The worthy design of the central entrance to the house sometimes creates a more favorable ...

|

|

Installing screw piles allows you to build a massive and strong foundation for ... |

One of the most difficult stages of repair is rightfully considered to be filled with screed. Really... |

How to glue glasshold

The glass hub has a large number of advantages, and therefore is often used in the decoration of the premises. We will consider about its features, varieties, as well as how to glue glassholst.

Table of contents:

- General concept and advantages of fiberglass

- The scope of use of fiberglass

- How to glue glasshold on the ceiling

- Maslar glasshold - Features of gluing on the walls

- Staining painting glassolt

- Recommendations for gluing fiberglass

General concept and advantages of fiberglass

Glassholst is an environmentally friendly and harmless material, which is created on the basis of mineral fiberglass and organic resins. It appears in the form of a continuous non -discharge canvas, without a pronounced texture, which has the highest strength to break.

Glasshold, is also called a masking web, due to its specific surface and soft structure. In composition, it looks like glass wallpaper, but has a number of features that differs from them. The fibers of the fiberglass are not intertwined like glass wallpaper, but simply accidentally glued in a chaotic manner.

The production of fiberglass is not connected with the machines, when manufacturing it is pressed with fiberglass. This process is similar to the production of paper. Ultimately, the manufacturer receives a very smooth sheet with a minimum density. The difference between the fiberglass and ordinary paper lies in the fact that the glasshold is not amenable to the effects of moisture, chemicals and mechanical influence, static electricity and dust are not accumulated in them, they perfectly reinforce the surface of the walls.

The similarity of the fiberglass with paper consists in passing air, environmental friendliness, harmlessness, anti -allergicism and antisepticity. The difference between the glasshold and the glass wallpaper consists in the smoothness of the surface, which is subject to multiple staining.

On the plastered walls, in the process of shrinkage or the influence of high temperatures, the subtlest network cracks occur, which destroy its integrity and become noticeable only when the walls are wet. If such walls are reinforced with fiberglass, then the cracks will not appear, and the surface will become clean and smooth.

Also, fiberglass is used to increase the strength of the paint, which is applied to the surface of the walls or ceiling. In this case, the paint acquires new properties, it does not become combustible, stronger and more waterproof.

The main functions of the fiberglass of the web are:

- elimination of small irregularities and smoothing the surface of the walls and ceilings;

- small cracks are small;

- subsequent application;

- An increase in the strength of the surface on which the glass chuck is applied.

Among the advantages of glass and power, such qualities should be distinguished:

- Fire safety,

- Anti -corrosion,

- antisepticity,

- Lightness in care,

- air passing,

- Anti -alleys,

- does not accumulate electricity

- harmlessness.

Among the large number of advantages, there are several flaws of the fiberglass:

- It's hard to work with glass -chick,

- Large cracks of glass chloride will not block, they must first be embedded,

- In the process of its use, it is necessary to use overalls, a mask and a respirator so that the small particles of the glass do not fall on the mucous membranes and do not irritate the skin.

The scope of use of fiberglass

The use of fiberglass is associated with the interior decoration of premises of residential or public purposes. It is used to decorate and reinforce walls or ceilings. Due to the presence of a dense structure, all irregularities are easily disguised and paint is perfectly applied.

The use of fiberglass during finishing work allows not to use the finish putty walls, it is enough to sparkle them only to the starting.

After the plastering coating on the walls is restored, they need to be fanned, and then treated with a deep penetration soil. The type of glue that is attached to the fiberglass should be taken into account based on the recommendations of the manufacturer.

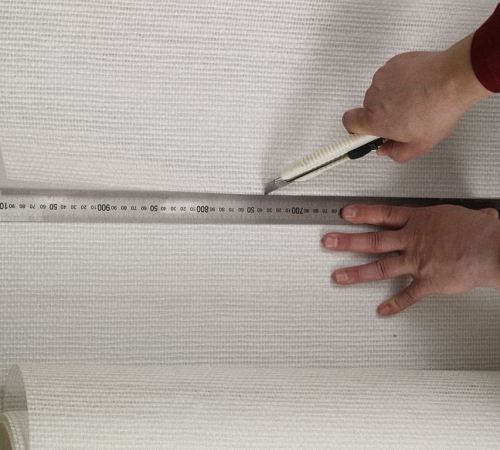

Application of glue is carried out directly on the wall. A canvas is cut off, which has a supply of about eight centimeters and is glued in a vertical direction. It is advisable to note the place in which pasting will be carried out. Glotting of subsequent fibers is like gluing wallpaper, they join each other. To smooth out irregularities, use a rubber roller or spatula. Excess glass chloride are cut off with an assembly knife. When the glue is completely dry, and for this it is necessary from one to two days, proceed to the staining process.

Due to the fact that the glasshold has a fibrous structure, there are much more paint. To avoid this, you should once again put the surface, but already with a glass -chip. The consistency of putty should be liquid, and the application is carried out using a rubber spatula. The putty, as it were, rubs into the glass -chip. This procedure is carried out carefully and slowly so that there are no small errors, since after it will be stained.

The advantage of the use of fiberglass is that in the process of wet cleaning, when using high -quality paint, the surface does not lose its original appearance for many years. Therefore, this material is indispensable in the process of finishing the kitchen or children's room. Also, fiberglass does not burn, perfectly passes the air, has antiseptic properties, and most importantly completely safe.

The recommended number of repainting of the fiberglass is about 3-5 times. If you repaint it more, the weight, accumulated paint will lead to detachment of paintings.

Glassholst photo:

Field of use of fiberglass:

- production of materials of waterproofing and roofing;

- manufacturing of floor panels and wall type of polyvinyl chloride;

- reinforcement of polyvinyl chloride;

- drainage systems;

- reinforcing basis before applying plaster;

- In the production of panels, fiberglassocle gives them a more presentable appearance, improves fire resistance and simplifies their installation;

- to protect the pipeline system from corrosion;

- when gluing roofing, to improve its quality;

- when laying tiles or kavrolin;

- In the device of floating floors, for the construction of special soundproofing screens.

How to glue glasshold on the ceiling

Work tools:

- building level,

- Installation knife,

- pencil,

- roller,

- brush,

- The bath is painted,

- Wallpaper spatula,

- The spatula is ordinary.

Before proceeding to direct gluing of a fiberglass on the ceiling, it must be pre -prepared for this process. The preparatory stage of work includes the following actions:

1. Take off the old plaster, paint, lime or wallpaper from the ceiling. For these purposes, use the spatula. To remove old wallpaper, you need to pre -soak them with water and wait half an hour.

2. If the ceiling is covered with a solution of lime, especially if there are several layers of this material on it, it is recommended to clean it with a spatula. So, as adhesion between glass and ceiling will be very weak.

Tip: if the lime ceiling is difficult to clean with a spatula, another option for processing it is possible. With the help of a brush or roller, moisten it with water and wash it with a woolen rag several times.

3. After cleaning, you should proceed with the sealing of small cracks and recesses that were formed during the cleansing of the surface. Before that, it is recommended to walk along the ceiling with a roller with a primer.

4. It is possible to glue the wallpaper directly on such a ceiling, but it is better if the entire surface is soldered.

5. When gluing a fiberglass on the ceiling made of drywall, you need to first close all the joints and hats of the screws and make the surface perfectly even. Before proceeding to the next stage, putty should dry completely.

6. If the fiberglass is glued to a layer of insulation, for example, extraction polystyrene foam, then the surface preparation also includes puttying all joints and dowels with which it is attached to the ceiling.

How to glue glassholst video:

The process of gluing glasshold includes:

1. Preliminary cutting of the paintings that will be glued to parts. To easily join the sheets with each other, leave one centimeter of the reserve at each segment.

2. Decide on the place of gluing the first sheet, using a level and a pencil, draw its location. Better yet, make the full marking on which gluing will be done.

3. Pour glue into the bath and apply a roller to the surface of the ceiling. Apply such a strip so that it is a little larger than the site on which glass chlorver is glued. On uncomfortable areas, such as corners or a place near the chandelier, apply glue with a brush.

4. Then attach the cut part of the fiberglass on the ceiling and smooth out with a rubber spatula. You should not press the edges much to do with ease to do with the next sheet.

5. The second sheet is glued in the same way, the junction is wiped with a dry cloth, and processed with a wallpaper spatula.

6. After gluing all the paintings of the glass chuckle, there should not be drafts in the room. This action will allow it to dry faster and tightly stay on the surface.

Maslar glasshold - Features of gluing on the walls

The procedure for gluing the masking glass chuck on the walls begins with their preparation and complete cleansing. Then the walls are aligned and covered with this material.

Consider the phased application of the fiberglass:

- Apply black starting putty to the surface of the walls;

- Wait for its complete drying and treat a deep penetration soil;

- After drying the primer, apply glue using a roller;

- start gluing the first sheet from the corner part;

- To improve the surface reinforcement of the surfaces on the edges of the glass chick by a roller;

- Pay special attention to the docking of the two paintings - apply one canvas on another with a gap, and then with the help of a mounting knife cut the junction and remove the excess of the fiberglass;

- The junction of the joint must be smoothed with a spatula;

- when the wall is completely dry, you need to cover the wall with the finish putty;

- after drying it, treat the wall with an abrasive net;

- Apply a primer and proceed to decorating the surface.

Tip: Apply glue with a thickness of about one millimeter to soak the wall and evenly distribute on the surface.

If the fiberglass pasted with qualitatively and correctly, the walls seem perfectly even. It is an excellent basis for decorating decorative plaster. Subject to all technologies, cracks, fungus and mold will not appear on the walls.

Staining painting glassolt

It is possible to use unpainted glass chloride, since this material looks very aesthetically pleasing. But, if necessary, in staining the walls, fiberglass is an excellent material that, in addition to ensuring a perfectly even surface, also increases the adhesion of paint and walls.

Advantages of using fiberglass when staining:

- If you need to drive a nail into the wall, the plaster will not be poured from the hole;

- Complete lack of cracks.

If a fiberglass is used, which is designed for further staining, it is recommended to use water -based paints. Thus, the material will not lose its properties, and after a while it is possible to repeat the staining procedure.

Among the choice of tone of paint, it is better to give preference to a semipomat. The question of the direct putty of the fiberglass depends on what type of decoration will be used further. If desired, in staining and obtaining a smooth surface, glass chicks must be putty, otherwise, immediately covered with paint.

To save on the flow of paint, it is cheaper to first cover the fiberglass with a layer of ordinary glue, and then paint.

In the process of staining, it is used:

- roller,

- brushes,

- wing,

- Bath.

The minimum number of layers are two. The gap between them is twelve hours.

The wing is used to roll seams, since the roller is not able to evenly paint this part.

Recommendations for gluing fiberglass

1. The recommended ceiling length, which is glued to the ceiling, should not exceed two meters, since if the glass chuckle is longer, there will be inconvenience in work.

2. Be sure to determine the front side of the fiberglass, since it practically does not differ from the wrong one. To do this, study the material label.

3. In order to avoid small particles of glass in the nose or skin, use gloves with long sleeves, respirator and glasses.

4. When gluing the fiberglass on the drywall surface, make sure that the seams of this material do not coincide with the joints of the drywall sheets. Otherwise, the surface will lose aesthetics and the seams will be very visible.

5. The optimum temperature for gluing fiberglass from 18 to 25 degrees. The absence of drafts is mandatory.

6. Start work from the side opposite to the door.

Glassholst Video:

Thanks for the advice. And where

Thanks for the advice. And where you can purchase high -quality fiberglass. There are a lot of companies on the Internet (vitrulan-moscow.ru, domfront.ru) and I will not decide in any way