In order to conduct supporting walls of the frame house, necessary...

|

|

Plastic windows are not such simple products as it might seem. Control... |

It is difficult to imagine a modern country house without a canopy. This architectural ... |

Waterproofing a bathroom for tiles with your own hands

The bathroom is a room with a high and constant level of humidity, therefore, to maintain the integrity of its walls, ceiling, floor and finishing materials, it is necessary to perform their high -quality waterproofing. There are several ways to carry out this process. We learn about their features and technology further.

Table of contents:

- Waterproofing of bathrooms: types and characteristics

- Bathroom - Paul waterproofing

- Waterproofing of the bathroom - technology and methods of protection against moisture

- Features of the waterproofing of the bathroom in a wooden house

Waterproofing of bathrooms: types and characteristics

Waterproofing in the bathroom is an indispensable and mandatory element of its arrangement. Reliable waterproofing will protect you from mold and fungus, which the microclimatic conditions in the room worsen. In addition, the penetration of water to the walls or floor can provoke contact with wires and a short circuit. Therefore, you need to choose a suitable waterproofing option for yourself and equip it in the bathroom.

There are several ways to protect the walls of the bathroom from moisture:

- Bitumen -based mastic;

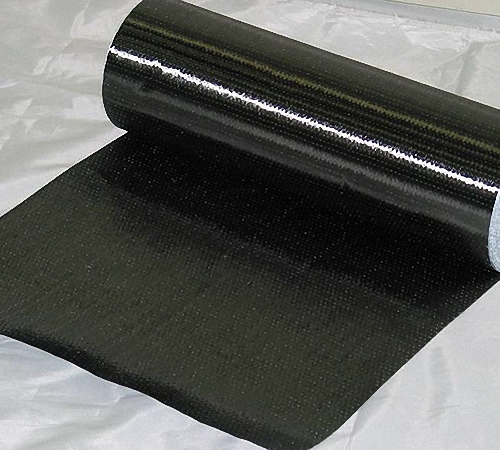

- Leaf or roller -type materials that are saturated with mastic;

- cement-polymer mixtures;

- hydraulic protection compositions of a penetrating type;

- Rubber hydraulic options for moisture protection.

We offer to familiarize yourself with the advantages and disadvantages of each of the above methods of protection against moisture of the bathroom.

Bitumen -based mastic is widely used as a reliable waterproofing material. This composition has a viscous structure and contains bitumen with additional additives. Two methods of applying mastic are distinguished:

1. The hot method implies preliminary warming up in a special device called bituminous. Used to waterproof large in size of the area. Not relevant in use for waterproofing bathrooms.

2. The cold way of applying mastic is more simplicity, but this composition is more expensive.

Among the advantages of using this material we note:

- the ability to cover any type of surface, even if dampness is present on it;

- After applying the composition, the surface is covered with a continuous seamless film, which protects not only from moisture, but also from steam;

- The material during operation does not crack, is characterized by high mechanical strength;

- mastic is not exposed to high or low temperature;

- It is used on various surfaces, both on concrete and wooden.

The second waterproofing option is gluttop. These materials are also based on the use of bitumen or resin on an epoxy basis. Environmental options have the shape of sheets, rolls or panel elements installed on the surface necessary for waterproofing. Among the main advantages of this method of waterproofing, we note:

- high speed in the installation work, for the installation of waterproofing material, it is enough to stick it to the surface, the waterproofing of large objects is performed quite quickly;

- The affordable cost of materials allows you to use them as hydrophobic barriers.

However, this method of waterproofing also has disadvantages:

- low level of mechanical strength, therefore, if the waterproofing layer is damaged, there is the possibility of moisture penetration into a previously protected object;

- low level of counteracting the development of decay, since most often for the manufacture of such materials, cardboard or fiberglass is used;

- For a short time of operation, it is a maximum of 5 years.

The third method of protecting the bathroom from moisture is the use of polymer -cement compositions. Among their advantages, we note:

- The absence of toxic substances in the composition, so they are reliable for use in bathrooms;

- The duration of operation is much higher than that of a bitumen -based compounds;

- The ease and ease of use allow waterproofing with an ordinary brush, thus, it is possible to qualitatively cover all wall defects in the form of irregularities and chips;

- Waterproofing prevents moisture to enter the wall, but passes steam, thereby allowing the walls to breathe and carry out natural air exchange;

- Materials are applied to the surface of moistened walls, so there is no need to wait for their complete drying;

- The resulting coating is characterized by a high level of plasticity, resistance before deformations and mechanical influences.

The most technological and progressive way to protect the bathroom from moisture is the use of penetrating waterproofing. This composition is distinguished by the following advantages:

1. Resistance before mechanical influences. Since the material penetrates into concrete, ensuring its crystallization.

2. The absence of the need to wait for the drying of the walls, the composition is applied to the wet surface.

3. The possibility of processing concrete structures from any angle. Waterproofing falls into the smallest cracks and pores, protecting them from moisture.

4. The material is characterized by a high level of frost resistance and high strength properties.

5. For applying the composition, additional special equipment is not required.

When choosing the waterproofing of the bathroom for the tile, which is better, it is necessary to proceed from the individual characteristics of the room, the price policy of waterproofing materials, type and sizes of tiles, etc.

Bathroom - Paul waterproofing

Initially, you should get rid of the old flooring, as well as the old waterproofing, if any. The floor in the bathroom should be cleaned to the concrete screed. If there are minor defects on the floor, take care of their removal. For these purposes, a cement mortar is used.

Next, you should get rid of construction waste, dust, wash and dry the base of the floor. Next, you should perform the mandatory primer of the base. We recommend using bitumen soil. The type of primer should coincide with the type of bitumen mastic, which will be applied to the surface. Wait for the primer drying, only after that, carry out subsequent work.

We offer to familiarize yourself with the instructions for the installation of the coating type hydraulic tank:

1. First, read the instructions proposed by the manufacturer. According to it, prepare the composition. Work should start with corner sites, then gradually moving to the center of the floor.

2. To process angles and other surfaces, use the brush. Between the floor and surface of the walls, gaps should not form, the floor should be qualitatively and fully processed by the composition. Additional reliability to the joints will be provided by a special tight tape.

3. To protect the places from which pipes or pipes themselves come out, put on special overlays on them, treat these areas with a waterproofing composition.

4. Next, apply the main waterproofing using a spatula. It should be distributed on the surface subtle and evenly. The number of layers of mastic is determined individually and is from two to five. An increase in the number of layers of mastic depends on increasing the height of the foundation.

5. The waterproofing of the floors is a very important process, when conducting which it is exactly necessary to follow all the above instructions. In the process of drying waterproofing, the appearance of drafts in the room should be avoided. Each layer is applied after the previous one dries.

What waterproofing of the bathroom is better to decide. We also offer to familiarize yourself with the instructions for the installation of waterproofing materials of a roll type:

1. Initially, the marking of an already prepared base is performed. Materials are cut out in the ratio with the place of installation.

2. All corner compounds and inaccessible places are treated with liquid compounds to provide additional moisture protection. If necessary, in warming up the material, it is warmed up by special devices.

3. If a self -adhesive option for waterproofing is used, then it does not need warm -up.

4. Vertical walls are glued with materials from the floor. If there are several lanes, lay them on the floor with a small overlap.

5. After the installation work, it is necessary to wait for the material to dry in the relationship with the instructions from the manufacturer.

Waterproofing of the bathroom - technology and methods of protection against moisture

We offer to get acquainted with the method of applying waterproofing of the polymer-cement composition. Initially, as in any option for applying waterproofing, it is necessary to prepare the basis for work. There should be no garbage and dirt on the floor. To fill in defects and irregularities - use the plaster composition.

Before you start applying the composition, read the recommendations from the manufacturer on its breeding and drying deadlines. Some manufacturers indicate the need to moisturize the surface before work. This factor is also must be taken into account.

Next, all components are combined to create the composition. The composition should become homogeneous. Pre -mark the surfaces that will be covered by the composition. To apply the solution, use a brush with hard bristles. Make sure that there are no unpainted parts left on the surface. Pay special attention to hard -to -reach places, as well as corner joints. In the place where communication systems pass, material is laid in the form of geotextiles, which must also be smeared with a waterproofing solution.

To dry out the first layer, you must wait for a certain time specified by the manufacturer. Do not use artificial heaters to accelerate the drying of waterproofing. This process should be performed naturally. Before applying the second layer, moisturize the surface again, if necessary, and repeat the processes. Next, surfaces are finished in a ratio with previously selected materials.

Application of polymer-cement compositions is performed at a temperature above zero. The polymerization time is indicated in the instructions, so get a mandatory job with it. It is recommended to apply waterproofing in two layers, while they should be contrasting colors to determine high -quality flooring. It is necessary to use this material waterproofing the bathroom in the event that the walls or floor are made of cement.

Features of the waterproofing of the bathroom in a wooden house

The bathroom, made in a wooden house, necessarily needs high -quality waterproofing. Since the tree wear out quickly under the influence of excessive humidity. In addition, fungus and mold develop on wooden surfaces, which adversely affect microclimatic conditions in the room.

The waterproofing of the bathroom with a wooden house implies protection against moisture not only the floor, but also the walls with the ceiling. Thus, the room becomes a hydraulic compartment, which is distinguished by good operational characteristics.

Waterproofing work is carried out in several stages. Initially, the walls are poured with bitumen mastic, and then glued with special materials. The combination of two methods of waterproofing allows you to achieve an excellent effect of moisture protection.

In addition, it should be mandatory to observe a certain height of the floor level, which is located lower than in all other rooms.

We recommend using reinforced bitumen based on a fiberglass with additional polymer components for waterproofing. These materials are both self -adhesive and installed by heating. These materials make it possible to reliably waterproof both walls and floor.

Work should be started with the floor in order to ensure the overlap on the walls. For additional reinforcement of butt sections on the walls, use fiberglass -based grids. Thus, it is possible to achieve an increase in the strength of the materials.

It is recommended to equip a cement -based screed in the room. If this option is not suitable, then two layers of special panels with moisture -resistant characteristics are laid on the black coating.

To perform waterproofing walls and ceiling, use roller materials that are fixed using a burner, self -adhesive base or stapler. The joints between the canvases are mandatory. For wall decoration, we additionally recommend using moisture -resistant drywall. The ceiling is most often made of stretch polyvinyl chloride materials.

Waterproofing of the bathtub video:

Crosses and filler seams

Crosses and filler sutures for laying tiles with good prices and free delivery. http://got.by/2dryz2

Through the service http://bit.ly/2pqd7ca cheaper by 3-8%