An important stage in construction or repair work is the implementation of high -quality ...

|

|

The arrangement of an invisible hatch helps to make the appearance of the bathroom more ... |

Laminate is a floor covering based on the CDF (material from ... |

The device is wet facade

Warming of the premises in the wet facade method is widely popular in the construction of private and multi -storey buildings. The prevalence of the method is due to significant advantages in comparison with alternative methods of decoration. The wet facade system minimizes the number of cold bridges and prevents the appearance of condensate on the internal walls of the house.

- Features of the finish wet facade

- The device is wet facade

- The selection of materials for arranging a wet facade system

- When to install a wet facade

- Methods of installation of insulation

- Wet facade device: installation technology

Features of the finish wet facade

Wet technology for insulation of the facade involves the use of aqueous solutions of plaster, paints and primer compositions. On the surface of the wall, a multilayer fortified pie is created. For comparison, during the installation of a dry facade, anhydrous methods of fastening are used: lining, panels with frame fastening and siding.

The system of insulation of houses, buildings with a wet method appeared in the 50s of the twentieth century in Germany and became widespread in the 70s.

Such a technique implies the application in a certain sequence of the primer, glue, thermal insulation and other materials. As a result, a single system is formed, which differs a number of undeniable advantages:

- Provides attractiveness and decorative facade. There are no salt spots on the outer walls.

- Small structure of the structure does not require a powerful foundation.

- External thermal insulation allows you to maintain and effectively accumulate heat in the room, blocking the bridges of the cold.

- On the inner surface of the walls, condensation is not formed. The dew point is carried out into the isolation material, and then evaporates through the outer breathable layer of plaster.

- A wet type facade gives the walls of sound and vibration isolation.

- The design of the house is reliably protected from moisture. In this case, corrosion of frame reinforcement and freezing in microcracks of concrete are excluded.

- Wet technologies in implementation are cheaper.

The disadvantages of such systems include the need to comply with special conditions during installation:

- installation of a wet facade occurs at a temperature of at least +5 C;

- installation work is not performed in rainy and wet weather;

- the hit of direct sunlight will provoke the drying out of the solution, this will negatively affect the quality of insulation.

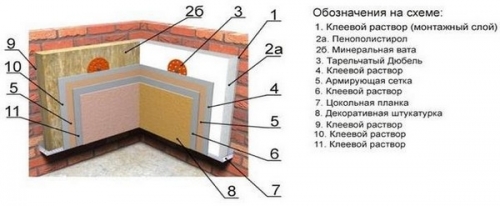

The device is wet facade

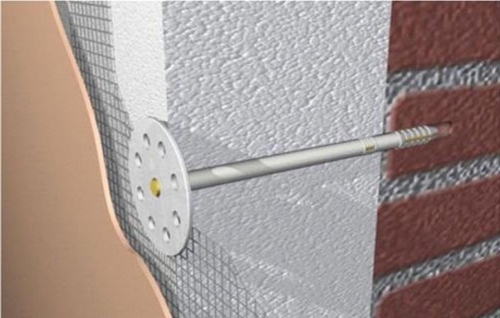

The wet facade is easy to manufacture. The unpretentious design is based on the simultaneous use of mechanical and adhesive fasteners.

Wet facade: installation technology

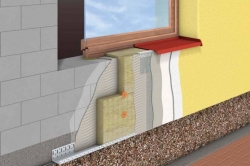

The facade pie includes the following layers:

Base.

- Thermal insulation. The insulation is attached to the wall on glue - usually it is a polymer -cement composition with high adhesion to the insulation and the bearing surface. As a thermal insulation material, foam or mineral wool slabs are used.

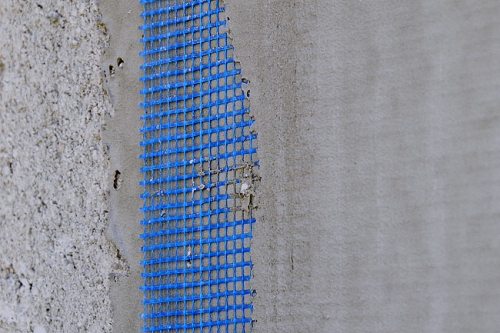

- The reinforcing mesh strengthens the structure. Without a metal mesh, not a single plaster solution or other adhesive composition will stick to the basalt plate or foam. For work, a reinforcing mesh of 1 meter wide is suitable for creating a whole plaster coating.

- Layers of glue for reinforcing mesh and insulation.

- Mechanical fastening of the insulation umbrella (plastic dowel is equipped with a wide hat). Five dowels are installed on one plate of insulation.

- Decorative coating. To finish the wet facade, textured plaster is used, which has significant advantages: simplicity of application, low weight and affordability in price.

House insulated with the Wet Facade: Video system

The selection of materials for arranging a wet facade system

Materials for the wet facade are sold by a system. In fact, this is a complex of materials with similar physical characteristics: waterwork, vapor permeability, thermal expansion and frost resistance.

Here are some recommendations for the choice of insulation materials for the wet facade:

- Basalt cotton wool with a density of 150 kg/m. Kub. And the strength of the strength of at least 15 kPa can be used for plaster facades.

- For insulation of the house, you can use only foam of facade brands, low -growing and self -adjacent. To increase fire safety, it is advisable to make cuts of mineral wool.

- For the arrangement of the wet facade, glass wool is not used. The structure of the material does not withstand increased loads.

- The mentioned issue is used to use extrusion polystyrene foam. Some experts do not recommend using this material, since it is a steam -proceeding (does not breathe) and has poor adhesion with adhesive compounds.

- An important criterion for choosing thermal insulating material density. This parameter for fibrous materials should be at least 150-180 kg/m. Kub.

- It is better to choose mineral wools for the facade on more waterproof phenolic binders.

- For thermal insulation, you can use the ecological material of arbolite related to the category of light concrete. 90% of the arbolite composition is natural fillers: husk, wood sawdust, flax fire, etc. The density of thermal insulation arbolite is 400-500 kg/m. Kub.

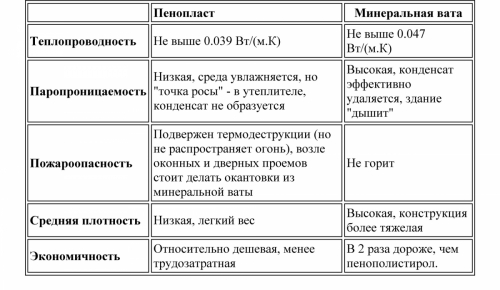

Comparative characteristics of the properties of foam and mineral wool

The composition of the glue is selected in accordance with the used insulation. For example, bitumen glue is used in the installation of polystyrene plates

When to install a wet facade

The arrangement of the wet facade is carried out after performing the following construction work:

- roof installation;

- the external waterproofing of the foundation is fully executed;

- there was a shrinkage of the building;

- ventilation, air conditioning system is mounted, windows and other systems are installed;

- the building is dried.

Facade work is best done in late spring of early autumn. Before starting installation, you need to see the weather forecast - there should not be rain and minus temperature for the next two to three weeks

Methods of installation of insulation

There are three technologies for the arrangement of fixation of thermal insulation material:

- Hard mounting insulation is fixed with dowels. In this method, the thickness of the layer of plaster does not exceed 8 mm.

- Fastening the insulation for movable hinges. The plaster mixture moves freely along the walls, compensating for the shrinkage. The thickness of the applied layers is about 30 mm.

- Thermal insulation fixation occurs with glue and dowels. In this case, plastic dowels with large hats are used.

Wet facade device: installation technology

Preparatory events

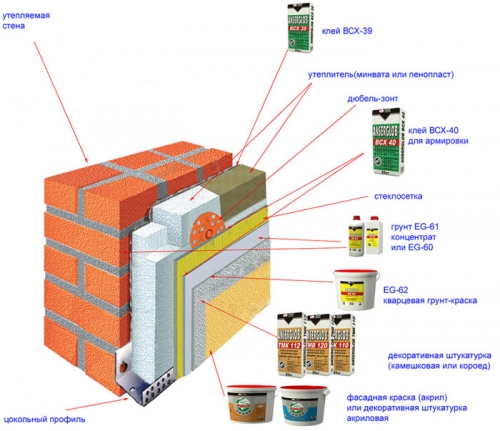

Before starting facade work, you need to prepare some materials and components:

- Heater polystyrene or mineral-fibrous slabs. 1 sq.m. We must take 1.05 sq.m. insulation (gap for cutting in the corners). The thickness of thermal insulation material depends on the climatic zone of residence.

- Fiberglass density 140-160 g/cubic meter.

- Dowel-zontics at the rate of 5-8 pieces per 1 sq.m.

- Corner and basement. The corner elements protect the wall from crowning with mechanical exposure. The basement elements are mounted horizontally from below the facade and are the basis for the installation of the first row plates. The basement protects thermal insulation material from mechanical damage and plays the role of casting.

- A primer for processing the base of the wall.

- Glue for fixing insulation and reinforcing mesh. The number of adhesive composition depends on the relief of the wall.

- Plaster for finishing. The consumption of the material is calculated based on the area of \u200b\u200bthe covered surface. It is necessary to lay a supply of 10% on window/doorways.

Preparatory events:

- The surface of the wall is thoroughly cleaned of the remains of the old coating and dirt.

- If it is necessary to align the wall, remove the damage, and fill in cracks.

- Peel the door/window slopes of the old plaster.

- Generate walls to increase adhesion.

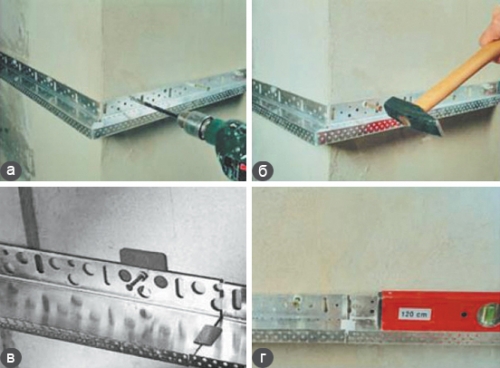

Installation of a basement

Mandatory operation installation of the support bar. The lower edge of the entire wet facade system rests on the P-shaped reference basement. Warming work with a wet facade begins with marking/fastening around the perimeter of the basement building.

The profile is mounted as follows:

- the height of the attachment of the basement is 40 cm from the ground level;

- between horizontal strips should remain a gap of about 30 mm, this distance is necessary for temperature expansion;

- the profile is fixed with self-tapping screws and dowels, a fastening step of 10-20 cm;

- the corners of the building must be finished with a special corner profile.

Fastening of heat -insulating plates

The wet facade of polystyrene or mineral watches is glued to the prepared surface of the outer wall of the house. The glue is applied with a wide strip around the perimeter of the heat -insulating plate. This method reduces the consumption of glue and provides sufficient strength strength.

There is an unspoken rule: glue should cover at least 40% of the area of \u200b\u200binsulation

High -quality installation of thermal insulation is provided when performing a number of rules:

- continuous vertical seams between several rows of seams of the plates in the neighboring rows must be overlapped;

- the back of the stove when gluing is pressed to the base of the wall, and the end of the insulation to the adjacent plate; The seams between thermal insulation slabs should be minimal;

- the glue protruding between the seams must be removed immediately.

After drying (about 3 days), a layer of thermal insulation must be additionally strengthened with dowels. The fasteners are deepened by 5-9 cm into the wall depending on the porosity of the insulation.

The sequence of fastening dowels:

- Make markings on the panel and drill holes to the desired depth.

- Make the nests under the dowels and the flush to install the plate parts.

- Gently score plastic nails.

Installation of a reinforcing layer

The installation of the reinforcing layer is started 3 days after fastening the insulation. First of all, the installation of a reinforcing mesh on slopes of doors/windows, vertical joints of slopes and jumpers, as well as external corners of the building, is installed. The flat surface of the walls is treated last.

The installation procedure for the reinforcing layer:

- Apply glue to the insulation.

- Put a fiberglass grid.

- Repeated a layer of glue, it must cover the structure completely.

Important! The total thickness of the reinforcing layer should be no more than 6 mm. The distance between the outer surface and the glass tower layer is up to 1-2 mm

The finishing of the facade

The final phase of the arrangement of the wet facade is plastered walls. This work can be proceeded no earlier than 3-7 days after the installation of a reinforced net. The finishing of the facade should be vapor permeable and moisture resistant. External plaster should withstand temperature fluctuations and do not deform under the influence of mechanical loads.

The plaster can be applied at a temperature of 5-30 C, a prerequisite for the lack of wind. When working in sunny and hot weather, a layer of finish plaster must be periodically wetted with water.

Plastering of wet facade: photo

Installation of the wet facade in the basement

When installing a wet facade on the base, there are some features:

- before installing the wet facade system, you need to take care of the waterproofing of the blind area and base;

- as a heat insulator, it is better to use material with minimal moisture heating;

- for insulation of the basement, slag, dolomite, lime and basalt wool is not used;

- thermal insulation slabs are strengthened by dowels at a distance of 30 cm from the ground level;

- the reinforcing mesh is laid in two layers;

- ceramic and facade slabs are suitable for cladding;

- purrender of the basement can be performed with mosaic plaster.

Wet facade Cerezit: installation technology