Let many people put PVC windows in their homes today, but most people, especially in ...

|

|

Directly laying parquet is just the first step for receiving ... |

Properly performed waterproofing of the floor avoids the problems associated with ... |

Types and design of the foundations of small laying

When planning the construction of the building, the first question is the type of foundation, which will be a reliable support that prevents the influence of groundwater and frost. For the correct construction of the foundation, we will get acquainted with the main types and rules for installing the foundations of small laying.

Table of contents:

- Small laying foundations device

- Types of fine foundations

- The concept and basics of constructing the foundations of fine lifting type

- Features in the design of the foundations of fine poultry

- Installation of a columnar foundation of small laying

Small laying foundations device

A distinctive feature of small -laying foundations is the depth of bookmark, which is from 40 to 90 cm. This allows you to save both labor and construction resources. Such foundations do not require a large amount of concrete for filling and a thick layer of gravel for filling. The costs of erecting the foundation of small laying are reduced by two to three times.

The foundations of small laying consist of:

- Walk of the upper part, which takes the load.

- Soles of the lower part, which transfers the load.

- The sides of the vertical parts of the foundation forming the foundation wall.

The foundation of small laying is used in such cases:

- When building wooden houses.

- When building houses made of light materials.

- For small brick buildings.

- In low -rise construction.

- For a small basement.

- With a low passage of groundwater, which does not lead to swelling.

Types of fine foundations

Ribbon, columnar and slab foundations are distinguished, which in turn are separated by design technology, and materials used for construction.

Classification of fine foundations according to design technology:

- Monolithic reinforcement is installed only on the slab of the foundation.

- Blood or column.

- Prefabricated using reinforced concrete pillows and concrete blocks.

- Combined or prefabricated monolithic.

Types of fine foundations based on materials:

- The foundations made of wood.

- Stone foundations.

- Concrete foundations.

- Reinforced concrete foundations.

The concept and basics of constructing the foundations of fine lifting type

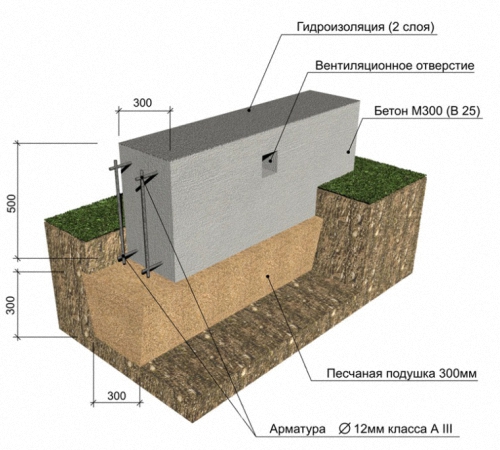

For a strip foundation, the most suitable type of soil, is the mainland soil that arose by natural tamping. Such a foundation is used in the construction of a building consisting of brick, adults or small concrete blocks.

The main advantage of the string foundation of small laying is the simplicity of construction.

According to the material, tape foundations are distinguished from:

- Brick.

- Concrete.

- Butoton.

- Boutor.

For the construction of a missile foundation, laundry stones are used, which are laid using a cement mortar. Such foundations are the most time -consuming and have the greatest weight. The usual height of the missile foundation is 55-65 cm. The scope of use is small in the houses or cabins.

For a bottled strip foundation, a lime-cement or cement mortar is used, which pour the base of crushed stone, gravel, broken brick or bottle stones.

Stages of work on the foundation of the tape type:

- Preparation of the site for the foundation. The surface is leveled and cleaned of vegetation.

- The marking of the site. We mark both external and internal corners.

- Digging a pit and leveling of the bottom of the foundation. The depth of the pit is from 30 to 120 cm. If necessary, installing the mount on the side walls of the foundation. The mount happens:

- The embedded walls of the foundation are strengthened by vertical racks of beams and wooden boards. Application: arrangement of a pit with inclined walls.

- Spuntor is made of slopes: wooden, metal, reinforced concrete. Application: the location of groundwater above the bottom of the pit.

- Filling the bottom of the pit building of the pillow. The main function is the junction of the bottom of the pit. To determine the type of pillow, it is recommended to take the soil analysis to determine the amount of groundwater.

- If clay soil is used sand pillow. When building the foundation on sandy soil, a layer of concrete is poured with a thickness of about 100-150 mm. After filling, this layer is compacted using special equipment.

- Installation of wooden formwork for filling the foundation. To improve concrete solidification, it is possible to lay a waterproofing film or waterproofing with resin.

- To reinforce the foundation, reinforcement with a section of 1.2 cm is used. Reinforcing rods are laid from one angle to another. The joints of the reinforcement are connected by clamps. With additional reinforcement of corners, using rods, the additional strength of the foundation increases.

- If the foundation is a brick or bottle layer of backfill.

- The next stage is pouring formwork. Use high -quality concrete more than 200 brand. Pour the foundation in several approaches of 15-20 cm for better solidification.

Tip: be sure to moisten the formwork with water before pouring so that moisture from concrete is not absorbed into the formwork.

Features in the design of the foundations of fine poultry

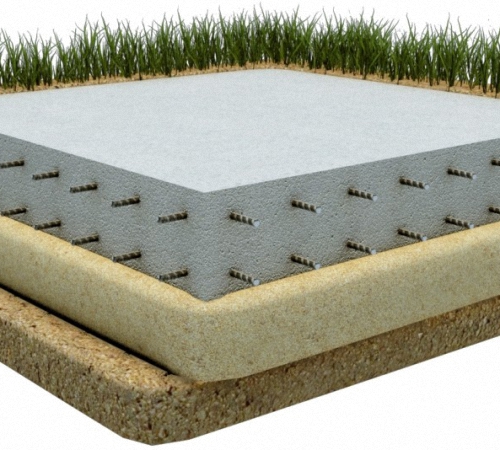

Above the poured layer of sand or crushed stone, the thickness of which is about 25 cm, laid the reinforced concrete plate, which is the basis of the foundation of the slab type. Such a foundation is more durable, reliable and durable, but the costs of building are more significant.

The advantages of the foundations of small laying of the slab type:

- The minimum cost of hired labor and lightness in the installation process. It is not necessary to have construction skills to build such a foundation. The main thing is to calculate everything correctly.

- High reliability.

- In the process of using the structure, the walls remain intact, since the plate reliably protects the building from deformation.

- The plate installed in the foundation is used for the floor of the lower floor, which provides additional savings in the funds.

- The slab foundation is the best option for soils of a complex type. When installing such a foundation, additional excavation work needs to be carried out.

Instructions for the construction of a tile shared foundation:

- Preparation of the base. Comers the surface and mark the surface.

- Remove the upper layer of soil over the entire area of \u200b\u200bthe foundation. When you get to a denser soil, smooth the surface.

- If the moisture content of the soil is highly constructed drainage. To do this, get trenches and install plastic pipes. Cover with geotextiles on top.

- It is advisable to warm the foundation with polystyrene from all sides by 100-130 mm, to prevent freezing.

- The next stage is the installation of a pillow of sand or crushed stone. Carefully compact, watering water with each separate layer. The thickness of the pillow is 10-20 cm.

- On top of the pillow, lay the polystyrene foam for insulation.

- The option of using the finished reinforced concrete slab is possible. Then, after the installation of the pillow, such a plate is installed, which will further act as a foundation and as a floor.

- If the plate is built on the spot, then the formwork is done. For formwork, the beam is best suited. The width of the formwork is equal to the width of the foundation. Fasten the formwork and insulate with a waterproofing film.

- To create a more durable design, it is better to reinforce two layers. For the first layer, the reinforcement of 12-15 mm is suitable, and for the second cell 20*20 cm.

- Pour the base of the stove. Pouring is done in stages, for a more durable drying of concrete. Be sure to use equipment to eliminate air bubbles in concrete.

Tip: To prevent cracks with rapid drying of concrete, water the stove with water or cover with plastic film.

Installation of a columnar foundation of small laying

This type of foundation is great for the construction of a bath, household premises or a small structure. Sometimes such a foundation is used in the construction of wooden houses.

The advantages of columnar shallow foundations include:

- A small amount of reinforcement.

- Short lines of manufacture.

- Minimum earthworks.

- Resistance to fusion or soil freezing.

Stages of working on a columnar foundation:

- First you need to design and calculate the perimeter of the foundation. Laboratory determine the density of the soil. Next, the length of the pillar is calculated based on the depth of freezing.

- The thickness of the pillars depends on the massiveness of the building, as well as the gap between them. If the pillars are monolithic, the distance between them is approximately 150-200 cm.

- Next, make the marking on the ground.

- Dig the pits around the perimeter of the foundation based on the thickness of the pillars.

- The next stage is backfill. It is advisable to use a crushed stone layer about 10 cm thick. Close this layer well.

- Reinforcement is performed by reinforcement with a cross section of 100-120 mm. First, rods are cut out, 30-40 cm long. Then they make a grill, connecting the rods with clamps.

- These lattices are laid on the bottom covered with gravel.

Tip: Put several fragments of bricks under the grilles to ensure the reliability of concrete mass when pouring.

- The pillows are poured with concrete of brand 250. Before installing the formwork for filling the pillar, 7-10 days should pass.

- Formwork is made from the overlaid boards. It turns out a long box without a bottom.

- The formwork is attached to pre -displayed reinforcement and begins to fill. Using a deep vibrator, air bubbles from concrete mass are removed. Use concrete of the same brand as when pouring a pillow.

- At the end of the fill, install a metal corner.

- After a week, remove the formwork, and after three weeks, make a strapping.

- To prevent snow, dirt or garbage, they make a clogging for the foundation. For manufacture, use brick or stone.

- To ensure waterproofing on the bolt, bitumen is laid, and then roofing ground.

For the long -term functioning of the foundation, it is necessary to remember the following rules:

- Correct calculations of the depth of the foundation will exclude subsidence.

- The load on the supports should be uniform.

- Use only high -quality materials. Indeed, the durability of the structure depends on the strength of the foundation.

- Be sure to assess the soil in the laboratory.

- The best time to build the foundation of summer or the beginning of autumn.

- Monolithic structures are built with mandatory concrete vibration.