The range of flooring has dozens of different names. Among all ...

|

|

Combined ceilings represented by the tandem of stretch paintings and sheets ... |

Glazing of facades is a fashionable direction of our time. Due to the original ... |

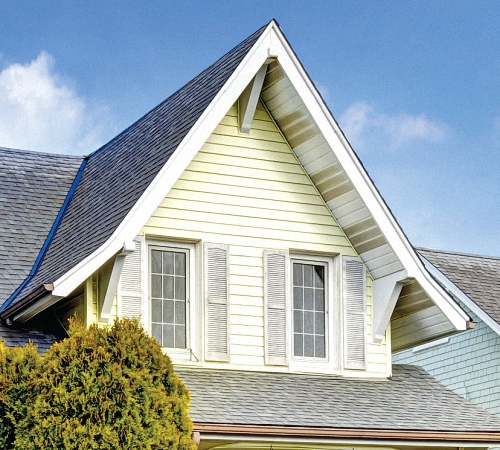

Roofing options

After the manufacture and finish of the roof, the process of its skin follows. This procedure forms the final type of roof, therefore it should be carried out with special seriousness. There are several ways by which the roof is carried out, we will talk about them further.

Table of contents:

- Roof overlooking: technology and structural characteristics

- The main options for the roof licking and their characteristic

- Features of the roof binder with siding

- Bearing of the cornices of the roof, options and technology for execution

- Roofing the roof and preparation of the base

Roof overlooking: technology and structural characteristics

After the installation of the rafter system and the final finish of the roof, the overwhelming process of overhang is followed. It is possible to carry out this process before finishing work, in this case, a number of actions should be performed:

- Before carrying out the overlooking, the evenness of the rafter system should be checked, all rafters should be located at the same level, this line should be a parallel building;

- Different materials are used to carry out the skin, but in most cases they suggest wooden boards, which must have the same width, so that the sheathing has an asymmetric appearance;

- Dip the channel sections of the rafter system in an upright position, and cover their end areas according to the same principle as the rest;

- After the rafters are already packed, you should navigate on the first stuffed board.

Keep in mind that if you plan to insulate the walls of the house outside, then this process should be carried out exclusively after the binder of the cornice of the roof.

The main options for the roof licking and their characteristic

There are many materials used in the roof. The choice of one or another option depends on the individual characteristics of the building, the material from which it is made, personal preferences of the owners, etc.

The main requirement for each of the binder options is to ensure reliability and protect the cornice areas from atmospheric and external influences. In addition, the proper and high -quality ventilation should be ensured in this area. In addition, the material with which the binder will be made should remain unchanged for a long period of time.

We offer to get acquainted with the main materials for lining of the roof and their features:

1. Bearing the roof with corrugated board - this material has the form of galvanized steel, on which a polymer coating is applied. It is with its help that it is possible to protect the material from external factors and get color or the desired shade. It is, due to the presence of galvanized steel, corrugated board is distinguished by high stiff and strength characteristics. In order to ensure the necessary ventilation using differences between the waves, a small gap is performed. There are many options for panels in width, so all the work is carried out quickly and simply.

2. Sofit for the roof lugging - this material has the shape of plastic panels that are used directly during the process of roofing. This finishing material is quite similar to siding. But, nevertheless, there are several differences between them, first of all, it is the thickness of plastic, which is much higher in Sofit. In addition, Sofit has special perforated areas that contribute to improving ventilation in the undercarbon space. The plastic from which Sofit is made is distinguished by the presence of ultraviolet stabilizers, which make it more persistent before exposure to the sun. These panels require perpendicular rather than a longitudinal installation.

3. Bearing the roof of a lining of wood - when choosing this material to perform work, you should carefully monitor the quality of the wood. Since a poor -quality lining will not be able to serve the owners of the house for a long period of time. In addition, follow the thickness of the material that should not be too thin, also check its humidity. Too wet wood will begin to rot over time, and the overdrede will crack. Before installing, it is desirable that the lining stays in the fresh air for about a month, aclimatizes and adapted to external stimuli.

4. Bearing the roof with wood - for these purposes, thickets of everything are used by a string torn board, between which a gap of 15-20 mm is left. The main advantage of such a system is excellent ventilation, which helps to prevent the accumulation of moisture in the undercarbon space.

5. The use of a plastic lining for the roof is also possible. The cost of such a finish will be the lowest. Keep in mind that you need to choose moisture resistant options for the lining. In addition, to fix the butt areas, the presence of special corners of plastic will be required.

Features of the roof binder with siding

There are several varieties of siding used in the process of roof lining:

- vinyl;

- wood;

- steel;

- galvanized.

The most popular is the first option, vinyl -based siding. Since it is this material that combines lightness, strength, affordable value, practicality and durability.

Each of the panels differs 300-350 cm long. In addition, they have special strips, on the end areas of which there are elements in the form of locks. Two main types of siding are distinguished, which differs in design features:

- continuous unprocessed siding panels;

- Sofites with partial perforation.

The second option is used in the process of baking the cornices of the roof. For work, a number of actions should be performed:

1. No need to store the material under the influence of direct sunlight or high temperature, which exceeds 50 degrees.

2. Keep in mind that the panels should be freely installed under the cornice to ensure normal ventilation of the undercarbon space.

3. In the process of fixing siding, do not press on the locks, as there is a risk of damage.

4. For fixation of sofitis, it is best to use self -tapping screws.

5. Keep in mind that there should not be a small gap should not remain in the siding, since there should be a small gap between the board and the panel space.

6. Do not use a sealant in an angular area.

To sheathe the cornice of the overhangs, you should take care of the manufacture of the box. It will require the presence of wooden bars or profiles, from aluminum. If a wooden lining is used for lining, then exclusively wood should be used to make a box.

Two boards will be required to install the box. The first of them is fixed on the wall, and the second is horizontally. Among the advantages of hemding of the roof pediments with the help of sophists are distinguished:

- ease of installation work;

- protection of the building from moisture and atmospheric exposure;

- The ability to obtain a cornice of any shape and configuration.

In order to establish sophites, perform a number of actions:

- fix two boards on a cornice overhang;

- Attach two profiles to one of them;

- Leve profiles in the ratio with the width of the overhang;

- Install one of the panels in the groove hole, and fasten the second side to the board;

- Using the bar, block the joints between the sofits.

In addition, we offer to familiarize yourself with the features of the roof lurks with siding:

- To begin with, drink all the rafters in such a way that they are at the same level, to each other;

- For skin casing, use conventional boards or special strips that are similar in color with the cornice;

- Sprinkle the rafters exclusively in the vertical direction;

- Warm the walls only after closing the overhang.

There are several options for embroidery of cornices using siding. To perform these works, the availability of:

- siding, the desired color palette;

- profiles;

- Self -tapping screws.

Keep in mind that the panels should not be too fixed with self -tapping screws, since natural ventilation of the undercarbon space should be provided.

Different binder options are distinguished, among them:

- installation of a freezer strip;

- Lack of strip.

Installation of siding is a fairly simple process, for the quality execution of which it is necessary to first correctly install the box. Keep in mind that all rafters should be perfectly even. Their final sections are cut vertically. Next, the initial board is extended, from which the crate is constructed.

The cornice on the roof is mounted only after the walls have already been insulated. In addition, you should take care of the installation of special grilles that will provide proper ventilation.

The most high -quality material with which the roof is baked is copper siding. The price for this material is quite large, so its use in this industry is not common. Despite this, this material has a number of advantages, among which they highlight:

- excellent color characteristics;

- high thermal conductivity;

- stability before corrosion;

- resistance before moisture and aggressive chemicals;

- Due to the presence of perforation, it is possible to provide excellent ventilation.

Bearing of the cornices of the roof, options and technology for execution

If we consider the options for lining the cornice overhang, then regardless of the material, distinguish two ways to carry out this process:

1. Technology of binder on the rafter system.

This option is used in the process of baking cornices on the roofs having a small angle of slope. In addition, its use is common if it is necessary to increase the height of the building. Keep in mind that in this case, the lower part of the rafter system should be at the same level. If this condition is not fulfilled, then in order to adjust the rafters should be placed under them. Next, the first and last strips are screwed and set. To check evenness, you should pull the threads over them.

2. The trimming procedure is used much more often.

On the lower and end parts, a board is fixed, and on the wall a wooden bar, providing deliverance from moisture. If the overhang width is more than 45 cm, it is necessary to take care of the additional installation of the board in the center.

Further, installation work is carried out according to the usual scheme. One board is stuffed on the crate, and the second is installed parallel to the first. Any finishing material is fixed on them.

Roofing the roof and preparation of the base

The first stage of work on roof bearing involves the preparation of rafters. In order to do this, perform a number of actions:

- The rafters should protrude beyond the roof by more than 20 cm;

- In the process of their installation, it is necessary to have a protrusion, which is selected depending on the size of the roof;

- In the process of cutting materials, the final sections of the rafters are treated with a vertical cut or a horizontal and vertical cut.

Next, aligning the cut line should be carried out.

Keep in mind that in the process of baking the roof, the walls should already be insulated so that the joints between the common and the bearing are reliably sealed. If this is not done, then moisture and cold air will fall into the undercarbon space.

Another important point is the procedure for choosing the type of ventilation system, which will contribute to the removal of excess moisture from the subcutaneous space. There are two technologies that provide ventilation:

- the presence of small gaps between the bearing and boards;

- Installation of ventilation holes that are closed with special grilles.

The second method is more common and technologically true. To carry out a direct roof hem, you should prepare tools in the form:

- Previously selected material, wood, lines, siding, sofitis, etc.;

- electric saw;

- electrodele;

- Bulgarians;

- hammer;

- construction level;

- stairs;

- screwdriver;

- roulette;

- fasteners, their type depends on the material by which the work will be done;

- antiseptics;

- cord;

- paints.

To perform the installation of the finish according to the rafter system, perform a number of actions:

1. Cut the material, depending on the size of the site on which it will be installed. To process all elements, especially wooden, use an antiseptic.

2. If certain of the parts of the binder will be painted in the future, then this should be done at this stage.

3. Check the rafter system for horizontal and vertical.

4. In the presence of uneven fragments, fill the boards on them.

5. Fix them using self -tapping screws or nails. In the ratio with the overhang line, set the strips in the end areas.

6. To check evenness, pull the cord. In the ratio with the line of the cord, install the binder.

7. Keep in mind that a gap should be left between the panels, at least 0.5 cm, which compensates for their temperature expansion.

The second option involves the creation of a box for a roof licking. To perform this process, use the instructions:

1. Cut and treat the material with an antipathic agent.

2. Fix the board on the bottom of the rafter system.

3. Install the beam, above the boards by 10 mm.

4. Install the binder, so that one part of it remains on the beam, and the second on the board.

5. Follow the presence of ventilation holes, and leave a gap of 15-20 mm between the bearing.

6. To fix the finish, use screws, corners and profile plates.

7. Keep in mind that if you plan to install too long boards, then the number of fasteners for their installation should be at least 3 pieces. Thus, it will be possible to prevent deformation of the boards.

Video roof binder: