The maximum sophistication, chic and originality is able to add both to the interior and in ...

|

|

Surely, you have repeatedly noticed that many private houses are covered with flexible tiles ... |

Quite often, after gluing wallpaper on the surface, bubbles become visible. This ... |

Keramzitobes: characteristics and features of the material. Do -it -yourself cloves from expanded clay blocks

The choice of building material for the construction of a new house is a responsible step. The heat and comfort in the house, its durability, strength and number of maintenance costs will depend on what kind of type will be given to its type.

Table of contents:

- What is expanded clay block?

- Characterization of expanded clay blocks

- Classification of expanded clay blocks

- Advantages of expanded clay blocks

- Cons of use of expanded clay -cement blocks in construction

- Using expanded clay -cement blocks

- Results

What is expanded clay block?

The variety of building materials in the modern world is amazing. However, preference is given to natural components with the highest energy efficiency indicators, environmentally friendly and inexpensive.

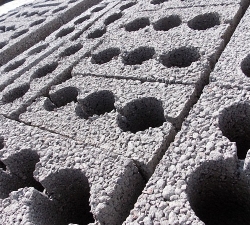

Among these materials were expanded clay blocks (in the photo are examples of various types).

These are rectangular building stones with or without voids (depending on the purpose). Produced from natural components:

- cement;

- sand;

- expanded clay (clay);

- water.

Ceramzit -cement blocks are made by means of semi -dry pressing. Produced by various in size and form of internal voids, expanded clay blocks are similar to large bricks. The relatively small weight of the unit is explained by the presence of coarse clammer filler. These are small balls, up to 10 mm from burned clay. The ease of this material allows you to significantly facilitate the weight of the entire building, which qualitatively affects the cost of arranging the foundation.

The scope of expanded clay blocks is to build external walls and internal partitions of buildings. It is also used as a comprehensive building material to improve thermal insulation and soundproofing characteristics of the construction, fill the frames of buildings from reinforced concrete, and decorative construction. Regarding strength, this building material can be compared with brick or foam concrete blocks.

Important! Expanded clay concrete blocks are not used in the installation of the foundation.

Characterization of expanded clay blocks

The composition of expanded clay blocks as a knitting substance includes the cement of the M-400 percentage of components, including cement, affects the characteristics of of course material, its heat, strength, strength and weight.

For example: blocks with a density of 1500 kg/m3 consist of:

- expanded clay (up to 10 mm) 34%;

- cement (M-400) 27%;

- big fraction sand 28%;

- the water is clean, without additional impurities 9%.

The less cement and sand is used, the easier the composition. So in blocks the density of1000 kg sand can be completely absent.

Classification of expanded clay blocks

Depending on the use, there are such types of expanded clay blocks:

- wall (for the construction of external and internal walls);

- particular.

By characteristics depending on the purpose:

- thermal insulation, used to warm the walls of buildings, with large inner voids, specific weight from 350 to 600 kg per cubic meter;

- thermal insulation and constructive with a specific weight of up to 1400G per cubic meter are used to install external single-layer walls;

- the structural greatest specific gravity up to 1800 kg per cubic meter. m, are used for the construction of supporting structures, including overpasses, bridges, houses up to 12 floors.

The purpose of expanded clay block affects its shape. There are blocks with voids of different shapes inside (through or deaf, round or rectangular) and full -bodied.

According to the quality of the lateral surfaces, expanded clay -cement blocks can be:

- private are used to install walls, which will subsequently be covered with facing materials;

- the front blocks have an attractive rough front surface that does not need additional processing, are not subject to environmental influences.

Advantages of expanded clay blocks

Compared to other similar materials that are widely used for the construction of buildings, expanded clay blocks have several advantages. Among them, such as: thermal insulation characteristics, relative lightness, environmental friendliness. Also, a light and porous expanded clay -cement block has a shrinkage at the level of heavy concrete. This indicator is especially important in the construction of high buildings and construction on floating soils, it allows you to save on reconstruction decoration.

The cost of the material varies in the middle range. It is a little more expensive than foam concrete and gas silicate and compare at a price with a cinder block. Also, the dimensions and shape of large expanded clay -cement blocks allow you to accelerate the construction process, save on the work force necessary for the construction of walls, as well as on the amount of cement mortar of the blocks necessary for laying.

The use of hollow blocks during wall installation allows you to create a peculiar skeleton of the structure and increase the bearing capacity of the frame.

Ceramzit cement blocks will last a long time because they have low hygroscopicity and, accordingly, high frost resistance. They are also practically not susceptible to fungal lesions, which allows you to save on additional measures to protect the surface of the walls. Next, we will consider in more detail the technical and operational parameters of this material.

- Thermal conductivity

The average heat conductivity of expanded clay concrete blocks is 0.14 0.66 W/MK, which compare natural wood. With an increase in the percentage of the cement in the solution, the quality of thermal conductivity is proportionally reduced. But even the blocks of the greatest strength (constructive) are less heat than brick or concrete.

- Soundproofing

Thermal insulation partitions have an average sound insulation indicator at 50dB. With an increase in the percentage of expanded clay, noise isolation level can be increased. This factor is successfully used in the installation of internal partitions in the house.

- Frost resistance

Ceramzit -cement blocks porous material, so they have a boundarily permissible number of freezing cycles. The frost resistance indicator is the smallest for thermal insulation blocks with a large porosity of 15 50 cycles. With an increase in density, the level of frost resistance of the material increases. Constructive blocks withstand up to 500 cycles, an intermediate type up to 150 cycles.

In other words, the house built from expanded clay -cement blocks without problems will spin at least 50 60 years.

- Hygroscopicity and vapor permeability

The material has a water absorption at a level of 5 10% of the mass. This indicator can be significantly reduced by adding special additives and plasticizers to the solution.

Ceramzit -cement blocks can be attributed to breathable materials that can pass moisture in the air, which provides an optimal microclimate in the room. The vapor permeability of this material is at the level of drywall plates or wood and twice as high as brick walls.

- Environmental friendliness

Their materials of natural origin, the quality of which during production is controlled by the appropriate GOSTs, clay -cement blocks are absolutely safe for human health and the environment. They do not contain toxic elements, do not secrete harmful substances over time.

- Fire resistance

The heat resistance of the material is quite high. At temperatures up to +1100 degrees, the material withstands up to 150 minutes without damage.

Cons of use of expanded clay -cement blocks in construction

It is worth noting the negative aspects, without which not one is complete, even the most ideal building material. One of the most significant negative factors is the unevenness of the forms and geometry of blocks. This entails a certain overrun of the cement mortar to fit the evenness of the walls, and also creates the risk of distortion in case of violation of the masonry technology.

When using this material for the construction of high buildings (up to 12 floors), it is necessary to use blocks with a high cement content in the composition. As a result, the mass will increase, and the quality of thermal insulation will decrease. As a result, the entire construction project will be several orders of magnitude more expensive.

The relatively low stability of the blocks to shock and vibration, a large fraction create certain difficulties in the process of cutting and installing expanded clay blocks.

Ceramzit -cement blocks can be transported by any type of transport. A prerequisite for transportation is their automated loading-unloading with packaged packets on pallets. In this case, the height of such a package should not exceed 1.3 m, are laid exclusively in one layer. Blocks with deaf voids are laid down the hole.

Using expanded clay -cement blocks

The masonry of the walls of expanded clay blocks is performed in the same way as masonry made of brick or cinder block. However, there are some features. Consider them by example.

To get started, it is necessary to prepare a tool and consumables.

- measuring devices level, roulette, cord, square, plumb line;

- rectangular cell, rubber hammer for blocking blocks;

- bulgarian and diamond circles for cutting with a diameter of more than 220 mm;

- devices for concrete work: shovel, concrete mixer, buckets for the solution;

- scaffolding.

From the materials you need to prepare:

1. Directly clay -cement blocks in the right amount.

2. Cement, dry finished mixture for masonry or separately components (cement, sand).

3. Water.

4. reinforcing material (fittings or net).

5. If necessary, simultaneous laying of insulation.

- Masonry solutions

Expanded clay blocks are placed in special adhesive solutions or ordinary cement-sand solution.

In the finished mixture, add water in the quantity indicated by the manufacturer. The adhesive components allow the seam to compact. A solution of cement (M-400), sand and water is prepared in a proportional ratio of 1: 3: (0.6 0.8). For greater plasticity and elasticity, river sand and plasticizers are added to the solution. Consumption of about 40 kg of a solution for laying 1 cubic meter of blocks. The thinner the seams, the lower the consumption. However, adhesive mixtures will cost more than cement-sand mortar.

The solution is prepared in small portions in a concrete mixer at the rate of 1 2 hours of work. It should be homogeneous, plastic, not dry and not fluid.

- The main methods of laying expanded clay blocks

1. In the floor of the block (in width). Such masonry is used to build summer houses, garages, and outbuildings. The usual dressing of blocks with reinforcement is performed every 4 rows. At the top of the wall, an armo -pile of 15 cm wide is performed. Such a wall can be insulated outside with mineral wool, polystyrene foam, etc.

2. In the block, bandaging and alternating tech and spoon rows. The reinforcement is performed every 4 rows. Thermal insulation characteristics increase with external insulation.

3. Two parallels with an intermediate insulation of the wall into half a block are tied up with each other with reinforcement, and a heater is laid between them (the outer wall can be made of facing brick).

4. Masonry 60 cm wide with voids (according to the principle of well brick treasures).

- Basic rules for masonry of expanded clay blocks

Any method of masonry requires compliance with basic rules:

- A double layer of waterproofing is laid on the surface of the foundation (base).

- The thickness of the first layer of the solution for the first row should not exceed 3 cm.

- The beginning of the masonry is from the corner.

- Monitoring the plane of the position of the first block using ordinary and water levels, laser level, angular plumb line.

- When masonry, it is necessary to press and add each block with a rubber hammer, a sealing seam.

- The row is laid on the cord between the installed corner blocks.

- The position of each new row should be checked in all planes and controlled on each element.

- Masonry of partitions and walls from expanded clay blocks is carried out simultaneously to perform uniform reinforcement throughout the construction.

- For reinforcement, reinforcement laid down in strobes, or mesh, is used.

- Poly -cheeked blocks of expanded clay cement are laid only with a poke method (the long side across the wall).

In more detail about how the installation of expanded clay blocks is carried out, will tell a video review that is at the end of the article.

Results

A large list of advantages of expanded clay -cement blocks covers the existing shortcomings of this building material. It is quite simple to build a house from expanded clay blocks with your own hands, the main thing is that when buying, the seller is able to provide quality certificates for the goods, where the compliance with the GOST will be spelled out, the party’s integrity is checked.

Resisted inexpensive and energy -efficient material does not lose the positions of popularity, and environmental friendliness and naturalness makes it more and more in demand in modern private construction.