaks.

Flaws:

- High cost of materials and equipment.

- The full dismantling of the finish is required.

- Only specialists can perform work.

- It is necessary to know exactly the place of leaks.

- The work is a complex of complex operations according to the technological instructions and are used on an industrial scale.

Only a specialist can make a decision on injection waterproofing.

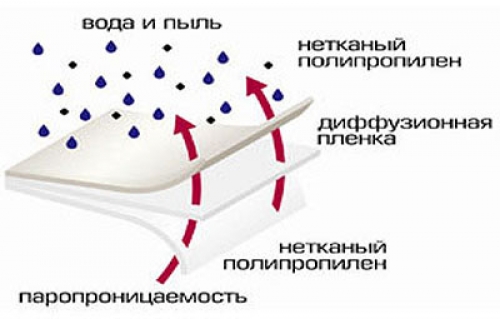

Superdiffusion and diffusion membranes for waterproofing

SuperDiffusion membranes They are a high -passive material, the structure of which is reinforced with polypropylene fibers. They are used to waterproof rock roofs and ventilated facades. These membranes can be laid directly on thermal insulation material.

Diffusion membranes They require the mandatory availability of two ventilation gaps: between the insulation and the material, as well as between the membrane and roofing material.

Appointment. In the pitched roofs, the use of superdiffusion membranes allows you to use lighter materials.

Advantages. The high vapor permeability of the membranes creates a favorable climate indoors, releasing steam from them. Walls or roof seem to breathe. They fit very simply, serve for a long time, do not require increased attention.

Flaws. Pores can be clogged, which reduces the vapor permeability of the membrane. They are not used with a Euro -shifer and metal tiles.

Bentonite mats

Bentonite mats The so -called mounted waterproofing. The mats are bentonite clay in granules concluded between two layers of cardboard or geotextiles. After installation to the surface, which is required to waterproof, for example, to the buried part of the foundation, the cardboard decomposes, and the clay remains to perform the function of the shield between the foundation and rainwater.

Bentonite after contact with water swells and turns into a gel. During the installation, mats are laid with overlap, and bentonite granules wake up in the joints.

This method of waterproofing has only one flaw high price. It can be used for waterproofing vertical and horizontal surfaces. For example, lay next to the foundation of the house on the ground, preventing the seeping of rainwater in the soil next to the house.

All work on the waterproofing of the building or structure is best carried out at the construction stage, taking care of the safety of the facility in advance. For monolithic concrete construction, it is recommended to use special additives in concrete that increase its water resistance. The hydraulic supplement Admix increases the waterproofness of concrete from W4 to W18-20 and is used for the construction of responsible facilities, and hydrochitis from W4 to W12 and is used for low-residual objects. Such additives differ not only in composition, but also by the principle of action. The choice of one or another type of waterproofing work is best entrusted to professionals, especially if everything is not unambiguous, such as with waterproofing of the foundation.

And how much does it pay to you

And how much is Penetron pays you for advertising his materials. Penetron is not a panacea. In addition to him, there are so many materials of penetrating action, including domestic production. "High -quality materials (penetron) are able to penetrate ..." Are other poor -quality or what? Pupils.

As coating

"Bitum and all bitumber -containing materials" But what about the materials on a cement basis? "What about coating waterproofing? Are they exclusively painting or what? Ladia articles.

Penetrating waterproofing

Penetrating waterproofing works only in words. In fact, when penetration, it destroys concrete with aggressive chemistry, makes microscopic pores in concrete. In the thickness of the concrete, it can stop part of the moisture, but not all the groundwater of the entire aquifer, which presses the weight of the building. She will pass these waters through the capillaries inside the room.

By the way, bitumen and

By the way, bitumen and bitumber-containing materials are less reliable than the materials of the synthetic direction, for example, here are used by new senstetic materials by hydrodoma-NN. Dmitry was still drying dry and not any bitumen.

The best waterproofing is

The best waterproofing is liquid polyethylene. I bought in the nozzle, I didn’t flood the neighbors, although it was knee -deep in the bathroom, it did not flow. How!

Waterproofing from the company

Waterproofing from the Optimum Price company throughout the territory of the Russian Federation-8 800 775-94-50.

St. Petersburg-8 (812) 612-23-50

Moscow-8 (495) 291-03-50

www.optpra.ru

Penetrating waterproofing

Penetrating waterproofing Russia

Good day!

We will be glad to friendship with us and your presence in our groups:

https://vk.com/dehidrol72

https://vk.com/apifleks_tmn

https://vk.com/hidrotyumen

https://vk.com/noise_in_house

would give this text

they would give this text to adjust the engineer hydraulic engineer. More than half is frank nonsense, the rest is simply not competent.