Despite the rapid development of the construction sphere and the emergence of the latest methods ...

|

|

Yacht varnish has long been successfully used to process wooden surfaces ... |

Today, many people are interested in the possibility of independent houses. Why... |

The facade insulation with polystyrene foam: step -by -step instructions

The feasibility of thermal insulation of walls is obvious to many owners of apartments and private houses. Currently, polystyrene foam is used as the most effective insulation. Thanks to such thermal insulation, it is possible to significantly reduce the cost of heating the premises. In addition, the insulation has a fairly lightweight, which greatly simplifies the installation procedure. The article will talk about how to insulate the facade of the house with polystyrene.

Content:

- Advantages of insulation of facades with extruded polystyrene foam

- Characterization of polystyrene foam

- Myths about polystyrene foam

- Comparison of polystyrene foam with another thermal insulation

- Choosing polystyrene foam for the facade

- Insulation of the facade of the house with polystyrene foam

- Materials and tools for work

- Preparatory work before insulation of the facade of polystyrene foam

- Sloping and installation of castings

- Installation of polystyrene foam on the facade

- Fastening the reinforcing mesh

- Preparation for finishing

- Compliance with technological norms of work with polystyrene foam

- Common errors when decorating facades with polystyrene foam

Advantages of insulation of facades with extruded polystyrene foam

Faced household insulation has several advantages.

- Insulation of the outer surface of the walls guarantees the location of the dew point outside the bearing wall. What is guaranteed to relieve the situations of freezing walls and moisture accumulation.

- The insulated facade of the building for thermal inertia will perform the function of a temperature stabilizer. Night lowering the temperature regime will not affect the changes in the climate indoors.

- External insulation, unlike the internal, does not affect the change in the area of \u200b\u200bthe rooms.

Characterization of polystyrene foam

The unique technology for the manufacture of facade polystyrene foam promotes high strength and durability of the material, in comparison with other types of insulation.

Production process:

- polymer granules are connected to a foaming catalyst;

- in the future, the finished mass is subjected to heat treatment using the active substance of the extruder. Its main task is the uniform distribution of components and the formation of a homogeneous substance;

- plates of various sizes and thickness are formed from the finished composition, after which they undergo a cooling procedure;

- the result is high -quality thermal insulation.

The advantages of polystyrene polystyrene:

- highness;

- waterproofing properties;

- low fire hazard (does not ignite, but with prolonged exposure to high temperatures or fire begins to melt)

- resistance to chemical effects;

- environmental friendliness;

- compliance: Price - quality.

Myths about polystyrene foam

The market for thermal insulation materials is represented by a wide choice of insulation of various shapes, sizes and structures. Polistyle foam appeared relatively recently, but has already managed to form myths and misconceptions regarding its quality.

- For insulation of the facade, it is more priority to choose extruded polystyrene foam instead of the usual. The only difference between these two materials lies in different production technologies. In the manufacture of foamed insulation, a higher temperature and a pressing method are used. The difference in thermal conductivity is 0.002 units. When choosing one of the materials, it should be borne in mind that extruded polystyrene foam under the influence of ultra -high temperatures is capable of deformation. In addition, its fastening, unlike other materials, is carried out using special glue.

- Walls covered with polystyrene foam are devoid of air exchange. This is true. The insulation comprehensively protects the building from the receipt of both warm and cold air. This is its purpose. And for air conditioning indoors, it is necessary to use ventilation systems.

- Polystyrene foam is an easily ignited material. This is not entirely true. The material can really get damage from fire, since it includes certain chemical components. However, competent installation and compliance with all its technical features completely exclude the fire of the material. In order to avoid a fire, polystyrene foam cannot be used to insulate chopped pipes, fireplaces, and sheathe the walls of the bath and the boiler room. The burning temperature of the insulation is +490 C0. This value is twice the value of the combustion of wood and paper.

- Foam polystyrene is short -lived. This is not quite reliable information. Polyteral foam slabs can withstand cyclic tests on average for 80 years. But, the material may affect the mechanical effects and ultraviolet radiation. However, being under decorative trim, the insulation has a sufficient supply of durability.

- Polistyle foam is a material dangerous to health and ecology. The harm of polystyrene foam has not yet been proven. In addition, it is constantly used as a material for creating food packages. The composition of polystyrene foam does not contain toxic substances, and its chemical formula is not able to harm human health. As for the ecology, this material should be disposed of in a special way, and not be thrown out in places of accumulation of public garbage.

- After installing the reinforcing mesh, you can immediately start painting. This is not so, on top of the reinforcing base of the wall it is necessary to dump or plastered. This is not carried out to create a beautiful texture, but to protect the thermal insulation layer from mechanical damage, but a reinforcing layer from moisture.

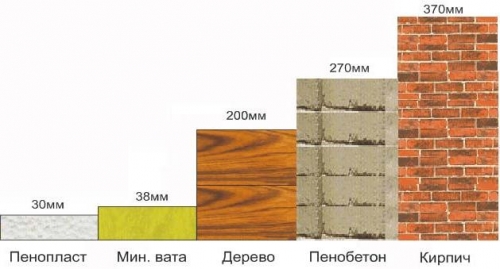

Comparison of polystyrene foam with another thermal insulation

In order to verify the need to purchase polystyrene foam as a material for insulation of the facade of the house, it is worth considering its distinctive characteristics with other insulation.

- Mineral waters. Mineral wool is considered no less popular material for insulation in recent years. Thermal insulation is a material based on fibers that are obtained during the melting of mountains and toxins. The main advantages, unlike all other materials, are high fire -fighting qualities. As for the shortcomings, the most noticeable is hygroscopicity. The insulation is able to import into itself all the surrounding moisture, which negatively affects the walls of the building. This factor complicates its safety before the start of work on insulation of the house. As for heat capacity, both heater: both polystyrene foam and mineral wool show the same results.

- Basalt cotton wool. The insulation is made of basalt breeds in the process of swimming until the fibrous structure is obtained. In addition, unlike the mineral analogue, it has water -repellent properties. During operation, it is not deformed and suitable for both internal and external insulation.

- Penophol. The material is presented in the form of foamed polyethylene, on one side covered with a layer of foil. It is used both for thermal insulation and waterproofing. It does not contain dangerous substances for the ecology. Unlike polystyrene foam, more suitable for internal work.

Polistyle foam is considered a universal material for thermal insulation, its properties in some cases are similar to other heater. But there are certain advantages: moisture resistance, ease of installation and excellent thermal insulation properties.

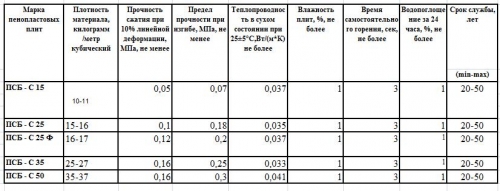

Choosing polystyrene foam for the facade

- The specificity of the insulation of facade walls involves the use of C-25 dense polystyrene foam. Such a density was not chosen by chance, since the higher its indicators, the better thermal insulation properties.

- Material with a density of 15 kg/m3 will no longer be able to provide the necessary structuralness for insulation of the facade of the building. In addition, there is a possibility of damage to the material during decoration and further operation of the house.

To date, the decor of the external walls is gaining popularity by elements of the facade of polystyrene foam. With a low cost, this is an easy way to transform the appearance of the house.

Insulation of the facade of the house with polystyrene foam

Materials and tools for work

In the process of insulation of the facade of the house, polystyrene foam will be needed by the following tools:

- drill;

- construction knife;

- a hammer;

- spatulas of different lengths;

- plumb and level.

In addition, the following materials should be prepared:

- sheets of polystyrene foam (density - 25 kg/m3, the thickness of the main sheets - 5 cm, the thickness of sheets for slopes - 3 cm);

- fasteners: broad -headed dowels, plastic nails;

- glue;

- mounting foam;

- reinforced mesh;

- decorative finish

- primer;

- basement profile.

Preparatory work before insulation of the facade of polystyrene foam

Before insulation of the facade, polystyrene foam should be carried out thorough preparation.

- Dismantling from the surface of the walls: storm drains, castings, ventilation grilles, control of control climate, lighting devices, decorative elements. Removing the previous finish: tiles, residues of plaster, paints.

- Next, check the smoothness of the surface and its deviation along the vertical line. For the installation of polystyrene polystyrene, the formation of a perfectly flat wall surface is not required. However, significant changes should be leveled with plaster, since moisture can accumulate in the recesses that will negatively affect the insulation layer.

- If the surface of the wall is covered with loose trim, it must be strengthened by a primer. And after drying, apply a layer of plaster.

- The insulation material does not need additional preparation only if the extruded type of polystyrene foam is not used in the work. This insulation has a smooth surface, which must be made more porous before installation. To do this, one side of the foam leaflet must be pierced with a needle roller. If this is not in the arsenal, you can use a construction knife, creating shallow notch.

Sloping and installation of castings

- The next step in the implementation of facade insulation work must be mounted and thermal insulation of slopes. The length of the tide should fully correspond to the thickness of the layer consisting of polystyrene foam, plaster and additional backlash of several centimeters.

- You need to insulate window slopes. For this, polystyrene foam is used at least 2 cm thick. It should be borne in mind that the insulation should protrude 1 cm from the material that covered the walls. Such a margin will make it possible to make a better docking of the insulation fixed on the slopes with the one that covers the walls.

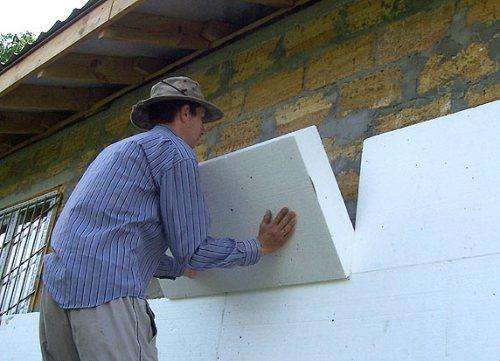

Installation of polystyrene foam on the facade

The gluing of polystyrene foam to the surface of the walls is carried out on the mounting glue. Additionally, the material is attached using broad -headed dowels.

Stages of work

- In the lower space of the wall, you need to install the starting profile. In the future, he will hold polystyrene foam on glue and deprive him of mobility.

- Next, you should apply the adhesive on the entire perimeter of the wall and additionally, by the point method, throw a large volume of the composition to the edges and middle of the leaf from polystyrene foam. At this stage, with the help of glue, you can adjust small irregularities in the surface of the wall.

- The sheets are tightly pressed against the wall one after another. You can glue the material only with a horizontal displacement. The clutch period of polystyrene foam with walls takes about three days.

The facade insulation with polystyrene technology

- The next step will be the consolidation of the polystyrene polystyrene sheets using dowels. The length of the mount should be calculated taking into account the entry into the wall of the building by at least 5 cm. They need to be placed in the joints and in the central part of the sheet. For this, holes with a diameter of 1 cm are prepared. In this case, the depth value should be higher than the length of the fasteners. Having installed the dowel in the groove, it is necessary to score a plastic nail.

Tip: Plastmass is not accidentally selected as a material for fasteners, since it does not have a conductivity of low temperatures, unlike metal.

- The distance between the sheets of polystyrene foam, exceeding the width of 0.5 cm, must be filled with foam. If the dispersion exceeds 2 cm, then it must be closed with strips of insulation, and then thoroughly dump. Five hours later, the foam finally freezes, and its surpluses are removed by a construction knife. Visible irregularities should be leveled with a grater intended for polystyrene foam.

Tip: When performing insulation in two layers, it is necessary to carry out fasteners with the intersection of the seams: longitudinal and transverse. Thus, we can avoid daring the joints of the lower layer.

- The hats of nails must be cleaned and thumbled. The uneven putty must be polished with medium -grained sandpaper.

Fastening the reinforcing mesh

The facade of the buildings is evenly covered with a reinforcing mesh, which is preliminarily attached to the Perfougans. For external work, a grid with a density of 150 g/m2 is suitable. The evenness of the finished surface will directly depend on the density indicator. You need to stick a net using mounting glue.

Fastening the grid on slopes and walls of the walls:

- for the design of the angles of walls and slopes, 30 cm should be cut from the grid of a strip. When preparing the material for decorating slopes, it is worth considering the height of the opening;

- next, the strip is bent in half;

- at the corner of the building, it is necessary to apply the mounting mixture using a wide spatula;

- the net is tightly pressed to the corner or slop and smoothed with a rubberized spatula.

Installation of the grid on the facade:

- the walls are covered with a net with small canvases;

- the mounting mixture is applied 0.3 cm thick;

- the material is applied in such a way that 10 cm of its surfaces lay on a polystyrene uncreased with a solution;

- next, you should smooth the reinforcing surface using a rubberized spatula, making movements from the center to the edges;

- if necessary, you can add a mounting solution for uniform coating of a construction grid;

- the solution is applied to the uncovered areas of the material and the next strip is laid;

- after complete hardening, it is grouting with sandpaper with fine grain.

Preparation for finishing

- Before the final decoration of the facade of the building, after the insulation procedure using polystyrene foam, it is necessary to carry out a number of preparatory work.

- The first step will be the application of the leveling layer. It is applied using a large spatula (35 cm). This layer is polished with fine -grained sandpaper.

- The next action will be the priming priming (with the exception of the moments when a decorative coating in the form of tile or brick is used).

- The work ends with finishing: decorative paint or plaster.

Compliance with technological norms of work with polystyrene foam

All stages of the process of insulation of the facade of the building with the help of stoves from polystyrene foam are needed to comply with the technological aspects of the work:

- temperature indicators should not be higher than 25 degrees of heat;

- humidity should not exceed 80%;

- throughout all stages, it is necessary to carefully protect the facade of the building from exposure to sunlight and precipitation.

Insulation of the facade by polystyrene video

Common errors when decorating facades with polystyrene foam

The insulation of the facade of the building from polystyrene foam has become the most common way of insulation. This is not at all surprising, since the installation of plates is quite simple and occupies a relatively small period of time. In addition, the process of insulation does not require special knowledge or use of professional technology. But, as a rule, with the first experience of working with polystyrene foam, certain errors and shortcomings are allowed, which in further operation will be manifested by unpleasant consequences. What is worth paying attention to in the process of thermal insulation.

- High -quality installation of a basement rail. As a rule, only the ends are fixed. The result of such actions is its deformation under the influence of high temperature, after which the rail is bending and contributes to the appearance of cracks in the facade decoration. In order to avoid such problems, it is necessary to cut off the lower part of the polystyrene foam in such a way as to compare the material with the basement and create an additional mounting point. On top of the cut area should be knocked out 10 cm of finishing, glue thermal insulation and construction mesh. On top of the prepared base you can apply finish.

- When using a guide rail, do not bend the grid under it. It must be cut along the lower edge of the rail. This is due to the fact that the adhesion of metal and plaster is relatively low. Otherwise, plaster can quickly fall off the wall.

- In the absence of a basement rail, polystyrene foam plates will be directly in contact with the soil. The result of this interaction will be the wet of the material, which will lead to a deterioration in its properties. When fastening thermal insulation in the basement, the best option would be to use extruded polystyrene foam. It has a greater density, repels moisture and has low heat conduction parameters. The construction grid in such a case should be wrapped directly under the heat -insulation sheets.

- Foam polystyrene can only be fixed on an even base. If the plaster has bulk properties, it needs to be pre -knocked down or strengthened with a primer. The same rule applies to wet walls. Before insulation, they must be drained and without fail to eliminate the cause of the wetting.

The facade of the polystyrene foam with your own hands will take a little time, and in return you can get warm rooms and significant savings when paying for heating services. Observing all the stages of installation, and given the most common errors in working with insulation, you can independently warm the house without involving professionals.

He considered it as an option

He considered the EPPS and PPS thermal panel. Still stopped at the last. He has a lot more thickness, took 100 mm and installation is easier in practice, no need to align the facade and the house is warm. It really turned out to be the buzz. And the EPS has a maximum of -60mm thick, you need to reinforce with calculations, so that later nothing falls off at the ends, in general, it is also more costly in the end.