The presence of a veranda in your home allows you to turn an ordinary house into an original and ...

|

|

To save heat in the house, it must be insulated. In this article we will tell you how ... |

Penophol is a thermal insulation material of the new generation. Among alternative ... |

Mineral wool for insulation: characteristics, types, features of choice

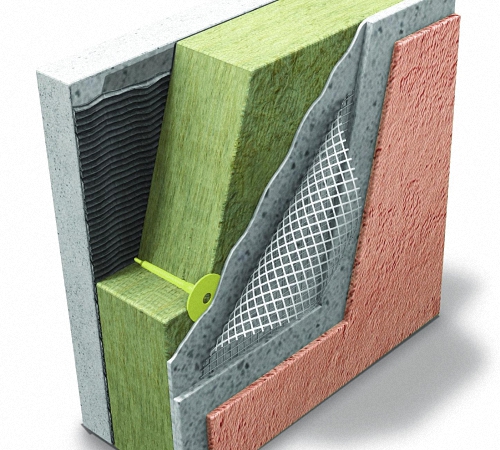

Mineral wool belongs to the category of universal insulation. Due to the huge number of its advantages, it has unlimited use. There are several varieties of this material. We will talk about their features and the advantages of mineral wool as a heater.

Table of contents:

- Mineral wool: The origin and features of manufacture

- Mineral wool characteristic: Advantages and disadvantages of insulation

- The scope of the use of mineral wool for insulation

- Types of mineral wool and their characteristic

- Thermal insulation mineral wool: Features of choice

Mineral wool: The origin and features of manufacture

Mineral wool is called material designed for thermal insulation, which consist of thin, intertwined fibers of vitreous. They are made in the process of spraying of a certain kind of slag, stones or basalt. The quality and density of mineral wool depends on the length and diameter of the fibers. The process of production of mineral wool is based primarily on the receipt of the minimum fibers, which are interconnected using a binder.

In order to better understand the properties of mineral wool, you should carefully study the process of its origin. The manufacture of mineral wool is conditionally divided into such stages:

1. Determination of the type of raw materials and its preparation for melting.

At this stage, the composition of mineral wool is determined, in which a certain proportionality of the ingredients is observed. It has the name - Shikhta. Most often, this composition contains two, a maximum of three components. Each of the manufacturers of mineral wool has its own proportions of the ingredients in this composition. It is on the proportionality and type of mineral ingredients that its further multifunctionality, stability before moisture, temperature changes and compression depends. In addition, the product should have high thermal insulation properties. The quality of mineral wool determines primarily its fiber, its size and chemical components. Before mixing the ingredients, they undergo the procedure of grinding and drying. Already in the dosage chamber, they are selected according to the specified proportions.

2. The melt of the components.

After all the ingredients have mixed well with each other, they are melted at a temperature of about one and a half thousand degrees Celsius. This stage is the main part of the mineral wool production process. The consistency of the resulting mixture and the length of the fibers of the finished product depends on the temperature in the furnace.

Most often, for heating such a furnace, fuel is used in the form of natural gas, it is with its help that it is possible to achieve such a high temperature.

3. Making the fibers of the material.

A molten mass that has a certain viscosity is in the area of \u200b\u200bthe formation of the fibers. For these purposes, special devices have been developed in the form of multi -wluest centrifuges and fiber distributors. The composition falls on the roll, which rotates at a very high speed. As a result, fibers are formed, in which various kinds of additives and water -repellent mixtures are also added. Then the fibers are in the cooling chamber and form a homogeneous canvas.

On a special kind of machine, the canvas undergoes special processing on fiber orientation. Thanks to this, mineral wool has almost zero shrinkage.

4. Polymerization procedure.

The canvas is in the heat treatment chamber, where it is hardened. All binders are endowed with certain physical properties, it is this process that further affects the quality of finished products.

5. Determination of form.

Mineral wool is produced both in the form of plates and in a roll version. At this stage, it is cut and packaged in size.

6. Packaging.

The latter, final stage involves packaging the finished material and sending it for sale.

Mineral wool characteristic: Advantages and disadvantages of insulation

To begin with, let's get acquainted with the advantages of mineral wool:

1. Good thermal insulation characteristics.

Due to the fact that the fibers of thermal insulation material are of particular subtlety, it is a universal and very good heat -insulating material. If we compare the indicators of its thermal conductivity with other alternative heaters, then mineral wool will certainly win.

2. Fire safety.

Mineral wool is used in any areas whose temperature does not exceed 1000 degrees. Before reaching this temperature, mineral wool is not able to melt. Therefore, it is an excellent option for insulation of walls, floors, ceiling and inter -story floors. Using mineral wool, to some extent it is possible to prevent a fire, since it is not capable of spreading fire.

3. Stability before chemical compositions.

This property also expands the scope of mineral wool. Its composition is absolutely stable before various kinds of chemical influences.

4. Biological stability.

This advantage is determined primarily by the fact that mineral wool is not eaten by rodents as rats or mice, in contrast to foam. And, therefore, throughout the entire period of its operation, it remains unchanged both in form and in composition. In addition, due to good moisture resistance, mineral wool is stable in front of the fungus and mold, which is especially important to provide a healthy atmosphere and microclimate in the room.

5. Great sound insulator.

The chaotic arrangement of mineral wool fibers allows you to use it not only as a heater, but also for the soundproofing of the premises. Mineral wool is used even for installation on the doors, as it is not able to let extraneous sounds into the room.

6. The ability to cope with static loads.

Due to good density, mineral wool perfectly withstands static loads, therefore, it is used to warm the floors, ceilings and other kinds of responsible elements. Even after 40 years of its operation, mineral wool does not give shrinkage. And the duration of its operation depends on the tendency of the insulation to deformation. Since, shrinkage, leads to the appearance of cold bridges and to increase thermal losses.

7. Steam -sailing characteristics.

Due to the fact that mineral wool passes air, a healthy atmosphere remains in the room and natural air exchange occurs.

8. Environmental safety.

There is a binder in the mineral wool based on formaldehyde resins, however, in the process of manufacturing the insulation, this resin becomes absolutely harmless, and with further operation, does not distinguish harmful substances.

9. A long period of use.

The service life of mineral wool is more than 45 years. Since this material is practically not amenable to shrinkage, it tolerates increased humidity, sharp temperature jumps and atmospheric phenomena, it is able to maintain its characteristics throughout its entire duration of its use.

In addition, mineral wool is an excellent insulation for facades, as it is characterized by high strength to break. This material is simple in processing and installation.

Despite this, mineral wool has several disadvantages, among which it should be highlighted:

- Mineral wool can function normally as a heater, exclusively in combination with additional materials of vapor barrier and waterproofing nature;

- In the process of working with mineral wool, it is necessary to use protective gloves, mask and glasses, since there is a risk of the smallest fibers on the skin and its irritation;

- It is not recommended to allow constant contact of mineral wool with moisture.

The scope of the use of mineral wool for insulation

Due to its versatility and a large number of positive characteristics, mineral wool has a wide range of application, namely:

- in the process of insulation of ventilated facades;

- in the arrangement of three -layer masonry;

- insulation of walls, ceilings, floors, inter -story floors;

- manufacturing roofing pies in the process of arranging a high -quality roof;

- as a thermal insulation material for the roof;

- with external wall insulation;

- during the manufacture of reinforced concrete products;

- with thermal insulation of communication systems: pipelines, gas pipelines, etc.;

- in most building structures;

- When warming balconies and attics, as well as loggias.

Types of mineral wool and their characteristic

In relation to the features of the production of mineral wool, it can be three types:

- based on fiberglass;

- based on slag;

- Stone mineral wool.

Each of the materials is characterized by individual characteristics, and in particular the length and arrangement of fibers, different resistance before deformation, moisture, loads, etc.

Mineral wool based on fiberglass or glass wool has fibers, the thickness of which is not more than 14 microns, and the length is up to five centimeters. This material is characterized by the highest strength and elasticity. Keep in mind that it requires the use of special protective equipment during operation, since small particles of glass are able to enter the skin and cause irritation.

The glass wool has a good coefficient of thermal conductivity, it is able to withstand the temperature of up to 450 degrees of heat and 50 degrees of cold.

The second option is the use of slag. For the manufacture of this insulation, a blank slag is used, the fibers of which do not exceed twelve microns in thickness, but in length, no more than one and a half millimeters.

The slag is unstable in front of the acidic environment, so it has limited use on metal surfaces. In addition, this insulation is characterized by high hygroscopic ability, so it cannot be used in the process of insulation of facades and other external structures. The cost of slag is an order of magnitude lower than, for example, glass wools. Due to its fragility, it is not used in the insulation of pipelines and communication systems.

The slag is capable of withstanding the temperature of up to 300 degrees of heat, when exposed to a higher temperature on it, it loses its properties of thermal insulation. In addition, it has high hygroscopicity, which significantly limits the scope of its application. The biggest advantage of this insulation is its lower cost, compared to alternative options.

Stone or basalt mineral wool - differs in the same small fibers as slag. However, this material is not inclined to cause irritation or allergies. In addition, it has high thermal insulation indicators, the best option of stone wool is material based on basalt rocks of stones. This material withstands the temperature of up to a thousand degrees of heat and up to two hundred degrees of frost, without changing thermal insulation characteristics.

Basalt stone cotton wool is sold both in rolled and plate version. It is very convenient in operation, not prone to deformation, not prone to burning. This version of mineral wool is the best choice for its use as insulation.

Thermal insulation mineral wool: Features of choice

In order to buy mineral wool, it is enough to contact any construction store or supermarket. For mineral wool, the price is determined primarily by its view, the cheapest slag, a little more expensive than the glass wool, but the most expensive option is basalt stone cotton wool.

The thickness of mineral wool is different, its choice depends on the type of coating on which the insulation will be installed.

In addition, in the ratio with the size of mineral wool, various kinds of plates and rolls are also distinguished. Each of the manufacturers has its own size grid of finished products.

Stone cotton wool is divided into such subspecies:

- granular - manufactured by a special compressor installation, is relevant for places in which the installation of ordinary insulation is not possible;

- In the form of boom -coated plates - an excellent option for laying roofing finishing materials;

- In the form of lamps - it differs in the presence of fibers, which are not located in chaotic, but in perpendicular, it has good elasticity and flexibility, suitable for thermal insulation of pipelines.

We offer to familiarize yourself with the main manufacturers of mineral wool:

1. Rockwool mineral wool - the material has a low heat conduction coefficient, perfectly passes air, does not absorb moisture, and differs in non -combustibility. In addition, the mineral wool of this manufacturer is stable before mold, insects and rodents, environmentally friendly and has good soundproofing characteristics. Among the huge range of products, it is possible to choose exactly the type of mineral wool that is suitable for individual characteristics of the site requiring insulation.

2. Mineral wool isover - made in the form of plates, rolls or mats, has two forms: hard and semi -rigid. The material is used in the process of insulation of the roof, inter -story floors, floors, facade parts of the building or walls. The material holds air by 99%, therefore, during operation, its quality of thermal conductivity only increases.

3. Mineral wool URSA - this insulation is based on fiberglass or quartz glass. The material is distinguished by good fire safety, it is practically not combustible, in addition, the minvat of this manufacturer is environmentally harmful to health.

Before buying mineral wool, you should also study the recommendations for its choice, which are presented below:

1. Pay attention to the place and storage conditions of the material. All products should be stored in such a package in which it was packed at the factory.

2. If, mineral wool is sold in boxes, then it should be minimized by its contact with moisture or with a humid environment.

3. Even for small money, you should not purchase wet wool, since after drying it loses its properties.

4. Determine several manufacturers for yourself, read reviews about them, and then make a purchase decision.

5. Pre -calculate the right amount of cotton wool, in relation to the area of \u200b\u200bthe insulated area.

Mineral wool video: