There are many varieties of foundations. If during the construction of residential buildings it is necessary ...

|

|

Initially, the ceiling beams were by no means decorative elements of the room, they are on ... |

Laminated doors fit perfectly into the interior of any room, thanks to ... |

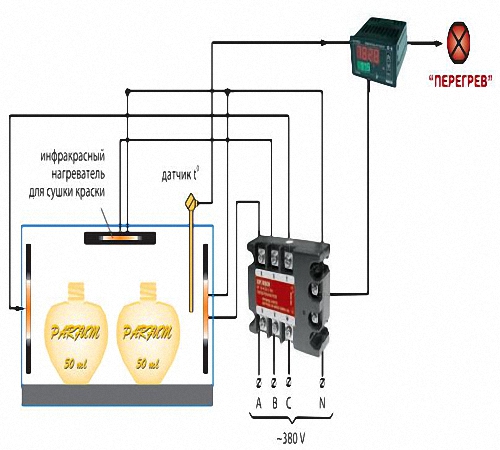

Solid -state relay: scheme, principle of operation, connection

To ensure non -contact communication of various devices without the use of electromagnets, a solid -state relay is used. We will talk about the features, principle of action and the connection scheme of this device.

Table of contents:

- Solid -state relay - principle of operation

- Advantages and scope of the solid -state relay

- Varieties of solid -state relay

- Selection and purchase of a solid -state relay

- Features of connecting a solid -state relay

Solid -state relay - principle of operation

A solid -state relay is a device that provides contact between low -voltage and high -voltage electric circuits.

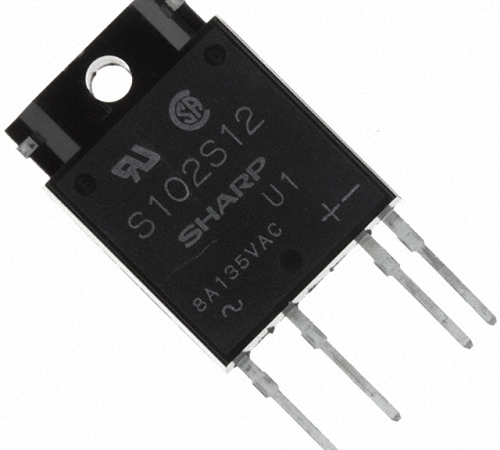

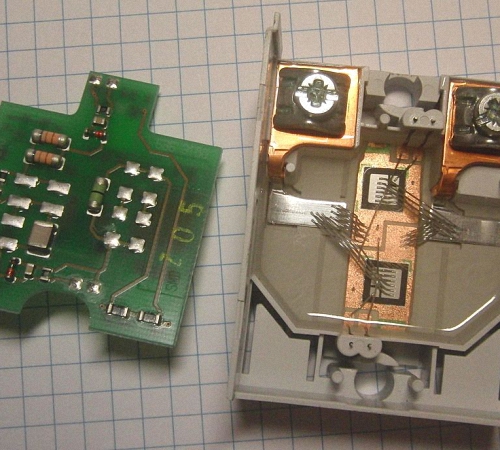

Considering the structure of this device, most models are similar to each other, have minor differences that do not affect the principle of their work.

The structure of a solid -state relay includes the presence:

- entrance,

- optical denouement,

- trigger chain,

- switch chains,

- Protection chains.

The entrance is the primary circuit, which is characterized by the presence of a resistor on a constant insulator, which has a sequential connection. The main function of the entry circuit is to accept the signal and transmit the command to the device of a solid -state relay that switching the load.

As an isolation of the input and output network with alternating current, the device of optical interchange is used. The type of relay and its principle of operation depends on the type of this component.

To process the input signal and switching output, the design of the trigger circuit is used. It acts as a separate element, and in some models it is part of the optical interchange.

To supply the voltage for the load, a switching type circuit is used, which includes a transistor, silicon diode and a simistor.

To protect the solid -state relay from failures in work or errors, a separate protective chain is used. This device can be of two types: internal and external.

The solid -state relay scheme consists of:

- control systems,

- solid -state relay devices,

- engine, pump, welding machine, transformer or heater.

In order to switch inductive load using a solid-state relay, it is necessary to increase the current of the current of 6-8 times.

The principle of operation of a solid -state relay is the closure or opening of contacts that transmit voltage directly on the relay. To bring contacts, the presence of an activator is necessary. Its role in a solid -state relay is played by a semiconductor or solid -state device. In devices that operate at alternating current, this is a thyristor or a symistor, and a transistor for direct current devices.

The device, which is characterized by the presence of a key transistor, is a solid -state relay. This, for example, is a motion or light sensor that, using a transistor, transmitted voltage.

Between the voltage in the coil and power contacts, the action of the galvanic interchange appears, which disappears as a result of the presence of an optical chain.

Advantages and scope of the solid -state relay

A solid-state relay often replaces ordinary contactors due to a large number of advantages in front of them. Consider the main advantages of a solid -state relay:

1. Small energy consumption - due to the lack of electromagnetic spacing, the electromagnetic relay consumes a lot of electricity, since a semiconductor is used in a solid -state relay, the amount of electricity for its operation is less than 90%.

2. A solid -state relay is a small -sized device, this quality allows it to be easily transported and installed.

3. This device is characterized by a high level of speed and does not require expectation to start.

4. Low noise production is another advantage of a solid -state relay over contactors.

5. Such devices differ in a longer service life and do not require additional maintenance.

6. They have a large sphere of use and are suitable for different devices.

7. The solid -state relay allows you to turn on the chain without allowing interference with an electromagnetic nature.

8. A high level of performance avoids the ratio of contacts during the operation of the device.

9. A solid -state relay allows more than a billion of the operation.

10. The presence of reliable isolation between the entry and switching chains increases the productivity of the device.

11. The relay is distinguished by the presence of a compact hermetic structure and persistent vibration before blows.

The scope of use of a solid -state relay is quite wide. They are used if there is a need to switch inductive load. Consider the main areas of application of this device:

- a system in which temperature is adjusted using a heater;

- to maintain a constant temperature in the technological process;

- for switching the control circuit;

- when performing replacement of non -contact reverse type starters;

- control of electric engines;

- control of heating, transformers and other technical devices;

- Registration of lighting level.

Varieties of solid -state relay

There are several varieties of a solid -state relay that differ in the features of the control and switching stress:

1. Solid -state relay of DC - is used under the action of constant electricity in the range from 3 to 32 W. It is characterized by high specific characteristics, LED indication, high reliability. Most models have a wide range of operating temperatures from -30 to +70 degrees.

2. The solid -state alternating current relay is characterized by a low level of electromagnetic interference, lack of noise during operation, low electricity consumption and high speed. The working interval is 90-250 watts.

3. Solid -state relay with manual controls, allow you to configure the type of work.

In relation to the type of load, they highlight:

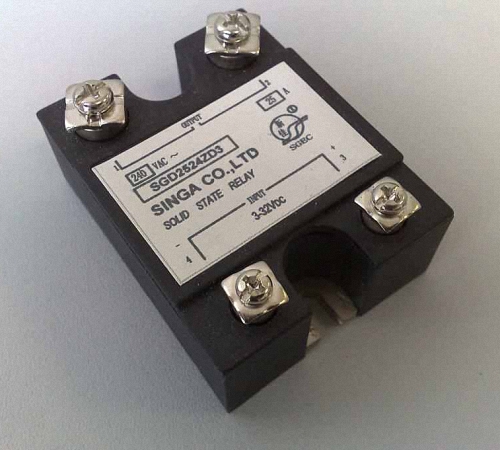

- single -phase solid -state relay,

- Three -phase solid -state relay.

A single-phase relay allows you to switch electricity in the range of 10-120 A, or in the range of 100-500 A. Phase control is carried out using an analog signal and a variable resistor. Three -phase relay is used to switch current at once on three phases at the same time. They have a working interval of 10 to 120 A. Among the three -phase relay, reverse type devices are distinguished, which differ in marking and contactless communication. Their function consists in reliable switching of each chain separately. Special devices can reliably protect the relay from false inclusions.

They are used during the launch and operation of the asynchronous engine that produces their reverse. When choosing this device, it is necessary to observe a large supply of current power, which is safe and efficiently operated by the device.

To avoid the occurrence of overstrain when using a relay, you must definitely purchase a varistor or a fast fuse.

Three -phase relays are distinguished by a longer service life than single -phase. Communication occurs due to the transition of current through zero and LED indication.

In relation to the communication method, they distinguish:

- devices performing the loads of a capacitive type, reducative type, weak induction;

- Relays with random or instant inclusion are used in the case when instant operation is required;

- Relays with the presence of phase control, allow you to configure heating elements, incandescent lamps.

There are solid -state relay in relation to the design:

- Mont.

- Universal, installed on transitional types.

Selection and purchase of a solid -state relay

To buy a solid -state relay, you should contact a specialized electronics store, in which experienced specialists will help you choose a device, in a ratio with the necessary power.

Solid -state relay price is determined by the following characteristics:

- type of device,

- the presence of fasteners,

- the material from which the case is made,

- instant or gradual inclusion,

- the presence of additional functions,

- manufacturer,

- power,

- electricity consumption,

- Dimensions of the device.

During the purchase of a solid -state relay, one very important point should be taken into account. These devices should work with a power supply that exceeds the power of the device by several times. If you do not adhere to this rule, with a slight increase in power, the device will instantly fail.

It is recommended to use special fuses that will help to avoid relay breakdown.

There are several varieties of fuses:

- G R - are used in a wide range of capacities, differ in a quick effect;

- G S - are used in the entire current range, I protect the elements of semiconductors from increased power networks;

- A R - protect the elements of a semiconductor type from short circuits.

Such devices have a fairly high cost, which is equated with the cost of the relay itself, but they provide highly effective protection of the device from breakdowns.

There are other fuses that belong to class B, C and D. They differ in a lower protection spectrum and cheaper cost.

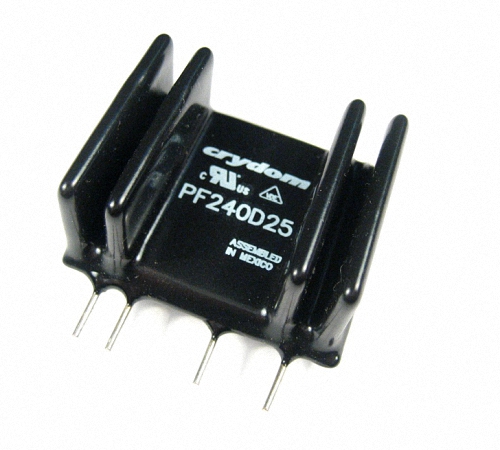

During the operation of a solid -state relay, it should be noted that this device heats up very quickly. If the device’s body is very heated, it is not able to switch the current in normal mode, the amount of current is very reduced. If the heating temperature reaches 65 degrees, then the device burns.

Therefore, during the use of the relay, the installation of a cooling radiator is required. And the current supply should be three, four times higher. If asynchronous engines are adjusted, then the current supply increases by eight to ten times.

Features of connecting a solid -state relay

Recommendations for independent connection of a solid -state relay:

1. Compounds do not require the use of soldering, but are carried out in a screw method.

2. To avoid damage to the device, it is impossible to allow dust or elements of metal origin.

3. It is not allowed to attach unacceptable external influences on the device case.

4. Do not place a solid -state relay next to easily flammable objects, and also do not touch the device, while it works to avoid receiving burns.

5. Before turning on the relay, verify the correct switching of the connections.

6. In the case of heating the cases above 60 degrees, it is recommended to install the relay on the cooling radiator.

7. To avoid damage to the device, you cannot allow a short circuit at the output.

Krutyak! I did not understand!

Krutyak! I did not understand!

I am developing myself

I myself develop equipment

Solid -state relay, not needed

Solid -state relay, you do not need a radiator

http://www.chipmaker.ru/topic/164495/

poor translation ....

poor translation ....

And where is the scheme here? Fuck

And where is the scheme here? Fucking the brains e ...?

how TTR turns on

how is TTR of DC turn on, in the upper or lower shoulder ??

I'm oak ... but simple and

I’m oak ... but simple and intelligible ... And for not oak, you see another site ...

The piece is awesome, disappeared

The thing is awesome, the need for mega was disappeared, where the copper and silver are full in the old Soviet ones, when the network disappears and the resources of a fairly small bedside table on tonymic wires for redirecting the lines, on the launch of engines, and wherever large currents are safer than hard -core and more conveniently even more conveniently more conveniently. They didn’t come up with, I even stuck it on opening the gate, I close it with a key. The fact that on the photos "FOTEC" never take, bullshit.

a lot has been written, but on the topic

a lot has been written, but nothing on the topic

The page is about solid -state

A page about solid -state relay was written by an absolutely illiterate person. At least check and read what they write !!!

who is the article for newcomers

for whom is the article? It will not be clear to beginners and the masters already know all this, the author is dead in torment.

Thank you very much for the article!

Thank you very much for the article!

In terms of inefficiency, filed 220

In terms of inefficiency, he filed 220 volts to control contacts + and - sparkled inside. Can I fix it?

Is it possible to manage work

Is it possible to manage the work / frequency of inclusion / TR Without a thermal controller, for example, a multivibrator, with an adjustable pulse frequency?

When working TR s

When working with inductance, it often burns. I wanted to know what nominal rates of the RS chain to include in parallel TR -I have unailed in this article. There are a lot of water.

This article has been translated

This article was translated by a car transmission, therefore stupid.