In order for the finishing of the ceiling to go as successfully as possible, it is necessary ...

|

|

Layout of the bathrooms and plumbing devices in country houses and dachas ... |

To date, many owners of housing in apartment buildings are thinking ... |

Paul waterproofing in the bath: step -by -step instructions

The bathhouse, sauna steam room refers to functional auxiliary buildings with high humidity, and the waterproofing of the floor in the bath determines its durability. A wooden building in the country can be built for the summer season, when cracks are made in the floors for natural drainage of water. However, the capital structure in the suburban area for a year -round visit must be built according to all the rules, with insulation and waterproofing of the floor.

Table of contents:

- What is important to know about the floors in the bath?

- Varieties of waterproofing of the lower surface

- Properties of penetrating waterproofing floor

- Features of waterproofing of wood floors in the bath

- Features of waterproofing of concrete floors

- Waterproofing flooring with liquid glass

What is important to know about the floors in the bath?

The country bath is constructed from different materials, including cast walls and brickwork, but in many regions it is habitually built from natural wood. This is a universal material, but with an excess of steam and moisture, any wood is subject to rot, mold and other fungal lesions. In order not to have to redo everything after a couple of seasons, it is better to provide competent insulation of the bath:

- foundation;

- floors;

- walls;

- ceilings;

- the output of all communications.

Water, even with single flooding, can damage the structure, especially when the construction is constantly increased humidity and water on the floor. Excess moisture destroys brickwork, fertiles, wood and finishing materials. A primitive building with a specific microclimate can be built without any delights. But even if it is a waterproofing of the floor in a bathhouse in a capital construction, regarding fire safety and bending protection, everything should be done thoroughly.

In order for the bath to bring some positive emotions for a long time, it is important to protect all the surfaces from the destruction of moisture in stages:

- waterproofing of the foundation and floors in all departments;

- vapor barrier and insulation of walls from condensate formation with waterproofing;

- vapor barrier and waterproofing of the attic or roof.

The absence of these measures and a full outflow of water with the possibility of ventilation after using the bath leads to stagnation of the used water and decay of materials. It is unpleasant for anyone to walk through dirty water and slide on wet surfaces. Dry, insulated and clean bath is hygienic, safe and comfortable. Therefore, the wise home master should take care of all the measures of protection yet to the construction design, starting from the foundation, as well as from the waterproofing of walls and floor in the bath.

When laying communications and the arrangement of the floor, the bathhouse should be provided in the bathhouse in all rooms and a small slope in the floor as in the figure:

If everything is done correctly, then all the water used will go into a special hole. This is the simplest self -combat system, but it also does not exclude the waterproofing of the floor in the bath. The drain groove should be made of stainless steel or polymers. The place of the word of water where the legs stand should be isolated from metal, not too hot or cold. It is desirable that the funnel of the drain is away from the place of adoption of water procedures.

Attention: when floor waterproofing in the bath, materials should be applied only to a dry surface, depending on whether it will be rolled or bulk materials with penetrating characteristics.

Varieties of waterproofing of the lower surface

High -quality insulation and waterproofing of the floor in the bath is carried out only taking into account the features of the base and the type of drainage of water from the room:

1. A solid non -flowing floor with a drain of traditional materials.

2. The flowing floor lined with polished boards with a small gap or with drilled holes, where the outflow is supposed. Cold floor with cracks and drainage under the bath only for the summer version.

Attention: When making a purchase of materials, it is important to make sure that there is a marking that denotes the installation of installation in a wet room. They also prefer non -wagging coniferous wood in wood processed with an antifungal composition.

Properties of penetrating waterproofing floor

The simplest method of waterproofing of non -flowing floor is processing with bitumen mastic on the smooth surface, after which the finish layer of the finish is lined. With this method, high -quality protection against moisture is ensured, but there are some disadvantages, for example, a specific smell of material that is eliminated for a long time.

Under the flooring of waterproofing, a polymer membrane, glass -ruble, hydraulic stroke and other ineffecting materials are used. The mastic is applied with a brush with an overlap on the walls of the walls up to 10 cm to make something waterproof pallet, over which wooden shields, tiles or other suitable flooring are laid.

Classical concrete waterproofing is an effective method, but it is inappropriate for a small summer cottage bath. It is used in the construction of pools and capital buildings or in the waterproofing of a concrete floor in a city bath.

Waterproofing with polymer -cement compositions are known for excellent adhesion, aligning the treated surface, strength, and environmental friendliness. Seamless waterproofing guarantees the greatest effect, and it is suitable for any room.

Important: by performing seamless waterproofing, special attention is paid to areas where communications pass, opening the passage to the foundation.

Sometimes for aligning the floor is used with a leveling (self -leveling) mixture, which provides an ideal surface. It perfectly interacts with any type of penetrating isolation of polymer-cement, concrete or polymer-large.

Features of waterproofing of wood floors in the bath

Tip: Before making a waterproofing of the floor in the bath, you need to wait for the temporary interval after the shrink of the foundation to guarantee the integrity of the coatings. All isolation processes are best combined with thermal insulation (expanded clay, mineral wool).

Wood is perfect eco -materials for the bath, since it is subject to fungal lesions and decay. High -quality waterproofing of a wooden floor in a bathhouse and impregnation of boards with protective compounds allows you to control these processes. This requires:

- process wooden lags for laying the floor of the bath;

- lay the crate on a black floor, including the spraying with drainage;

- fill the beam up to 100 mm on the base and lay the layer of a film -boar;

- between the beam, fall asleep expanded clay;

- lay the black floor;

- complete the finish flooring.

As the main isolation material, Euro -Ruberoid, membrane materials or aquaizol are used. Ruberoid at the junction is welded or glued with hot bitumen. Between the insulating layer and a wooden flooring, it is imperative to leave a gap for 2-3 kg for ventilation and counteracting the formation of condensate.

No less effective is the waterproofing of the concrete floor in the bath using waterproof. At the same time, plywood sheets are nailed to a black base. On this basis, the polymer canvas is laid with the end of the segments on the adjacent walls. It makes sense to temporarily leave the lower ends of the finishing board on the wall with unimportant, and complete the process after the completion of the main work.

Features of waterproofing of concrete floors

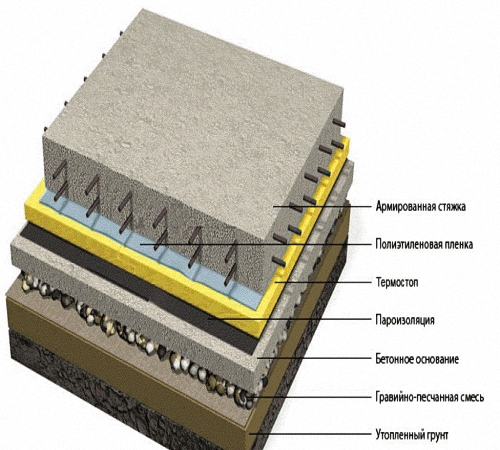

For those who do not know how to properly make a waterproofing in a bathhouse on top of the concrete floor, it is important to consider their specifics. Concrete is known for its reliability, the strength of the coating and the durability of operation, but in such a bath a waterproofing bath it is properly performed. When the concrete screed seizes, they proceed to the arrangement of protection from the penetration of water under the floor, as is done with any other type of base.

In regions with a cold climate on the floor, ice is possible if the bathhouse does not have proper thermal insulation. At the same time, even rapid warming up the room is not effective. The use of easily ignited polystyrene foam is undesirable. A layer of waterproofing is necessarily applied on top of the thermal insulation layer to protect against freezing in the winter.

A concrete mixture is applied to the flat black surface of the floor, as well as aligned so that there are no distortions when finishing the floor. 2-3 layers of waterproofing mastic are applied to the purified surface, on which rolled materials are laid a thin membrane or a denser roofing material.

The construction hairdryer is spike the seams. A mesh for reinforcing is applied over the waterproof and a layer of concrete screed is again made. It is important to ensure that you do not stain the wall decoration using masking tape. On top of the layer of screed and waterproofing of the floor in the bathhouse, nonsense porcelain tiles or another suitable finish is laid under the tile.

Attention: if the bathhouse is a typical log house with a concrete base, then all work on heat and waterproofing is done after the primary shrinkage of wood. That is, the main work is carried out 1-2 years after the completion of the draft stage of construction, but before the finish.

Waterproofing flooring with liquid glass

The process of processing the floor of the bath with liquid glass almost does not differ from a similar technology during silicatization of concrete structures. This is the most economical method, and less time and time passes. Using liquid glass for waterproofing the floor in the bath, we make an analogue of penetrating isolation, but with another material. This substance when processing applying on reinforced concrete, foam concrete, concrete or bricks gives a crystalline base to fill in a solid base.

Liquid glass resembles molten rubber or resin, and this semi -liquid medium forms a waterproof layer. After pouring the foundation and the rough preparation of the floor, this viscous transparent mass eliminates the penetration of the air and humid media. The basis of such waterproofing calcium silicate (sodium) with the addition of quartz sand and soda. The molten and frozen mass is crushed into powder, which is then diluted to a certain consistency. The main properties of the viscous mass after hardening:

- water -repellent;

- antiseptic;

- chemically neutral;

- firefighter;

- antistatic;

- high adhesion.

The life of such waterproofing is small, a lock of 5 years, silicate mass is prone to self -destruction. The larger the thickness of the insulating layer, the longer it will last, especially if it is covered with protective paint.

A lot of solution at a time does not have to do fast crystallization. After half an hour, he grabs, and nothing can be redone and added. It is advisable to have skills in the application of liquid construction suspensions, so that in half an hour, until the liquid glass loses its properties, have time to process a significant area of \u200b\u200bthe floor. For beginners in the repair, such high -speed processing causes difficulty. The less the solution is prepared, the easier it is to control it. But this waterproofing has advantages of the possibility of working in high humidity conditions, penetrating into cracks or holes processed by other materials.

Experts learned to add a liquid silicate mixture to other solutions to get new properties. For example, often a liquid glass is poured with a solution of cement, in a ratio of 10: 1. It is important not to violate the ratio, since in case of violation of the proportions (towards the increase in liquid glass), the mixture immediately overtakes. But this property can be used to quickly fill in the suddenly formed cracks or cracks in the foundation and floor of the bath.

Attention: In case of violation of the proportions of building mixtures, excessive crystallization can break the seams and joints of surfaces. The crystalline structure is also subject to cracking with a sharp blow or other mechanical influences.

If the liquid glass is ready to use with a sealed container, then it does not lose properties even at temperature differences. The solution first penetrates all the cracks, after which you can add a little more to the failed areas. When the liquid glass dries (hardens), after about half an hour it comes time to apply the next layer of insulation.

It is better to spill the purified surface to increase the adhesion of the solution with a screed. If there are doubts about the integrity of the cover, it is better to additionally clean the surface with a spatula and a hard brush to remove all unstable particles. After that, the prepared liquid glass is applied with a small layer with a brush or roller, and after crystallization the process is repeated.

Specialists apply waterproofing with liquid glass with uniform stripes, for example, parallel to the wall removed from the door. In a small section of the floor, you can pour a portionly solution, distributing on the surface a wide spatula or other tool. It is convenient to work with a wide painting spatula on a long handle or a spiken nozzle of the roller.

Important: in the solution, when applying, air bubbles can form, which must be eliminated.

The finished layer of insulation is removed at least 35 mm. Since the material is transparent, it is important not to miss bald areas. The finished surface after complete crystallization is covered with a protective layer of polyurethane or acrylic varnish.

A warm floor in a bathhouse, which is best entrusted to specialists, deserves special attention. However, all work on arranging high -quality waterproofing is available independently. When working with any type of waterproofing, it is important to observe safety precautions to work in protective clothing, to ventilate the room well.