Many owners of private houses and cottages are thinking about building a veranda. This ...

|

|

Parquet is one of the best, natural flooring and with ... |

Linoleum is a great option for the flooring is diverse, inexpensive and ... |

Paroc insulation: characteristics, properties, application

The Finnish company PAROC has been producing a basalt -based mineral wool for more than half a century. This material is widely used for thermal insulation of construction facilities of any purpose. The main raw material for thermal insulation material is stone fiber. Thanks to this basis, the final product meets high fire retardant requirements. The company is trying to diversify the assortment so that each consumer can purchase a heater with appropriate characteristics. The article will talk about Paroc insulation.

Content:

- Advantages of PAROC insulation

- Paroc insulation characteristics

- A variety of PAROC insulation

- PAROC insulation

Advantages of PAROC insulation

It is impractical to save on the acquisition of heat -insulating materials. After some time, it is quite possible that it will be necessary to lay out the amount for the removal of work exceeding the initial costs at times.

Therefore, it is important to choose a heater that will not lose its functional qualities for the entire service life. A combination of high quality and attractive price is different from PAROC, which has received many positive reviews.

You can note such advantages as:

- the use of stone cotton wool has no restrictions, it is installed at objects of any purpose;

- the possibility of installation without using a special tool and skills. You can give the plate the necessary shape or size by means of an ordinary knife without effort and dust;

- the fire safety of the building is on top. The melting temperature of the fibers is about 1000 ° C;

- chemical resistance to oils, solvents and moderate acidic media contributes to high quality insulation;

- temperature changes do not affect the material, so expansion or compression for stone wool is not characteristic;

- hydrophobic properties provide small absorption of moisture with material (not more than 10%). After drying, cotton completely restores its thermal insulation properties;

- the structure of the cotton wool provides dense fit to the structural elements of the structure;

- The form of the material is preserved throughout the service life.

Paroc insulation characteristics

This functional element of the structure, of different purposeful purposes, makes it possible:

- create an optimal microclimate indoors;

- reduce heat loss;

- increase the energy efficiency of the entire building;

- increase the life of the construction structure.

Thermal insulation

- The insignificant density of the material is caused by randomly alternated thin fibers between which air contains. Such a construction provides low thermal conductivity, and the lower this indicator, the higher the thermal insulation of the plate.

- It should be noted that the thermal resistance of basalt wool 100 mm thick is equal to wood with a thickness of almost 400 mm, brickwork - 1800 mm, concrete - 4700 mm.

- The thermal conductivity of the same material may vary, depending on the state. So, for example, moist operating conditions significantly increase the thermal conductivity. This is due to the fact that water increases the area of \u200b\u200bcontact between cotton fibers.

- Therefore, when choosing a heater, in addition to thermal insulating properties, it is necessary to pay attention to its hydronemous properties.

The thickness of the insulation

- Properly calculated thickness of the insulation will help to ensure the required thermal resistance. This indicator determines the requirements of SNiP corresponding to each climatic zone.

- The thickness of the heat -insulating layer PAROC is calculated depending on the coefficient of thermal conductivity of the type of stone wool, its location in the construction structure and the presence of other materials.

- To calculate thermal resistance, it is necessary to divide the thickness of the cotton wool into its thermal conductivity. Here, the so -called, calculated thermal conductivity (), which corresponds to the climatic zone under consideration, is taken into account.

- All presented materials belong to the group of the maximum effective heater and have the appropriate indicators for the exact calculation of thermotechnical properties.

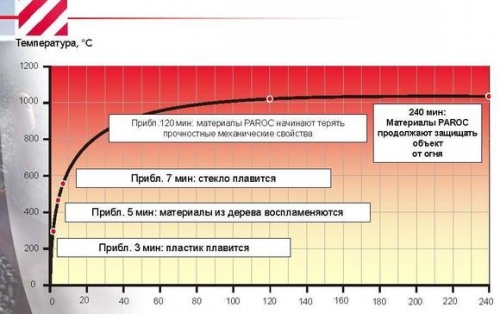

Fire

- The main material for the production of products is the basalt breed. Since cotton wool consists for the most part of stone threads and only a small content of various additives, it does not support active burning. The maximum damage to the product can be obtained at a temperature of more than 1000 ° C.

- Thus, the produced PAROC insulation complies with the most stringent fire safety requirements and can be used as fire protection and fire insulation in structures of any type without restriction.

Environmental friendliness

- The composition and shape of the fibers does not cause a negative impact on human health when installing and operating the product. Biologically persistent material does not provide the opportunity to develop on its surface to pathogenic microorganisms.

- Stone cotton wool does not contain asbestos and other harmful substances. This allows you to classify it to the group of safe materials for the issue of particles. The concern strictly monitors compliance with safety and technological process, paying close attention to environmental protection.

Hydrophobic

- Thermal insulation material PAROC shows the greatest efficiency in a dry state. However, it is impossible to ensure, and even more to guarantee optimal conditions of operation of the structure. In this regard, it is important to know the attitude of the material to moisture.

- In itself, stone fibers have natural water -repellent properties. In the process of wool production, special additives are added, which enhance the hydrophobic of the material. Thus, significantly expanding the scope of its application, providing the opportunity to install in various climatic zones.

- Basalt wool absorbs a small amount of moisture. So when immersing the material in water for a couple of hours, the water volume absorbed by the plate will be no more than 1%, with prolonged immersion (2 days) 3%. It is worth noting that after drying, cotton wool does not lose its positive qualities.

- High vapor -permeable properties allow cotton to remain almost dry. Water pairs, inevitably formed during the operation of the building, freely pass through the structure of the material.

- Properties such as hydrophobic and vapor permeability provide not only a healthy microclimate inside the structure, but also the durability of the entire structure.

Chemical resistance

- PAROC insulation is highly resistant to organic substances. He is not afraid of any effects by either solvents, by alkalis, nor moderately acidic media.

- Vata from basalt fibers cannot cause corrosion of metal elements, but also unable to prevent it. Therefore, all structural parts made of metal must be protected from premature formation of corrosion processes.

- Thanks to the neutral environment, this material is successfully used in the isolation of pipelines, in ventilation systems, frame structures.

Mechanical strength

- The presented assortment of thermal insulation materials PAROC includes both slabs (hard and semi -rigid) and rolled material. The purpose of application determines the choice of material with the required compression strength. This indicator from the type of cotton wool can be from 5 to 80 kPa.

- The strength properties depend on the density of the material, the amount of binding substances, the orientation of the fibers. But at the same time, there is an erroneous opinion that the higher the density, the stronger the stone cotton wool. In this case, we should talk about the specific gravity. A light insulation with high load characteristics gives additional opportunities for arranging a particular system.

- The plates are of low weight, however, have indicators that allow them to be used in various designs. High technical characteristics provide reliability, quality and long -term operation of structures.

Size stability. Easy installation

- Vata does not give shrinkage, is not subjected to deformations at temperature differences. Products retain their shape for the entire service life, thereby guaranteeing the absence of temperature bridges, sometimes arising at the junction of the plates.

- Material of low density is cut by an ordinary knife, slabs with a denser structure by means of a manual saw.

Soundproofing properties of Paroc insulation

- The porous fibrous structure of the plates perfectly isolates the structure from the noise penetrating through the walls and the roof, the inter -story floors and the internal walls. Soundproofing plates are also used to reduce shock noise in floors, and reduce air noise in internal partitions.

- The requirements for soundproofing are influenced by various factors, and here only the characteristics of the slab and the structural element, for example, such as an inter -story ceiling or a carrier wall, are considered incorrectly.

- Therefore, when arranging buildings or premises with high requirements for sound insulation, it is better to use the recommendations of highly qualified specialists.

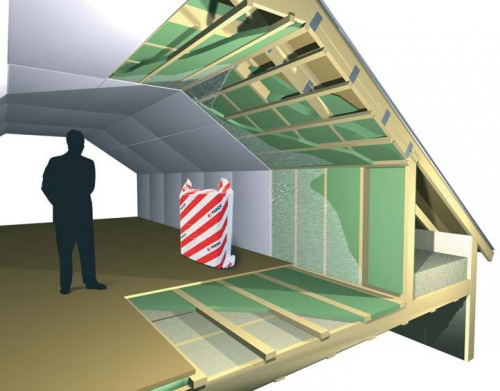

A variety of PAROC insulation

Today you can buy PAROC insulation for any appointments. Mats (roller materials) and plates that differ in technical characteristics are used to isolate all elements of the construction structure. They are distinguished by non -combustibility and thermal insulation properties. Their installation is carried out by a dense insert into the frame cells without additional fixation. No special skills, a special installation tool is required.

Thanks to the light weight and the location of the fibers, the material will not settle between the elements of the frame and will not lose its shape during the entire life of the structure.

Such universal slabs and mats are used in designs where there are no external loads:

- floors;

- attic floors and attic;

- external walls and internal partitions.

Fire boards PAROC

- Steel structures, stoves, smoke pipes and other elements operated at high temperatures need a special insulation. It is for fire protection that plates with the minimum content of additional components are made.

- Such materials will reduce temperature fluctuations, thereby extending the life of the structure. Plates effectively reduce heat transfer through the enclosing elements of the system. The thickness of fire -retardant material for each case is selected separately.

PAROC plates for ventilated facades

Systems are designed for high -rise buildings, where facing material gives them architectural completeness. The ventilation facades contain a set of elements that together provide stable and long -term thermal protection of the building, and therefore isolated rooms.

For such systems, they are used:

- wall slabs with a coating of non -woven glass chilling material, with a thickness of 30 to 180 mm;

- wall compressed material with a coating of the dumbest waterproofing membrane (secret), 30-150 mm thick. Some products are equipped with connecting grooves that provide tight fitting plates;

- plates with a fiberglass coated and secret, the thickness of which can be 20-70 mm. Such materials have a high coefficient of protection of the structure from wind and moisture.

At the request of the client, the company is ready to make products of non -standard sizes with a coating of Thai -Kevek, fiberglass and equip the products with connecting grooves.

Vata is characterized by fire safety and high resistance to mechanical stress. The material does not create an environment for the development of corrosion processes. It is also characterized by high hydrophobic and effective breathability.

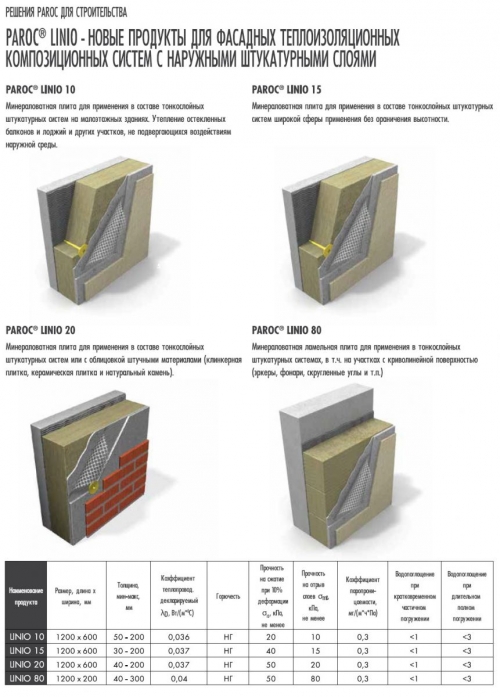

PAROC plates for plastering systems

- Plates designed for facade plaster systems provide a stable even surface for applying the corresponding solutions. Such a device allows you to keep the temperature and humidity regime inside the buildings at the proper level.

- Warming for wet facades are divided into 2 groups:

- light systems where plates are used with a thickness of 20-140 mm. These products are often used as additional thermal insulation of reconstructed buildings;

- systems for heavy plaster. Here are used slabs 30-160 mm thick. The manufacturer also offers lamellas, which are distinguished by high bending strength, which allows them to be used to arrange curved structures.

- These products are distinguished by high thermal insulation properties, they are able to hold glue, reinforcing and finishing layers. The plates are not seated, not deformed in the places of fastening with plate dowels.

- High hydrophobic properties and chemical stability allow the use of various adhesive, plaster compounds, including containing alkaloids.

- On one of the surfaces of the plate, a red mark is applied. When installing, the marking should be turned inside.

PAROC plates for flat roofs

- For thermal insulation of flat roofs, a reliable and effective solution of the Paroc Extra insulation plate is offered, which withstand significant mechanical loads that inevitably occur during installation work and operation of the roof.

- The thickness of the plates can vary from 20 to 180 mm, the letter marking means the presence of a fiberglass coating (T) and the presence of ventilation ducts (G). The strength of the compression of the products is 30-80 kPa.

- Requirements for the loads and functional features of the roof determine the choice of plates. Here, the consumer offers single -layer and two -layer products, as well as ventilated plates, that is, equipped with special ventilated channels.

- These stone cotton wools are characterized by increased compression strength (retain the original shape), and are not subjected to temperature deformations. Plates with special ventilation ducts provide reliability and durability of the entire roof structure.

PAROC plates for reinforced concrete structures

- Hard building codes dictate the requirements for the quality of the enclosing structures. Thermal conductivity, combustibility and moisture resistance of the entire system depends on the well -chosen thermal insulation material.

- Specially designed COS plates are ideal for use in reinforced concrete structures. After all, if the finishing material has less vapor permeability than the concrete, then condensation is formed on the surface.

- In such cases, it is recommended to use stone slabs equipped with grooves (recesses), along which moisture is removed. Drinkanals can be vertical or horizontal, depending on the features of the structure. The thickness of such plates can be both 30 and 180 mm.

- Thus, the railway structure remains dry, and the finishing material is not exfoliated due to increased humidity. Basalt fiber plates are produced both with a fiberglass coated and without it.

PAROC plates for floors

- To insulate the foundation and the arrangement of floating floors, special plates are used. Horizontally oriented fibers significantly reduce dynamic elasticity, thereby the soundproofing properties improve.

- They have high indicators of the strength limit. A flat and dense surface provides excellent adhesion to used solutions (bulk floors). High -quality sound insulation is achieved due to the low reflection of sound waves.

- The thickness of the material is 30-150 mm, compression strength of 15-20 kPa, thermal conductivity 0.034-0.035 W/m ° C.

PAROC insulation

- Products with decent characteristics allows you to solve heat and sound insulation tasks of any complexity. Chaotic oriented thin and long basalt fibers give the slabs and lamella excellent elasticity and strength. Such properties allow you to repeatedly restore the form after forced or not forced deformation of the material.

- The cotton structure gives light weight to the entire product, and air pores provide a decrease in thermal conductivity. Hydrophobic and fire resistant characteristics complete the list of virtues of stone wool.

The above advantages allow the use of material in the construction of residential and commercial buildings, the arrangement of pipelines and shipbuilding, as well as in the construction of industrial structures with increased requirements for fire protection. In addition, the price of PAROC insulation allows you to achieve an optimal ratio of price and quality.