The most important element of the house, which affects the entire building, is the roof. Her...

|

|

From such an event as sealing seams in panel houses, in... |

Kaleo Trade company produces and implements an infrared film floor ... |

DIY insulation with foam

Penophol is a thermal insulation material of the new generation. Among the alternative variants of insulation, it is highlighted primarily by the presence of a foil layer, due to which it has certain advantages. We will consider further about the features of the installation of foam and its use.

Table of contents:

- Characteristic and properties of foamed foam

- Penophol foil use and advantages

- House insulation with foam - Features of installation

- Disadvantages of insulation with foam from the inside and outside

- DIY insulation with foam

Characteristic and properties of foamed foam

Penophol is called foam polyethylene, covered on one or two sides with the thinnest layer of foil, with heat loss, heat is transmitted in two ways:

- convection;

- Through thermal radiation.

But, most heaters are designed to prevent heat transfer in one of the above methods. Penophol is able to prevent both convection and heat transfer of heat. Therefore, its thermal insulation indicators are much higher than that of alternative types of insulation.

It is precisely due to this structure that Penophol is an excellent heat reflector, and does not allow air convection. With a heat thickness of 10 cm, it is able to maintain heat several times higher than the wall made of brick, 50 cm thick.

In addition, this type of insulation is characterized by the ease of installation, steamability and good protection against various kinds of radiation. Due to the presence of good technical characteristics, the material is used both in the insulation of residential and public premises, and for thermal insulation of baths, warehouses and pipeline systems.

Foam -type foam is referred to as reflective thermal insulation. Since it is distinguished by the presence of closed pores and polished foil, which allow him to maintain heat at a very high level.

In the process of installing foil foams, there is no need for the installation of waterproofing and vapor barrier materials, and, as a result, the costs of carrying out this kind of work are reduced.

The most common are three types of foil penofol:

1. Materials A class - differ in the presence of foil only on one side of the insulation. It is used in the process of insulation of the roofing sections of the building and utilities.

2. The insulation in the class has a double -sided foil coating. It is used in the process of insulation of inter -story floors and various kinds of internal partitions.

3. Penophol from the class is characterized by the presence of a foil coating on one side and the adhesive layer on the other. It is used during installation work in uncomfortable areas of insulation.

In addition, there are options for a foam with the presence of a mesh layer and foil, with a foil coating and a laminated film made of polyethylene, with a relief foam polyethylene structure, etc.

The material is most often released in a roll form, it differs in thickness from 3 to 10 mm.

Penophol foil use and advantages

Since the foam coating is made of aluminum foil, it is able to reflect about 98% of thermal energy. Thanks to this, a comfortable temperature in the room is maintained: in the summer it is cool, and in winter it is warm. Due to its strength and flexibility, Penophols falls perfectly on any surfaces, in addition, it has significant steam and sound insulation characteristics that persist throughout the entire period of its use.

The scope of use of the penopol applies not only to residential buildings, but also to industrial and civil construction. It is used for thermal insulation on ceiling and attic floors, when arranging floors, installing wall panels, to improve thermal insulation of basements, attics, balconies, air conditioners, air ducts, technical pipelines, etc.

The material has high insulating properties, and therefore is suitable for thermal insulation of areas on which both hot and cold products are transported. The use of penopol is associated with thermal insulation of transport, tents or sleeping bags, in hikes.

Among the advantages of insulation with foam should be highlighted:

1. The multifunctionality of the insulation.

When using a foam, it will not be necessary to carry out additional work aimed at ensuring steam and sound insulation. The installation of additional membranes, films and other waterproofing materials is not required. In addition, the foam is installed both inside and outside the room, which ensures its moisture resistance and universality of use.

2. Small thickness of the material - high thermal insulation characteristics.

With a slight thickness, the foam provides several types of thermal insulation at once, which is very important when arranging areas of an inaccessible nature. When installing insulation in the internal areas of the room, the useful area is practically not lost.

3. The presence of a wide range of products.

There is a wide variety of species of foam that helps to choose exactly the material that is able to fully ensure the satisfaction of the individual needs of the insulated building or object. With the help of foam, the buildings are insulated both inside and outside the rooms.

4. High strength and good quality.

Due to the use of advanced technologies for the manufacture of material, it provides minimal heat loss, which make up only a maximum of four percent. Another advantage of this material is the fact that it is capable of not only holding heat, but also convets it back into the room. Due to the special structure, moisture does not penetrate its surface, and the temperature of use is from -55 to +100 degrees. The principle of its work is similar to the thermos, in the warm season it gives coolness, and in cold weather - so necessary heat.

5. Convenience of work and ease of installation.

Since the insulation has the shape of a roll, it is quite convenient during installation and easily lays on any surface. In addition, for hard -to -reach areas, a special form is used, on the one side of which a foil coating is applied, and on the other, a layer of glue. To install the insulation, it will not be required to install additional supports or frame structures, it has lightweight and is fixed directly on the insulated surface. Simple scissors are used to cut off the desired size. For work, one person is enough.

6. Environmental safety and affordable price.

There are no substances that are harmful to human health or the environment, so it is used without restrictions for internal insulation. Since additional hydraulic, steam and sound work will not be required, using this insulation it will be possible to save significantly.

House insulation with foam - Features of installation

This material is used as an independent insulation or in combination with other materials of the same purpose. In a wooden house, the insulation of the loggia by Pelophol is very simple and easy. Since it is glued to the wall before performing its finish. In addition, insulation of the floor with a foam does not require hiring specialists, since this procedure can be easily performed independently.

To attach the material to the surface of the walls, use glue, stapler or nails. For gluing seams, aluminum adhesive tape is perfect, which will help prevent a violation of the integral structure of the reflective coating. Keep in mind that the material is installed by the reflecting side into the room, since it is this side that contributes to the return of heat to the room.

In addition, the use of foil foams in the process of insulation of ducts and chimneys is common. This procedure is not complex, since the material is particularly plastic and the presence of an adhesive base, which is simply glued to them. Installation work is carried out at any time of the year and at any temperature, and no special equipment is required to carry out them.

In order to avoid moisture accumulation, leave a small gap between the foam and other material on which it is attached. The service life of this insulation is very high, since it consists of polyethylene foam, which is able to function normally for more than two hundred years.

Disadvantages of insulation with foam from the inside and outside

Although the penofol is characterized by a huge number of advantages that distinguish it against the background of other heater, it still has certain shortcomings, which we will talk about later.

Penophol is not enough, which makes it impossible to further decorate the walls, immediately after its application.

The use of brackets for the installation of foam is possible, but its thermal insulation functioning is deteriorated. Therefore, it is better to use glue.

To ensure full -fledged insulation of the walls of the residential building, it will be necessary to carry out comprehensive work of thermal insulation nature, which include the installation of several types of insulation along with foam.

Tip: If a deformation or a cut of foament occurred in the process of work, then to restore it, it is enough to process this place using aluminum tape.

To improve the thermal insulation properties, lay several layers of the foam one on the other.

Penophol is an excellent insulation of baths or saunas, since in these rooms it provides quick warming up and a long cooling of the walls. Keep in mind that from the side of the foil coating there should be a small gap that prevents the formation of condensate.

DIY insulation with foam

We will talk about the process of insulation of walls in a brick house further. We offer to familiarize yourself with the instructions for the conduct of thermal insulation work indoors:

1. The benefit of insulation of brick walls with a fenophol consists in using a minimum of a useful area, which is so important for owners of small apartments or houses.

2. The brick house is better to insulate from the inside, since loading - is characterized by a beautiful external species, which the foam is able to spoil.

3. The primary conduct of internal thermal insulation involves attaching the film using liquid nails. The thickness of this layer is two millimeters. In the presence of electrical wiring, additional thermal insulation is not required, since aluminum is an excellent electricity conductor.

4. To fix thermal insulation on the surface of the wall, it will be necessary to build a wooden frame. Keep in mind that you need to leave a ventilation gap of at least two centimeters.

5. Using the construction stapler, lay the foam on the walls and fix it.

6. In order to eliminate the resulting gaps, pour from with the help of foam or silicone. To fix the joints - enough aluminum tape.

7. The second wooden frame is also made of bars, two centimeters thick. Drywall is attached to it. Further finish is carried out in accordance with the personal preferences of the hosts.

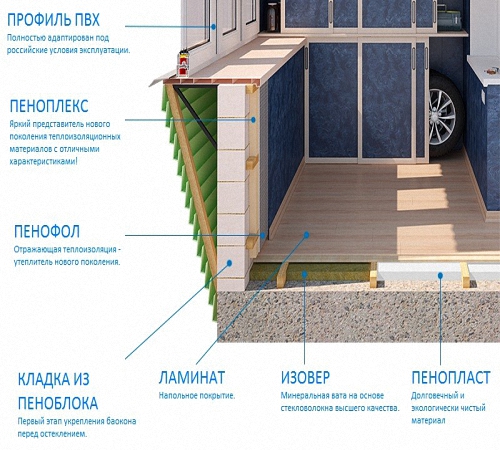

The insulation of the balcony with a foam has a slightly different technology, we will talk about it further:

1. The first stage is the installation of lining. Its thickness is about two millimeters.

2. Further, with the help of umbrella dowels, the foam is fixed on the surface of the wall. Its thickness is the same as that of the previous layer, and the diameter of dowels is 0.6 cm. This material provides fire safety and moisture resistance.

3. Pay attention to the corner areas, they should not contain joints, since it is these places that are prone to the formation of mold and fungus.

4. To sew joints, use high -quality metal tape. It will provide vapor barrier.

5. Penophol is laid on the foam. To carry out the installation process, use self -tapping screws, 0.4 cm thick, and a half -meter styling step.

6. To ensure a high level of thermal insulation and vapor permeability, use metal tape to seal the joints of the foam.

7. Make a crate from wood and dowel-gvo. It will be required as a fastening of the base for the finish.

8. Carry out work on the arrangement of electricity, if necessary.

9. Close areas on the windowsill, if it is available.

10. Leave an air gap with a thickness of 1.5 to 4 cm, to prevent moisture accumulation. Install drywall and proceed to the finish finishing of the balcony.

Please note that all thermal insulation work is carried out exclusively after glazing the balcony.

The procedure for insulation of external walls is more complex and requires compliance with certain technologies, which we offer to familiarize yourself with:

1. The first stage is a thorough removal of the facade coating.

2. Next, the wooden frame is installed on which the insulation will be attached.

3. After completion of the work, the foam is installed and fixed on the surface with the help of glue or stapler.

4. The next stage is the installation of wind protection and waterproofing. For these purposes, a superdiffusion membrane or OSB slab is suitable.

5. Then remote bars are mounted on which further facade trim is carried out.

6. In addition, one should not forget about the wind gap that prevents moisture accumulation.

7. The final stage is the installation of facade coating, for example, siding.

Penophol insulation video:

you can fix the profile directly

can you fix the profile right on the penofol with a wave vertically and where to outside? Thanks

Absolutely dull article.

Absolutely dull article. Everything is mixed - and the truth and the facts sucked from the finger. The manager clearly wrote, but he doesn’t have to know anything in a non -romance - he will damage "effectiveness".