The development of screw piles in domestic construction began recently. But that ...

|

|

The choice of building material for the construction of a new house is a responsible step. From... |

Stretch ceilings are a very spectacular and modern solution for repairing rooms ... |

Mineral wool or polystyrene: what to choose

In the process of insulation, the question very often arises between the choice of cheaper foam and mineral wool. In order not to be mistaken in the insulation of the building, you should first study the characteristics of these two materials, their properties and features. In addition, each of them has its own advantages and disadvantages of which we will talk about later.

Table of contents:

- Minvata - characteristics, features and advantages

- What is good foam: features and advantages of the material

- Foam or mineral wool, which is better for the facade

- Mineral wool or polystyrene: the scope of use

Minvata - characteristics, features and advantages

One of the most affordable and at the same time high -quality materials for insulation is mineral wool. In addition to high thermal insulation qualities, it is an excellent sound insulator, ease of installation and harmlessness to human health.

The scope of the use of mineral wool is quite wide, it is used in the process of insulation of walls, inter -story floors, attic, balconies, attics, basements, etc.

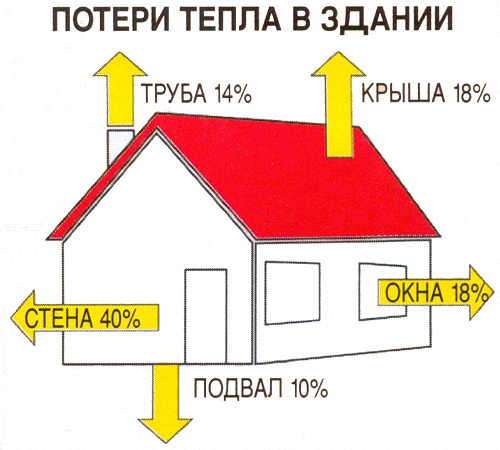

Before the construction of the building, all the nuances should be thought out, including its insulation. In modern construction, there are a large number of materials for insulation of the house, therefore, before giving your preference to one of them, you should well study all the features of each and compare them with the individual characteristics of the structure that needs to be insulated.

Mineral wool has high practicality. It is a large -fiber insulation made from rocks, glass and slag. This insulation has a wide scope of use, which applies to insulation of facades, floors, roofs, communications, as well as mineral wool, is part of widespread sandwich panels.

In relation to the type of material used in the production of the material, it is divided into three main groups:

- Material based on slag wool - domain waste is used in the manufacturing process;

- glass wool consists of material based on the use of silicon oxide;

- The basalt rocks of stones are the main component of stone mineral wool.

In the ratio with the form of release, mineral wool happens:

- rolled;

- segment;

- in the form of plates;

- in the form of a shell;

- corrugated, etc.

Different manufacturers make this material in special forms and their variations.

The use of cotton slag allows you to achieve a good effect of thermal insulation. In addition, it is resistant to chemical exposure, but at the same time differs in the smallest density. This type of mineral wool has an affordable cost, but does not tolerate temperature changes. If we compare its duration of operation with other types, then slag mineral wool will last much less stone or glass wool. The scope of use of slag wool applies to insulation of temporary buildings or economic structures in the form of sheds, warehouse or summer buildings.

Glass wool is much superior to slag in terms of stiffness and strength characteristics. Its life is much higher than that of the slag, due to the higher length of its fibers. Therefore, glass wool has good elasticity and does not give shrinkage. The scope of its use applies to insulation of structures of construction, aviation, engineering and communication purposes. In addition, this material tolerates high temperatures perfectly, therefore, it is used in the process of insulation of pipelines.

The best insulation among the varieties of mineral wool is stone wool made of basalt rocks. Its cost is the highest, although it is fully justified by operational characteristics. The rigidity of this type of mineral wool is 100 percent, and the minimum service life, subject to installation technology, is 60 years. The presence of a low thermal conductivity coefficient provides reliable heat and sound insulation.

Among the advantages of using mineral wool, it should be noted:

- fire safety and stability before ignition make this material popular in the process of insulation of warehouses and buildings in which fire -hazardous substances are stored;

- high level of strength and stability before biological influences in the form of insects, rodents, mold and fungus;

- good vapor permeability and stability before moisture provide not only reliable insulation, but also make the atmosphere in the room comfortable for living;

- Providing high -quality soundproofing allows you to save on the purchase of soundproofing materials by installing mineral wool as a heater;

- Environmental harmlessness is ensured by the use of only natural components in the process of making material, therefore, mineral wool is used as a heater in children's, medical and sanatorium-resort institutions;

- practical lack of shrinkage as a result of thermal or natural impact;

- low thermal conductivity makes mineral wool the most popular material for insulation;

- Stone cotton wool has a high service life and will serve its owner almost the same time as the whole building;

- Simplicity of installation and quick installation - it will not take much time to carry out insulation work, and to cut cotton, it is enough to have a sharp stationery knife;

- Mineral stone wool holds the shape well on any surface.

What is good foam: features and advantages of the material

Foam is popular due to its cheapness and environmental safety. It is an effective heat insulator, due to the presence of a porous structure filled with air.

In order to understand the features of the foam, we suggest that you familiarize yourself with its advantages:

- Foam - environmentally friendly and harmless material - this condition is regulated by hygienic conclusions of research;

- The low level of specific thermal conductivity - the foam perfectly passes the air, but at the same time holds heat, it contains 97% of the air, which contributes to thermal insulation;

- The presence of stability and fire safety allow the foam to not change their physical and chemical properties at temperature changes, in addition, foam is characterized by fire resistance and belongs to materials that are capable of producing carbon dioxide and water, the use of high -quality foam guarantees the lack of burning, so as the presence of antipirin in it allows him to self -adjust;

- low level of dynamic stiffness makes the foam an excellent sound insulator;

- In addition, the polystyrene is resistant to various kinds of technical influences, as well as to microorganisms, the material is not able to secrete water -soluble substances, therefore, in the process of entering the environment, it does not have a negative effect on it.

Keep in mind that the polystyrene is unstable before exposure to alcohol, turpentine, acetone, kerosene, gasoline and other solvents, since their interaction leads to the dissolution of this material.

Despite this, the foam is stable before biological factors in the form of fungi and bacteria. No mold is formed on its surface. Although the density of foam is minimal, it has a very lightweight, so it has no effect on the total mass and load of the building.

If we consider the issue of choosing polystyrene or mineral wool in terms of value, then in this case, the use of polystyrene is recommended. This material is the cheapest means of insulation, among all the insulation in the modern market. In addition, the polystyrene is light in processing and installation. Its service life is unlimited, subject to all installation and manufacturing technologies.

When using foam for insulation of the building, it has a fairly low thermal conductivity, which provides low heat loss and high -quality insulation. Foam as a heater has such advantages:

- reduces the cost of insulation of the entire building in winter;

- allows you to save a useful space;

- reduces transportation costs;

- reduces the cost of using special equipment or equipment for installing insulation;

- does not need waterproofing work;

- reduces the time for insulation.

Foam is well compatible with materials in the form of cement, lime, gypsum, foamed colors, roofing material, etc.

In addition, the polystyrene is widespread in the process of arranging a warm floor system, as well as in the process of thermal insulation of the foundation, walls and roofs. The scope of use of foam applies to the production of refrigeration equipment, thermal insulation of communications and storage facilities of low -temperature purposes.

The disadvantages of using foam as a heater include:

- restrictions in mechanical strength - after setting foam, it is required to create additional protection against damage;

- It has low vapor permeability compared to mineral wool, which is capable of providing a comfortable microclimate, polystyrene does not have such properties;

- Under the influence of a certain kind of chemicals, such as nitro -painting or paintwork materials that have the same basis before exposure.

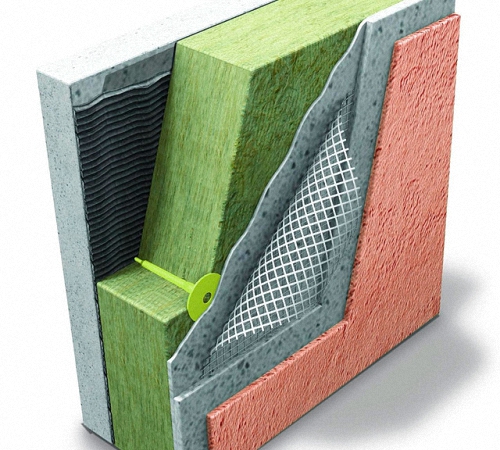

Foam or mineral wool, which is better for the facade

Most inexperienced owners tend to use mineral wool for insulation of the facade, due to the fact that it has a higher vapor permeability and environmental harmlessness.

However, due to the fact that mineral wool passes air, it is also capable of moisture, which settles in the inside of the facade and leads to freezing and destruction. The decorative layer begins to gradually deform, and mineral wool becomes similar to a sponge that has accumulated moisture. In addition, increased humidity leads to the destruction of decorative layers of the facade. This thermal insulation will last in such conditions no more than six years, since the facade will gradually begin to crumble. In addition, the microclimate in the room will not be healthy in any way, due to the large amount of mold and fungus on the surface of the walls.

Foam, in turn, passes the air, but in moderate quantities. Due to the lack of pores and the presence of good density, he is not able to miss moisture with air. Thanks to the passing of the air through the surface of the seams and the air gap, a certain ventilation is created, which provides a longer service life of both thermal insulation and the facade.

In addition, the use of polystyrene as a heater of the facade surface allows you to retain heat in winter at a higher level than mineral wool. Installation of polystyrene as a heater avoids the appearance of cracks or deformations on the surface of the facade, due to a sharp difference in temperature regime.

The use of mineral wool for insulation of facades is quite acceptable, but only if the facade has good ventilation that will get rid of excess moisture. But, for the arrangement of the ventilated facade, many funds are required both cash and temporary. Such facades are more common in high new buildings, administrative buildings, shopping and entertainment complexes, but not in residential buildings.

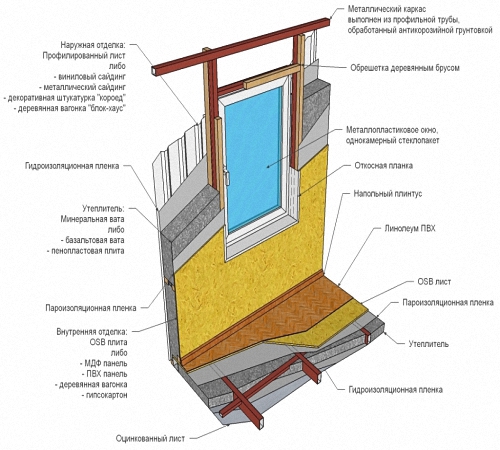

Mineral wool or polystyrene: the scope of use

Each of these materials has its own individual characteristics, and in response to the question of the question that the foam or minvat is warm, it should be based on the peculiarities of their use. Since both of these materials have a fairly low thermal conductivity, only the quality of their work will be noticeable only if the installation and material that is designed to warm it is correct.

For insulation with foam, you should choose places with a sufficiently high humidity, but at the same time with the need to warm them:

- The foam is perfectly in contact with wet soil, so it is an excellent insulation of the foundation, as well as engineering structures that have been in the underground space, even after several tens of years, the insulation will not lose its properties, it is used as a central layer when warming a multi -layer foundation, while The foundation has excellent quality and reliability;

- In the process of arranging a house that does not have a basement and a monolithic type built on the foundation, it is also better to use foam, it will be necessary to pre -level the site for laying the plates, and then they are filled with concrete solution, further work involves the construction of the walls of the building;

- In order to avoid freezing of the foundation itself, it is not only horizontal, but also vertical insulation, polystyrene slabs are laid along the perimeter of the foundation, then they are filled with soil and waterproofing is laid, so the foundation receives reliable protection against low temperatures;

- The internal and external walls of the buildings are also insulated with polystyrene, while the most optimal option for such walls is their manufacture of blocks or bricks, the internal insulation of walls is distinguished by high thermal insulation characteristics, while there is no condensation formation;

- When arranging an unentilled roof, a foam of a special brand is used, on the upper part of which, the waterproofing is mandatory, the foam is installed in the heat -insulation of the ventilated roof, the condensation is not formed;

- The foam copes well with the insulation of inter -story ceilings and floors, and after laying it, the floor is filled with concrete.

Mineral wool is good when warming:

- wooden buildings and surfaces, since the use of foam in this case does not allow the tree to breathe, and the atmosphere in the house becomes not comfortable, the use of mineral wool provides reliable ventilation;

- Minvata is suitable for thermal insulation of attics, attic, balconies, pitched roofs;

- The use of mineral wool applies to two -story brick buildings, three -layer concrete panels and a sandwich panel that have a metal membrane;

- The maximum temperature that the stone wool can withstand is about 1000 degrees, therefore it is widespread when warming high -temperature objects;

- Frame houses are suitable for insulation with mineral wool, in addition, in such buildings it avoids the cost of installing soundproofing;

- Rolled stone cotton wool allows you to ensure reliable thermal insulation of communication systems in the form of a water supply, gas system or industrial equipment.

I would take polystyrene. He

I would take polystyrene. It is cheaper.

Cheaper of course yes, but he

The cheaper is, of course, yes, but it is flammable and toxic.

Better to pay a little and

It is better to pay a little and take the stone cotton wool http://www.isover.ru/kamennaya-vata, it is better than foam in the parameters.

Foam is not

Foam, is not a source of combustion, i.e. The source does not burn, the foam does not burn. Stone cotton wool is dangerous for asthmatics.