It happens that it is required to refresh or change the bored plastered facade of the building. AT...

|

|

Not every homeowner is building a house from scratch. Someone is inherited by suburban ... |

Question " How to install input metal doors? " Surely tormenting ... |

Shifer installation: step -by -step instructions

Roofs, for the installation of which asbestos slate are used, have been characterized by high popularity in the construction sector for many decades, and, despite the fact that in recent years, many modern roofing materials have appeared on the market that meet all requirements, asbestos-cement sheets still do not lose their own relevance. Due to the relatively low cost of the material, its chemical inertia and static stress stability, neither roofing and metal tiles have the right to compete with it. The aesthetic properties and technical parameters of the slate, as well as the ease of installation and a long -term operational period are not inferior to it for its more expensive analogues, which also has a significant effect on the popularity of roofing material. The steady popularity of slate, as well as any material used in the field of construction, experienced ups and falling, however, the use of slate in summer and individual construction revived when multi -colored asbestos -cement sheets were delivered. But their appearance did not affect the popularity of the classic slate, who, having passed the test of time, did not lose his consumer. The first question that faces the master when the conversation comes to the slate is how to lay this roofing material. Like any construction process, the laying of the slate includes several stages, each of which is characterized by certain nuances. Their observance play an important role in the effectiveness of the final result, and, accordingly, the duration of the operational period of the roof. In this regard, in this article we will answer the question: how to cover the roof with slate?.

Content

- Slate: basic information about the material

- The advantages and disadvantages of the slate: what do you need to know about the slate roof?

- How to choose a slate: Basic rules

- Technology for the installation of slate roofs: the main stages

- How to calculate the required number of slate sheets? The main recommendations

- Preparatory stage: arrangement of supporting structures

- Shifer styling technology: specialists' recommendations

- How to maintain the integrity of the slate: Basic safety rules

- Chering roof care rules: main points

Slate: basic information about the material

The slate is a traditional roofing material made on the basis of asbestos cement, and are characterized by high mechanical strength and durability. To date, on sale there is both flat and wavy slate, as well as models released in multi -colored design. Asbestos -cement sheets cannot be attributed to environmentally friendly materials, as it is proved that asbest can harm human health during operation. Given this circumstance, slate can only be used for external work.

Important!The wave slate can only be used for the installation of roofs with a slope, the angle of which should be at least 22 degrees. If the slope of the roof is small, it is necessary to carry out additional sealing of the joints, increase the overlap of the slate and use additional fasteners. To maintain the integrity of the slate leaf, the hole for the fasteners must not be pierced, but to drill.

Important!The material based on asbestos cement is delivered in packages, where slate sheets are shifted with polyethylene. They must be stored in this form until they are used in work.

Before laying the slate, experienced masters recommend covering it with acrylic paint, which helps to extend the operational period of material. The service life of unpainted material is about 20 years, while slate, covered with acrylic paint, serves several times longer.

Before we answer the question: how to put slate?, It should be noted that the installation of the slate, like any other construction event, needs preliminary planning. Given this, first of all, it is necessary to consider all the possible options for the shape of the future roofing, since this is a determining factor when calculating the slate.

Important! The roofs, for the installation of which leaf materials are used, can be flat, that is, single-sloping with a slope of not more than 1-2 degrees, unrequited (single-sloping and gable with a slope of not more than 7%), as well as attic, the design of which implies a slope of a slope of more than 40 degrees . It is important to know that experts do not recommend giving preference to intermediate options (for example, roofing with a slope of 25-35 degrees), since it is in this case that the maximum amount of snow accumulates on the roof. The modern development of building technologies allows you to equip complex roofing structures of any configuration, including four slopes, however, it is recommended to choose a more simple geometry for the arrangement of slate roofs.

The advantages and disadvantages of the slate: what do you need to know about the slate roof?

Features of modern equipment and the development of innovative technologies significantly improved not only the appearance of the slate, but also its operational characteristics. Among the main advantages of slate, the following can be noted:

- Frost resistance and resistance to sharp temperature changes;

- Resistance to high humidity;

- Good tolerance of ultraviolet radiation;

- The ease of installation measures and the possibility of their independent implementation of another reason to pay attention to this roofing material.

Despite the wide range of advantages, certain shortcomings are also characterized by certain deficiencies that significantly complicate installation measures and are the reason for the refusal to use this roofing material.

Shifer disadvantages:

- Relatively large weight of slate sheets;

- The fragility of the slate requires accuracy in the process of transporting the material and installation measures;

- The slate is made on the basis of asbestos cement, which includes asbestos, which has a negative effect on human health;

- Given the previous factor, it is necessary to know that in the process of installing the slate roof, provided that the slate cutting is required, personal protective equipment must be used.

Important! Experts recommend processing the cut line with acrylic paint.

How to choose a slate: Basic rules

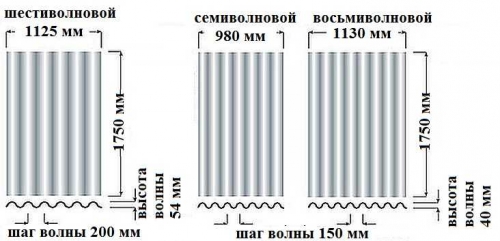

In most cases, the construction sites use the head of domestic production, the dimensions of which are regulated by GOST 30340-95:

- for a six -wave slate: the thickness of the leaf is 5, 6 and 7 mm; width 1125 mm;

- for seven and eight-wave slate: sheet thickness 5 and 8 mm; The width is 980 and 1130 mm, respectively.

The length of the sheet, regardless of the type of slate, is 1750 mm.

Knowing the brand of Shifer, it is possible to determine not only the number of waves, but also the height of the wave, which is the distance between the comb and the bottom, as well as the step of the wave, which is equal to the distance between any points of neighboring waves. Consider this on the example of the brand 40/150-8. 8 In this case, it means that this sipher eight -wave, 40 mm wave height, 150 mm step length. These parameters must be taken into account when calculating the slate, since when laying a range that implies the overlap of waves of vertical sheets, the consumption of the six -wave slate exceeds the eight -wave consumption. This is due to the width of the wave of the wave, which the six -wave slate in the eight -wave, and therefore, increases the area of \u200b\u200bthe material, which goes for overlap.

The sedimentary water collection system is another factor that affects the order of laying the slate roof. If you plan to equip the drainage groove under the overhang of the last slate row, it is enough to carry out installation so that the sheets of the last row slave protrude beyond the facade of no more than 200-250 mm. If you prefer a direct type of water discharge system, which provides for the discharge of water from the roof directly to the house territory, the dimensions of the protrusion should be at least 400-500 mm.

Technology for the installation of slate roofs: the main stages

The installation of slate roof is carried out in several stages.

- Preparatory measures, including the calculation of the required amount of material, as well as its acquisition and delivery to the construction site;

- Installation of the rafter system and the process of arranging the crate for slate, combined with laying waterproofing materials;

- The final stage is the installation of roofing material. It is the most responsible, since it depends on it the quality and duration of the operational period of the roof.

How to calculate the required number of slate sheets? The main recommendations

Before you put the slate, it is necessary to calculate the amount of material that will be required for the installation of slate roof. To find out this, it is necessary to carry out simple calculations, the procedure for which will be considered further:

- Firstly, the length of the slopes of the roof is multiplied by their height;

- The result, corresponding to the area of \u200b\u200bthe roof, must be divided into the area of \u200b\u200bthe slate leaf;

- As a result of these calculations, we received the required number of slate sheets, which must be increased by 10 %, due to the installation technology of slate roof, which provides for its overlap.

Preparatory stage: arrangement of supporting structures

The preparatory stage includes the installation of the crate, for the arrangement of which it is necessary to prepare material from durable wood species, but it is not necessary to choose oak or larch. This is due to the fact that slate is a fairly light material, and therefore, any dense wood can be used to install the crate. Before the installation of the slate with your own hands at the stage of arranging the crate, wood must be treated with rot.

It is important to note that before the start of installation measures, the slate should be stored in the room in factory packaging and horizontal position, being shifted with plastic film.

Having decided on the design and angle of the slope, before installing the slate on the roof, it is necessary to lay the rafters, for the manufacture of which the beam 50x180 is used. The installation of the rafters is carried out in such a way that the narrow side is located vertically.

For the manufacture of the crate, it is recommended to use a non-coded board of 15-25 mm or a 60x60 beam, which is installed perpendicular to the rafters.

Important! If you use boards for the manufacture of the crate, the distance between them should be from 200 to 1250 mm. In the case of using bars, they must be laid in such a way that each slate of slate is based on at least three timber, that is, the distance between them should be approximately 400-450 mm.

If you plan to equip the drainage gutter, it must be installed before the installation of slate sheets. On the sheets of the last row of the roof to the lower edge, it is necessary to nail the metal strip, the width of which is 300 mm and a thickness of 2-3 mm, which is necessary to prevent the leaks. On a metal strip from the inner and outer side, it is necessary to apply a layer of waterproofing material. In the places of fastening of the slate in the metal, the required number of fasteners is drilled.

Important! To improve the performance of the attic roof, experts recommend laying a vapor barrier membrane under the slate.

Shifer styling technology: specialists' recommendations

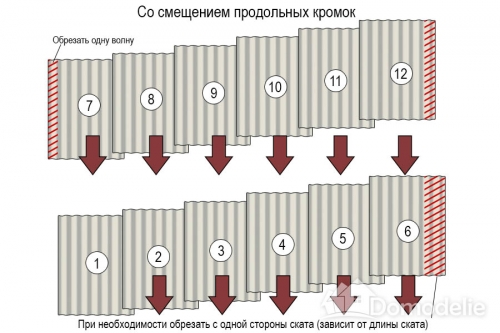

It is important to know that horizontally located neighboring sheets of slate must always be overlapping, which can be one or two waves, while the last option is more expensive, but it is it that it guarantees higher strength characteristics of the roof. Due to the fact that when fixing more than two sheets of slate at one point, problems often arise, there are several ways to solve them, and, consequently, methods of laying roofing material.

The most popular way of installing slate roof is to lay a frame, which implies laying each new series with a shift relative to the previous one. Thanks to the use of such a technique, there is no coincidence of waves of waves in each of the rows, as a result of which only two sheets are possible at each individual point. In order to shift in this case, it is necessary to trim several waves from the extreme sheet. The disadvantage of this method can be assumed that during the installation of the last vertical rows of the slate, an uneven roofing is formed, which needs additional leveling.

As for the eight -wave slate, there is a more practical modification of this styling method. In accordance with it, it is necessary to cut in half all the first sheets of odd horizontal rows (i.e. 4 waves), which will lead to a fairly clear (through row) repetition of displacement lines and a more aesthetic appearance of the roof. In addition, using two sawn halves of the slate sheet, you can start the installation of two rows at once. After you installed the first sheets, including halves, you can simply lay the sheets horizontally without taking care of the displacement, since the formation of a shift occurs naturally. However, in the process of aligning the end edge, trimming may be required.

If you are concerned about the excessive consumption of the material that is most preferable for you, although more time -consuming, can be styling without displacement. In accordance with this technology, in the case of laying sheets from left to right, it is necessary to cut the angles of sheets that form the upper row of the roof at least 100 mm along the width of the wave, and at least 120-140 mm along the wavelength. In this case, cut the lower corner from the side covering the previous sheet horizontally oriented row. Experts argue that thanks to the use of this technique, the most optimal overlap of all sheets of material is achieved not only in horizontal, but also vertically.

In the process of laying the slate, it is necessary to use nails, screws or special screws characterized by the presence of an enlarged hat and rubber gasket under it.

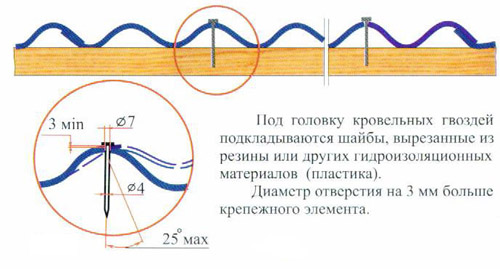

Important! To prevent damage to the roofing material during installation, it is necessary to mark the slate in advance and drill holes in it for fasteners. It must be remembered that the diameter of the hole should be 2-3 mm larger than the diameter of the screw or nail.

The holes for the fasteners should be located as follows: the first hole in the lower corner of the slate leaf, the second in the second overlapped wave, the third symmetrically relative to the previous one, that is, in the second overlapped wave. The final sheet of the row, located horizontally, must be additionally fixed in the sixth (penultimate) wave.

Important!It must be remembered that regardless of the type of fasteners, they should be installed in the crest of the wave, since other placement of screws or nails will cause premature (and sufficiently fast) destruction of the roofing. At the same time, taking into account the size of the vertical overflow between the rows, 120-150 mm retreat from the transverse edge of the row.

How to maintain the integrity of the slate: Basic safety rules

In the process of laying slate, it is important to observe not only the technology of installation measures, but also safety measures. In order for the operation of the roof to be cleaned during the operation of the roof, as well as to carry out such work on top of the slate, it is necessary to install wooden stage, complementing them with transverse stiplings. If the roof installation is carried out on the building above 6 m, a fence of metal reinforcement should be provided around it. In order to carefully raise the slate of slate to the construction site, experts recommend using the block system and a nylon cable. If the roof installation is carried out on a low construction, assistants can serve the material.

Important! Moving on the mounted coating must be carried out carefully. For free movement along the slate roof during its repair or maintenance, lay wooden ramps on it, thanks to which the load will be distributed evenly.

In the process of work, it is necessary to use safety cables and other devices. As for safety precautions when working with asbestos -cement materials (cutting and drilling slate), they involve the use of individual respiratory organs (respirators), which will protect the respiratory system from harmful dust.

To equip skates, cornices, roof joints, adjacents to pipes and similar areas, experienced craftsmen recommend using special elements from asbestos cement, after installing and fixing with cement and bitumen mastic, you can not worry about the strength of the mounted roof. Sometimes for these purposes wooden boards or galvanized stripes are used, however, in view of the low aesthetics and inefficiency of this method, it is not widespread.

In the case of all the technological stages of laying this roofing material, the operational period of the slate roof without repair (with the exception of emergency situations, the cause of which are heavy influences) reaches 50 years or more.

Chering roof care rules: main points

The slate coating needs simple care, which will significantly extend its operational period.

Its main provisions are as follows:

- Inspection measures and roof cleaning must be carried out twice a year before and after the precipitation season;

- Despite the fact that even a broom can be used to clean the roof, these measures can be significantly accelerated using the electric pump;

- In winter, it is recommended not to neglect the need to clean ice and snow;

- If you are not able to carry out independent roof care, use the services of specialized brigades.