Bath, sauna steam room belong to functional auxiliary buildings with increased ...

|

|

The choice of finishing materials for the repair of a small room is not so simple ... |

Bathroom - a room with a high and constant level of humidity, so for ... |

Mineral wool wall insulation technology

During the construction or during a thorough repair, the question arises of insulation of the house or apartment, and so that after the end of work there is no bitter regret about the means spent, it is necessary to know as much as possible about the materials used. The article will talk about the insulation of walls with mineral wool outside and inside.

Content:

- What gives high -quality wall insulation

- Choosing material for wall insulation

- Advantages and disadvantages of mineral wool

- How to choose mineral wool for wall insulation

- Mineral wool wall insulation technology

- Insulation of external walls with mineral wool

- Mineral wool manufacturers

Insulation is an important process in which any deviation from technology is simply unacceptable. Nevertently completed work will aggravate the situation. At first this will not be noticeable at all, much later, the accumulation of dampness will lead to the propagation of the dangerous fungus of black mold.

Recently, thermal insulation work is gaining momentum, and this does not happen because the winter months have become more severe, but because it is more economical. Wall insulation both inside and out of the structure can do any, but as for multi -storey buildings, the involvement of specialists is required here.

What gives high -quality wall insulation

- First of all, it is comfort and significant saving on heating. If the protection of the walls from the cold is performed competently, then this makes it possible to configure the desired level of heat in the room. In the summer months, this system acts differently: thermal insulation does not allow the walls to warm up, which means that the temperature will be almost constant.

- The lack of thermal insulation can lead to the process of developing fungi, and as a result and the appearance of black mold, which, incidentally, is very difficult to get rid of. Inhaled disputes are dangerous for a healthy person, not to mention children, elderly people and allergies.

- When warming, the same temperature of the walls and air indoors will not allow condensate and, accordingly, dampness. Of course, for a greater effect, along with thermal insulation of walls, it is recommended to change radiators, replace the old windows with modern 3 chamber double-glazed windows, as well as perform similar work on loggia, balcony.

Choosing material for wall insulation

Minvat, polyethylene, cork material can act as a heater. I would like to note that they all cope with their purpose, as they have a low degree of thermal conductivity. Despite all the diversity presented in the building materials market, it is especially popular mineral wool.

Its fibrous structure was obtained by cooling the crushed, and then elongated threads (up to 12 μm) of mineral eutectic. Depending on the starting raw materials, it happens:

- stone. It is produced using basalt, porphyrite, granite. This cotton wool is of high quality, it is used to thermal insulation of especially important buildings, where strength is required for many years.

- slag. Accordingly, it is made of metallurgical waste. This product in quality is inferior to stone cotton wool. It poorly tolerates sharp temperature changes and increased loads, not so durable under wet conditions. It is more often used for insulation of sheds, temporary buildings, summer houses.

- glass. It is obtained from melted glass with the addition of soda, dolomite and limestone. Such a product is quite elastic and resistant to vibrations. It is recommended to use for structures with increased fire safety requirements.

Mineral wool is produced in rolls or in the form of plates, where the strength of the fibers is achieved by processing with special astringent material. To arrange the thermal insulation layer of large areas, mats are used, they allow you to perform work with minimal gaps.

The degree of rigidity determines its application. The soft species is mainly designed for the work of the room using frame structures. Hard and semi -wire mineral wool is more suitable for walls exposed to mechanical influences.

Advantages and disadvantages of mineral wool

This non -combustible material, coupled with a good heat -insulating property, is favorably different from other heater.

- It does not change the shape of temperature jumps, so it is used at objects where the surface temperature can be from -200 to +600, and in some cases up to 1000C.

- Vata has a biological, chemical resistance and an inert medium, even if metal elements are in contact with it, they are not corroded.

- This thermal insulation product is easily lended on cutting with a knife, sawn with a hacksaw, which greatly facilitates installation work.

- If the finishing layer is made of material with low vapor permeability, then the entire condensation will concentrate in the layers of the mineral wool. When getting wet, its heat -insulating properties are significantly reduced, loss of geometric shapes is possible here. Therefore, when thermal insulation is arranged, both facades and walls indoors, it should be covered with a membrane film.

- There is a statement that this material does not affect health, highlighting hazardous substances. This is not entirely true. When working with it, it is necessary to use gloves and respiratory masks so that the formed dust does not get into the respiratory tract during cutting. In addition, after laying it is closed with vapor barrier film, drywall and/or other finishing materials.

How to choose mineral wool for wall insulation

The selection of material is carried out according to the following criteria:

- thermal conductivity. This indicator is directly proportional to the conservation of heat directly in the house. Therefore, the less it is, the lower the cost of heating the structure;

- durability. With competent installation, mineral wool has practically an unlimited service life;

- vapor permeability. A high vapor barrier coefficient will allow you to quickly dry the plaster on the facade, made in a wet method and remove excess moisture in a ventilated structure;

- fire safety. This property is important for material used in both external and internal works.

- For facades with a frame device, a minvat, produced on the basis of rocks or glass, is mainly selected. The material should have excellent moisture -resistant characteristics, and the vapor permeability indicator is at least 0.5 mg/MCh Pa.

- If this insulation carries a load, for example, a plaster layer, then special attention is paid to density, it is recommended that the material with a density of at least 150 kg/m and vapor permeability should be equal to a minimum of 0.35 mg/MCh Pa.

- Internal partitions or walls are insulated with basalt and fiberglass wool. Light cotton wool with a density of 10-90 kg/m is suitable here. In addition to thermal conductivity, it is important such a property as absorption of noise, so you should choose a product with an index from 42 dB.

Mineral wool wall insulation technology

It is not always possible to carry out thermal insulation from the outside of housing, this applies more to the owner of the apartment of a multi -storey building. Here, a change in the facade occurs, for which it is necessary to obtain permission from the relevant authorities. And, as a rule, the project of insulation of one apartment does not undergo approval.

The way out of this situation is to carry out similar works from the inside. But, opponents of this method claim that such insulation will not lead to the expected effect. And this is not entirely true, if you insulate the walls with mineral wool correctly, in compliance with the technology, then the main goal will be achieved.

The main stages of work:

- complete cleaning of surfaces is carried out, especially if traces of mold are visible. This is performed by manually a spatula or construction vacuum cleaner. For drying, a special hair dryer, infrared heaters are used. If necessary, surfaces are treated with antiseptics;

- all cracks and fossa are sealed with cement mixture. For recesses up to 3 cm, mounting foam is used, deeper voids are filled with bags and foam;

- antiseptic agents and primers are treated. They should be applied with a significant time interval, allowing each layer to completely dry;

- the final stage of preparatory work is performed alignment of surfaces for a denser adjustment of the structure or frameless insulation.

detailed instructions

- Brick, gas or foam concrete blocks are plastered and treated with a solution of liquid waterproofing material. After drying, he forms a film that prevents the formation and the development of dampness between the wall and the layer of insulation.

- The frame is made of wooden rails or metal profiles taking into account the width of the roll, or rather, the distance between the vertical supports should be slightly less than the width of the selected material. This will ensure its tight adjustment to the structure.

- The distance from the wall is taken with the calculation of the thickness of the plate plus a few centimeters for the air gap, which is created due to the adhesive solution applied by a point method.

- It is more advisable to use plates, they do not roll on vertical surfaces like roll mineral wool. It is recommended to set horizontal strips to reduce the load of their own weight.

- It is recommended to start placing a layer of vapor barrier film from the upper part of the structure in the horizontal direction. Fixation to the frame can be made by bilateral tape. If this is a wooden structure, then you can use a furniture stapler. The membrane is mounted with an overlap of about 10 cm or more and in the corners, floor and ceiling of the room.

- The joints of the connection are glued with a mounting ribbon or construction tape. It is advisable to close the places where the film adjoins the surfaces with a liquid sealant. On top of a peculiar pie, a double-width of 15-25 mm with a width of 15-25 mm is attached. This is done so that a ventilation gap forms between a vapor barrier layer and internal cladding. Here you can mount the selected finishing material: drywall, panels, lining and so on.

- But vapor barrier material can not be used if you purchase foil mineral wool. In this case, the side with foil should look inside the room. This coating provides this material with additional heat -saving properties.

- If preference was given to rolled material, then work is carried out in a slightly different way. On the surfaces, the brackets of the U-shaped form for the installation of metal profiles are fixed. As a rule, in vertically, the distance between them is 60 cm, and in horizontal the step is 50-60 cm. Such parameters are enough to lay the insulation.

- Further, the minvat of the desired length should be measured, be sure to leave about 10 cm. The properties of the material allow you to freely pass under the bent brackets. They will reliably fix the insulation in an upright position. Then the profiles are installed and sheets of drywall are mounted.

West insulation mineral wool video

Insulation of external walls with mineral wool

Experts recommend insulation from the outside of the structure. This is the most productive option to keep the heat in the premises, in addition, useful centimeters of the area do not climb here, and condensation is not formed. In addition, an additional layer of thermal insulation will avoid cold bridges that are inevitably formed due to the crate for the insulation.

There are two most popular ways.

Wet method

- Its principle consists in the installation of insulating material directly on the wall, on top of which finishing work is performed. Thus, a homogeneous seamless coating is obtained. In this case, the thickness of the insulation should be about 15 cm.

- The mineral wool is fixed on the surface with an adhesive composition, as the main fastener I act as an umbrella. Further, the finished base is reinforced. The finish stage consists in facade decoration, for example, decorative plaster, which will perform a protective function and give an attractive appearance to the structure.

- This method is ideal for houses built of brick, gas-concrete blocks. For frame buildings near Minvat, a hard flooring of OSB stamps is first mounted. It is strictly forbidden to carry out work during the rain, if the insulation gets wet, wait until it dries, it will have to have a very long time.

Dry method

- Performing work on thermal insulation of the structure in this way, as a result we get a ventilated facade. The material is mounted in cells or honeycombs formed by the design of the frame. If a beam is used for the manufacture of the skeleton, then it should be covered with an antiseptic.

Tip: When making a crate for fixing the insulation, the distance between horizontal rails is most convenient to leave more narrow, along the width of the insulation. But it will turn out to save well, if you make them less often, with a step equal to the length of the mineral wool slab.

- A moisture -proof film is necessarily laid on top of the insulation, which can be fixed with bilateral tape or a construction stapler.

- Then the rails are attached to the main frame, forming a crate. Here it performs 2 functions: it creates an air cushion and serves as the basis for the installation of cladding, such as siding or asbestos -cement plates.

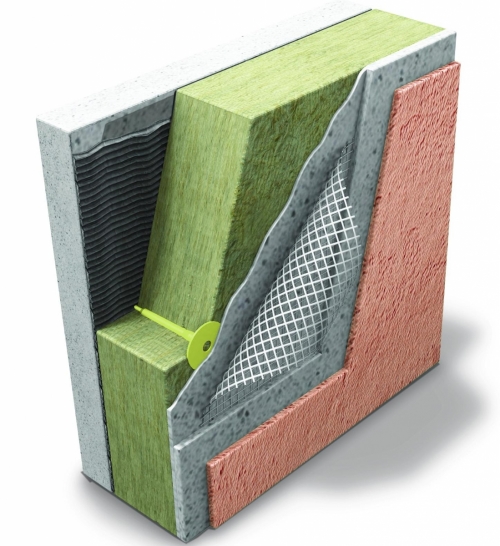

To achieve the goal, work associated with insulation must be carried out on both internal and external surfaces. A peculiar pie consists of the following layers (from the inside):

- finishing material: putty, wallpaper, painting;

- gim -plane sheets;

- vapor barrier membrane;

- mineral wool;

- the main wall;

- mineral wool;

- moisture -proof material;

- finishing material: siding, lining and so on.

Compliance with the basic requirements during construction will help protect the house from moisture, wind and, accordingly, damp, thereby forming comfortable living conditions.

Mineral wool manufacturers

- To date, the consumer is offered this thermal insulation material for many manufacturers. The most famous are: ISOVER, KNAUF, URSA and Rockwool. These brands always provide certificates for their goods, hygiene assessment of goods, test protocols, and so on.

- Some companies specialize in the release of a certain type of cotton wool, for example, Ursa produces for the most part a wool based on fiberglass. But still, large factories make products of all types.

- To understand what designs or climatic conditions this or that minvat is intended for labeling. But, unfortunately, each manufacturer has its own, and the question of unified indicators has already been raised.

- If the packaging indicates thermal conductivity, size, purpose of the material, and if it is also accompanied by a package of relevant documents, then this gives a guarantee that the purchased goods are high -quality and reliable. Such a mineral wool will last a long time, without losing its thermal and acoustic characteristics.

- After all, if it is incorrect to choose the material, then you can not get the expected result, on the contrary, this will significantly reduce energy -saving properties and may well destroy the structure. Ultimately, the additional costs of correcting errors cannot be avoided.

I have a very big desire

I have a very big desire to insulate my country house, because, after the thermal imager checking, I was convinced that very large heat losses. Before hiring specialists, it is not cost to understand the technology of wall insulation yourself in order to know exactly what and how to be done in order to get the greatest effect with less costs. Now there are a lot of specialists in the market offering their services, and even more hack workers promising at least what my money and guarantees, including, when a month is found, you call on the phone. The answer is standard here of such a company, the phone is an apartment, please don’t call anymore. Having read your article, it is difficult to understand that you can understand some solid common phrases and there is nothing specific. If you have already taken to describe the technology, so describe specifically.

I had a bitter experience with

I had a bitter experience with Minvata. I insulated the house according to all the rules of the mineral wreck of a well -known company. But after 8 years, the house became cold, I frankly could not even think about it until I checked the house with a thermal imager. 8 years of service, is it normal or something? I began to read the forums, so I'm not the only one. Somewhere, I even found an article with information that even if you do everything according to the rules, then the insulation will last 8-10 years, if you put it wrong, then there are generally a few years. Manufacturers put a completely different service life, so I will not be surprised if the amount of phenol -formaldehyde there is more than they claim, I do not advise Minvat to anyone !!!