To get rid of moisture, which accumulates in the underground space, in the foundation ...

|

|

In the light of a bad environmental situation in big cities and our welfare growth ... |

The rack ceiling is a suspended structure with an attractive design ... |

Liquid rubber for waterproofing: characteristics and application

Despite the fact that the last decade is associated with the emergence of many of the latest materials in the construction market, which meets all quality standards as much as possible, unresolved problems remain in the waterproofing sector due to the need to arrange reliable waterproofing systems. Specialists associate these problems with the constant search for the most effective waterproofing materials, which, despite the modern construction paradise, is still relevant. Specialists who carry out their activities in the field of waterproofing set themselves the goal of finding modern waterproofing materials that meet several most relevant requirements at once. Among them, it is necessary to especially note the maximum protection against moisture penetration, the process of exploitation in the harsh climate of central Russia, compliance with the regulatory rules of environmental environmental safety, as well as minimal material costs for waterproofing. Despite the fact that the modern construction market is currently dominated by classic roller building materials, they do not meet 100 % all the requirements for high -quality waterproofing materials. This is due, at first glance, the low cost of familiar materials and a long experience of their operation, during which they have established themselves as optimal material. But how optimal are they? This is easy to verify by studying the characteristics of an alternative modern waterproofing material with liquid rubber, which currently competes quite reasonably with traditional roller materials. Consider its main characteristics and areas of use.

Content

- Liquid waterproofing: Advantages of use

- What is liquid rubber: market prospects

- Features of liquid rubber: scope of use of material

- Varieties of liquid rubber for waterproofing

- Advantages and disadvantages of liquid rubber

- The technology of arranging sprayed roof waterproofing: the main features

- Arrangement of sprayed liquid waterproofing of roofs: step -by -step guide

- Roof repair with liquid rubber: main points

Liquid waterproofing: Advantages of use

An integral stage of any construction is the creation of a reliable waterproofing system, and despite the fact that the market demonstrates the abundance of materials for its implementation, the most popular and meteen materials are those that belong to the category of liquid waterproofing. The materials of this group are characterized by an extensive list of advantages, the main of which are worthy of consideration. These include:

- High adhesive characteristics that do not depend on the material of the base;

- The possibility of timely correction of arising defects in cracks, irregularities and all kinds of defects;

- Due to the fact that there are many ways to apply liquid waterproofing, you can choose the most optimal option for yourself depending on professional skills and design features of the roof;

- Resistance to negative influences of both natural and anthropogenic nature;

- The versatility of application and the environmental safety of the material allow you to use it to arrange waterproofing systems as outside and indoors.

What is liquid rubber: market prospects

Given the constantly growing demand for the materials of this group, manufacturers do not cease to surprise the consumer with new materials, while improving the old ones who have already gained consumer confidence. The most popular materials of this group are:

- Liquid glass;

- Liquid rubber.

Despite the fact that liquid rubber is relatively new materials in the construction market, the prospects for its use are already obvious not only to professionals, but also to beginners. Liquid rubber is a modified bitumen-lakel emulsion, consisting of two mutually insoluble components of bitumen and water. Thus, liquid rubber is a material made on the basis of a bitumen emulsion, the characteristics of which are improved by including latex in its composition.

The popularity of this material among consumers is due to a number of undeniable advantages of liquid rubber, thanks to which the consumer who chose it receives a seamless and fairly light coating, characterized by resistance to high humidity and temperature changes, as well as the possibility of applying complex configuration on the surface. And these are far from all the advantages of liquid rubber for waterproofing, the price of which is also recognized as one of the advantages of this material.

Important! Experts recommend that the most effective waterproofing system can be equipped as soon as possible only if the materials of this category are used.

Liquid rubber photo

Features of liquid rubber: scope of use of material

Despite the fact that this material has visual resemblance to rubber (black, viscous consistency and waterproof), it is not entirely correct to call it liquid rubber. Unlike rubber, the basis of which is rubber, the basis of liquid waterproofing is bitumen. The name liquid rubber has taken root only because it is convenient for the consumer, while the name offered by the manufacturer seamless sprayed waterproofing did not find its recognition due to the difficulty for consumer perception.

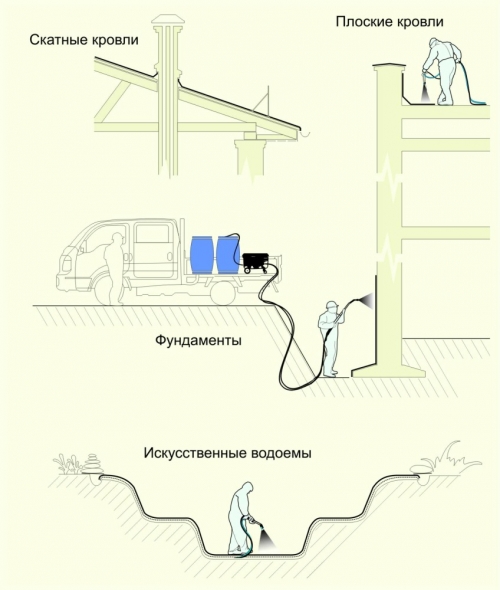

The use of liquid rubber as waterproofing material is widely practiced in the following areas of construction:

- Using liquid rubber, the consumer gets the opportunity to equip the protection of the roof, foundations, basements and intert -wisdom from moisture;

- Arrangement of waterproofing of ponds and pools. Unlike waterproofing made of plastic materials, insulation using liquid rubber for pools repeats the configuration of the reservoir, and is also characterized by resistance to mechanical stresses;

- The arrangement of waterproofing of surfaces characterized by a large number of junctions is impractical to equip with roller materials, and therefore, experts prefer liquid waterproofing;

- The waterproofing of the roof characterized by the presence of ventilation outputs can also be equipped using liquid rubber, in view of its resistance to vibration loads.

The quality of waterproofing based on liquid rubber can be proved by the example of specific situations.

Situation No. 1.

The durability and operational characteristics of the building depend on the quality of the foundation, as a result of which it is important to ensure that its waterproofing layer has become a reliable obstacle to the penetration of groundwater. The arrangement of the waterproofing system of the foundation implies a set of measures, including the application of liquid rubber to the walls and stoves of the foundation. Using liquid rubber, you can be sure that the waterproofing coating will be resistant to shrinkage, and high hydraulic resistance indicators will be a guarantee of reliable and durable coating.

Situation No. 2.

An important arrangement of flooring is also the installation of a waterproofing system that protects it from damp, mold and fungus, and, consequently, destruction. Using liquid rubber, you can equip a reliable waterproofing coating with a long operational period, which can be both a finish coating and the basis for the arrangement of other decorative coatings.

Varieties of liquid rubber for waterproofing

At this stage in the development of the construction market, experts offer the following varieties of liquid rubber:

- One -component liquid rubberThe waterproofing material, which is a liquid mass with a small indicator of viscosity and is characterized by a large variety of tint palette. According to manufacturers, it is completely ready for use;

- Two -component liquid rubber, which is based on several components, the main substance and hardener.

Liquid rubberAnother parameter, according to which it is possible to classify material from the category of liquid waterproofing. In accordance with the method of applying liquid rubber, the following varieties are distinguished:

- Sprayed rubber, The application of which will require specialized equipment. Due to the fact that this method of applying liquid rubber is characterized by the highest quality of the final coating, as well as the highest speed of the entire cycle of work on the arrangement of liquid waterproofing, it is the most promising. Liquid rubber, which is offered to buy all construction supermarkets, is a leader among its analogues and the classic of liquid waterproofing;

- Coloring rubber, the liquid and pasty consistency of which, as well as a tendency to film formation, implies its manual application with a spatula or painting hand;

- Rubber rubberrelated to the lowest price category, while its manufacture is carried out immediately before the installation of the waterproofing system.

Advantages and disadvantages of liquid rubber

- The waterproofing system, the installation of which was carried out using liquid rubber, is a monolithic coating, absolutely devoid of even the slightest joints;

- The highest adhesive characteristics to all surfaces, regardless of their origin. These are wooden, concrete and metal surfaces;

- If you have chosen sprayed rubber, you can be sure that the waterproofing layer will fill all the microcracks available on the surface, which is the key to the effective adhesion of liquid rubber with the subject;

- Elasticity, implying ability, increasing in size, return to its original position by another advantage of liquid rubber, due to which liquid waterproofing is resistant to temperature and humidity changes;

Important! Due to the fact that in the summer period of time, the volume of liquid rubber is inclined to increase, and in winter to decrease, this coating will relieve the cold painlessly without acquiring additional damage. If the waterproofing is made using materials that are not characterized by elasticity, after several winters, cracks will appear on its surface.

- Liquid rubber can be applied not only by manually, but also by mechanized way, which will significantly reduce the time spent on the installation of the waterproofing system, and will also allow you to qualitatively apply the coating on the protruding surfaces, such as pipes, caps and antennas;

- High performance due to the high speed of liquid rubber another advantage of liquid rubber. If you have at least one assistant and specialized equipment, you can install a roof with an area of \u200b\u200b800 square meters. meters for two days, while you spend at least 14 days on the installation of similar roofs using roller materials;

- The absence of toxic components in the composition of liquid rubber guarantees its absolute environmental safety;

- The next advantage of liquid rubber is its multifunctionality, thanks to which, liquid rubber can be used not only to arrange a waterproofing system;

- It is allowed to apply various finish coatings to the surface treated with liquid rubber, which in the case of arranging the roof waterproofing is quite convenient, since it turns into a useful area and can be used in the future;

- The production of this waterproofing material is carried out in a fairly wide color scheme, which will appeal to creative natures and lovers of aesthetics;

- If during the operation of the liquid roof it was damaged, you can quickly restore it, since during the repair the only local processing of the damaged surface is enough.

Despite the fact that we have indicated a large number of advantages of liquid rubber, it, like any building material, is not devoid of certain shortcomings. Consider them further.

Disadvantages of liquid rubber:

- For the installation of waterproofing, a mechanized method will require quite expensive equipment;

Here, perhaps, is all the nuances that are able to slightly overshadow the arrangement of the waterproofing of the roof with liquid rubber.

The technology of arranging sprayed roof waterproofing: the main features

In order to install the sprayed coating with liquid rubber, it is necessary to prepare specialized equipment, namely a mobile spray gun equipped with a dosing and mixing device. In most cases, the use of equipment with a gasoline engine is practiced. Due to the fact that the spray gun is characterized by sufficient compactness, you can carry out effective and high -quality installation of roof waterproofing with liquid rubber even in hard -to -reach areas of the roof. The degree of mobility of the spray gun increases due to the lack of the need to connect to the electric network. In addition, the design features of the spray gun imply its equipment with hoses up to 150 meters long. Due to this, it is possible to install liquid waterproofing without moving the equipment.

Important!Due to the fact that there are no toxic components in the composition of liquid rubber, even in the case of arranging waterproofing indoors, there is no need to use special respiratory protection products.

Arrangement of sprayed liquid waterproofing of roofs: step -by -step guide

Installation measures for the arrangement of sprayed roof waterproofing must be carried out in the warm season, if there is no rain. The lower threshold of the operating temperature range is +5 degrees;

First of all, it is necessary to prepare the working surface, which consists in cleaning surfaces from all available contaminants: dust particles, extraneous deposits and fat spots. To increase the efficiency of preparatory measures, experts recommend using a hydraulic installation, with which the base is washed using a water jet under pressure. After that, it is necessary to thoroughly dry the surface during the day;

In case of detection on the surface of fat spots, it is necessary to get rid of them by burning;

The next stage in the arrangement of liquid waterproofing is priming, which implies the application of the first waterproofing layer on a pre -prepared base. The subsequent operation of the roof and its technical characteristics depend on the quality of this layer. The purpose of the priming is the final removal of all pollution (dust particles), which significantly increase the adhesive characteristics of the waterproofing material used;

The final stage in the arrangement of waterproofing involves the spraying of a layer of liquid rubber, which should be applied as evenly as possible. To achieve this, a layer of liquid rubber is applied perpendicular to the treated surface. The free distance between the working tool and the processed surface should be at least 40 cm. In this case, in the process of spraying, the components of the composition are mixed. Liquid rubber is applied in stripes, the width of which reaches 1-1.5 meters. As for the transitions, they are performed in a cruciate direction;

In most cases, during the arrangement of waterproofing of a flat roof, liquid rubber is applied to two, sometimes in three layers. At the same time, geotextiles or fiberglass reinforcing material are laid between the layers.

To deal with the technology of arranging sprayed waterproofing, read the video materials presented in this article. They clearly demonstrate all the stages of arrangement of sprayed waterproofing.

Roof repair with liquid rubber: main points

Liquid rubber can be used not only to arrange roof waterproofing, but also for the repair of old coatings. What to implement it is not necessary to fully remove the operated coating. There is a complete repair of the roof, when a new layer of liquid rubber is sprayed over the old waterproofing, as well as partial, the so -called lance repairs, which implies the removal of damaged waterproofing sites and the application of a new layer of liquid rubber in their place. If bubbles are formed on the waterproofing layer, they are cut in places of the greatest bloating and poured with liquid rubber.

As for the consumption of liquid rubber, when processing one square meter of roof, it is 3 liters, provided that the layer is 2 mm thick. With air humidity, not more than 50 % and a temperature of 20 degrees, complete polymerization of liquid rubber occurs within 72 hours from the moment it is applied to the surface. Do not be afraid if during these 72 hours you find the protruding water drops on the surface of the waterproofing layer. This is the norm and occurs as a result of the effect of the catalyst.

Liquid rubber video

hoses to a spray gun 150

hoses to a spray gun 150 (!!!!!!!!!!!!!!!) meters ??? Yes, they just do not raise them :)) And the installation in the photo will die, trying to pump the emulsion and solution for such a length :)))))))))))))))

http: // Takes.rf/ Zhidny rubber

http: // Takes.rf/ Zhidny rubber for waterproofing Delsa t.

Liquid rubber for

Liquid rubber for waterproofing Delsa tf http: // medium.rf/

Liquid rubber for spraying

Liquid rubber for spraying iso. PBK Izostop is used for the waterproofing of the pond, tanks, foundation, roof, overhaul of old roller coatings, waterproofing of open verandas, terraces, balconies. Frost -resistant, one -component. It is applied to any surfaces: concrete, brick, metal, wood, screed, on roller coatings, etc. It is possible to apply a brush, a roller. You can buy and find out more here izostop.com

But you can with this liquid rubber

And you can sealed the holes with this liquid rubber tightly, in the auto -through rubber chamber of the car wheel, which they perforated? I think that you can glue them like that!