Modern construction teams very often turn to waterproofing for help ...

|

|

Polish polishing is a mandatory stage of their decoration. This action allows you to improve ... |

The most standard finish of the surface of the fireplace or furnace is brick. But not... |

Isolation Energoflex: characteristics, advantages, use

Energy -saving technologies have become a guide star of the 21st century. People learn not only to uncontrollably spend the natural resources of the planet, but to use them wisely. Various heater and insulation schemes are used both in industry and at the household level. Thermal insulation of equipment and various units is technological necessity. The insulation of pipelines is laid to maintain the temperature of the coolant, whether it is overheated steam or cooling liquids.

Content

- Types of insulating materials of pipelines

- ROLS ISOMARKET products video

- Energoflex Russian product

- Technical characteristics of thermal insulation Energoflex

- Preparation for the installation of thermal insulation Energoflex

- Tools and devices

- Gluing the isolation of Energoflex video

- Installation of thermal insulation Energoflex video

Types of insulating materials of pipelines

The insulating material is used to maintain the required temperature of the coolant. It is used for thermal insulation:

- ventilation systems;

- pipe freezers;

- sewage pipes;

- hot and cold water supply pipelines;

- central heating pipelines.

Various materials are used for thermal insulation of pipelines: stone cotton wool, polyurethane foam, polystyrene foam, foam, foamed polyethylene. Due to the simplicity of installation and accessibility in price, the latter, in turn, occupies up to 90% of the market in household use.

ROLS ISOMARKET products

ROLS ISOMARKET produces thermal insulation under several brands: Energoflex (Energoflex), Energofloor (Energoflor), Energopack (Energopak). The company's plant is equipped with Kraussmaffei Barstorff GmbH equipment of one of the leaders of extrusion technology manufacturers for polymers.

Thermal insulation is available in the form of flexible tubes, mats and paintings.

The material has great elasticity, high resistance to an aggressive environment. Carries out additional protection of metal pipes from corrosion, protects pipelines during installation and operation.

The company produces more than a hundred sizes of insulating pipes and about two dozen sizes of sheet and roll material. A system of proprietary accessories was also developed for the convenience of installation.

Energoflex Russian product

In September 2000, the first plant in Russia was launched for the production of technological isolation from foamed polyethylene. Production is a joint project of StroyCOM and the LIT information technology factory. The company's products received the necessary certificates of the quality of the State Construction of Russia and international ISO quality certificates. The manufactured brands have excellent performance properties that are not inferior to foreign analogues, meet the requirements of fire and hygienic safety. Thermal insulation material is released from high -pressure polyethylene (PVD). The structure of the material has a closed cellular structure, which makes the material an excellent heat insulator. The material has low thermal conductivity and good resistance to penetrate moisture, effectively reduces structural noise, is not subject to decay. When working with it, there is no need to use personal protective equipment. It is widely used to warm heating, ventilation systems, water supply and air conditioning systems. It is a vivid example of good quality for an acceptable price.

Technical characteristics of thermal insulation Energoflex

The technical characteristics of thermal insulation depend on the type of insulating material. Consider each in detail.

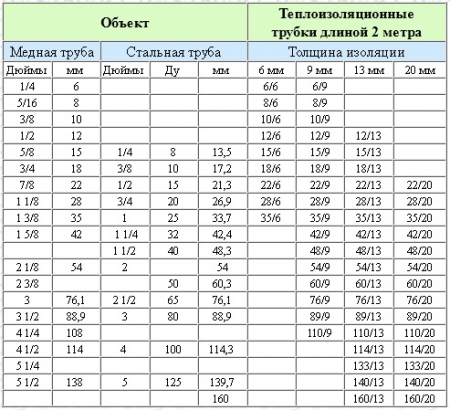

Pipe isolation

Pipe isolation of Energoflex is available in three colors: gray, red and blue, for ease of identification of pipelines during installation. The thermal conductivity of lambda isolaii at an environment of +20C is 0.036 W/ms. Thermal insulation owns a wide range of operating temperatures of the coolant from -40C to +100C. Fire characteristics meet GOST 30244-94 Construction materials. Testing methods for combustible refers to the group of burning materials G1.

Energoflex is environmentally friendly and safe material, does not contain chlorftho -carbon fiber and freon. The density of the material is 25 kg/m35kg.

Rolled and slab insulation

Rolonal insulating material is produced 3-20mm thick. Thermal conductivity l 0.036-0.038 W/ms. The density of the material is 2030kg. Adhesion of the adhesive layer to the metal surface is at least 300 g/cm2. Belongs to the combustibility group G1. The temperature regime for the operation of thermal insulation is -40+80C.

The elasticity module under loads of up to 2 kPa is 0.39MPA, under a load of 5kPa 0.77MPA. The strength of the longitudinal direction is 0.2 MPa, in a transverse 0.1 MPa.

Relative compression under loads of up to 2 kPa is 0.09MPA, at a load of 5 kPa 0.2MPA.

The water absorption of material in volume is not more than 2%. Energoflex is also a good sound insulator. The percentage of noise absorption at frequencies is 200-1250 Hz. It is 25-55%, at frequencies of 1600-3600Hz 30-60%.

Preparation for the installation of thermal insulation Energoflex

Thermal insulation is intended for operation in the open air and indoors at an ambient temperature from -40C to +70C and relative humidity to 100%. The manufacturer is not recommended to use thermal insulation under direct sunlight. When working with a heater, use only high -quality materials, accessories, devices and tools.

The surface of thermal insulation should be continuous, rough, without recesses, dents and holes. If there is contamination for thermal insulation, it must be removed by the cleaner until the installation starts.

The surface of the pipelines should be without pollution, stains of oil and rust. Cleaned the polluted surfaces with the Energoflex by the Cleaner or other cleansing agent. When installing thermal insulation on air ducts of ventilation and air conditioning systems, anti -corrosion coating must first apply to them. When installing thermal insulation in two or more layers, installation must be done with a displacement of the seam.

Thermal insulation of pipelines and equipment is carried out in a disabled state. You can continue the operation of the system no earlier than 24 hours from the date of installation.

When insulating pipes in the open air, it is necessary to choose insulation with covering material according to SNiP 2.04.14-88.

During installation, it is forbidden to stretch thermal insulation in the longitudinal or transverse direction. It is recommended to squeeze it slightly.

Tools and devices

For the installation of thermal insulation, special tools and devices will be required

- energoflex crept for installing the angles of rotation of pipes and for cutting corner wedges;

- a knife with a long blade (~ 300mm) for cutting the roll material and large diameter pipes;

- short knife (~ 70mm) for small diameter pipes;

- adhesive brush;

- annular punch for making holes in isolation;

- construction line;

- roulette;

- smooth spatula for applying glue;

- pen or pencil.

Gluing the isolation of Energoflex

Before applying the adhesive composition, the energy flex must be thoroughly mixed. It is recommended to use glue in a container of 0.5l. The glue is applied with a thin layer on both glued surfaces. Combine the surfaces five minutes after applying the glue. If the glue is dry on the surface, it is applied again. The use of glue is recommended at ambient temperature not lower than +17C, optimally +20C. If the glue thickens, it can be diluted with an energy -fuel solvent.

Installation of thermal insulation Energoflex

When installing thermal insulation pipes, various methods of work are used.

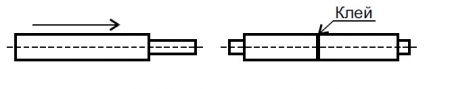

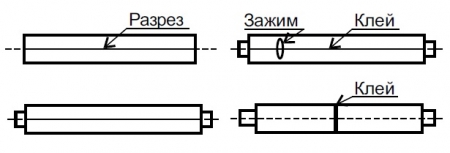

The tension method. It is recommended to be used for still unstonted pipelines. Energoflex is put on pipes, the ends of thermal insulation are glued.

If the pipes must be boiled, thermal insulation must be shifted from the welding site by 250-300mm and welding. Glue the ends of thermal insulation.

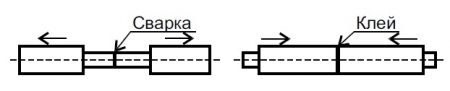

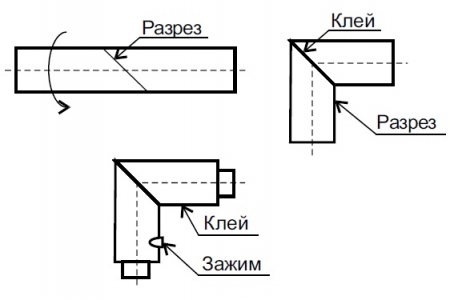

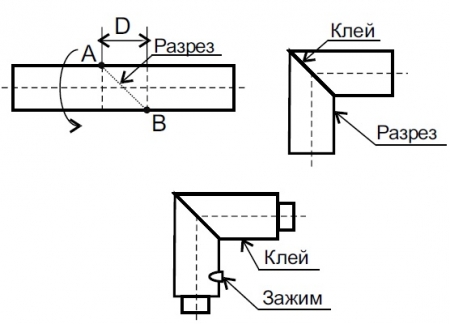

Prodial cutting method. Thermal insulation is mounted on already installed pipeline systems. The thermal insulation tube must be cut with a knife with a short blade along the axis, mounted on the pipeline. Close the cut and additionally strengthen the clip, glue the ends of the tubes among themselves.

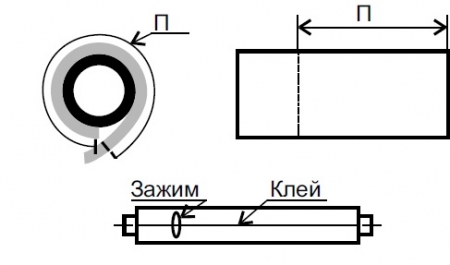

Installation of rolls. Thermal insulation of pipes with a diameter of over 160 mm is carried out with roll material. This installation method is also used to install several layers of thermal insulation. To do this, measure the required circumference length, cut off the site required in length and width from the roll and installation is carried out.

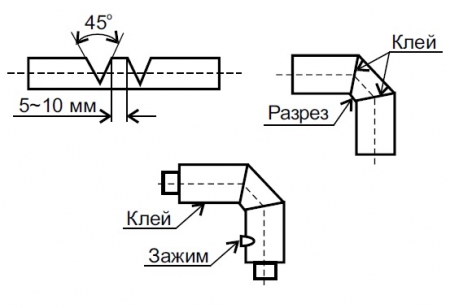

Clane cutting method. It is necessary to use this method on pipelines with a diameter of up to 90 mm. In the isolation tube, using a knock on the inside, the wedge is cut at an angle of 22 or 45, depending on the angle of rotation. The distance between neighboring wedges is 5-10 mm. All cuts are glued and fastened with a clamp.

Cutting at an angle. The method is used to obtain straight turns. Subsequent operations are similar to previous methods.

Diameter marking.

It is recommended to use roll insulation with a diameter of 90 mm and above pipes with a diameter of 90 mm and above.

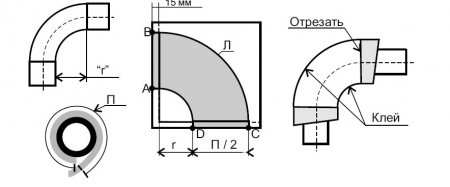

To do this, two ABCD hemispheres are cut out, which are glued along the line l, thermal insulation is installed on the pipe and glued the inner angle. The remains are cut perpendicular to the pipe.

From the whole variety of insulating materials of pipelines, you can easily choose the one that you will need in this particular case. The use of thermal insulation will save money, maintain the necessary temperature of the coolant or prevent the liquids in the pipeline, and prevent condensation.

and if you just put on

and if you just put hot water on the pipeline and fix the effect of insulation to decrease by tape at times?

Is it non -combustible

Is it a non -combustible material in case of fire

How to insulate the air

How to insulate the air heating main to the trucking thickness of the energy -fuel tube should be?