When warming the house, it is very important to predict the special attention of the floor. It is much more pleasant to walk ...

|

|

The frame house is a light structure that is being erected on all types of foundations ... |

When building a house, it is important to choose a material that can combine in yourself as ... |

DIY wet facade. Warming technology

Due to the indefatigable increase in heating prices, each developer considers it his duty to find and subsequently take into service technological solutions that contribute to the maximum preservation of heat in residential buildings and structures. At the moment, the wet facade technology is recognized as the most effective means of outdoor insulation, using which you can get a significant result at relatively low costs. Having analyzed this, builders and contractors came to the conclusion that wet facades, having a simplified structure, worthily perform their functional purpose of the external thermal protection of buildings.

Content

- Warming technology wet facade: main advantages

- Varieties of the heat -insulating system depending on the insulation

- Cerezite is wet facade: products for creating impeccable thermal insulation

- Installation of the system of wet facade: Preparatory events

- Installation of the basement and mounting of insulation plates: Features

- Additional strengthening of the plates and the arrangement of the reinforcing layer

- Application of a decorative layer

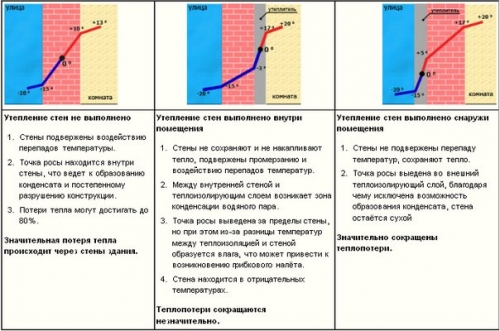

Warming technology wet facade: main advantages

The wet facade system promotes not only saving funds for heating and facing the building, but also increases the performance of the residential structure in the conditions of unstable Russian climate.

Using technology wet facade is an ideal way to solve all the problems that arose with the onset of cold weather and reduce heating costs by almost a third. The undeniable effectiveness of this method is confirmed by a number of its advantages, among which it can be distinguished:

- A steady increase in thermal insulation characteristics of the building, as well as getting rid of cold bridges;

- Capital renewal of the facade while maintaining its former architectural forms;

- Low weight that does not change the bearing abilities of the residential structure;

- The trouble -free adaptability of thermal insulation plates to the existing architectural features of the building.

Varieties of the heat -insulating system depending on the insulation

Before answering the question: how to make a wet facade, it is necessary to clarify that this system of external insulation is classified in accordance with the types of insulation used for wet facade insulation. The most common material for creating the insulation layer is polystyrene foam. The system, which is based on the use of polystyrene foam, is used for insulation of multi -storey buildings and is considered absolutely non -hazardous.

Mineral wool can also be used as a heater for the wet facade. The insulation system based on a mineral wool component provides high heat -protective properties and can be used for insulation of buildings for which there are no restrictions on the class of fire hazard.

Cerezite is wet facade: products for creating impeccable thermal insulation

In the process of installing wet type plastering systems, experts recommend using Cerezite products. The plastering facades based on the materials of the specified manufacturer are durable and high operational characteristics. The company's products of Cerezit is a wet facade are also divided in accordance with the type of insulation.

The construction of a wet facade, the price of which is relatively low and allows you to justify all the expectations of the developer, is carried out strictly at a temperature above zero and the absence of precipitation, as evidenced by the instructions for the use of building mixtures for its arrangement.

Installation of the system of wet facade: Preparatory events

Installation of the wet facade, the video instruction is presented below, is a number of measures that are necessary to carry out in a strictly established sequence. The first stage, the essence of which is to remove the old coating, is preparatory. The preparation of the draft facade is of great importance, in connection with which the outer walls with the help of steel brushes, the chisel and the scarves are freed from an obsolete coating that has lost its adhesion to the structure.

To remove irregularities and strengthen the crumbling surfaces, the base is treated with a primer. In addition, this allows you to reduce the absorption capacity of the surface. Deeper irregularities, cracks and areas of crumbling plaster are also treated with a primer. For these purposes, you can use the products of Ceresit with a wet facade, which will perfectly cope with its functional purpose.

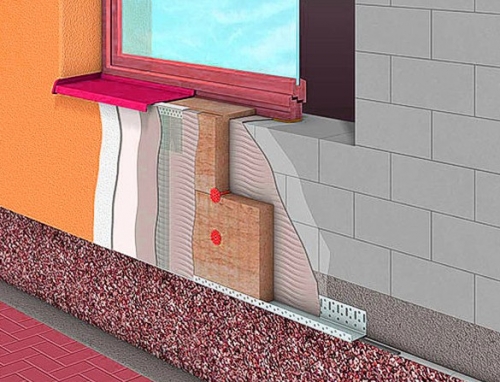

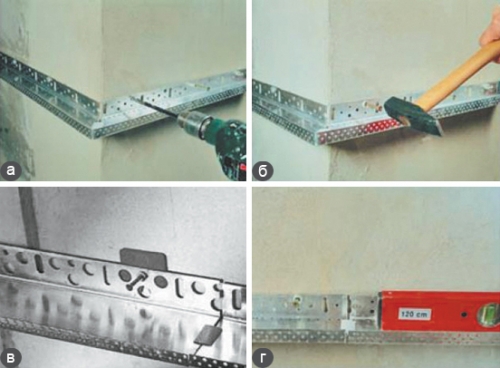

Installation of the basement and mounting of insulation plates: Features

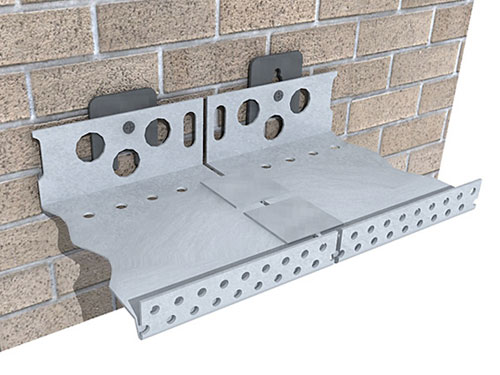

Next, the installation of a basement for a wet facade is installed.

It is a guide, which is designed to protect the lower part of the plates of thermal insulation material, while the width of the profile should coincide with the width of the insulation plates. Installation of the basement implies its mount to the base through dowels, the distance between which should not be more than 30 cm. For the connection of profiles, the connecting elements of plastic are used.

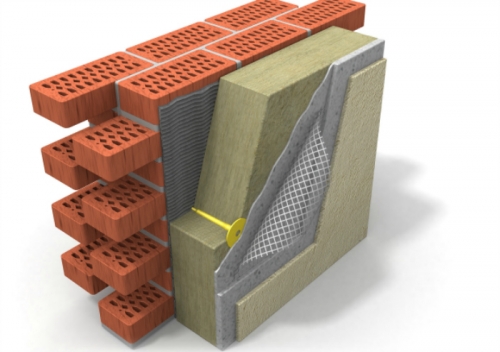

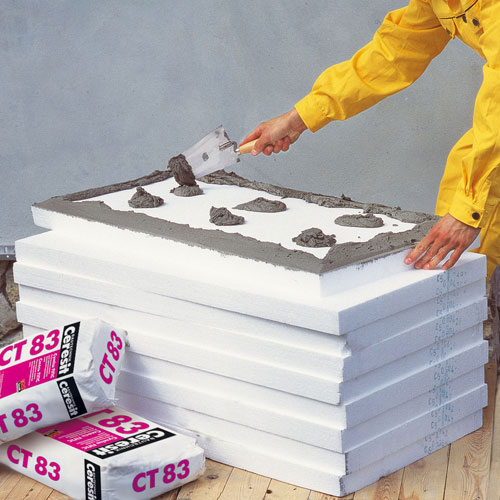

The next step is to fasten the plates of thermal insulation material using adhesive mixtures, the preparation of which is carried out directly on the site where construction work is carried out. To do this, the dry mixture is added to the plastic container with water, the amount of which is indicated on the packaging of the adhesive composition, and mixed until the mixture acquires a homogeneous consistency. After the solution was exposed for 5 minutes, the composition must be used no later than two hours from the moment of preparation.

The method of applying the adhesive is determined by the curvature of the walls and irregularities of the base. If the size of the irregularities does not exceed 3 mm, the adhesive mixture is applied to the heat -insulating plates with a continuous layer using a spatula, taking into account the retreat from the edge of at least 2 cm. It is important to remember that the solid mixture is not applied to the side surfaces of the plates. After applying the adhesive mixture, the slabs are strengthened in the design position, starting from the lower row, in contact with the profile, and pressed. Next, the plates are fastened along the same principle from the bottom up, taking into account the displacement of the rows according to the type of brickwork.

Additional strengthening of the plates and the arrangement of the reinforcing layer

After three days after the installation, grinding the insulation plates is carried out by means of a grinding grater, after which the garbage remaining after surface treatment is thoroughly removed from the surface of the material. The device of the system is wet facade, photos confirm this, implies additional strengthening of insulation plates by mechanically, which is carried out three to four days after they are strengthened with adhesive compounds. To do this, mark the holes for the dowels, their drilling and cleaning of debris and dust. After that, putty discs are installed in the holes and only then screw the dowels. It is such a two -stage attachment system that allows the design to give the necessary strength and immobility, on which the ability of the system depends on the ability of frequent changes in weather conditions.

After a two -stage strengthening of the plates, reinforcement is carried out, which implies the application of the same adhesive composition to the insulation. To prevent the appearance of cracks in the area of \u200b\u200bthe window, openings often resort to an additional strengthening of the reinforcing layer using a mesh for the wet facade. In the area of \u200b\u200bthe lower floor, experts advise strengthening reinforcement using another layer of reinforcing mesh.

Reinforcement is carried out as follows. The adhesive composition is applied to the insulation using a steel brush with a uniform layer, the thickness of which does not exceed 2 mm. Without waiting for its drying, they strengthen pre -prepared clips with an overlap up to 10 cm.

Another layer of adhesive composition is applied to the laid mesh, after which they wait for its complete drying for 3 days. After that, a primer layer is applied, which will serve as the basis for the decorative layer.

Application of a decorative layer

The device of the system of the wet facade involves further application of plaster on top of the reinforcing layer.

Experts recommend that specialized facade plaster can take on the complete load of aggressive influences of the environment.

In order not to prevent the output of excess moisture from the insulation, it is recommended to choose materials for decorative finishes with high vapor permeability. Most often it is a finished decorative plaster or clinker tiles.