Roofs, for the installation of which asbestos slate are used, for many ...

|

|

Enough part in the process of flooring, such a material as chipboard is used. Among... |

During construction work, the covering grid is widely used. The product serves ... |

Waterproofing materials: types

The purpose of waterproofing materials Protection of structural elements from the harmful effects of humidity. Isolation from water is necessary for the normal operation of equipment and structures. In addition, the use of insulating products helps to increase the life and reliability of structures.

Conducting waterproofing measures should be carried out in compliance with the norms of the technological process and using properly selected material. Each type of waterproofing has its own advantages and disadvantages, each material is designed for certain conditions of application and operation.

- Requirements for waterproofing materials

- Classification of waterproofing materials

- Waterproofing materials: types, properties and features of application

- Modern waterproofing materials: Review of manufacturers

Requirements for waterproofing materials

The destructive effect of humidity is subject to all structural elements of the house, this negatively affects the durability and reliability of the construction. In order to minimize the undesirable effect of moisture and extend the life of the premises, at each stage of construction, special attention should be paid to the issue of waterproofing. Depending on the structural elements (foundation, walls, roofs or interior decoration) and operating conditions of the building, the type of waterproofing material is selected.

Waterproofing building materials must comply with a number of requirements:

- high hydrophobic (water resistance) should not absorb or pass moisture;

- high mechanical strength;

- elasticity of the material;

- the possibility of use in a wide temperature range;

- vapor permeability;

- resistance to ultraviolet radiation and the effects of negative natural factors.

The listed requirements are common to most waterproofing materials. An important condition is the ability to breathe and not provoke the formation of condensate. This requirement must be carried out during the waterproofing of attic and operated attic premises.

Mechanical strength determines the ability of the protective layer to withstand the loads created by people's weight, equipment and snow masses.

Such a quality as elasticity is especially relevant when arranging roofs that have a complex configuration.

Classification of waterproofing materials

Waterproofing building materials are classified according to the following criteria:

- At the place of application:

- external waterproofing is performed outside the structure when erecting the foundation and building a roof;

- internal waterproofing a complex of protective measures carried out indoors for waterproofing floor and walls in rooms with high humidity (bathroom, pool, sauna, etc.).

- By the features of the appointment:

- Anthopapard waterproofing protects against positive water pressure. With a high groundwater level, the external walls of the basement are covered with anti -napor waterproofing. A similar technology is often called the effect on the clamp - water tightly presses the waterproofing material to the walls. To arrange the internal walls of the foundation, this method is not suitable for water pressure there.

- Surface protection of the roof from moisture.

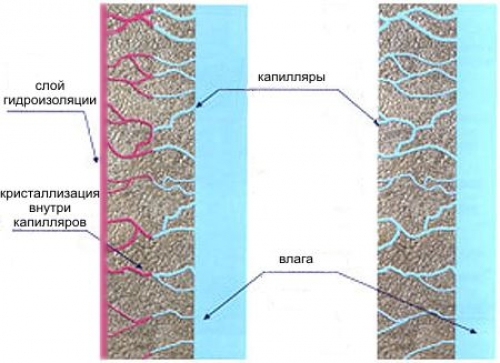

- Anticapillary waterproofing protection of the structure from increasing moisture levels by capillaries. Such waterproofing material is necessary to protect brick and concrete.

- Nonsense waterproofing protects the coating from negative pressure. If, as a result of spring floods or abundant precipitation around the foundation, water has accumulated, then it will turn out to protect against it from the inside of the basement. In this case, the water pressure is small and works on the separation of the material from the base.

- Comprehensive purpose universal materials used to protect different structural elements of the building.

- According to the application technology:

- Sticked canvases and membranes, which are glued to the protected surface and form a hydraulic protection barrier.

- Coloring compositions are applied to the base with a brush, roller or spray. The waterproofing forms a hydrophobic thin film with a thickness of about 2 mm on the surface.

- Plaster, putty and putty, applied to the surface with a spatula and form an insurmountable barrier. Such waterproofing is suitable for both internal and external work.

- Penetrating compounds are applied with a brush or using a spray gun. The product changes the physical properties of the processed building material, increasing the frost resistance and hydrophobic surface.

- Injection waterproofers are pumped under pressure and create a reliable barrier directly in the thickness of the ceiling or walls.

- According to the type of astringent: tar, bitumen, bitumen-polymer, rubber-bitumen, polymer and mineral.

- In appearance and physical condition: liquid, solid, elastic and plastic-high.

To say exactly which waterproofing is better is quite difficult. The listed options demonstrate different effectiveness, but their price is different. Therefore, in order to make the right choice, it is necessary to delve into the characteristics and technologies of the use of different compositions.

Waterproofing materials: types, properties and features of application

Roll roofing and waterproofing materials

Rolled hydrisolators are made by applying a bitumen-polymer binder on a fiberglass or polyester non-woven base. The outer surface is covered with mineral sprinkling, polymer film or sand. A polymer film is applied to the lower part.

Rolonon waterproofing material is used for anti -napor external insulation. They can be glued to horizontal (flat roofs) and vertical surfaces (foundation, walls).

A classic example of a waterproofing coating roofing material. The material has high hydrophobic and elasticity. After heating, the canvas of the waterproofing material can be laid on the roof with any profile.

Modern coatings containing polymer additives are not subject to mold or rot, unlike their predecessor of the roofing material. Improved technical characteristics extend the life of polymer materials.

Among the additional advantages of roll (glow) waterproofing include:

- the possibility of using metal, wood, concrete, flat slate, asphalt concrete or old roller coating;

- the waterproofing canvases are economical, moisture and immune to aggressive environments.

The main disadvantages of roofing material and its analogues are associated with complex application technology:

- before laying, it is necessary to thoroughly align the surface inadmissibility of irregularities of more than 2 mm;

- setting materials requires caution from the contractor and certain skills in working with heating equipment;

- waterproofing work should be carried out at an ambient temperature of at least +10C;

- the coating is unstable to mechanical loads and sharp objects (when arranging the foundation, you need to perform a clamping wall);

- before applying waterproofing, concrete coating must be dried with a wet surface of adhesion;

- it is important to control the tightness of the overlaps of materials and docking seams;

- apply roll waterproofing is desirable in several layers.

Standard surface gluing scheme:

- Apply thick tar or bitumen to the processed area.

- On the adhesive composition, roll out roll insulation with an overlap of about 10 cm. Transverse joints are placed in a run with a step at least 30 cm.

- Play horizontal surfaces with the release of the material beyond the edges of the protected area, vertical with fixation (packaging) of the finish layer with resin or bitumen. The waterproofing of the basement/foundation is fixed with soil (preferably a sandy-clay fraction or clay).

Crystal waterproofing

Crystal waterproofing takes second place in popularity after rolled materials. This group is represented by liquid compounds of mastics and sludges (solutions) to create solid seamless waterproofing layers. Mastic plastic adhesive compositions of hot and cold type. Visitic insulators are made on the basis of bitumen and various polymers.

Depending on the sphere of application and the required protective functions, the amount of mastic strata applied is determined. The total thickness of all layers can be from 2 mm to 5-6 cm.

Crystal waterproofing is used in such cases:

- waterproofing of the foundation, processing of a flat roof;

- internal waterproofing of the basement of the basement and bathroom;

- sealing cracks on the walls;

- polymer cement is used for waterproofing pools.

Important! Polymer and bitumen mastics are used only when arranging non -residential premises or outside residential buildings. The heated coating is toxic and undesirable to use in the residential area

The use of coating waterproofing has some disadvantages:

- at low temperature, bitumen loses elasticity any deformation at a temperature of less than 0C will lead to ruptures and cracks of the protective coating, and after a while the mastic coating will exfoliate from the base;

- a short service life of not more than 5-6 years (under adverse weather conditions, the material loses its hydrophobic qualities through three winter cycles);

- the difficulty of applying hot mastics is not excluded by production injuries;

- preliminary thorough preparation of the base is required;

- work is carried out exclusively in dry weather;

- reconstruction of coating waterproofing will cost 3-4 times more than primary processing.

Advice. The use of bituminous waterproofing materials is advisable where the probability of leaks is small. To protect the roof, it is not worth using mastic, since by spring, after frost, the coating will crack and lose its tightness.

Penetrating waterproofing

Special compositions of Portland cement of silicate sand/small quartz and active chemicals when processing concrete surfaces form insoluble crystals that fill cracks and pores to a depth of 20 cm. The validity of such protection is equal to the life of the concrete itself.

The main properties of waterproofing materials of the penetrating action:

- the processing of the composition extends the service life of the building by 20%;

- mixtures of penetrating waterproofing have the quality of constant self -ensuring - crystalline formations are opposed by corrosion, moisture, frosts;

- the processed surface breathes;

- the composition of the insulator inerte does not contain solvents and does not emit evaporation;

- processed concrete is not afraid of mechanical exposure.

Cons of penetrating waterproofing:

- a narrow focus is suitable for processing screed and plaster based on a brand cement not lower than M150 (stone and bricks are not amenable to the effects of penetrating trains);

- waterproofing work is carried out at air temperature from +5C.

Advice. Penetrating compounds act more efficiently on new concrete. Old coatings before processing require special cleaning with a sandblasting tool, since during their operation the pores of concrete are clogged.

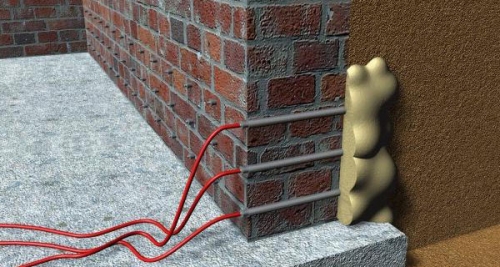

Injection waterproofing

The injection method is based on the process of forming a membrane between the processed structure and a layer of moisture -related soil. A hydrophobic gel is injected into the outer space of the protecting structure, which freezes and clogs pores in the ground and in the wall.

Depending on the variety of injection material, such a membrane has varying degrees of rigidity. In fact, the gel plays not only the role of a hydraulic boar, but also acts as a reinforcing frame.

The scope of the injection method: planned or emergency repair of subway tunels, underground parking, artificial reservoirs, main sewers, basements and other objects.

The use at the industrial and household level of injection protection promises the following advantages:

- Time saving. The use of injection is possible in the process of construction or after the survey of the facility.

- Saving funds at full repair, when opening a surface covered with soil is required.

- High quality of the protective membrane enveloping the entire surface.

- The ability to use in the process of local repair.

Important! Injection technology is only possible for experienced craftsmen, since it is necessary to work with the composition very accurately and quickly the material thickens in a matter of minutes

Materials for waterproofing by injection:

- polyurethane gels;

- epoxy solutions;

- cement-sand mixtures of micro-cement;

- acrylate gels, which are based on acrylic acid esters.

Bentonite mats

Bentonite mats geotextile material, which consists of two layers of a synthetic canvas, in the middle of which a layer of modified granular bentonite clay is fixed.

The main advantage of insulating mats is the maximum waterproofing ability that combines reliability and durability. The material is resistant to mechanical damage and has the ability to self -ensure. In contact with moisture, concrete granules are converted into a gel, which delays minor punctures and damage. A significant plus of bentonite waterproofing is high resistance to temperature fluctuations (the composition withstands many cycles of freezing and tangling).

Scope:

- mats are used as roofing and waterproofing materials of vertical/horizontal surfaces: multi -storey parking lots, pedestrian crossings, pools, transport tunnels, water tanks, walls and roofs of buildings;

- the arrangement of anti -filtration screens during the construction of building landfills of industrial/household waste, tanks for storing fuel and lubricants/oil, decorative reservoirs, etc.

Disadvantages of bentonite mats:

- high price;

- before laying mats, it is necessary to prevent premature hydrotation to protect the material from snow, rain, etc.

Sprayed waterproofing

As a result of the use of sprayed waterproofing, a monolithic, seamless coating is formed. The sprayed composition is an acrylic, polyurethane or bituminous compounds of accelerated vulcanization. This method is applicable for metal, concrete, glass, ceramic and other surfaces.

Today, sprayed waterproofing gains its popularity, both in household and industrial use due to its unique qualities:

- high anti -corrosion, noise insulation, wear resistance, resistance to rupture, chemicals and fracture;

- anti -slip properties of the finished coating;

- the sprayed composition can be colored, which is convenient when marking playing and sports grounds.

The purpose of liquid rubber:

- construction: new and old roofs, waterproofing loggias, balconies, foundations, basement;

- agriculture: protection from the water of granaries, dams, irrigation channels;

- water supply systems: waterproofing of drainage/drainage complexes, water towers, water tanks and storage facilities;

- roads and railway tracks;

- processing of parts and bodies of the car.

Sprayed waterproofing has disadvantages:

- the temperature regime of use from +5C;

- coating is susceptible to punctures;

- work cannot be carried out in windy weather;

- high cost of waterproofing;

- for spraying, special equipment is required;

- suitable only for external work.

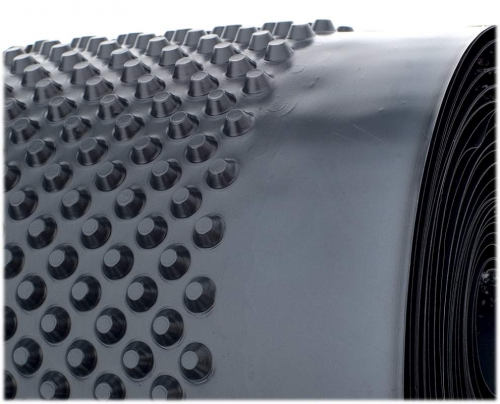

Membrane waterproofing

Membrane waterproofing material of a new generation. The membrane is a self-adhesive film consisting of 3 layers: a polyethylene film, a bitumen-polymer sticky layer and an anti-adhesion layer.

The product is not afraid of sudden temperature differences, easy to install and does not require special care during operation. Separate elements of the membrane are interconnected by a stream of hot air. Due to heat treatment, a monolithic canvas is formed.

Using the membrane, it will be possible to protect objects of different configurations and forms. Minus of this method is the high cost of a waterproofing membrane.

Modern waterproofing materials: Review of manufacturers

The following manufacturers have proven themselves in the building materials market:

- Maris-Polymers production of liquid polyurethane materials of cold curing;

- Pazkar leader in the manufacture of bitumen-polymer mastic and emulsion waterproofing products;

- Ceresit polymer-cement isolation materials for waterproofing in the repair and construction;

- Technonikol waterproofing mastics and roller materials (Euro -Ruberoid).

Modern waterproofing: waterproofing materials and their use

We did waterproofing

We did waterproofing with liquid glass! Due to its unique properties, liquid glass is well suited for waterproofing walls, floors, ceilings of basement and attic premises.

A very useful topic for yourself

A very useful topic, I personally noted a lot for myself) I personally used the services of http: //strport.ru/izolyatsionnye-waterly/gerMetiki/gidroizolyatsionnye ..., which is the official representation of Maris Polymers in the Russian Federation. They made surprisingly very quickly and apparently high quality, since I did not notice any cracks and gaps. Here is another phone number +7 (495) 134-29-89, if you are suddenly interested.

Hello! What

Hello! What material can waterproof the basement with negative water pressure (2m.) With the outside to make waterproofing anymore ...

Hello! We are offering to you

Hello!

We offer you to get acquainted with unique products in the market of waterproofing materials that quickly and effectively help solve the issues of waterproofing of roofs, facades, balconies, attic, basements, etc.

Innovative products of Russian production

"Liquid roof", "liquid permamine", a liquid membrane. "

Unique properties:

- all -zeroism and all -conquest of use (work in the rain, wet snow and at a negative temperature up to minus 15);

- there is no need for preliminary preparation of the surface (can be applied to wet, contaminated surfaces and even under a layer of water);

- frost resistance (there is no formation of cracks and detachment, throughout operation);

-simplicity of use (one-component composition: discovered and tweeped-nursed);

- the extension of the material, according to tests, is more than 1000% (with deformations of roof elements, expansion/narrowing from temperature changes, vibrations, etc. - the material retains its properties);

- effective for repairing all types of roofing (soft roofs, metal, slate, tiled, etc.)

- Guarantee of preservation of protective properties from 12 years or more.

Ideal for waterproofing complex places

§ joints and adjacency of roofing material;

§ places of installation of aerators and various engineering mounts (stretch marks, antennas, thunderbones, etc.);

§ places of adjustment of roofing material to ventilation/stove pipes;

§ cracks on the walls of ventilation and elevator shafts (through which moisture falls under the roof);

§ pediments, corners, etc.

It is applied with a brush or spill. Very simple: opened, mixed, applied.

The essence of the proposal is that by processing our material all the "problem areas" on the roof/facade (cracks on the walls and adjoins, pieces of soft roof, holes in the roof, at corners and joints, etc.), your customers, exfolved from parapets, your customers The issue with possible leaks for a period of 5 to 20 years or more is guaranteed to resolve.

Given the small cost of polymer compositions, as well as the simplicity of their application, your customers will significantly save both time and money.

We give a 100% guarantee for all the declared properties of the product and are ready to return the money to your customers if the material does not clarify with the wet/contaminated surface, it will exfoliate or crack within 5 years after its application.

DELIVERY

We ship the average and large orders from 5 buckets by any transport company (PEC, business lines).

Small orders from 2-12 cans or 1-2 buckets are sent, as a rule, by the company SDEK to a pickup point in your city https://www.cdek.ru

You can pay for the goods when it is received at a pickup point in your city - in this case, cash payment.

8-977-756-67-07 Jean.