The garage is the second house. At least for a man. And if the apartment is in order ...

|

|

The roofing and waterproofing carpet from the rubles is durable and ... |

It is difficult to imagine a comfortable accommodation in a house without constant water supply. However... |

Installation of sliding gates

The sliding gates become popular and gradually replace standard swing, due to the convenience of operation and aesthetic appearance. Consider the main varieties and features of the installation of sliding gates.

Table of contents:

- Features and design of sliding gates

- Varieties of sliding gates

- Sliding gates of prices

- DIY sliding gates

- Recommendations for the installation of sliding gates

Features and design of sliding gates

Sliding gates - a type of gate that differ in a smooth opening in one or different sides, without requiring additional space in front of the gate.

The main difference between the sliding gates from the usual is the savings of space.

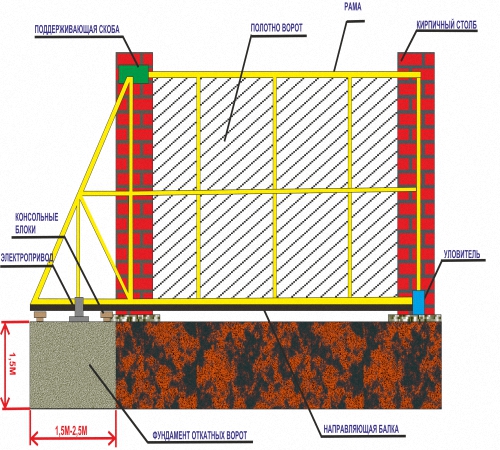

Standard sliding gates include:

- directing P-shaped bar;

- two roller supports;

- Removable end video;

- Lower Lovener;

- upper loser;

- upper latch - bracket;

- fixing plate.

Before installing the sliding gate, a special foundation should be prepared on which roller supports will be fixed. A guide plank, P-shaped, is installed on the lower edge of the metal frame. Thanks to roller supports, a smooth movement of the gate on the surface occurs. The supports are attached to the foundation with mortgage bolts or a special plate.

Advantages of installing sliding gates:

- The design of the sliding gates is compact and does not require additional space for opening;

- They are highly reliable and are able to withstand even a strong wind;

- do not make noise during work;

- possibility of remote control;

- ease of operation and additional maintenance;

- The sliding gates are not able to damage the car during opening.

Disadvantages of sliding gates:

- cost - higher compared to swing,

- The complexity of the installation,

- the need for a special foundation,

- The need to clean roller supports.

Sliding gates photo:

Varieties of sliding gates

Three types of sliding gates are distinguished depending on the design:

1. The sliding gates of the console type is one of the best types of sliding gates. The design of the console gates is a beam fixed on the foundation, to which the collar canvas is attached with roller carts. These gates are distinguished by the following advantages:

- Installation is carried out at a distance of 80-90 mm from the surface of the Earth. Thus, the gates do not contact the ground, and in the winter season they work perfectly, despite the presence of snow;

- The console gates are not limited in height and are of any size;

- For the operation of the console gates, the installation of additional beams is not required, which limit the height of entering transport;

- A lot of money is not required to install the gate data to equip the foundation, this design is easily mounted;

- The console gates do not need a finished opening;

- The sliding gates of the console type do not make extraneous sounds during operation, and allow you to open both manually and automatically.

Flaws:

- Such gates are quite complicated in design;

- need to arrange a smooth surface from the side;

- In the space from the sliding side there should not be extra objects that will prevent opening.

2. The sliding gates of the suspension type are common at industrial enterprises. They differ in high cost, and have no particular popularity. The design of the suspended gate consists of a beam, which is suspended above the opening, a collar canvas is attached to it.

Advantages of the suspended gate:

- stability before wind loads;

- hacking resistance and reliability;

- withstand large casing;

- They have no limitations in size.

Disadvantages of the suspended gate:

- high price;

- the presence of restrictions on the height of entering transport;

- bulky;

- The need for a finished opening.

3. Railing rail -type gates - the simplest design of the sliding gate. Such gates consist of rails located along the opening, on which a collar canvas is installed. To hold the canvas in an upright position, a bracket is used, which is attached to the pillar.

Advantages of the rail gate:

- ability to overlap large openings;

- high stability before wind loads;

- The possibility of any casing.

Disadvantages of the rail gate:

- the need to arrange the opening;

- require additional cleaning of the rail.

The sliding gate is highlighted in the ratio with the type of work:

- manual;

- Electric gates with electric drive.

Automatic sliding gates have an electric drive, which saves time to open and close the gate.

An electric drive is a fairly expensive pleasure, so it is possible to open a gate manually.

Sliding gates of prices

The cost of the finished set of sliding gates depends on the following factors:

- the size of the opening of the gate;

- type of sliding gate;

- the length of the guide beam;

- gate weight;

- Furniture manufacturer;

- number of fasteners;

- Management: manual or automatic;

- Installation work.

The average cost of the sliding gate canvas is $ 600. Additionally, you should purchase guides, accessories, automation.

Before buying sliding gates, you should decide on the size of the opening and type of gate, which are suitable for individual characteristics of the consumer.

With independent manufacture of sliding gates, the cost of such a gate will be several times less than purchased.

DIY sliding gates

In the sliding gates of the modern type, there are no guides in the upper or in the lower part, so the transport of any length will easily pass through the opening of the gate data.

The movement of the sliding gate occurs due to the presence of a console - a hard guide profile, which is welded to the frame of the structure. The guide profile produces the movement of the gate according to roller sliding deepening, which is fixed on the foundation.

For the manufacture of rollers for sliding gates, closed bearings are used, which do not require additional lubrication. The inside of the guides is equipped with sliding carts that are protected from moisture. Each sliding trolley contains eight bearings that are pressed using metal or polymer rollers.

The average number of opening cycles is 45,000.

The sliding gates do not require additional lubrication, if they are lubrication, small particles of dust and sand stick to the sliding mechanism and the gate begin to creak.

As a skin of sliding gates, it is possible to use:

- corrugated board,

- metal forging,

- wooden panels,

- polycarbonate,

- metal sheet.

Sliding gates drawing:

Before starting work on the manufacture of sliding gates with your own hands, determine the size of the opening in which the gate will be installed. The size of the opening affects the number of necessary materials and accessories. The gate should be such a width that the transport will calmly pass through them. To decide on the size, forget two pegs into the ground, and try to drive through them by car.

The size of the gate affects the distance that will need to be left for rollback. This distance should exceed the size of the gate one and a half times.

The installation of sliding gates begins with the construction of the support pillars. As a support, it is possible to use:

- Scheveler,

- metal pipe,

- wooden timber,

- a pillar made of concrete or brick.

Tip: set the support for at least 100 cm deep into the autumn-spring period of the pillar does not move away from the vertical and does not violate the integrity of the entire structure.

Use concrete to install poles. The time of solidification of concrete is about 7-10 days.

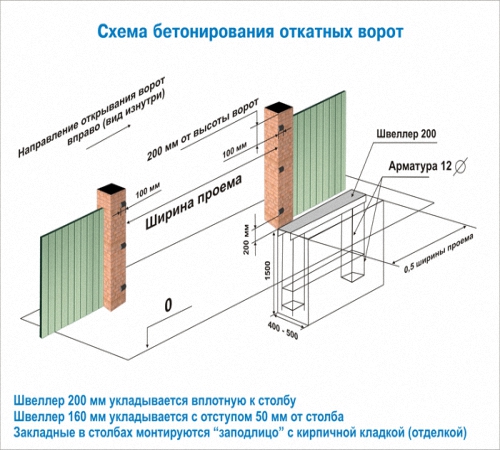

To equip the foundation for the operation of the sliding gates, use a metal channel with a width of 160-200 mm and a reinforcement with a section of 100-140 mm. Cut the reinforcement into pieces in size 100 cm, and weld to the channel shelves.

Dig a hole, the length of which is half the size of the gateway, the width is 400 mm, and the depth is 100-125 cm. Lower the channel into the pit and pour concrete.

The channel is installed in accordance with the level. The upper part of the channel must correspond to the territory of the race.

At the end, you will get even area on which sliding videos will be installed.

The minimum time for the foundation to stand 7-8 days. At that time, while the foundation is set to build a metal frame.

To make the frame you need:

- guide profile,

- Bulgarians or electric drill,

- metal brush,

- gasoline.

From metal pipes you need to clean the scale, and degrease the pipes with gasoline or solvent. Then, apply an anti -corrosion primer for metal products to the surface of the pipes.

The next stage is welding work on the construction of the gate frame. To do this, use pre -designed drawings for sliding gates.

To make a frame use a profiled pipe with a cross section of 6x4 or 5x5 cm. Such pipes are suitable for the formation of an external frame.

To ensure additional stiffness of the construction of the gate, build an internal frame, which is also an element of mounting the gate boiling.

For welding pipes, use tacks, interval between 200-300 mm tacks.

Tip: In order to avoid twisting the collar canvas, welding work should be carried out sequentially in a checkerboard pattern.

Use the grinder to cleanse welds. Apply another layer of anti -corrosion primer on a metal surface.

After the primer will dry out, take care of painting the frame. The best option for paint will be the use of alkyd enamel. Apply paint in two or three layers.

When the last layer of paint dries, you should take care of the gate. For fixing the lining of the material, use rivets or screws. To reduce physical costs in this process, use drill screws. To perform the skin, use a drill or a screwdriver.

Recommendations for the installation of sliding gates

1. Installation of rollers that guide profile and canvas is carried out to the surface of the channel.

2. Check the evenness of the gate installation using the level.

3. Use welding to welding the rollers to the surface of the lower channel.

4. Fasten the upper rollers with welding.

Tip: Do not use studs or nuts to fix the canvas, since this material is not able to reliably fix the gate in the opening. It is better to use welding right away.

Gate sliding videos:

Good article. Many things

Good article. A lot of interesting and cognitive things have been written.

Slopping information can

You can still take information on sliding here http://www.delionkzn.ru/sdvizhnye-otkatnye-vorota/

Sliding gates sliding

Sliding gates

Railing gates - a popular modular fence installed at the entrance to the private territory. Our company specializes in the production and installation of turnkey sliding gates within Moscow and the region. We guarantee the low cost and quality of work performed.

http://metallicheskie-zabori.ru/otkatnye-vorota/