Sooner or later everyone has to face the need to install pipes. AT...

|

|

In modern private construction, the rafter system of the attic roof gives ... |

In multi -storey and private construction, it is impossible to do without floor slabs, ... |

Walls insulation in the bathroom

Foam is in wide demand in the building materials market. Among its advantages, good thermal insulation characteristics, the duration of operation and ease of installation are distinguished. We will consider how to insulate the walls in the bathroom with a foam.

Table of contents:

- Wall insulation with foam: the advantages and features of the material

- Wall insulation with foam complex - technology and varieties of material

- Wall insulation from the inside with a foam in the bathroom

- Wall insulation with a foam for siding: technology for installation of insulation

Wall insulation with foam: the advantages and features of the material

Foam is attributed to materials that perform the function of protecting the room from thermal losses. Its installation can significantly reduce the thermal conductivity of the section of the building on which it is installed.

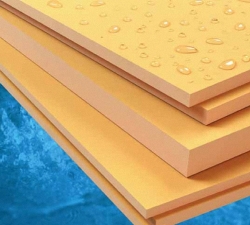

The foam is produced as plates, which are extruded foamed polystyrene. In appearance and structure, this material is often confused with polystyrene. However, the polystyks have a higher level of stiffness and strength.

In addition, this material is distinguished by the following advantages:

- low thermal conductivity, due to which the material is able to retain heat in the room;

- high level of strength both before the bend and compression;

- Sustainability before moisture is ensured by low moisture -release of the material, this advantage allows to reduce the level of development on the warmer of mold and fungus and increases its service life;

- low vapor permeability;

- the duration of operation, which is more than 50 years;

- stability before fire and a high level of fire safety;

- environmental safety, lack of harmful human health;

- The possibility of operation at temperatures is from -40 to +70.

In addition, the installation of a foamyplex does not require special work or special equipment skills. One day is enough for work. The cost of the material, in comparison with other types of insulation, is average, therefore, comparing the quality and price of the foam, it is possible to get a high -quality insulation for a moderate amount of money.

However, the use of a foam for outdoor insulation of the building, and in particular for facade systems, leads to a gradual intoxication. This is due to the fact that the material has a high density that does not allow it to absorb glue, therefore, some time after the installation of the foam, under the influence of moisture and other external factors, it exfoliates from the surface and the appearance of the facade, spoils.

Therefore, to prevent this unpleasant factor, special fasteners should be used - fungi. Also, the option of replacing the foam with foam, which in external insulation is more practical, is possible.

Wall insulation with foam complex - technology and varieties of material

There are several types of foams, which differ in the relationship with the density and the sphere of application. The plates have a standard size, but if necessary, they are easy to cut and install on the surface. Depending on the thickness of the foam for insulation of walls, a foam is distinguished from 2 to 10 cm.

In addition, such varieties of the foam are distinguished:

1. The walls used for insulation - allows you to insulate the walls of the building both inside and outside. In addition, with its help, the base and interior partitions are insulated. The material is suitable for the construction of walls using the method of well masonry.

If the wall insulation is performed by the foam from the outside, then siding, tile or wall is placed on top of the thermal insulation material.

2. Foamine for insulation of the foundation. Used in the process of basement construction. This material has zero moisture heating and increased density.

3. Roof insulation is also possible with a foam. It is used for insulation of the roof of both flat and pitched species. The material has excellent thermal insulation characteristics, due to its lightness it does not load the structure.

4. Warming of roads and runways - even in such cases, the use of a foam is mandatory.

5. Another version of the foamyplex is designed for internal insulation of the house or apartment. With it, it is possible to insulate the walls, floor and ceiling of any room.

In order to warm the walls with a foam, perform the following actions:

1. Preparation of the base.

This stage implies the preparation of the surface for the fastening of insulation on it. The surface, regardless of its type, should be clean, dry, cleaned of the finish and paint. To align the walls use plaster. Next, the processing process of surface with an antiseptic effect follows.

2. Installation of plates with glue.

In order to glue the stove, we recommend using a special glue that is in configuration to the insulation or recommended by its manufacturer. Glue is applied directly to the surface of the plate.

3. The mechanical method of installation.

After gluing the slab to the surface, the process of its mechanical fixation follows. This is necessary in order for the stove, when it is peeled off, it still holds on the surface. One meter square slabs will require the installation of four dowels. If the plate is installed near the window, door or in the corner, then the number of fasteners must be increased.

4. Fixing the insulation by plaster solution.

In order for the insulation to clarify better with plaster, we recommend using a karshchka that will help to make its texture more rough. On the first layer of reinforcement, a polymer grid with a reinforcing effect is replaced. Further, the plaster solution is applied a second time and further wall decoration is performed.

5. Installation of insulation indoors.

It is possible to use a foam for insulation of the external walls, it is also used indoors. We recommend that if possible to install the foam from the outside. However, with internal insulation, after the installation of the insulation should be installed on it with a foil coating made of polyethylene. It will provide proper vapor barrier. Next, the plasterboard is installed and work is carried out on the decoration of the room. To install the frame under the installation of drywall, use dowels, which, having passed the turn of the foam, reach the wall and fix the profile on it.

Wall insulation from the inside with a foam in the bathroom

The bathroom is a place with a high level of humidity, and proper insulation will prevent the formation of condensate, which adversely affects the decoration of the room. There are several options for insulation that are used in the bathroom, among them they note:

- cork - material in a roll form, which differs in the convenience of operation, and is easily installed on the surface of the walls and in the underlying system, among its advantages, non -possessions of decay, stability before moisture and the duration of operation are noted;

- Mineral wool is more popular than the previous option, however, it is distinguished by hygroscopicity and unstable before moisture, therefore, in the process of its use, proper waterproofing should be ensured;

- The foam, although it is cheap, it also absorbs moisture because of its porosity, after its installation, it is necessary to install a plywood or drywall with moisture-repellent properties;

- The foam is characterized by low thermal conductivity, but at the same time it has a high density, it is used for insulation of both the screed and the walls of the bathroom.

The choice of a particular type of insulation primarily depends on the material abilities of the owners of the house or apartment. More inexpensive materials have a low density, and therefore they steal the living space, since to obtain the proper effect of insulation, they should be laid in several layers. If you use the polystomplex, then a maximum of 50 mm is lost.

We offer to familiarize yourself with the process of insulation of the floor in the bathroom:

1. At the initial stage, the arrangement of proper waterproofing is arranged, which will prevent contacting the insulation with moisture. In the presence of a concrete floor, the most optimal solution will be the use of waterproofing an impregnation type. It is able to penetrate 5-10 cm deep into concrete and creates a crystalized surface that does not allow moisture to penetrate to the insulation.

2. If there is a cold floor in the bathroom, the foam is laid, lay the mats with which the system of warm electric floor will function. Next, the system is connected to the mains, checked for performance and poured with concrete solution. Further actions are associated with the flooring using tiles or other finishing materials. Installation of the thermostat will maintain the temperature at the right level.

To insulate the wall in the bathroom room, we recommend using plates designed for further plastering. Foamyplex, insulation of the brick wall in the bathroom - the procedure:

- The use of plates for plaster will preserve the living space;

- In addition, the surface of the walls will be protected from mechanical damage by plaster;

- Before starting the installation of the foamyplex, you should take care of the preparation of the walls, their equalization, cleaning from paint or finishes, with its presence and coating with a primer with an antiseptic effect;

- The adhesive solution is applied to the stove using a toothy spatula, then the plates are installed, starting from the lower part of the wall, gradually moving to the top;

- After insulation of the walls, they are pasted with a painting grid and further putty, it is possible to install a frame for drywall or moisture -resistant plywood;

- Further actions are associated with the implementation of finishing work.

Wall insulation with a foam for siding: technology for installation of insulation

The preparation of the surface for the installation of the insulation is as follows:

1. Cleaning the walls of dirt, dust, paint and other kinds of decoration, if any. The dismantling of various kinds of structural elements is also carried out that prevent the installation of the foam.

2. Walls are checked for the presence of fungus, mold, processing them using an antiseptic.

3. Using the level, check the evenness of the walls and remember the deviations from the norm. If steel elements are on the walls, then they need anti -corrosion treatment.

4. In addition, markings are made according to which the installation of profiles will be installed on which siding will be recorded. Fasteners are also installed for fixing the air conditioner, lighting or drainage systems.

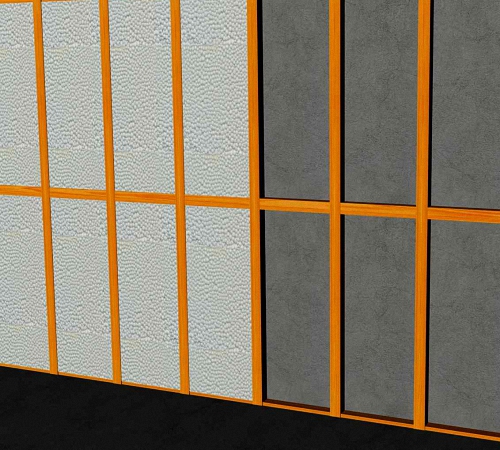

Before starting the installation of brackets, the vapor barrier film should be installed on the surface of the walls. Next, markings are made for installation of suspensions. Installation of the profile system is vertically. If you plan to install vinyl siding, then the interval between the profile is about 400 mm, if siding is installed, then the distance increases to 600 mm.

To perform work, the availability of:

- tool for testing evenness;

- roulette;

- plumbing;

- hammer;

- a perforator for a building with brick walls;

- screwdriver;

- electrodele;

- hacksaw.

Installation work begins with the installation of the profile on the basement of the building. Before starting thermal insulation work, a starting profile is installed. The place of its installation is below the building. Thus, the foam will be protected from rodents, moisture or mechanical damage.

Instructions on how to install a basement:

- The profile is mounted with an interval of 30 cm, for these purposes it is recommended when warming a wooden wall with a foam, use wood screws;

- If the wall of the building is made of bricks or concrete, then the use of dowel-gvo, the size of which is from 4 to 10 cm;

- Keep in mind that the profile should fit very tightly to the wall, if there is little space between the profile and the wall, then it is necessary to install special lining washers;

- To connect the profiles with each other, use special locks located on its end part;

- It is forbidden to install the profile in overlap.

Tip: To provide reliable moisture on the facade system and to prevent the warming of the insulation, we recommend buying a special profile that has a drip system.

To install the foam, perform a number of actions:

1. Install the first row on the surface of the basement.

2. Install the P-shaped suspension in the working position, at the junction of the foamyplex with the suspension, it is necessary to cut out a small area to string the material on its surface.

3. After the installation of the first row of insulation, the wall should be checked for evenness and quality adjustment of the insulation to the wall.

4. To fix the insulation on the wall, special fasteners are used. They have large hats, for the installation of a foamyplex on one square meter, you need to use at least four fasteners. If the installation of insulation is carried out in a wooden house, then lining washers and screws are used.

5. For the installation of the second and subsequent rows of foam, apply the method of laying brick. That is, the material should not coincide with each other at the seams. The seams should diverge at least 20 cm.

6. After the installation of the foamyplex, a visual examination of the wall is performed, if there are large joints on its surface, the foams should be installed in them.

Keep in mind that filling the joints with glue, mounting foam or sealant is unacceptable, since over time, when wet, these materials will lead to corruption of the facade.

Wall insulation with a foamlex video: