In the construction of the building, the finished chord is the arrangement of the roof. The main role in ...

|

|

Not many of us know today, how to use a gun for ... |

In order to ensure ventilation in the bathroom, the threshold is built. Threshold in the bathroom or in ... |

Fill the foundation in parts: Advantages and disadvantages. How to fill the foundation correctly

Pouring a monolithic foundation requires a large amount of concrete, which is not always possible to cook at a time. Large construction sites are equipped with special equipment and a large -sized concrete mixer, but in private construction, it is not always possible to rent or order this equipment. In this case, the question arises: whether it is allowed to fill the foundation in parts. We will find out the answer to him later.

Table of contents:

- Concrete for the foundation: characteristics and stage of maturation

- Partial foundation filling - advantages and disadvantages

- The technology of filling the foundation in parts - calculation of the settling intervals

- How to fill the strip foundation correctly: recommendations for partial filling of the foundation

- Features of manual filling of the foundation in parts

Concrete for the foundation: characteristics and stage of maturation

For the manufacture of concrete, cement and additional fillers are used, such as gravel, sand or expanded clay. Water helps to improve the fluidity of the solution, and plasticizers and additives are added to protect against frost.

After preparing the concrete composition, it is poured into the formwork, then the ripening follows:

1. The first stage is the setting of the concrete composition. The substance, falling into the formwork, begins to harden, this occurs when the cement with water interacts. The connections between the components are not yet particularly durable, and when loading on the surface, they are easily destroyed. At the same time, it is unrealistic to achieve repeated setting.

The duration of this stage is determined by the temperature indicators of the external environment and air humidity and is from four hours to a day. A decrease in temperature increases the time of grasping of concrete. At the same time, at the beginning of grasping, the consistency of the composition remains liquid. If at this time a solution is added to the composition, then the connections between them are not violated. At a temperature of 18-19 degrees, the liquid stage is about two hours. At a temperature of 0-1 degrees - more than six hours.

It is possible to increase this indicator by mixing the composition, but do not abuse this method, as this negatively affects the operational properties of concrete.

2. The second working stage is the hardening of the concrete composition. This process is quite long and implies a gradual hydration of concrete components to give concrete the maximum strength characteristics in the ratio with the brand of the working mixture. The hardening process on the first day of the pouring occurs accelerated, further the development rate of this process is reduced.

In the first hour after grasping, concrete is minimal strength, adding a new portion of the solution will lead to cracking of the surface. Only 3 days after pouring, the composition gains the desired strength.

Depending on the features of the working cycle of concrete, we draw conclusions that the gradual filling of the foundation under the house with your own hands is possible, subject to certain recommendations:

- The sequential mixing of each portion of concrete, the time between the filling of which does not exceed two hours in warm weather and four with cool, the seams are not formed, the concrete remains as strong as with continuous filling;

- In case of long breaks in the work, it is allowed to fill in a maximum of 64 hours, no more, after a break, the surface is cleaned of dust and moisture, cleaned with the help of a brush, thus increases the clutch between the seams.

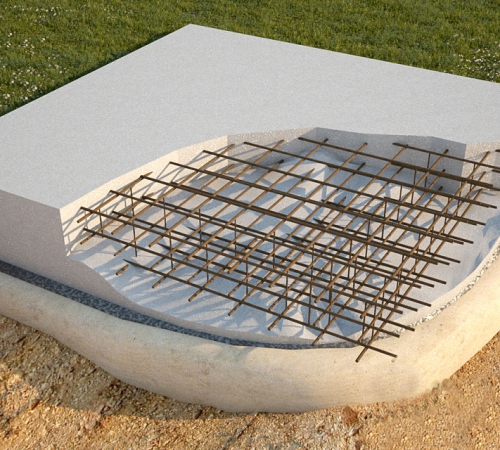

When pouring the foundation in parts, do not forget about reinforcement. It is mandatory in any case.

Partial foundation filling - advantages and disadvantages

The process of periodic filling of the foundation has the following advantages:

1. The lack of the need to use heavy special equipment.

Quite often during construction work, there is no possibility of entering the site with specialized equipment and even a concrete mixer. In this case, the only option is the periodic filling of the foundation. Since it is unrealistic to prepare a large amount of solution without specialized concrete mixers.

2. Increasing comfort in the construction work.

It is not always possible to complete the full filling of the foundation, there are reasons when the construction process stops. In this case, the gradual filling of the foundation - solves this issue.

Despite this, such shortcomings of the filling of the foundation in parts are distinguished:

- decrease in the strength of the base;

- with improper technology of work - the appearance of cracks on the foundation;

- the need for the exact follow -up of the technology.

The full filling of the foundation allows you to get a monolithic structure, with maximum strength characteristics. In any case, the quality of the foundation - after the work on partial filling is at a lower level, compared to monolithic structures.

The technology of filling the foundation in parts - calculation of the settling intervals

Before starting to fill the foundation, read the rules to determine the time and interval of solidification of the concrete composition. Incorrect pouring will adversely affect the quality of the foundation.

Only two stages of concrete solidification are distinguished:

- grasping;

- hardening.

Each of these processes is characterized by individual characteristics and completion time. Immediately after pouring the concrete composition into the formwork, grasping begins. Separate components are interconnected. Touching concrete solution at this time is strictly prohibited, in order to avoid violation of its integrity. In warm and hot weather, a concrete solution grabs after three hours. In late autumn or early spring, this time increases to 24 hours.

After setting, the structure of the composition remains liquid, therefore, during this process, it is allowed to pour concrete in small portions. However, filling after a day is already unacceptable.

The next process is hardening. Its duration is about four weeks. After this time, concrete is complete hardening and the ability to take loads. After three days, after the start of hardening, it is allowed to perform additional pouring concrete on the already finished coating. In the period from 1 to 3 days after the start of hardening, it is strictly not allowed to fill the solution. Since concrete - without gaining additional power, cracks under the load of the new composition, the microcracks, although not visible, but their consequences will appear after the construction of the house. Through these defects, water will fall into the foundation, gradually destroying it.

Keep in mind that the time of filling in the summer and winter season is significantly different. So, at high temperatures in the summer, filling the second layer is performed four hours after the main fill, in winter this time increases to eight hours. When pouring after the solution dries, pre -dry, clean and clean the base with a brush.

How to fill the strip foundation correctly: recommendations for partial filling of the foundation

In addition to determining the time of partial filling, decide on the technology of performing this process. They are distinguished by two:

- block;

- layer.

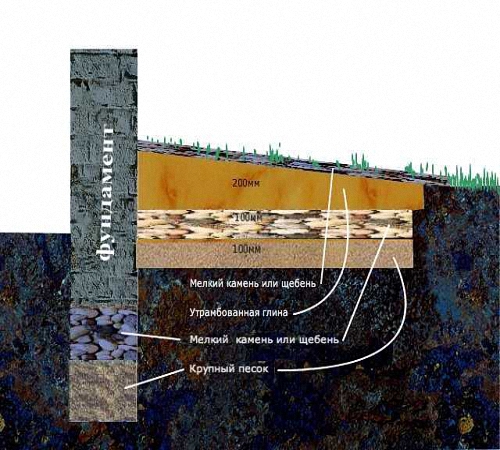

When pouring a strip foundation and the device of an underground trench, the formwork is poured strictly on the soil. In this case, the fill is performed in compliance with the joints, that is, in layers.

During the construction of a strip monolithic foundation - stop on a block filling. That is, the seams are located in a position perpendicular to the joints. With a layer of laying such a foundation, it is mandatory reinforced.

Before the start of the fill, decide on the method and make drawings in the form of a voluminous foundation scheme. On it, the total area of \u200b\u200bthe foundation is indicated and it is divided into several parts, in relation to the type of filling. In relation to division, we select three options for the scheme:

- Vertical division - the base of the foundation is divided into separate parts, divided by steel partitions, after completely solidified, the partitions are removed and poured with concrete;

- The oblique version of the pouring is the most difficult way, in this case the territory is divided by diagonally, for its implementation a certain experience is necessary, used in complex structural foundations;

- Horizontal partial fill - the foundation in depth is divided into parts, no partitions are installed between them, it is enough to determine the height of each of the layers, further filling is performed in the ratio with the scheme and interval of the introduction of a new portion of concrete.

In addition, on the sketch, indicate the dimensions of the poured part, in relation to these indicators, determine the amount of concrete for filling.

Features of manual filling of the foundation in parts

After drawing up the drawings, proceed to direct partial filling. First, build the formwork in the places of primary fill. For its manufacture, use wood, metal or plastic. A wooden formwork should have a laminated coating in order to avoid excessive absorption of moisture with wood.

Using metal structures, choose materials with an anti -corrosion coating. Plastic formwork is characterized by lightweight and ease of operation.

In addition, two formwork options are distinguished depending on its design:

- team;

- solid.

In our case, we recommend stopping on the first option. Collective types of formwork are easily disassembled and collected if necessary.

Next, prepare the reinforcement. The strip foundation is must be reinforced. Select such a marking of reinforcement:

- welded;

- Anti -corrosion.

The reinforcement for the foundation should have two options for this marking. Weld reinforcement is durable and prevents the cracking of the foundation. Before filling the concrete structures at the bottom of the structure, pour sand. Remember it using special equipment. Next, proceed to the preparation of concrete solution.

As the main ingredients for the preparation of the solution, they use:

- sand;

- cement;

- water;

- filler.

Fill the foundation is performed by a high -quality composition of the brand 300 or 400. If there are about 85 kg of dry composition, you will need about 42 liters of water. Use only dry sand for work.

It is recommended to fill the foundation in dry and warm weather. When working in the summer, cover concrete with a film, in order to avoid excessive evaporation of moisture. The gradual pouring involves the portioned preparation of concrete. To calculate the composition for a certain site, first determine its volume. Measure indicators of height, width and depth of the structure, multiply the obtained values \u200b\u200band you get the number of cubic meters of concrete composition for work. Prepare concrete in a concrete mixer, such a composition is characterized by maximum uniformity and high quality.

Further, the foundation of the foundation with your own hands follows. When pouring the foundation in the form of a tape horizontal method, divide the structure into several parts. For example, with a foundation height of 1 meter, it is recommended to perform concreting in three or four layers.

After pouring concrete, compact the composition with a vibrator. This device will be removed from the design of the excess air and improves its adhesion with reinforcement. In addition, each of the layers is aligned with a special device or ordinary wooden bar.

After exposure of a certain time, prepare a new portion of the solution and repeat the process. Be sure to seal each of the layers with a vibrator. If you do not have this device, replace it with ordinary reinforcement, with which a solution is pierced along the foundation. Just keep in mind that you need to do this at maximum speed, before the start of the solution is hardened.

Cover each of the layers of concrete with plastic film, in order to avoid the rapid evaporation of moisture or rain to the surface. If the interval between the filling of the layers exceeds the day, then before the start of filling the next layer, clean the surface of dust and dirt.

If the gradual filling of the foundation is already performed on a fully dried base, then pre -process it with a brush on metal, to improve roughness and adhesion with concrete.

Filling a strip foundation is a complex process, however, if you approach it with responsibility and correctly calculate the time of solidification of the solution, the result of the fill will be no worse than that of monolithic structures.

Fill the foundation of the video:

http: //stroy-in.rf/forums/

http: //stroy-in.rf/forums/

Good stuff. Finally

Good stuff. Finally, I realized which brand of concrete to choose from this variety http://beton-tvs.by/. And then for 2 months I could not choose a suitable solution for filling the foundation, which very much delayed the construction time. He approached the foundation with all responsibility, as this is the basis of the whole house. And if you take into account the swampy terrain on my site, then it was definitely not necessary to lose concrete with concrete. Thanks!,

I recommend everyone to read this article, it is worth the time spent. Bye.

read and welcome everyone

read and welcome everyone

Thanks a lot for

Thank you very much for the information.