It is difficult to imagine a comfortable accommodation in a house without constant water supply. However...

|

|

Since ancient times, man has tried to protect his housing as much as possible, installing ... |

The word parquet is French by its origin and translated from ... |

Linoleum substrate on a concrete floor: choice and styling

Linoleum is an excellent floor covering variant, inexpensive and durable material will justify all the expectations associated with it. But, when it comes directly about its styling, then two completely opposite technologies are clarified: on the substrate or without it. This issue is not as simple as it might seem from the first consideration, therefore, as they say, you need to dig deeper. The article will talk about how to lay a substrate under linoleum.

Content:

- What is a linoleum substrate and why it is needed

- Types and characteristics of substrates on the floor under linoleum

- Discussion about the foundation

- Linoleum substrate on a concrete floor

- Buy a linoleum substrate on a concrete floor

- When can you do without a substrate?

What is a linoleum substrate and why it is needed

The substrate is a special material made of natural fibers or from raw materials of non -living origin, which serves as a layer between the base and directly the flooring. It is also used in laying the laminate.

The substrate is not only called to be a buffer that increases the life of linoleum, but also has insulating properties. Its purpose can be laid out in three main categories.

- Smoothing minor defects and irregularities of concrete floor. Perfectly even surfaces do not exist. Of course, before laying linoleum, the base is aligned. A substrate will help to bring the result to perfection. Those who believe, her panacea from any tubercles, pits and potholes are mistaken in the floor. Large shortcomings will break through both the substrate, and through linoleum, spoiling it.

Linoleum substrate photo

- Soundproofing. Regardless of its origin, the material under consideration to a greater or lesser extent contributes to the absorption of noise. The neighbors from below will appreciate this (deprived of the opportunity to hear which of the people living above where it went) and the happy owners of the bed linoleum.

- Thermal insulation. For the same reason why the fibers of the substrates extinguish sounds, they contribute to the insulation of heat. Apartments on the first floors, private houses, where the base is flooded on the ground most in need of an additional layer that guarantees heat.

Types and characteristics of substrates on the floor under linoleum

Several types of this material have their name based on the raw materials, which served as the basis for its manufacture. Before choosing which substrate for linoleum is better, you should get acquainted with their characteristics.

- Juetaya substrate for linoleum. Until recently, the fibers of this plant were used only for gross fabrics (such as burlap), ropes and ropes. Currently, it is widely used in many industries, including for the production of building materials that claim to be a high level of environmental friendliness and naturalness. Of its advantages, one can especially distinguish the ability to gain moisture and with time to take it out without getting wet and not letting it further through yourself. So that such a substrate can withstand fire, parasites and mold, it undergoes special treatment with appropriate drugs. Of the negative characteristics, only high cost. Therefore, there is no great demand for such a substrate.

- Croofing substrate for linoleum. And if more accurately crushed wood bark. The heat and sound insulation indicators of this natural and made without any synthetics of the material are really on top, as well as the cost. And one more drawback if it is selected in a room that will be furnished with heavy, massive objects, then they will sell it along with the coating. The shape of the substrate will not be restored, so when rearranging the floor will decorate extremely noticeable recesses from the legs of furniture. It is chosen either with the expectation of a constant arrangement of furniture, or in a room where there will not be a massive chest of drawers or an oak table with a cabinet. In all other cases, its soft spring structure is inappropriate.

- Linoleum linen substrate. The substrate, made on its basis, provides natural and sufficient ventilation, which is a guarantee of the absence of colonies of fungi that love moisture and stagnant air. The fact that this product is natural is understandable and so. And as a result, it needs to be processed from insects and impedes rot. Antipyrene protect it from fire.

- Combined substrate. Heat, dryness, a proper level of sound insulation will provide a material, which is a team of a hodgepodge of linen, wool and jute. This combination gives it both increased wear resistance and the necessary hardness.

- Linoleum. Despite popularity, it has the only constant advantage of a low price. Under linoleum in the process of constant operation, it will soon lose its shape. Along with this, the already low other indicators will leave.

Discussion about the foundation

Disputes about what surface is better to lay linoleum on will unlikely to ever end. But it should be noted that general requirements in this regard still exist. Paul, arranged according to all the rules, has the following characteristics:

- strong foundation;

- the most solid base;

- even location in a horizontal plane. Small differences are permissible, provided that they do not exceed 2-7 mm and are smooth, without obvious bulges and hollows. Then the use of the substrate compensates for this;

- lack of moisture during installation and damp sources in the future;

- lack of spots (oil, fat) and paints.

- Concrete coatingwell suits the above description. Ideally, it should be leveled with the help of independently leafing mixtures. But even they do not exclude the use of the substrate, thermal insulation does not exist excess. Laying should be done on a completely dried base. The just performed concrete screed (depending on the thickness, temperature in the room and ventilation) will dry out and gain hardness at least a month. The check is made using an inverted can or a piece of polyethylene fixed with tape. If, after the night, the condensate of the surface is not accumulated on them for the final finish by the flooring.

- Use as a leveling base plywood on the concrete floor It is possible only if a waterproofing layer will be laid first. Only on it is the installation of sheets on which the substrate and linoleum are creeping.

- Wooden floor It is quite allowed as a base. First, they get rid of bulging nails, and large cracks, irregularities are eliminated by laying plywood (8-12 mm thick). The screws are deeply recessed into its surface so as not to damage the coating later.

- Old linoleum In principle, it does not have contraindications for styling on top of a new coating. The former use of the material will have to degrease, make sure that it is firmly attached to the floor, does not have torn areas. Linoleum can also be laid on the carpet. In this case, the substrates are not required.

- Ceramic tile The same reliable basis as the concrete floor. If she has flaws, the same leveling composition is used.

Linoleum substrate on a concrete floor

From tools and additional materials may come in handy:

- sharp construction knives;

- wide spatula;

- long ruler;

- double-sided tape;

- glue.

If we assume that there is a concrete base, linoleum without a base and a substrate, then a sequence of laying a substrate under linoleum will be such.

- Lining linoleum involves an absolutely empty room. First of all, this is necessary for the fact that immediately after the purchase it cannot be laid out. Therefore, linoleum needs to be cut to the size of the room, adding at least 10 centimeters on each side.

- The material is rolled out of the roll on the floor and left for a couple of days at rest. At room temperature, he will deal, and at the edges it can be additionally pressed, for example, a stack of books.

- The concrete surface of the floor is completely ready for installation: leveled, cleaned, has no cracks and absolutely dry. A substrate is spreading into it. Before laying the substrate under the linoleum, it must be carefully straightened and ensured that it evenly covers the entire area of \u200b\u200bthe floor. If possible, you can let her lay down for a while. When the substrate forms an even coating, it is carefully cut in places where there are excess material. Between themselves, the canvases are fastened with mounting tape.

- Linoleum is put on the corner that will be in sight, that is, the least forced by furniture. Since the material has already dealt with the days that lay on the floor, it will be easier to work with it. It is necessary to check the direction of the picture again, if any matters.

- When one piece is not enough to close the floor in the room in width, you will have to dock and glue two pieces. The stripes cut off with the allowance are laid so that an overlap is formed, equal to 10 cm. The part that is located below is bent, smear the floor with glue and glue tightly. The layers in the place of overwhelming are removed with a sharp knife, and the formed two edges are glued to their places. This technology allows you to perform the joint as imperceptibly as possible.

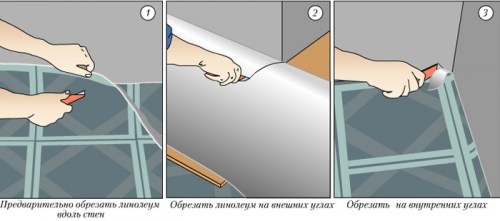

- Now you need to remove the supply of linoleum left along the edges. First of all, this cutting operation is performed in the corners. Then the coating will fall tight enough so as not to make mistakes with trim around the perimeter.

- For the convenience of cutting, you can use a spatula. It is put at the place of excess at the wall, additionally presses linoleum, and a cut is already performed on top of it. Building knives are best suited for such operations.

- If the preparation stage, when the linoleum was previously spread out to deal, was missed, then at the stage of trimming it is necessary to ensure that the edge of the coating does not reach the wall a couple of millimeters. After that, it will still have to be left alone for at least a day. Linoleum will deal and lay exactly along the wall. If after 24 hours he will hump and rest against the walls in some places, then he is again cut.

- The final stage will be the installation of the skirting board.

Buy a linoleum substrate on a concrete floor

LLC Technotex - The Russian manufacturer of insulation and other materials from Jute offers its products in the following versions.

- The substrate exclusively from this plant is produced with a thickness of 2 to 5 mm and has a different density (from 450 to 750 g/m). The price per square meter ranges from 42 to 58 rubles. The width of the proposed rolls is 1-2 meters, the length in both cases is the same 10 m.

- The combined version (jute + wool + flax) is available in the same thickness and density indicators. The price depending on the characteristics from 39 to 55 rubles. The dimensions of the roll are identical to the above option.

- The linen substrate is also produced by this company, but only on order.

- It is worth making a reservation that prices are taken from the official website of the manufacturer, and in retail sale may differ from the declared. If you believe the reviews of buyers, then a square meter of such material can cost from 80 to 150 rubles.

The price of a cork substrate for linoleum on a concrete floor egen (Portugal) 3 mm thick will be 135 rubles/m. Similar material from the manufacturer Porto (2 mm) will be even more expensive than 180 rubles. There are manufacturers offering material from 95 rubles/m.

- Almost 16 square meters of foamed substrate with a thickness of 2 mm can be purchased from 130 rubles. For a roll. As stated, this is the most budgetary, but also the least preferred option.

When can you do without a substrate?

With a careful reading of the above, the question suggests itself: if all surfaces are pre -aligned, then why use a substrate, which is quite expensive in its quality design?

- The answer is. If the material under consideration was needed as a leveling layer, then on even floors the need for its use disappears. This also applies to those types of linoleums that are already produced with a substrate. They are reliably fastened with each other, and this type of flooring is much more expensive than a simple analogue that has no base. If an expensive linoleum is purchased with a qualitative basis, then it makes no sense to duplicate it.

- In all other cases, it is not worth neglecting the substrate, especially if the old flooring is not previously aligned, and the room needs additional thermal insulation.

Pdressing for linoleum video

Lay the material

Lay the material across the future location of the laminate panels. Takws protect yourself from the possibility of converging from your place of fragments of the floor. Read more - http://polprofy.ru

You write that on the carpet

You write that "linoleum can also be laid on the carpet. In this case, the substrate will not be required." We laid linoleum on the carpet. We have a whole linoleum twisted. I had to clean the carpet and lay linoleum in its place.